%(#BF00FF)[<Postby brandy20 on Sun Oct 30, 2011 6:17 pm

Hi Dave,

this is exactly what I did and the match is fine on the external path, but not internally. I also tried to run the follow me on the complete loop and paste it in place separately in every component but the result is the same.>]

Luca

Brandy FYI

The way the follow me tool works is it's projecting along sequential vectors define by the path you select. At the very first step, if the surface is not perpendicular, then the surface is basically reduced in size by the cosine of the angular error. To get the size you want make sure this criteria is followed=> it will be in error all the way around however.

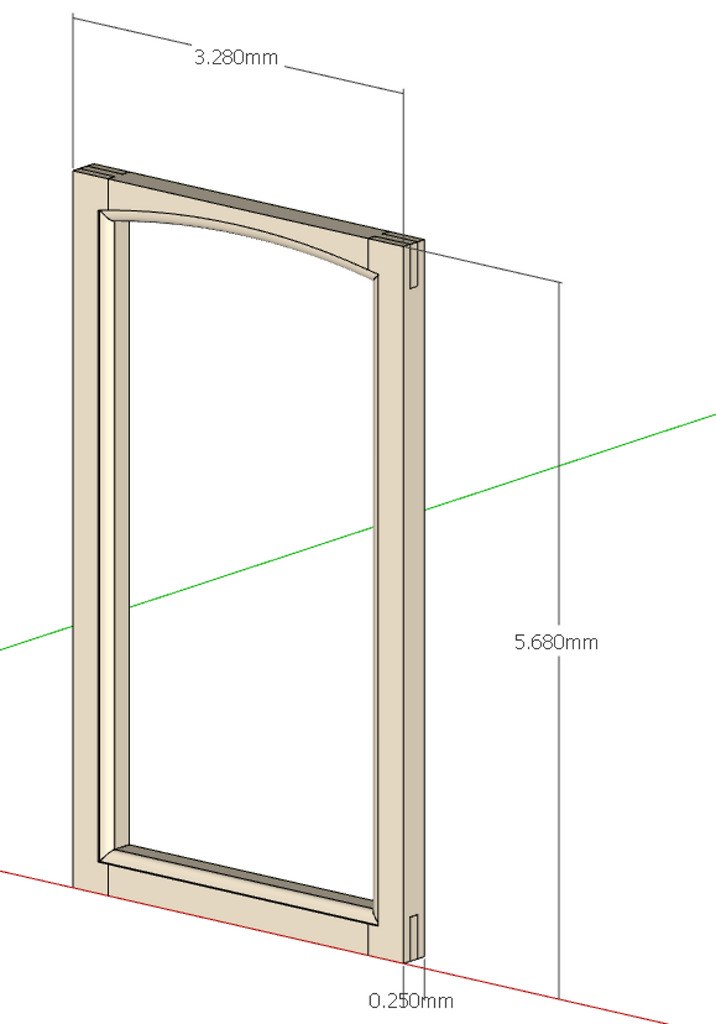

Because of this projection and my assumption were you were trying to do the extrusion on each component separately (not with standing your above comment) you are not giving the program enough info to allow for correct corner formation and thus the errors. I exploded your 1000 scale model and did the loop approach and it worked just fine. I then scaled down by 1/100 and then 1/10 with the first step ok but the second was not very good. I then used the tape tool to resize to your .568 mm height and that worked fine. Scaling up more than back down ( based on previous postings ) will probably work but did not try that.

Why so small to start with?? ~ 1mm is the break point

Just some thoughts

Not really I have better things to do.

Not really I have better things to do. If you do it this way the follow tool will work very nicely.

If you do it this way the follow tool will work very nicely.

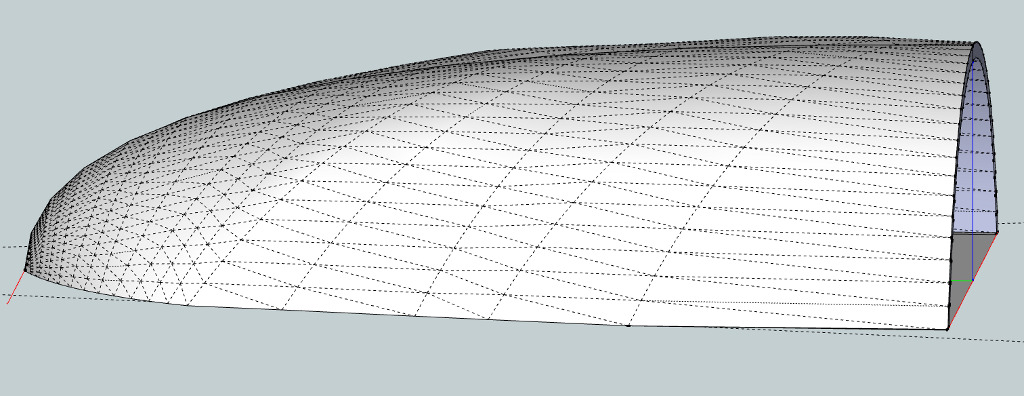

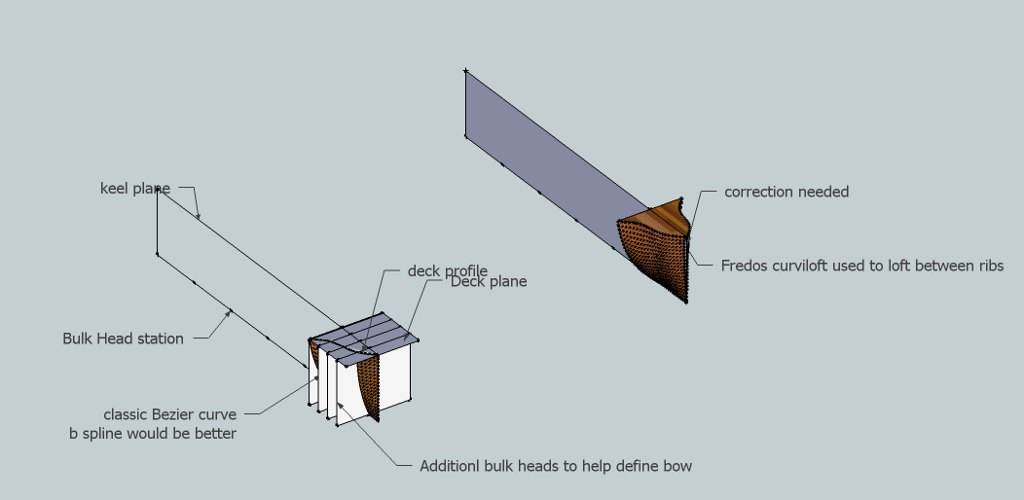

Here is a concept that may work for you. Probably have two many points on the bezier splines. You choice on how you want the contour to look.

Here is a concept that may work for you. Probably have two many points on the bezier splines. You choice on how you want the contour to look.