Oops, your profile's looking a bit empty! To help us tailor your experience, please fill in key details like your SketchUp version, skill level, operating system, and more. Update and save your info on your profile page today!

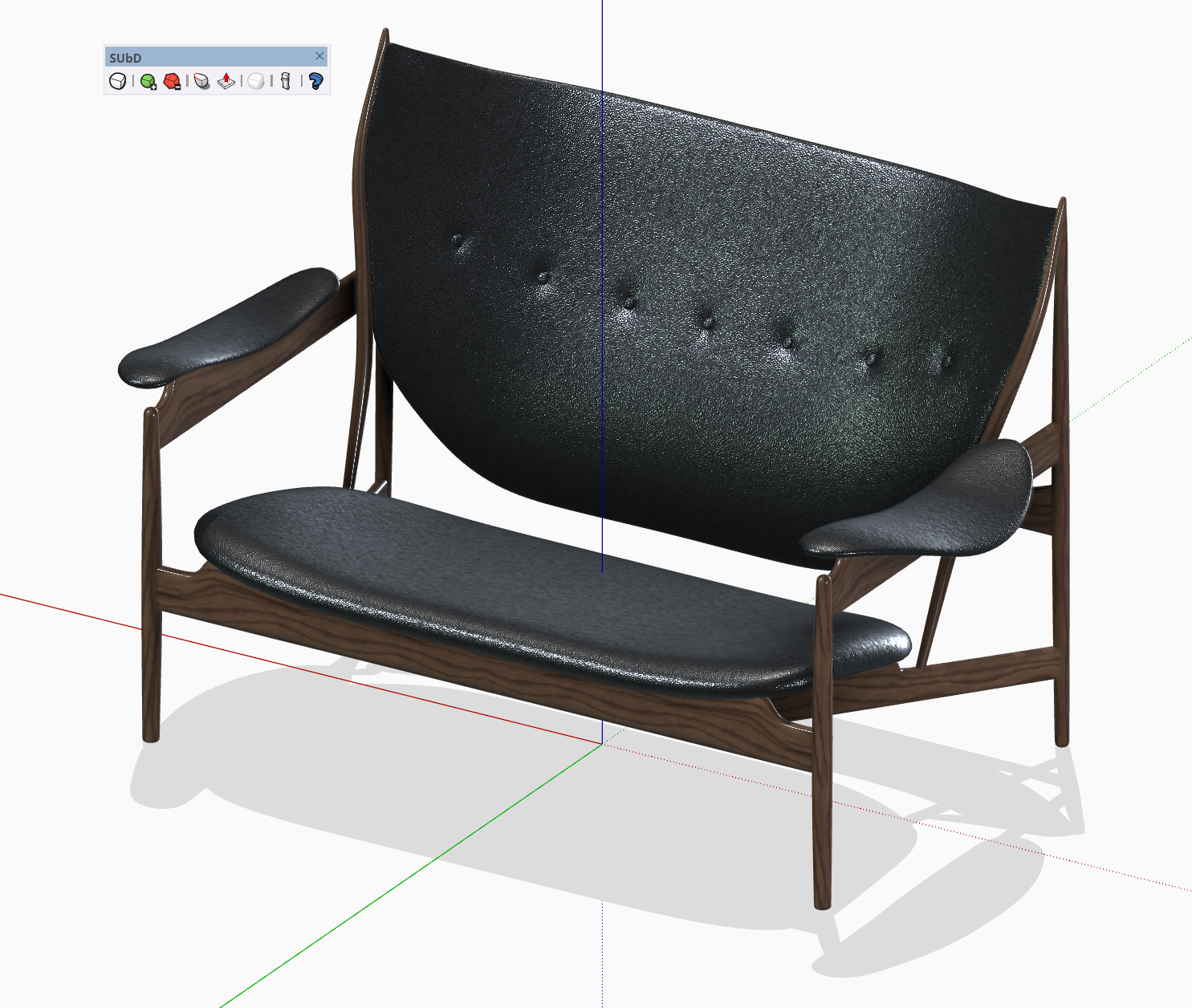

🔌 Smart Spline | Fluid way to handle splines for furniture design and complex structures. Download

Subcategories

-

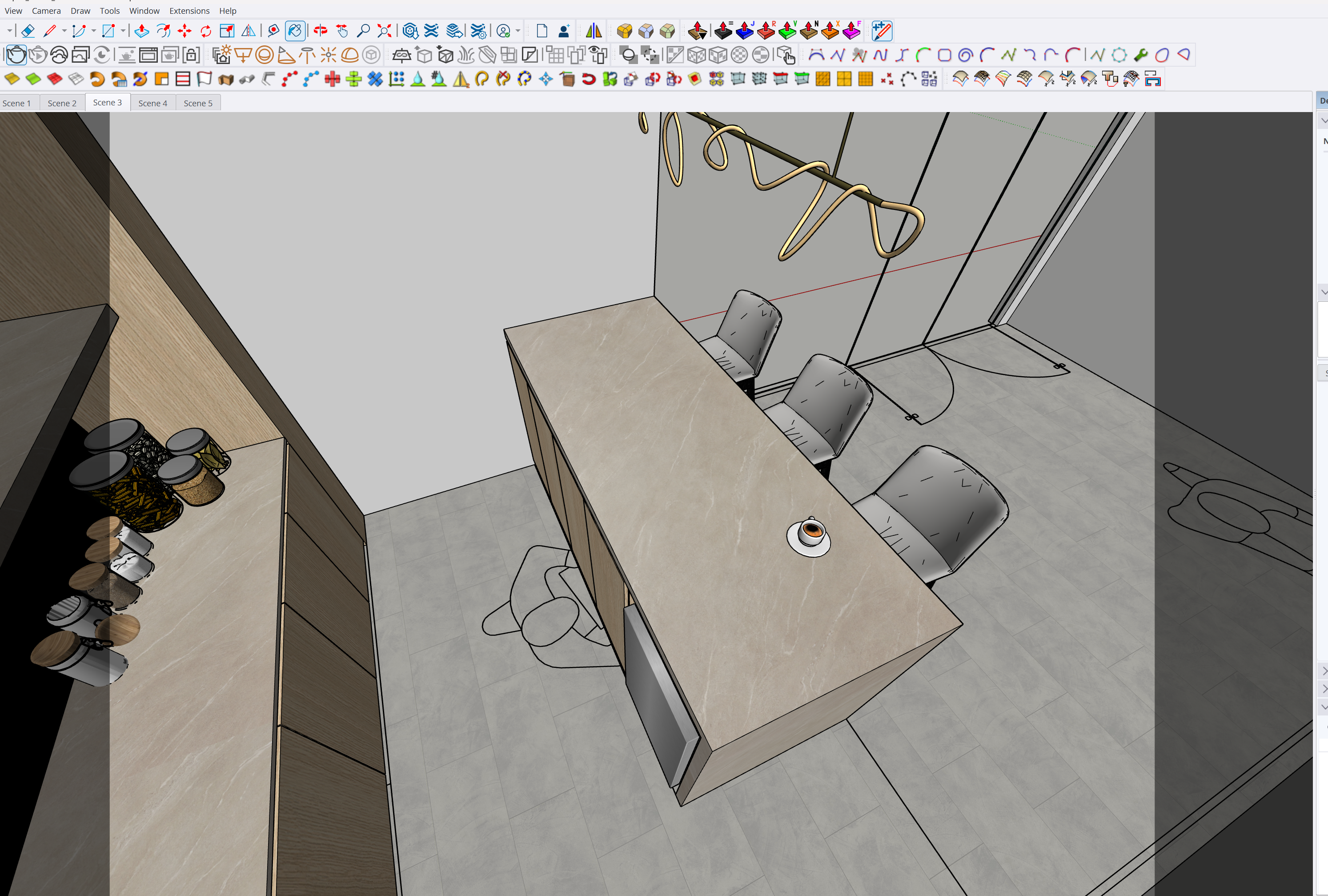

SketchUp Discussions

General discussion related to SketchUp

-

-

-

-

-

Advertisement