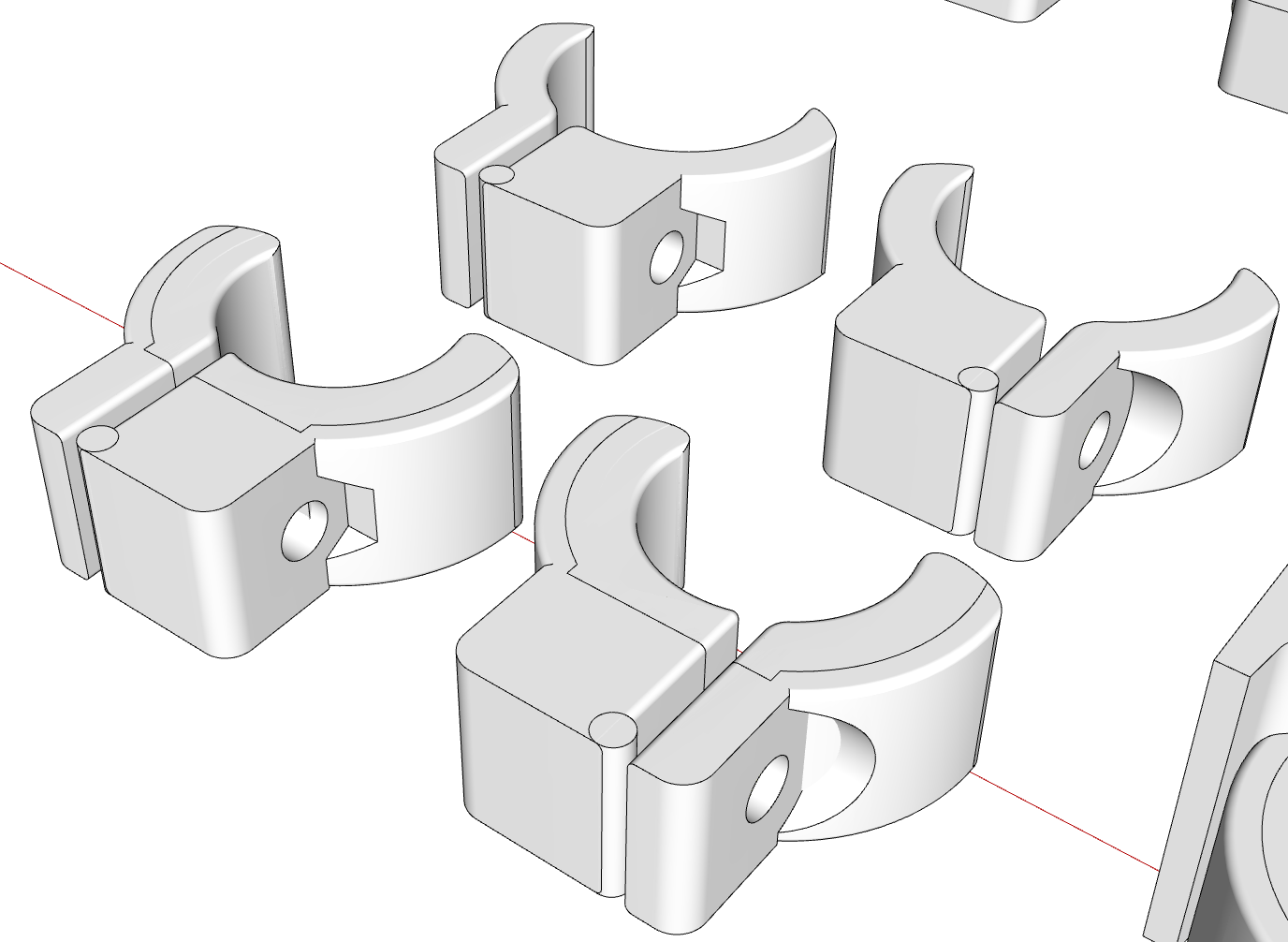

@Nicklaus-Tang said in Image Trimmer Plugin issue:

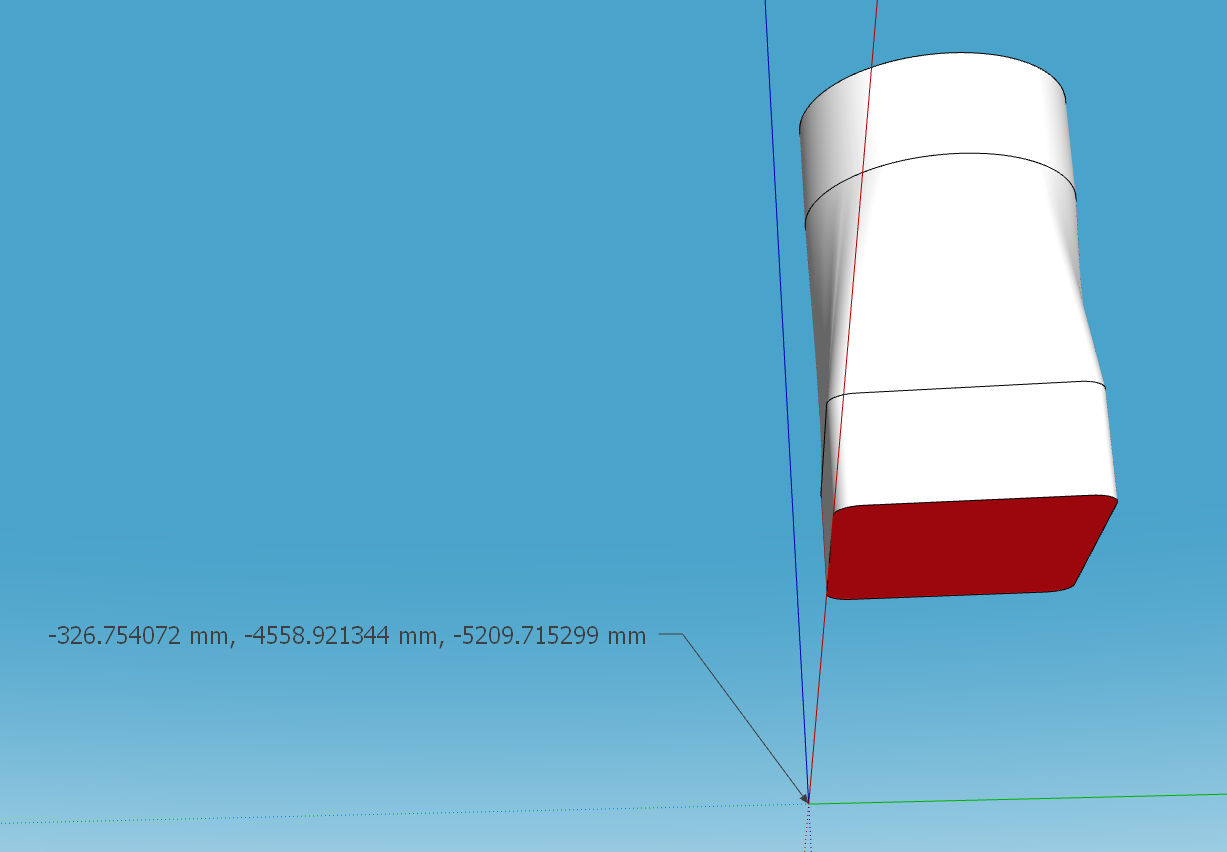

but everytime I use the plugin, sketchup freezes

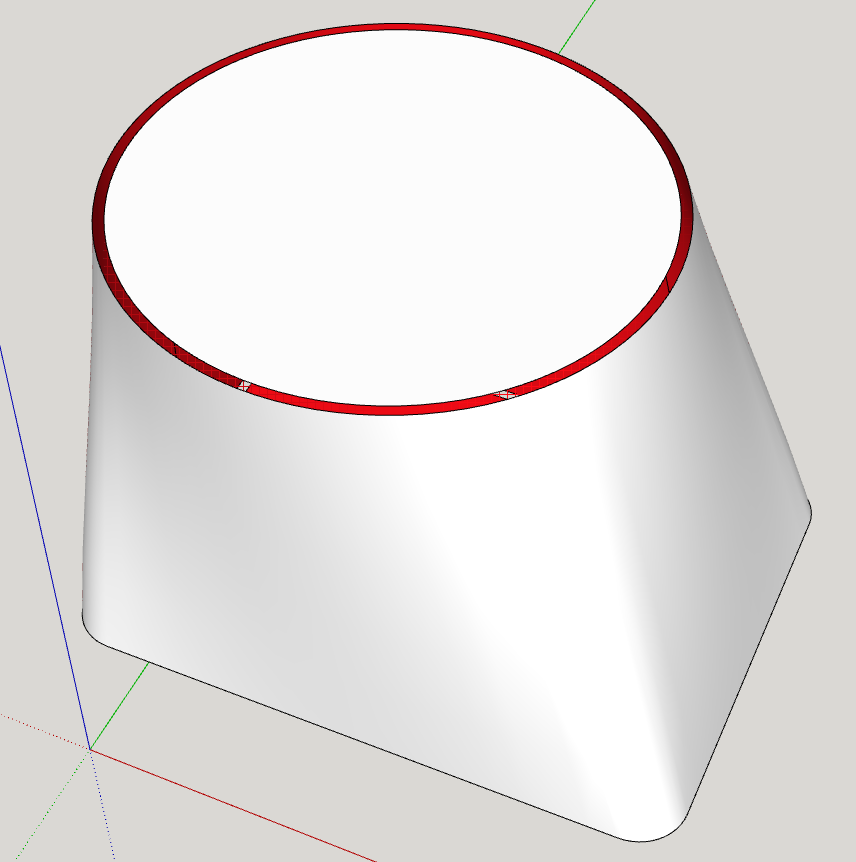

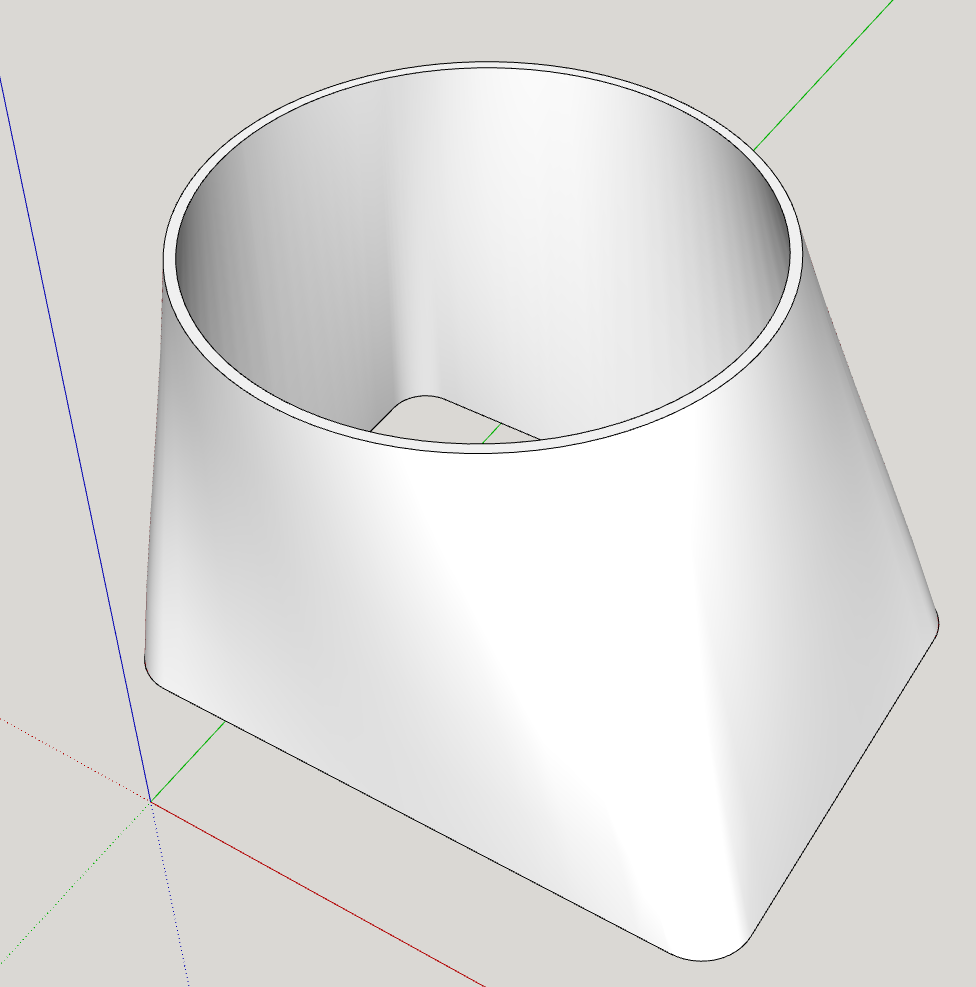

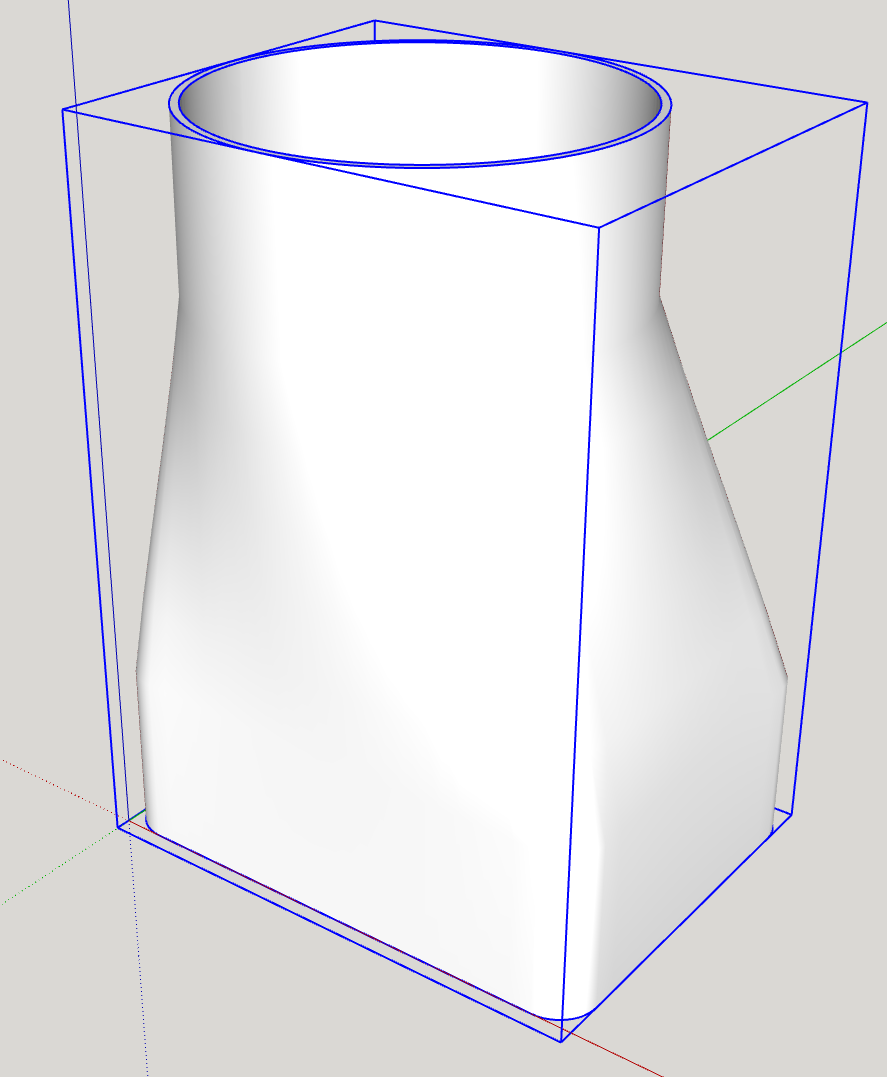

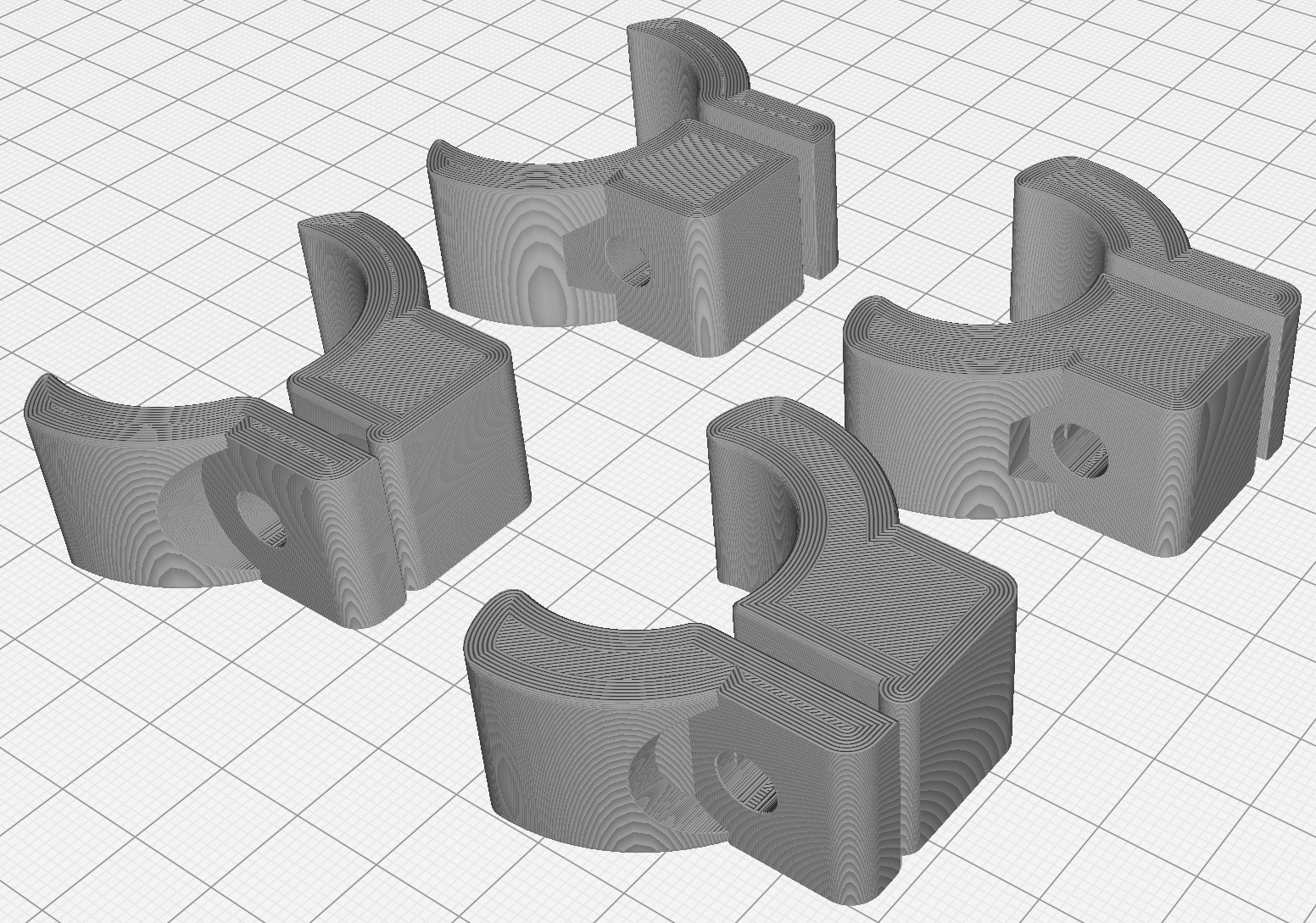

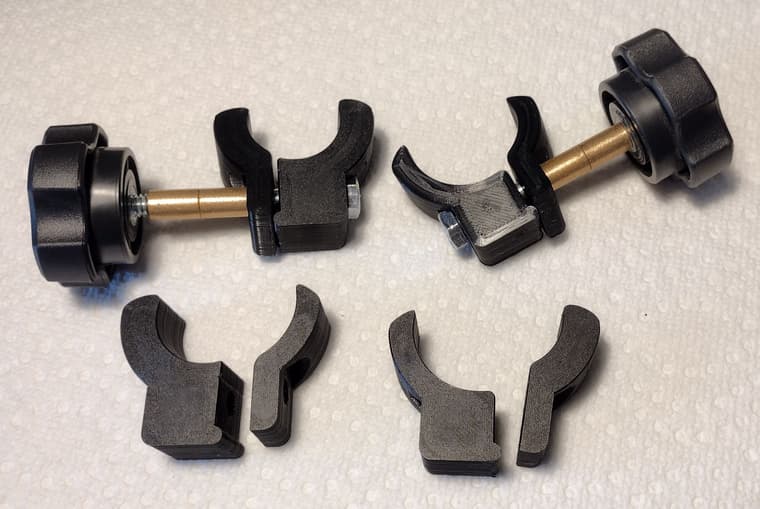

That isn't a surprise. You're asking the extension to create many thousands of edges. That will take a long time. You could speed it up some by eliminating the excessive detail with a simpler silhouette.