You're welcome.

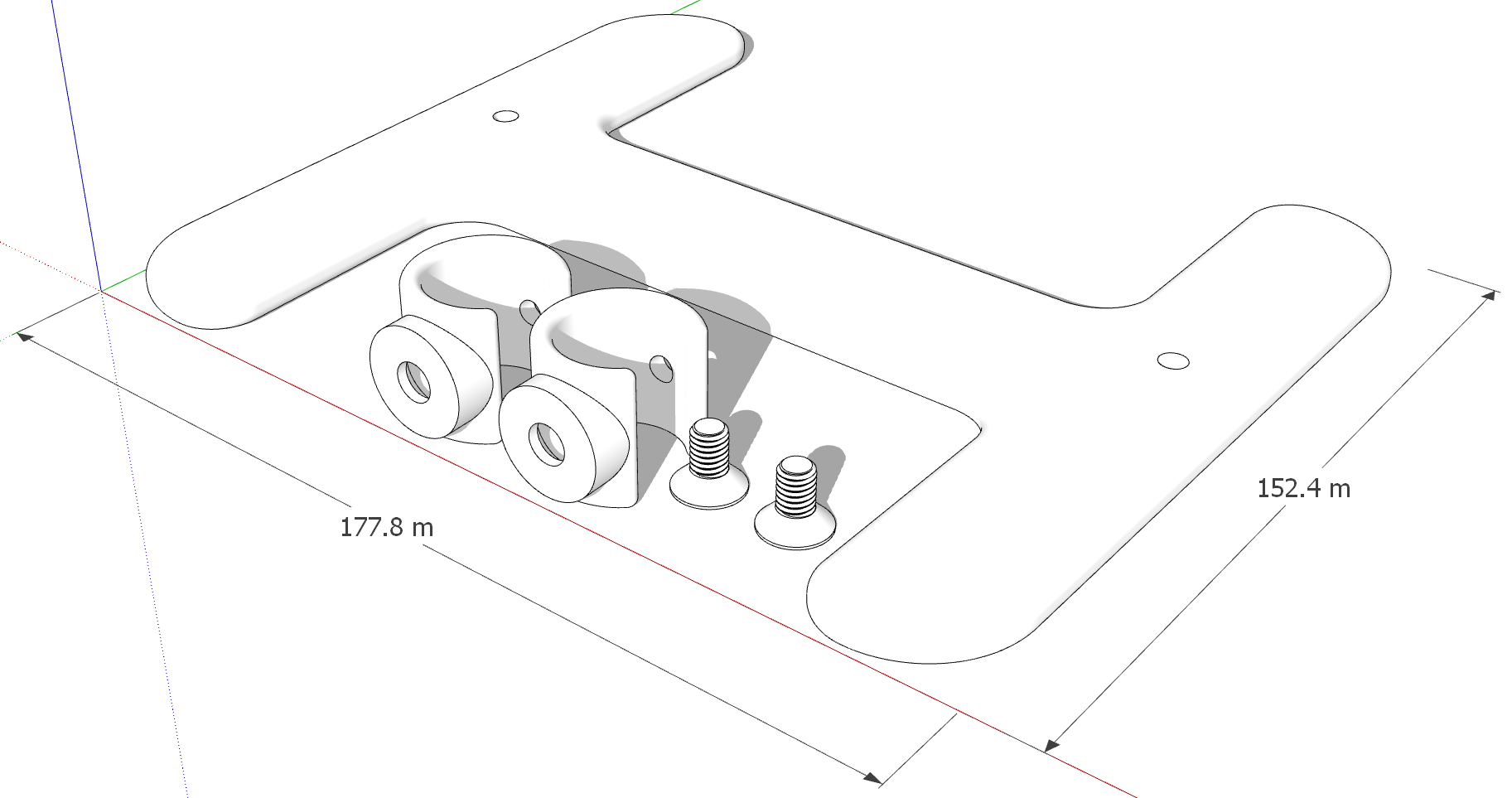

@jgb said in Model for 3D print will not make solid (SU 2015):

I never knew about using "tab" in Solid Inspector 2.

It's a good idea to check out the message line at the lower left of the model window whenver you start a tool.

@jgb said in Model for 3D print will not make solid (SU 2015):

Next model I will try using meters instead of centimetres. Just that 10:1 is easier to work with than 100:1 as I have to visualize the model against a ruler to get some sizing correct.

You misunderstand what I told you. There's no need to deal with 10:1 or 100:1 at all. Set the model units to meters. Read millimeters off your ruler and just enter them without doing any math at all. If you measure 15 millimeters on the ruler enter 15 in SketchUp. It'll go in as meters but you don't need to do anything with that. When you export the .stl export it with Model Units set to meters. When you open it in the slicer it'll be in millimeters and you don't have to do anything as far as the scale goes.

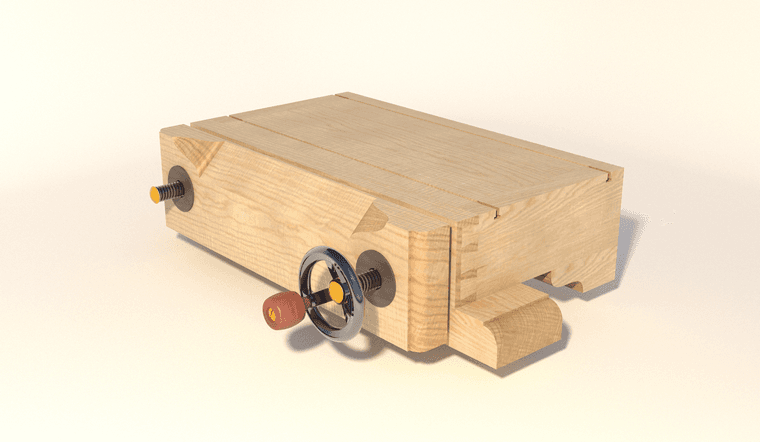

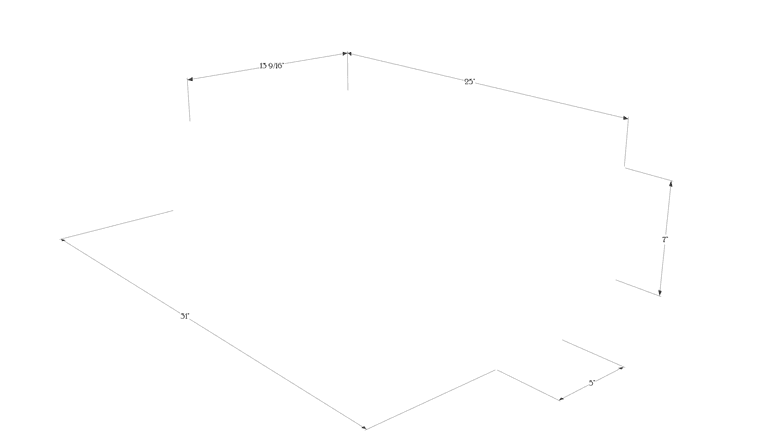

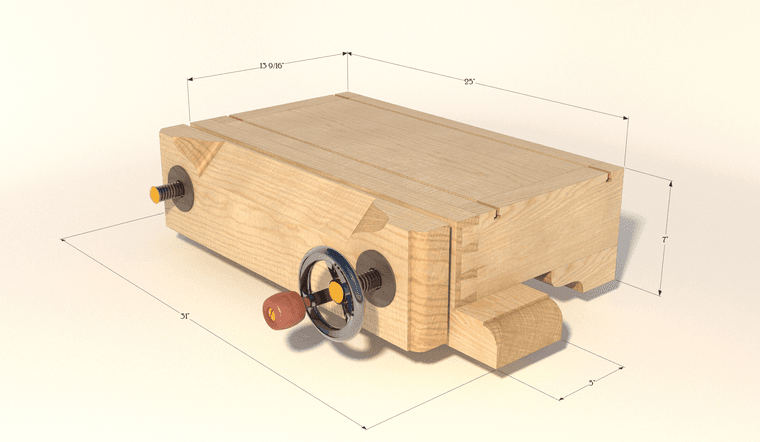

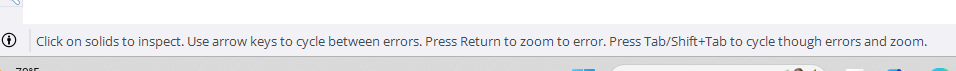

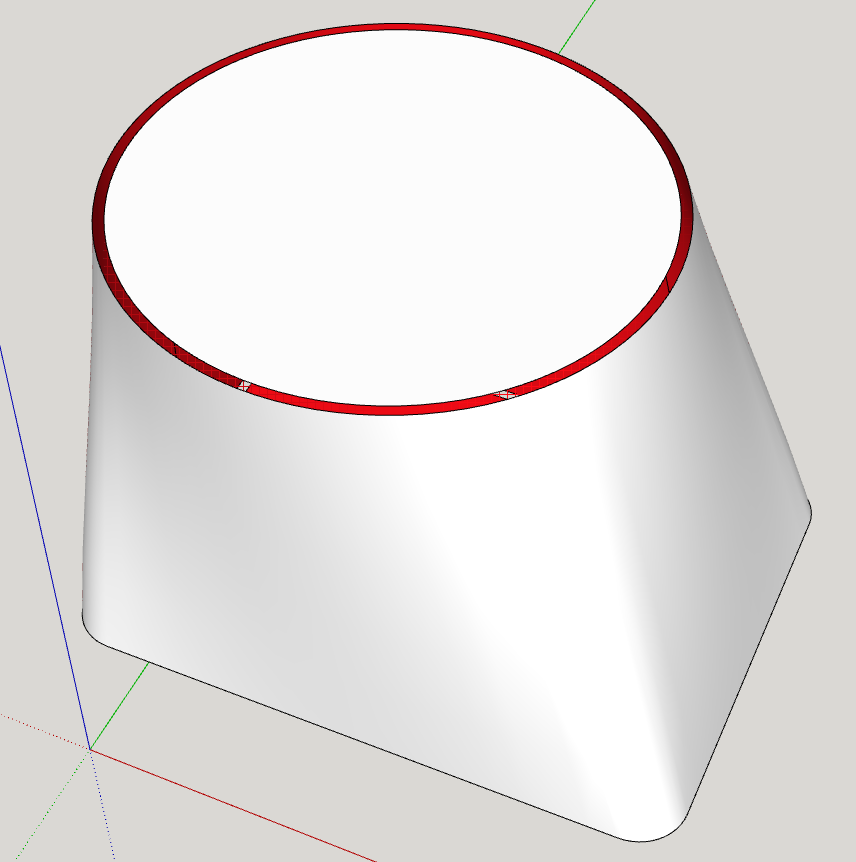

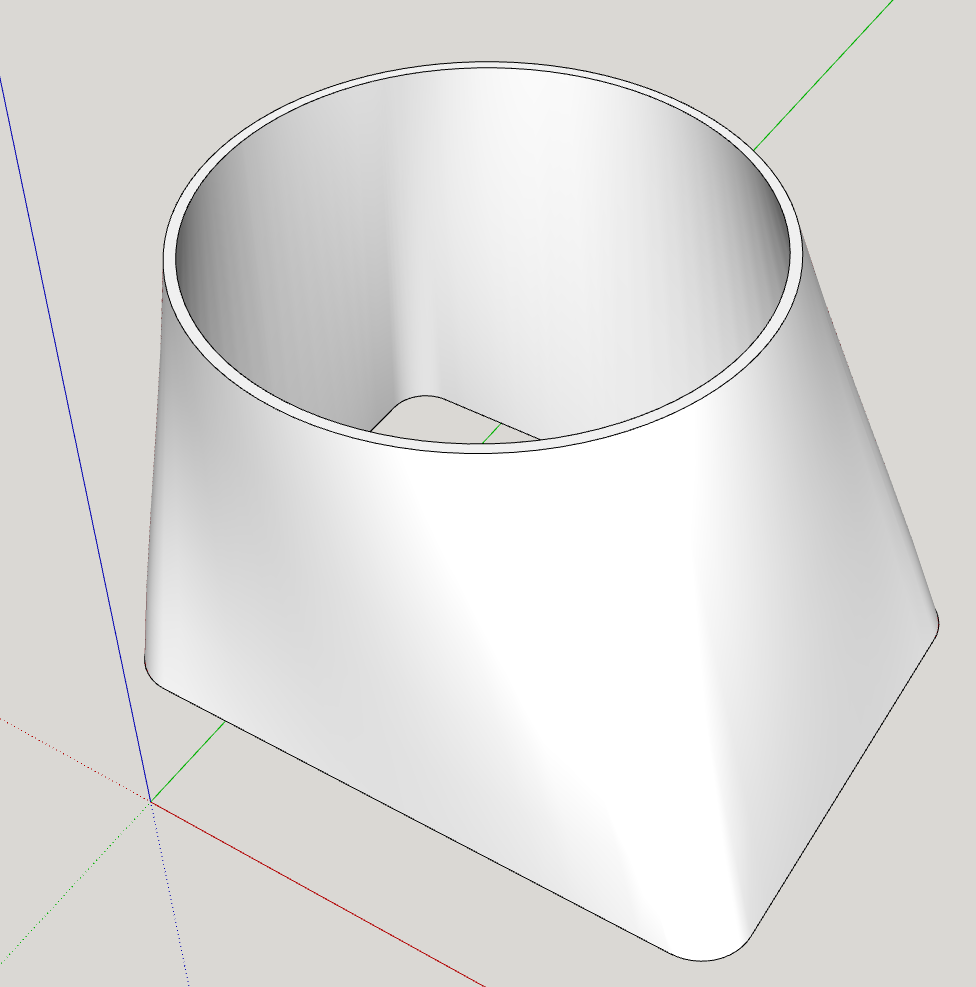

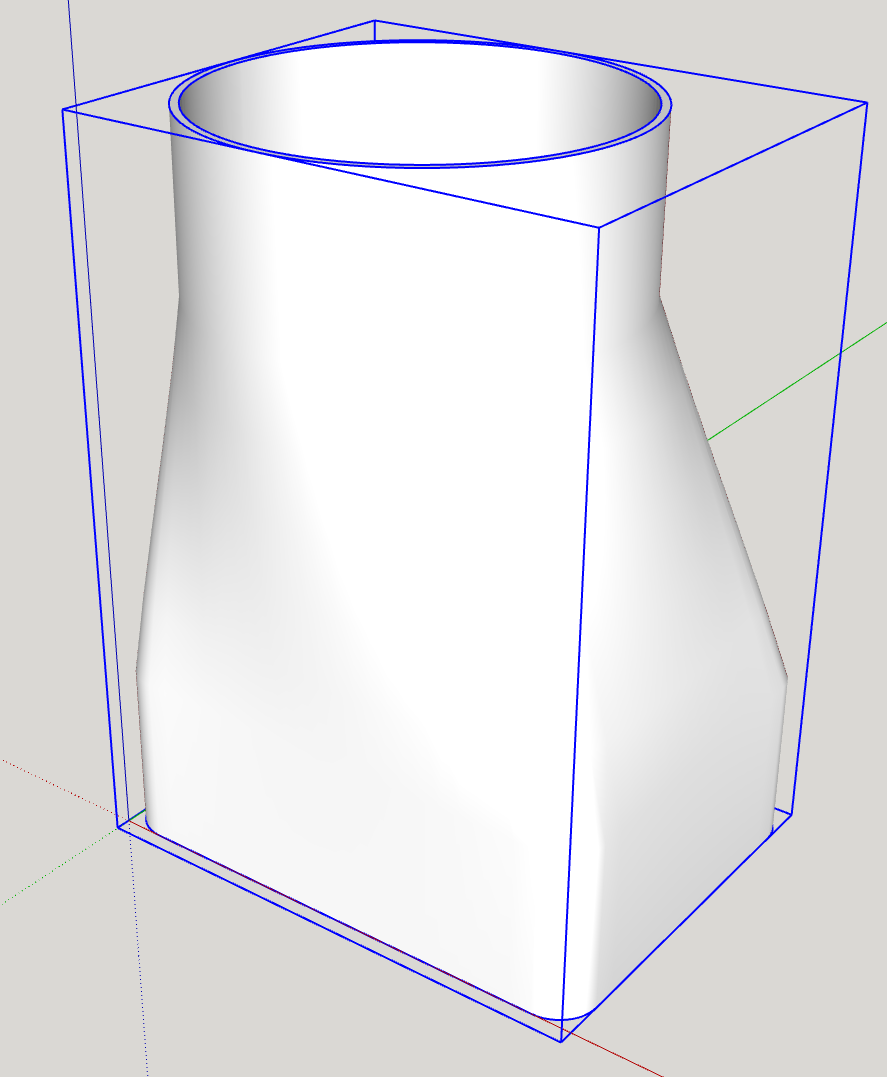

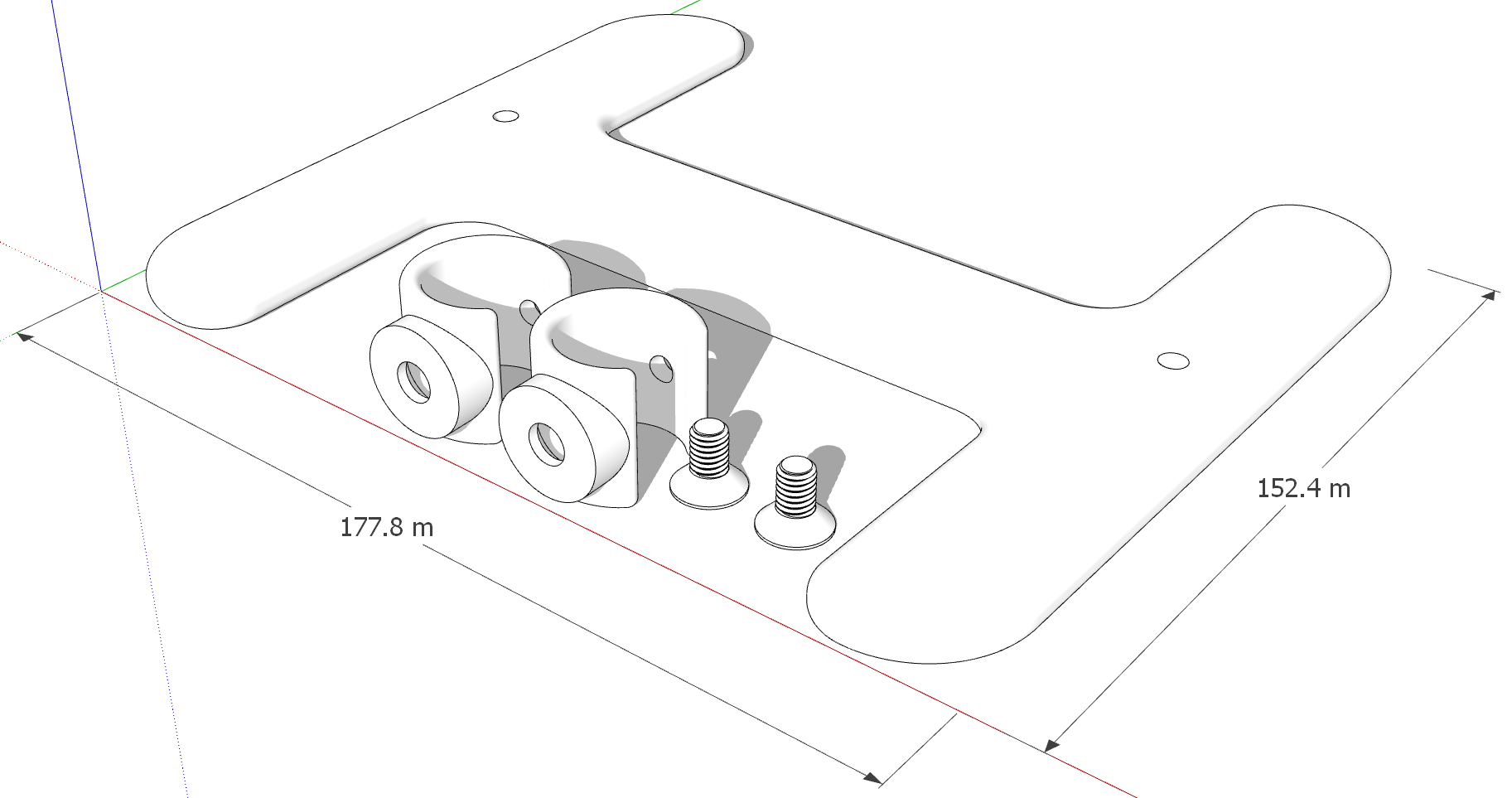

Here's another example. Model in SketchUp with units set to meters. The screws are M6 but the threaded part is modeled at a hair under 6 meters in diameter.

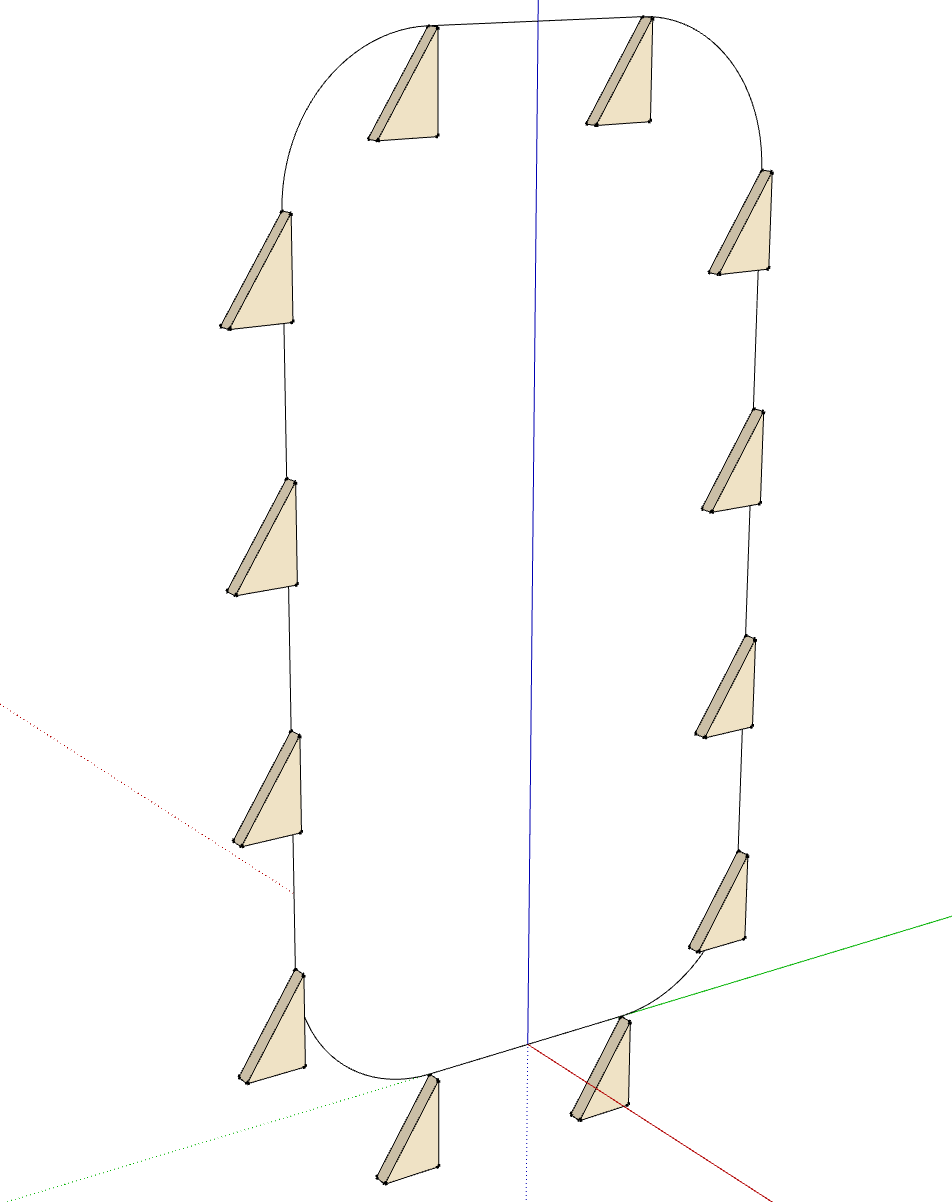

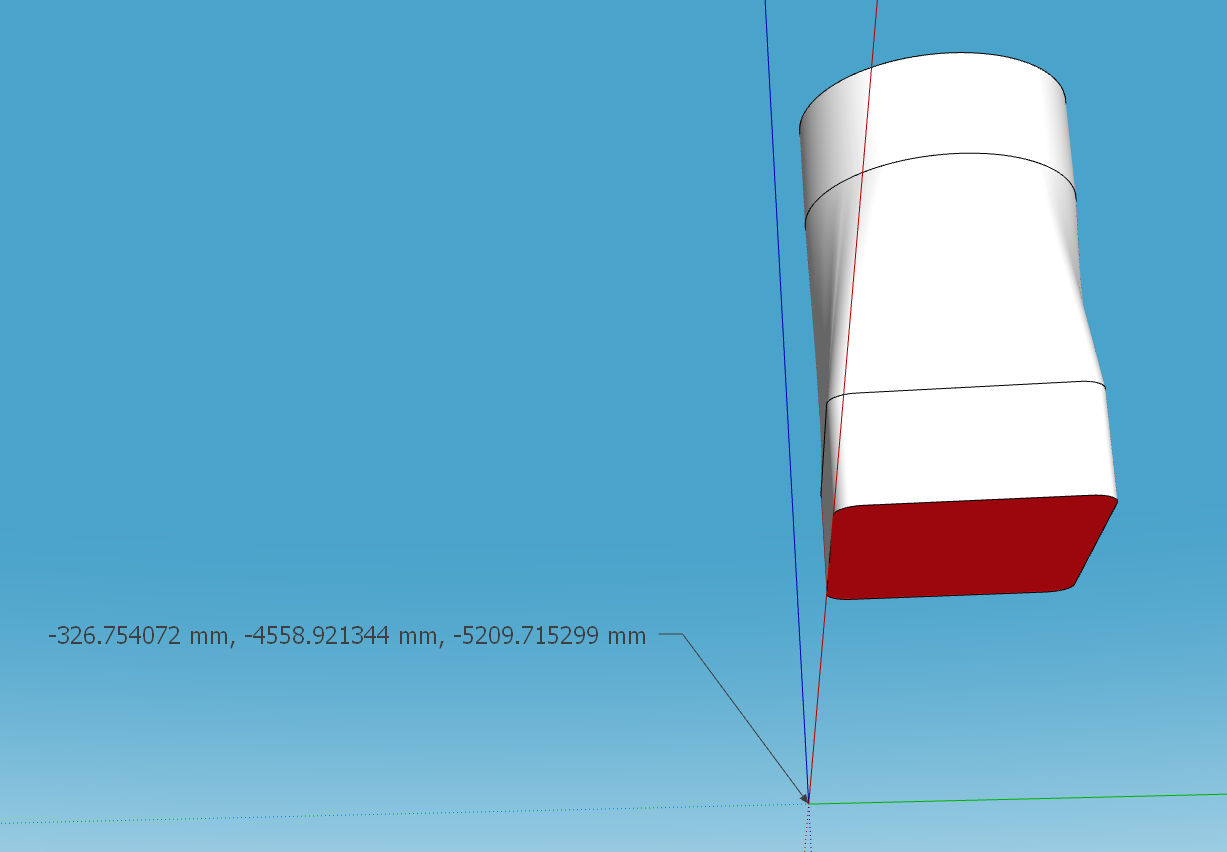

And the 3D printed parts.

The M6 screws fit into the tapped M6 holes just like their commercially made metal counterparts would.

@jgb said in Model for 3D print will not make solid (SU 2015):

Alternatively, just open the group or component and activate the tool. Saves you from jumping in and out of the object while editing.

Doesn't work for me. What am I missing here?

I guess you'd have to ask Thom Thom about that one.