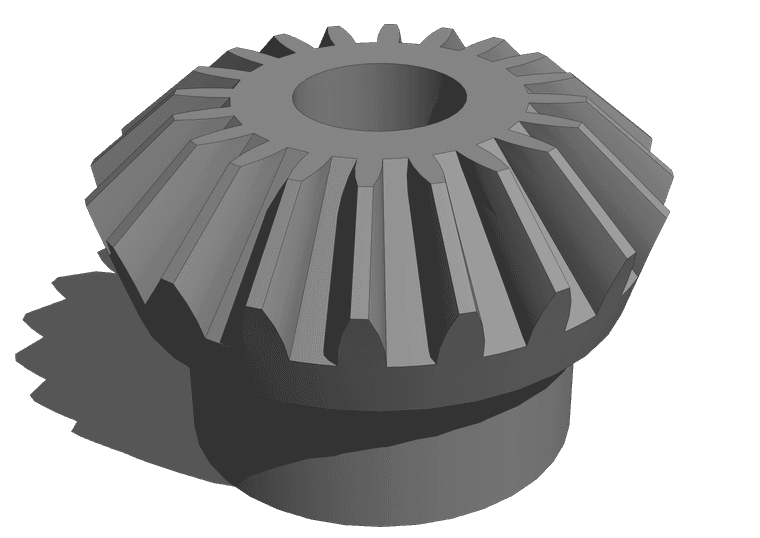

FWIW, here's what it takes to make a solid object from a gear created by SP Gears.

Posts

-

RE: Any good tutorials on BEVEL gear design in SU?

-

RE: Any good tutorials on BEVEL gear design in SU?

@jgb said in Any good tutorials on BEVEL gear design in SU?:

Info says the gears are mainly for SP and may not be OK if 3D printed.

You can certainly modify the geometry output of SP Gears to make solids suitable for 3D printing.

You could also modify standard gears like the one I showed to make any custom sized gears.

-

RE: Fredo6 plugins and SU2024

@MikeG73 What version of SketchUp? What operating system?

-

RE: Any good tutorials on BEVEL gear design in SU?

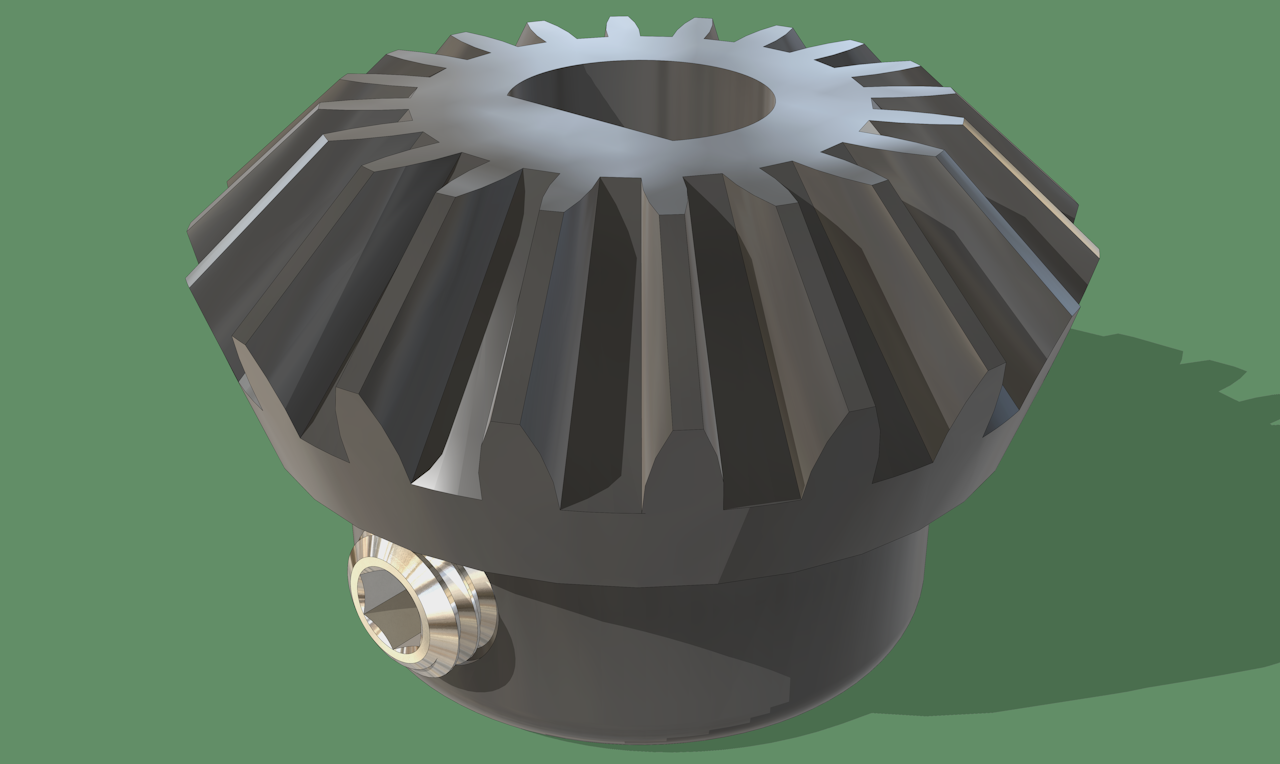

As Rich suggests, SPGears is a good option. If you can use standard bevel gears you might check manufacturers and suppliers for files you can use in SketchUp. For example I got a STEP file for the gear shown here from McMaster-Carr which I imported into SketchUp using the Universal Importer available in the ExtensionStore. The result can easily be modified for the shaft it needs to fit and so on.

Since you are modeling for 3D printing, do the modeling in meters to avoid issues with tiny faces.

Couldn't help but do a little playing while avoiding work I should do.

-

RE: Sketchucation Tools 5.0.5

As you can see, it requires the Sketchucation ExtensionStore.

-

RE: Measurement window location in 2025

@joshvt said in Measurement window location in 2025:

for some reason was having trouble floating/ undocking it.

If you untick the box for Measurements in the View>Toolbars panel the window should be displayed in the default lower right corner location.

-

RE: Measurement window location in 2025

It should have been in the lower right corner by default. Presuming you are using SketchUp on Windows, go into View>Toolbars and deselect Measurements.

-

RE: Sketchucation Tools 5.0.5

@hydrokiwi what version of SketchUp?

-

RE: S4U Make Face

The author of s4u Make Face started selling it before February, 2019. See this post.

s4u Stair was a paid extension at least in 2020.

-

RE: Strange corners

@Leggy said in Strange corners:

the layer lines go up from there

So there's an overhang? Might need to add support. Check to see that all movements on the printer and the bed are tight enough. I had an issue on my printer where the screws holding the bed to the carriage were loose. Once in a while the bed would shift during a paid movement and cause a deformation in the print. I tighted the screws and the problem disappeared.

-

RE: help with a thread

@Leggy said in help with a thread:

I think it’s the shrinkage on the printer that’s causing the problem

That's probably it. You'll have to work that out based on the material.

-

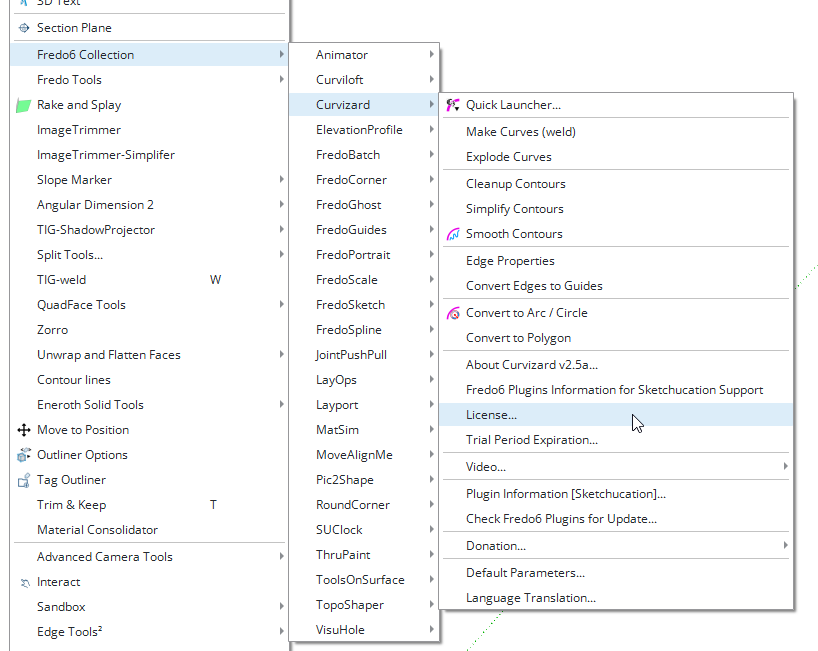

RE: Fragen zur CurviLoft Installation

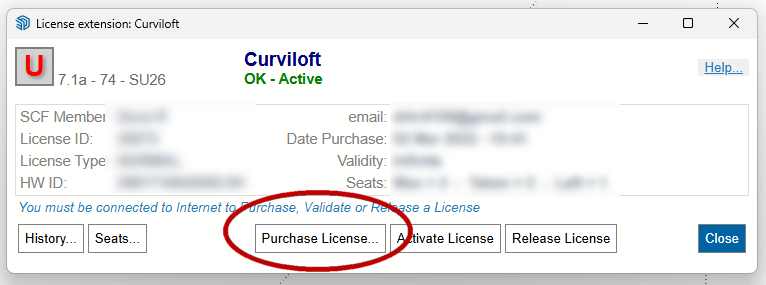

@Rosketch install the Sketchucation ExtensionStore (it is required for license management, anyway) and use it to install Curviloft and the required LibFredo6. Once they are installed go to Tools>Fredo6 Collection>Curviloft>License.

In the license panel click on Purchase License.

-

RE: Sketchucation plugin make my Sketchup crash

What version of SketchUp? What operating system?

-

RE: Fredo6 Round Corner Crash Sketchup

You could try switching to the classic graphics engine and see what happens.

Also make sure you have the latest graphics drivers from nVidia.

-

RE: Fredo6 Round Corner Crash Sketchup

What graphics card? Which graphic engine is selected?

-

RE: Fredo6 Round Corner Crash Sketchup

@DoCelikkol what version of SketchUp? What's the radius of the round over? Your GIF leaves out important information.

-

RE: help with a thread

@Leggy said in help with a thread:

I'm making progress.

OK. So you don't need the video tutorial I did? Good enough.

-

RE: [Plugin] 3D Text Editor

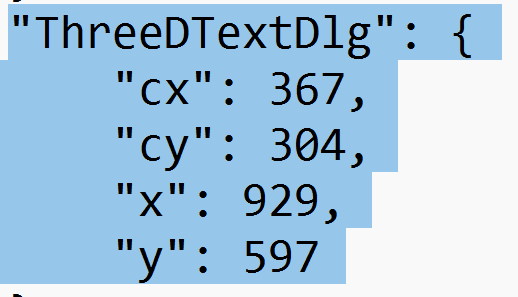

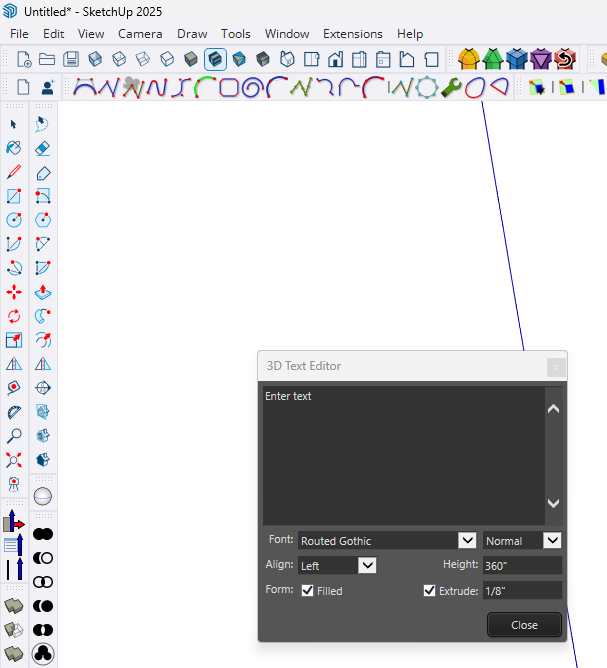

Close Sketchup. Go to user/AppData/Local/SketchUp/SketchUp 2025/SketchUp and open PrivatePreferences.json. Look for "ThreeDTextDlg". What are the "x" and "y" values? Edit those to move the dialog onto the correct screen. This is what it looks like on my computer.

And here's the dialog relative to the top left corner.

Note that the user/AppData folder is normally hidden so you'll need to make hidden folders visible in File Explorer.Did you install SketchUp 2025 correctly? That requires right clicking on the downloaded installer and selecting Run as administrator. If you didn't do that it's possible that Windows is preventing SketchUp from making suitable updates to PrivatePreferences.json. To ensure SketchUp is installed correctly, close SketchUp, find the installer in your Downloads folder, right click on it, choose Run as administrator, and when prompted, click Repair. No matter what, it won't hurt to do it.

-

RE: [Plugin] 3D Text Editor

@puttea what version of SketchUp? What operating system?