It is clear that there is always a good (user-induced) cause when it does not work. Anything else would be a bug, which is probably rarer.

Meanwhile I had discovered this irregularity myself.

It is clear that there is always a good (user-induced) cause when it does not work. Anything else would be a bug, which is probably rarer.

Meanwhile I had discovered this irregularity myself.

Thank you for your responses and for the description how to do it.

But why does'nt Push/pull not work? I don't understand that.

Length snapping is not enabled.

Hello,

Why can't I reduce the width of this part from 50mm to 45mm?

Kind regards

Aloohaa

@Alan-Fraser Vielen Dank!

An Ihren Deutschkenntnissen ist absolut nichts auszusetzen!

und Ihre Kreise sind wirklich rund!

Hallo,

ich wollte 4 Kreise zeichnen, von 380, 385, 480 und 485 mm.

Obschon ich die Segmente auf 96 erhöhe, werden sie nicht rund, sodass ich die Segmente 380-385mm und 480-485mm nicht extrudieren kann.

Ich habe es zuerst in mm versucht, dann in Metern, ohne Unterschied.

Wie kriege ich diese Kreise rund?

Mit freundlichen Grüßen

Alohaa

Thank you very much for all the work you have done with my faulty drawings!

@Dave-R said in Part not printed as drawn:

neither one of the objects is a solid in SketchUp.

I don't quite understand what it means that it's not solid.

That would mean that I am not proceeding correctly by drawing a surface and extruding it!

@Dave-R said in Part not printed as drawn:

loose geometry between them

What do you mean by that?

I proceeded in such a way that I put both parts on top of each other, and on. 2 sides by creating inclined planes by drawing the individual lines to connect the parts more strongly.

@Dave-R said in Part not printed as drawn:

a lot of garbage geometry and there were some reversed faces, as well.

What is garbage geometry?

I looked closely for superfluous geometry by displaying the part in the X-ray mode and found nothing superfluous.

@Dave-R said in Part not printed as drawn:

I've cleaned them up so they are both solids.

What did you do exactly?

@Dave-R said in Part not printed as drawn:

Why are you modeling these so small? We already gave you the advice to model in meters, export in meters, and import the .stl into the slicer in millimeters.

I had forgotten it again, but this is only necessary in various (although I don't know in which!) situations, or not? The fact that I drew these parts in mm didn't cause any problems, or am I seeing it wrong?

Incidentally, I recently printed a part I had drawn in metres without scaling it down because I had forgotten it was in metres, and it printed correctly, which I was amazed at and still don't understand!

Hello,

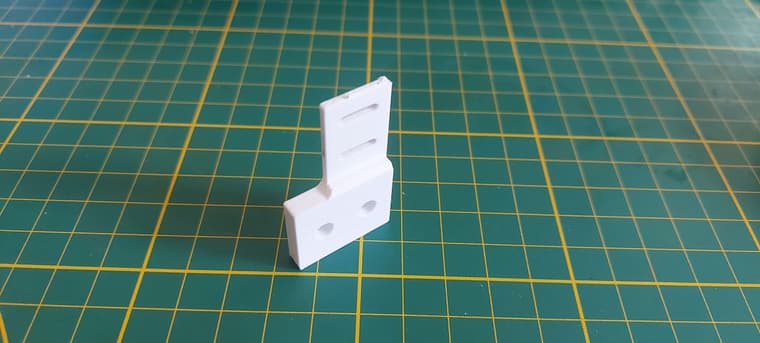

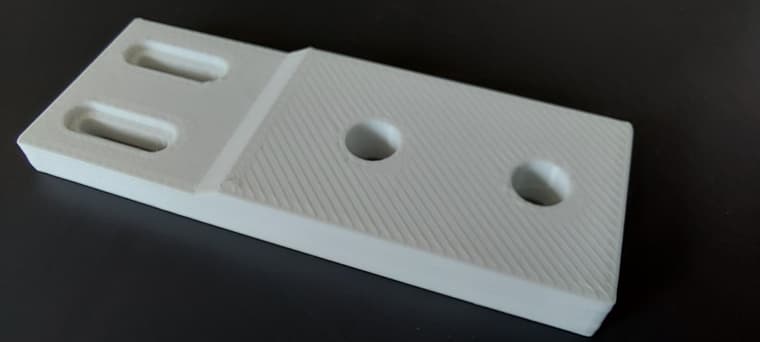

I have drawn and printed an adapter to attach a limit switch to my drawing machine.

A first part (the left one in the SU file) was printed as drawn, a second, slightly modified one, was not. This should be 4mm thick at the top but only has 2; what is missing is 2mm and the countersinks around the slotted holes.

It should be noted that I did not touch the upper part in comparison to the first one, except that I rotated it by 90°.

What could be the reason for this?

Kind regards

Alohaa

Isn't there an explanation for this strange fact?

Why, is the exciting question!

@Dave-R Thank you! I am not really familiar with the section function.

@Jean-Lemire: Merci beaucoup! Très intéressant et très instructif! Tu dois bien maîtriser SU!

@Dave-R I have replaced the fround tub e by a square one.

I don't manage to close the open surface in the interior. I presume it's open because it has another color than the other ones?

@Alohaa

I can't manage that.

That's why I drew a new part without rounding.

However, I can't close an area on the inside and I don't know how to connect the circle with the square.

@Dave-R

As the berries do not remain in the funnel but only the outer ones are in contact with the material, and only for a short time, this is probably not so important.

There are probably other methods, such as the one you mentioned, but for me it's not just the goal that is the goal, but also the way to get there that appeals to me to design and print such a funnel.

However, I still have my problems with the design: how did you add those edges?

@Dave-R

Hi,

I'm trying to understand your explanations.

A word of explanation: I have a lot of blackberries that I freeze individually (so they don't stick together) on a plate to put them in a bag when they are frozen. I always have to hurry so that they don't start to thaw, and that's when I had the idea of a funnel like this, which I actually want to 3D print. I still have to find out how food-safe PLA is.

Hello,

How can I create a funnel from this geometry, i.e. how can I connect the rectangle to the cylinder?

Kind regards

Alohaa

ok, I understand the principle.

What I have some difficulties to understand is the method how you fill the surface.

The rounding that can be seen in my first post and that I only managed to draw until the corner.