Hi! I don't have AutoCAD, but i tested exporting files from Blender and importing them to SketchUp:

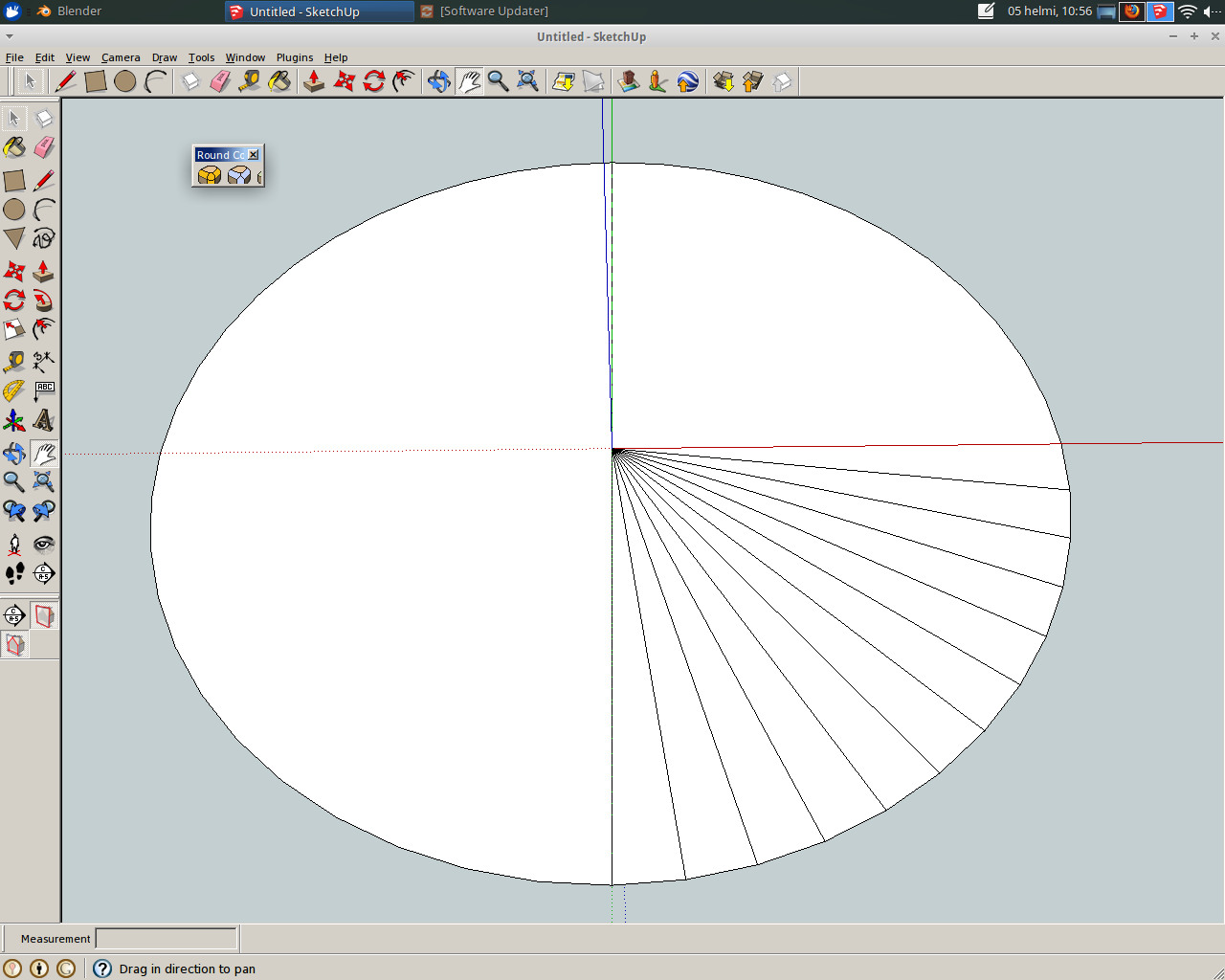

48 sides circle:

.stl comes out as 24s, but Collada .dae comes out with 48 sides !

Hi! I don't have AutoCAD, but i tested exporting files from Blender and importing them to SketchUp:

48 sides circle:

.stl comes out as 24s, but Collada .dae comes out with 48 sides !

I'm not sure if this helps, but there is: Window --> Model Info and Units. You can set precision to centimeters / 0cm .

Perhaps some heavy actions could have backup action joined and then you can end the process without loss of work? Usually I just save my work before something heavy and if the software freezes or crashes I just end the process on task manager and and then continue again ( I use this on many software ).

This technique allows you to make flat crest and root for the thread. I have tried to draw the profile and use the Helix plug-in with the Follow Me And Keep, but they give me a lot of holes, not a solid piece? Here only the helix plug-in is needed.

Not so exact for everything, but at least I managed to make a coarse M24 inner and outer threads. Perhaps useful for something else than screw threads...

If someone can make the booleans work to make easily outer thread? Nice! I had to draw the outer thread "by hand"...

3D printed parts at the end of the video.

Yes, some slow movements from me when doing the sphere "decoration".

Jaaaa, Hot air blower plugin could do some organic... FDM printing is just easier with a one side flat model...

Late answer, there are still places on this sphere without the web.

No plugins needed. This heart shape is slimmer from the down part. With this technique it is easier to modify the shape making different "ovals" (I hope so). Some dimensions are not so strict, I'm just talking...

Starting from the sphere. I'm using select, scale and move tools mostly. It was a surprise for me how easy photo mapping is in SketchUp.

Some basic techniques. Easy to make different versions and still have the manifold closed. The holes can appear if you stretch or bend it too much. I checked mine and few similar ones with the solid inspector plugin and NetFabb. Bend the printed one with the hot air blower gun if you want.

With real time workflow and strange accent narration...

How to draw a basic 3D printable snap-fit ball joint in SketchUp. Consumer & hobby grade printer results vary, so this is a little bit tricky with ABS plastic and delamination problems etc. Perhaps Nylon works very well.

If your parts still tend to broke, make a double "C" opening both sides as on the video, making an intersection piece (deformed ball) 0.80 scale instead of 0.9. And even without the opening scaling.

Use your imagination how to continue design of the part.

I have here the undercut / opening calculations formula, but the drawing is just estimated close to it. Perhaps you have to experiment with the shell thickness & infill etc. I had them 0.8-1.2mm and 15%.

The printer was Reprap Prusa i3. Clean the parts well...Still trying fine tune and make better ones ,but this joint has been working already well.

One way to arrange blueprints for car modeling in SketchUp. I made final use and touch in Blender. I fast modeled Citroen DS 19 with the push/pull tool in SketchUp. Not accurate at all, but good enough for my little Blender world project.

Hi! It is easier to make "box" selections when using parallel projection and standard views. In Blender 3D software for example parallel views are used very often. You need it for many things...3D from image etc... After using the parallel projection it can be forgotten ticked on. Perhaps then the problem shows up?

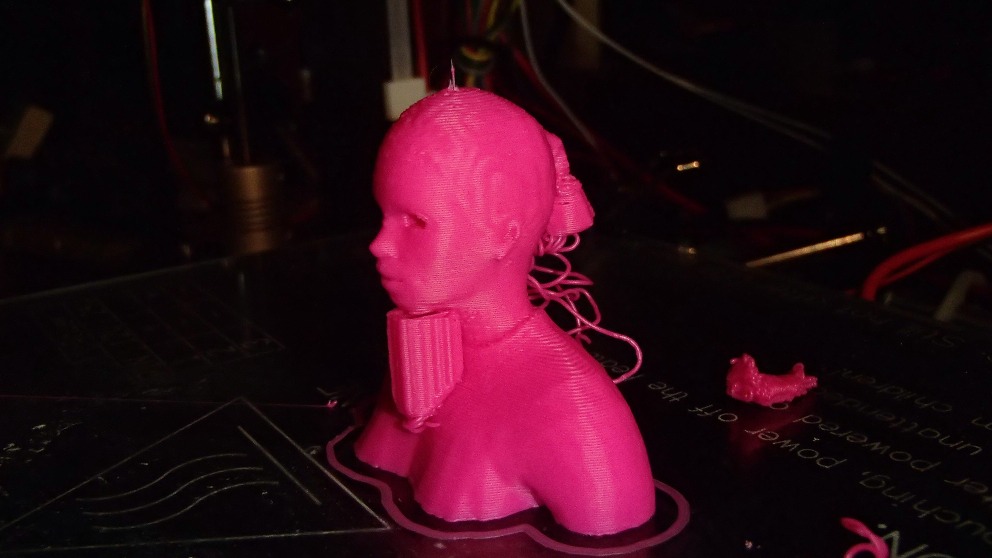

Yes, 3D printer doing it's work.

Nice! Thanks! I was thinking somethink like that https, but I did not try...

This works at least on Linux and SU 8.

Video embedding not working anymore?

https://youtu.be/b6O_BRPLkvI

Here is one nice example of bad "automatic" support structure which I tried just few minutes ago. The slicing software did ok under the chin. But the ponytail behind was like an elephant standing on a chicken leg. Perhaps new slic3r has better and more clear options. There is a lot of options on Cura & Slic3r, but it has been a little roulette what kind of support comes out. Or I just don't understand enough...

Yes it is, but after three Mr. Wrongs I decided to draw my own support. And this is not the only object with problems . Perhaps it is just because ABS plastic is much more curly than PLA. Perhaps newer slicing soft versions have already better support structures.

I tried MeshMixer, but for some reason it did not want to do straight pillars or when it did they were not touching the base plate of my figure.

I really needed SU to draw better support structures for a figure made using Makehuman + Blender.

Hi! Everyone do not like Microsoft's closed format:

http://fabribles.com/forum/vox-pop/70-microsofts-3mf-file-format-no-thanks

Slic3r & Cura can run on Windows, Mac OS X and Linux. They seems to have continuing updates & fast development which I cannot always say from MS products.

Slic3r & Cura also have model fixing. I just think that a good model do not need holes filled with small triangles. Probably slowing the printing process? Or at least I try to do so clean model as possible usually.

One part of the 1:3 skull: GrabCAD -> Meshlab -> SketchUp -> NetFabb -> Cura -> 3D Printer.

A solid two colors SketchUp file: SmallAndBigHeart-Solid.skp

I check my stl files on Netfabb Or before that SU Solid Inspector. Sometimes NF says that my file is printable even when SketchUp Solid Inspector shows problems. NetFabb can export amf,but not import. And it's only a repairing models software.

For 3D printing the model has to be solid. Usually I prefer to do:SU -> Netfabb -> SU or print.

Slic3r also do not recognize inches. A bunch of other slicers do not accept amf, yet.

Well, if the units are ignored, then you just have to know, that you have to convert your work to mm for 3D printing software, for now. This problem does not stop using possible amf exporter? This is a s frontline thing now. Slic3r & Cura at least ahead now, perhaps others come soon to support amf. I'm trying to find information...