No master here. FYI is what turned up in a quick search http://forums.sketchucation.com/search.php?st=0&sk=t&sd=d&sr=posts&keywords=organic+modeling&fid[]=18&start=15

Posts

-

RE: Not so new, need master's advice

-

RE: Filling in lines and arcs

OOps I should have also suggested Tom Toms clean up tool.http://forums.sketchucation.com/viewtopic.php?t=22920

-

RE: Filling in lines and arcs

There is a plugin called stray lines that can help you trouble shoot also. Many times you will have "gaps" at the arc's.

See this link http://www.smustard.com/script/StrayLines -

RE: Why can't I resize components?

As Jeff suggested use the stretch tool in Freedo's scale tool. You can do the two components ( door and box) separately. Here is the link and pay attention to his installation instructions http://forums.sketchucation.com/viewtopic.php?t=17948

-

RE: [Plugin][$] Curviloft 2.0a - 31 Mar 24 (Loft & Skinning)

FAK keep will not twist but does not keep elevation in 100% of cases. 1001 bit tools will work. It has a free eval period that you my want to check it out...

Clarification: FAK elevation comes into play when you go over a "hill" and for railing this should not be an issue

-

RE: HELP!!! lost ruby functions

Would not take that step yet:

- What is in your present plugin folder? I think 7 does not have a repair option and if you reinstalled your plugin folder it may have been over written or did you delete SU with the and / remove option before reinstalling?. You still have the tool bar after reinstall so that means they were not over written;

- I have not used this plugin. Have you checked the window, preferences, extensions and see if you have to activate it first. Also check and see what is in the view tool bar drop down:

- You can remove the tool bar plugins and see if you can get back to a base line but you will have to make sure you do not remove some rb's used by other programs.

Yor screen shot shows the archive. How did you extract?. What you have in the plugin folder should mirror what is shown it the screen shot. I checked CadFather's down load site but did not find any install instruction there. It maybe in one of the rb's?

BTW I always keep my rb"s in a separate folder apart from SU and then load form there so you will have the zip files etc. If you copy vs move them to SU

-

Free User Attribut Report

In this thread http://forums.sketchucation.com/viewtopic.php?f=79&t=38020 Jeff created a very useful scv report that could be used in Excel. As a learning process I want to replicate the report using Su7 free after using TIG's volume plugin to calculate the vols of one of the groups. This plugin will show the vol as a group name if one selects its entity info http://sketchup.google.com/3dwarehouse/details?mid=56f87af526c83696fbae97082232979f. I have tried attriburtes . rb, attribs.rb, attrib_repoorter.rb and TIG's component+rp plugin and several searches.The only success I have is with TIG's script but the data was buried down in the group mined data. IMHO I think it should be easy to get a simple vol report.

Search results for Attribute dictionary, keys, tags, values mostly return plugin script writing questions except few very simple cases for a general user and none showing how to set the dictionary to extract this type of variable data.

If anyone knows of any good tuts for a general user please let me know so I can get off my sword.

Thanks

PS if you are going to just point me to a plugin then please show and example. What's obvious to everyone is not to me

-

RE: More help

serpentine 5

Started with your model post , changed to SU7, quick check showed 78 broken lines , 39 stray lines. Flatten it to remove any question about planer. If you select various faces in the model you will see areas where they are selected and they should not based on wall etc. Some are caused by coplanar lines , duplicate faces etc. Where these errors came from? Probably as TIG stated but they can also be caused by you as you make the model. Make sure you spend some time on the video tuts so you under stand inferenceing use. Once you get to this model level it can get difficult to correct so slow down and hurry up is the best approach. There are plugins that can help you trouble shoot but best to under stand the SU basic capability first. -

RE: Downloaded component question

@ecohomes said:

@dave r said:

As to the furniture flying off, I imagine it is like the car example you posted last week. The car looked like it was placed correctly from one angle but you hadn't actually placed the car on the driveway. It was floating in space. You need to get to grips with placing components properly. I would suggest that you spend some time working on learning to use the Move tool and Inferencing. Getting those skills nailed down will go a long way in helping you make your models look like you want them.

Thank you Dave - I have in the mean time ascertained that one must bring them into the model from the "Gluepot" for them to stick.

Thank you again for your courtesy and time.

HansI often use the VCB for moving my models vs the move tool. Say you have a model and you want to move to the origin pick the desire point with the move tool to start and the type [0,0,0] and that will move to there. If you want to keep the same y dim then type [x,,z]. Check manual I find this method very helpful

-

RE: Quantities from model

Jeff

great work as usual

Ref Su8 upgrade. I don't need and will change over to free when my eval time runs out. At present my main use is as file converter.I do have both installed. -

RE: Quantities from model

@jemagnussen said:

Hi again,

Come to think about it, it might be much easier to make the quantity take out by taking the volume of the first and last 1 m slice and enter the numbers in Excel and let it figure out the even distibution in between. Think that is an easier approach.

Question this. Do you have an spread sheet to do this and checked it. The vol as you step down your model may not be linear and you may have as much work as just using SU. I have not checked this however.

I'm working hard to use 3D visualization in my profession as Production Manager on construction projects, the model here is part of a new groyne, and being able to use Sketchup to produce and present the 3D visualization of the project and the steps in between is really a benefit for all parties involved.

The quantification would also look good if being able to present it visually in 3D, slice by slice, but it is probably overkill as an Excel sheet will just as well show the factual quantities and for the time being be most trustworthy for the parties involved as it is a sort of a defacto standard.

Op Site. I had help on previous post on getting estimates of grain vol in a silo bins and it is not real straight forward. Used EXCEL there but this is more complictaed.

Do you have to show each slice for visualization. May contention is once you have the work flow set then getting the vol of each slice can be done quickly. One of your problem areas seems to be getting the solid vol to run calculations. I think there are some plugins which can help. Namely make faces and ?? ( Need to find for you). Some time ago I ran a number of test on TIG's cal I ref above using the prismatoid approach as an easy check point and it is most certainly accurate enough for what you are doing. I am like wise certain the SU 8 included capability is accurate too.

For presentation using scenes to separate the 3 materials maybe useful.

Well get the plugin info and get back with you

Good LuckBest regards

Jesper -

RE: Lifting capacity of a bolt ?

@unknownuser said:

hey mac, thanks

yeah, i'm ok in that dept.. the floor is level and has 22' ceilings throughout.. at the tightest part of the move (laterally), i'll have 3' clearance on either side.. there's one spot in the concrete that could be a bit of a problem (kinky expansion joint) but i have some 16 gauge sheet stock to lay over it..fwiw, i've moved much(much!) heavier objects before for longer (much longer!) distances but i've had a crew and heavy duty machinery.. my crew doesn't live in nyc and there's no way to get any sort of forklift or crane inside this building..

i'm feeling ok about this safety wise especially because i'm only going up less than an inch.. i guess my main worry is being halfway into the raising or lowering process and have one of the bolts strip out.

Roger sounds like you have the bases covered.

FYI: Don't know the dollar value of the item you are moving nor your liability. For ground handing equipment we usually apply a large safety factor.

Have moved ( technical management resp.)items via Fed X , air ride vans, bought the total first class section seats of United 727 one time so all the electronics could be strapped in the first class seats, over the road coast to coast and even almost filled a C5A with 1 item. All total maybe around 3/4 billion dollars. Move never goes as smooth as I would like( Had a really bad experience with D ring )

Good Luck -

RE: Lifting capacity of a bolt ?

@unknownuser said:

@unknownuser said:

@unknownuser said:

what do you think the torque listings mean on that chart?

Its the value at which the bolt is considered tight. Where as your 'invention' isn't relying on bolt tightness but drive. That's a different kettle of fish.

I can't view the file as I'm browsing on iPad. But I'm presuming you're raising and lowering this skirt that's 1600lbs? In order to roll this doodad about?

If so the skirt is suspended on the nuts. Tightness or torque isn't necessary but you'll apply torque to raise it. The force acting down on those nuts will mean sweaty Jeff. If you had a threaded spacer/bushing it would mean more mechanical action than brute force. Also a bolt with a double start would reduce the number of rotations needed as John mentioned. And a nice acme or buttress thread would ensure longevity.

I could be looking at this incorrectly

nah.. i think you're seeing it right. (except i don't need longevity.. lift/move/lower/done.

i definitely don't mind getting sweaty though so that's not a problem:D

the problem with some of the welding suggestions etc. are more of a logistical problem.. my welding machine is in storage in long island city (queens) and the lift is in hell's kitchen (west side manhattan).. and i don't own a vehicle..

these people are loaded though so if i said you need suchANDsuch contraption to move this thing then they'd do it.. it's more of a personal challenge of mine to move it for 25 bucks or less

.. well, that and i have a chance to resell some steel and casters that i happen to have which are doing nothing but taking up space and collecting dust.

.. well, that and i have a chance to resell some steel and casters that i happen to have which are doing nothing but taking up space and collecting dust.i think i'm good to go.. i'll post a picture of the thing when it's being moved.

it's a pretty cool object (at least to an american? you euros might give it a meh..)Jeff

Make sure you look at what, if any, move obstacles you have to cross. I am sure you have seen the pics of Obama limo getting high centered. When moving equipment we usually worried any ramps, thresholds etc we had to cross to make sure there was clearance in our design and for your case possible over turning -

RE: Quantities from model

@jemagnussen said:

Hi Mac1,

You lost me there. When I use the Volume plugin v 2.1 as you refer to, but when I right click and ask for volume then I only get different color on the slice but no volumes indicated anywhere but in the Entity box...?

I attached my sorry attampt to get the volumes...Brgds

JesperThat naybe a change TIG made to that for Su8 but I don't know. My work flow;

- Use section plane to cut at the 1m ref;

- contex on the plane and select option to make plane a group;

- Use edit menu to do an intersect with model;

- You can then convert that section to a component and use the vol cal to get the vol. My test of the first meter( made error here. It is really 4+

)shows 405.918 cu m.Note I did not keep you name convention on the layers.!

)shows 405.918 cu m.Note I did not keep you name convention on the layers.!

See this http://sketchup.google.com/3dwarehouse/details?mid=5e06e125de23b706fbae97082232979f

Ok

Using your model above:

In SU 7 first section is 62.027cu m and second is 60.624 cu m

In SU 8 using only the entity info box first and second sections give the same result without the plugin

It looks like some auto folding is occurring with you sections so make sure to use care? -

RE: Quantities from model

@jemagnussen said:

Hi Mac1,

I need the 1 m slices parallel to the end face of the model.

Hi TIG,

When I use your Volume Plugin, it can only give me the volume after I have cleaned the slice up and then when I group it I get the volume in the Entity info box anyway...

Best regards

JesperDon't use entity info. I think that is bounding box also. The geo you presented is very close to the defininiton of a prismatoid. For geo meeting that def the vol is just the face area x extrusion length. That can give you a quick but inaccurate check of reults you are getting . Check using the plugin above show about +2% error for the slice I checked

note I am using Su 7+ don't know how SU8 has changed. Think it is suppose to accurately cal vol.??

note I am using Su 7+ don't know how SU8 has changed. Think it is suppose to accurately cal vol.?? -

RE: Quantities from model

@jemagnussen said:

Hi TIG,

Thank's I will try both options (on a copy

) and see which on works best.

) and see which on works best.Best regards

JesperCannot not answer your specific question but alternate thought:

Convert each of you material layers to a component. You can then use the section tool( or you can draw your own cutting plane) to get the 1m slice of each of those and the vol plugin to get its vol. NOTE: some vol plugins give the bounding box vol others give the actual geo vol. so make sure you check that. Question: Is the 1m measured normal to the face or along one axis?

This is the one of TIG's I use http://rhin.crai.archi.fr/rld/plugin_details.php?id=464 -

RE: Organic modeling from photos?

Not my area but maybe worth a read

$$ http://www.brainstormllc.com/ but has 30 trial

$$ http://www.brainstormllc.com/ but has 30 trial -

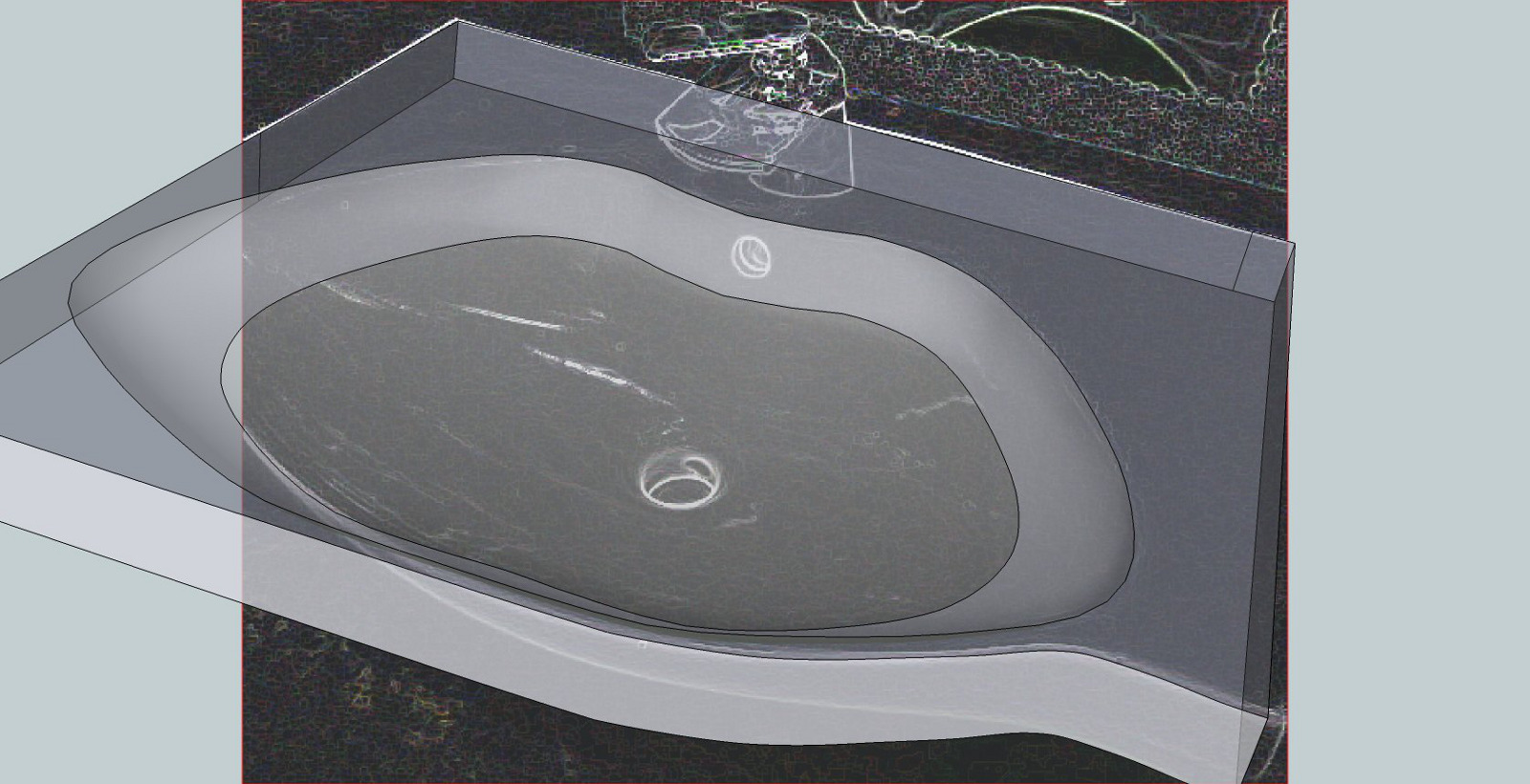

RE: Any advice on this complicated shape?

I worry important problems fist

Myshtern

Here is the skp model warts and all http://sketchup.google.com/3dwarehouse/details?mid=2b987ce710e4b89fbae97082232979f

As I noted above there are many unknowns you will have to determine such as sink bowl profile, its size and the exact location of drain and over flows. Note in many sinks the drain is near the back edge and the hole profile is some what conical vs circular to allow sealing when it is drawn down from the bottom and on bottom there is a cylindrical protion for the drain tail pipe seals and nuts to seat against. TIG's extrude tool was used to create the bowl on my guess of the profile. Several things you should do: 1) Draw a portion of the top profile and use the mirror tool so you make errors in marking the edges points from the PIC the same so mirroring in subsequent steps does not cause " mismatches"; 2) Try and keep the segs counts in the curves non prime numbers or you will get a lots of faces to deal with; 3) Model only a portion and then mirror. Check Fredo's tool rounded edges to put radius on bowl.

Good Luck all the suggestions I have -

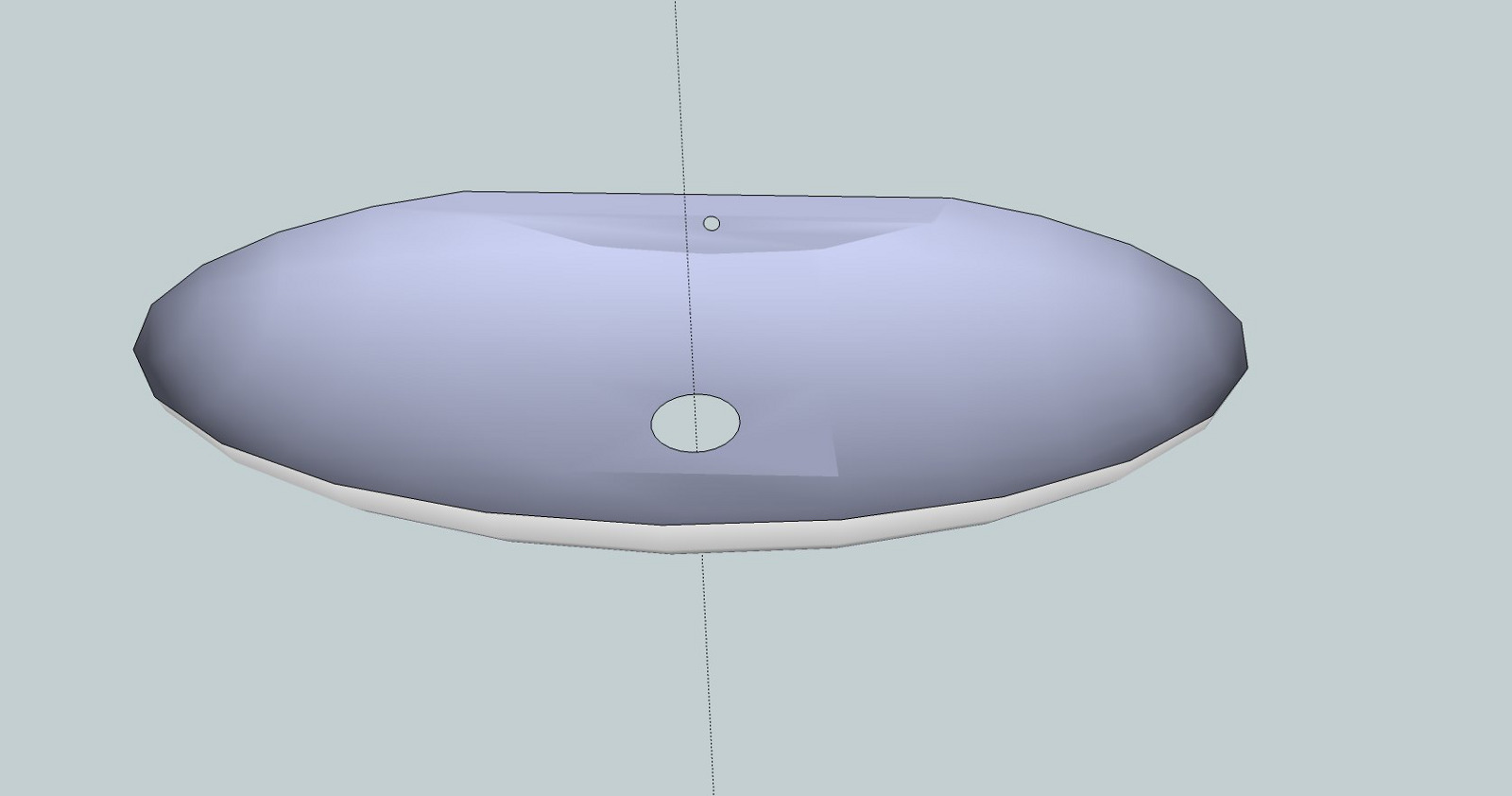

RE: Any advice on this complicated shape?

Attempted to find edges without much joy

So when all else fails guess

As noted there is not enough info in your picts I can model maybe someone else can.

This feeblle attempt

was made by creating an ellipse and then using Tig's extrude by rail plugin twice for the bowl. There are many questions about the bowls actual profile so you need to get more info. I was lazy with the drain and over flows and just used a cutting plane to get the flat surface. Maybe it gives you some ideas -

RE: Any advice on this complicated shape?

myshtern

The jpgs do not provide enough info to model, at least for me.Have you checked the sink supplier? Some manufactures will have cad ,or even skp if you are lucky, files of their design which you can use. If not ,do you have other jgs that give more info.? I am looking for a better plan view and / or some thing with more 90 deg edges for ref.