Quite fast from 2D with follow me tool to 3D printable ball joint parts. The boom locking seems to work well and there was no problems to make a solid pieces with SketchUp. The scale was of course 100x and it helps a lot when intersecting faces. I used Solid Inspector to check parts ans CleanUp 3 to speed up things. There is some other 3D printing tips at the end of the video.

Posts

-

Multi Use Ball Joint / Selfie Stick, Recording Boom etc.

-

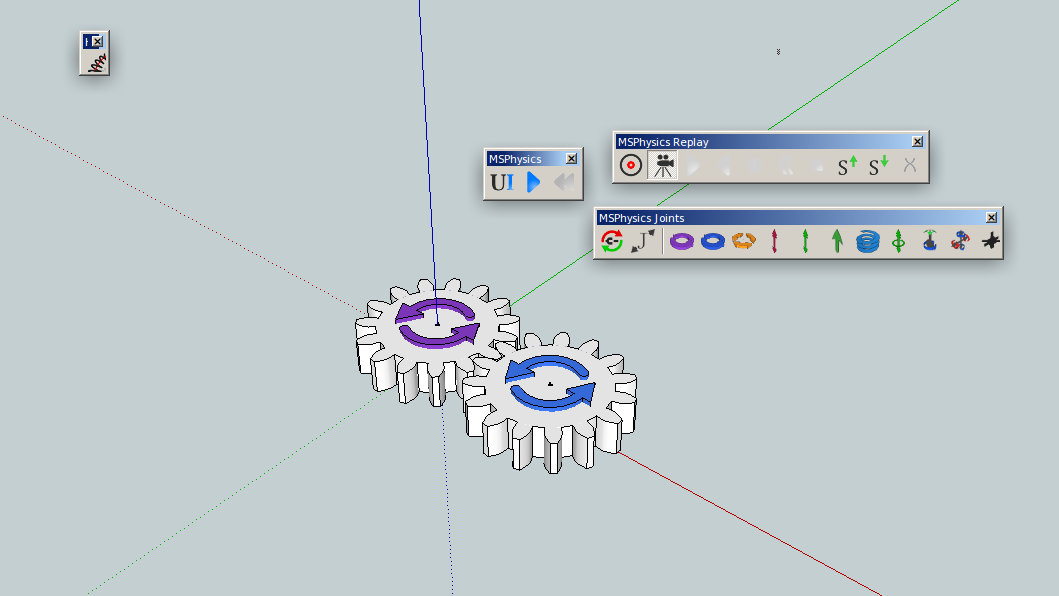

RE: MSPhysics 1.0.3 (16 October 2017)

At first glance MSPhysics working "mostly", nicely with SPGears & Linux SU8. When Using UI only simulation tab works on Linux / Wine.

-

Easy Bevel Gears Arrangement With Online Calculator

SPGears by Mark Jason Grundman & online calculator http://www.daycounter.com/Calculators/Bevel-Gear-Calculator.phtml and it's easy to arrange bevel gears with different ratios in SketchUp (for gearbox design etc). Close holes in the gears with NetFabb and 3D printing is ok.

Edit: Added video testing gears with SketchyPhysics.

Also one nice calculator: http://www.hercus.com.au/uploads/29161/ufiles/Gear_Calculations_rev3.xls

-

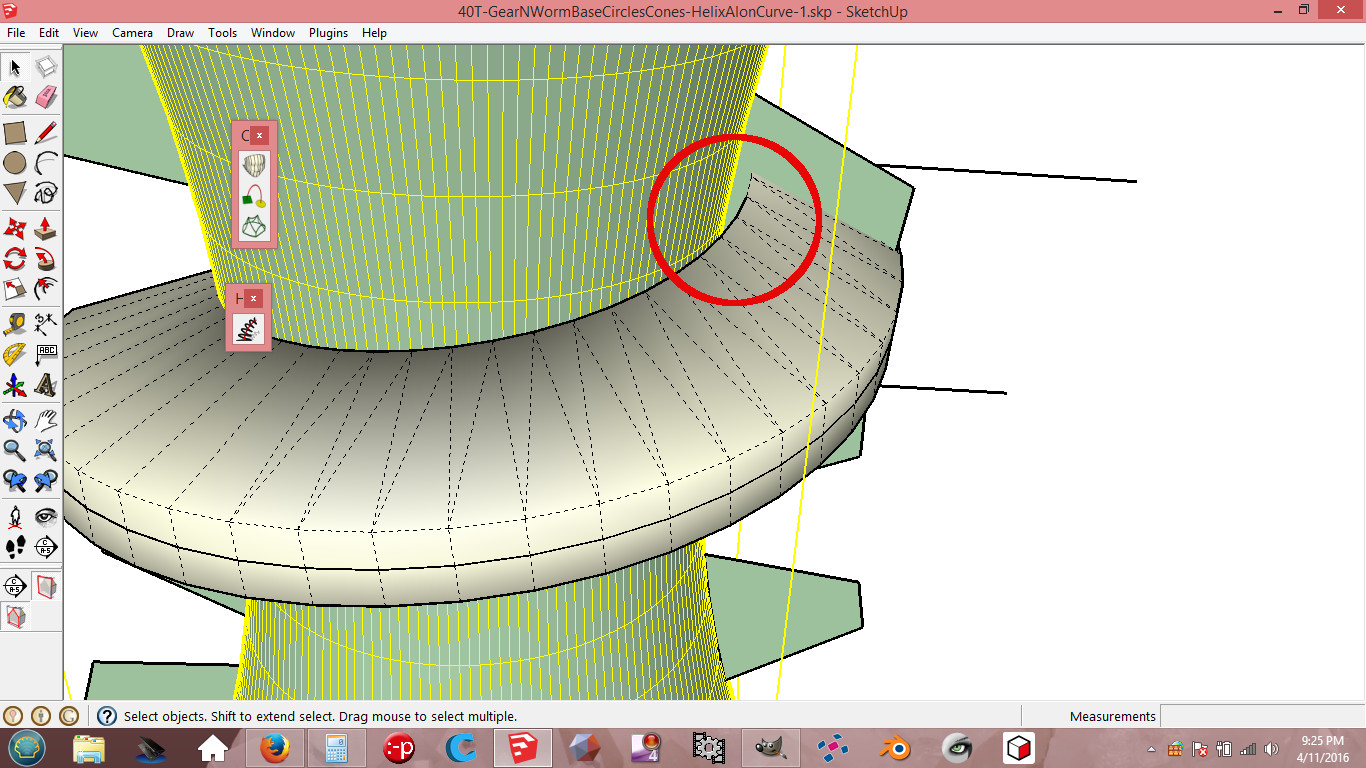

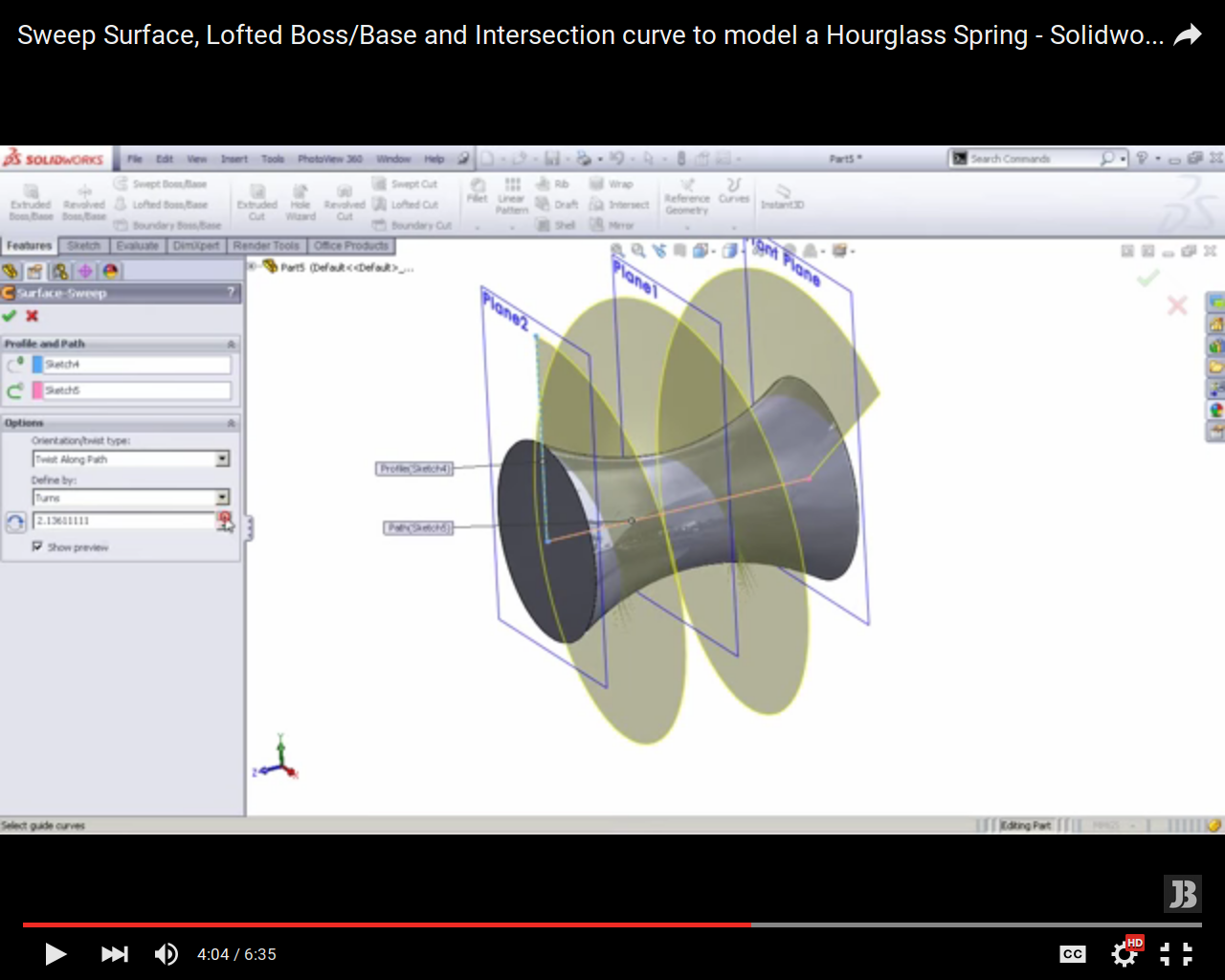

RE: Hourglass Helix?

This came out from involute gear plug-in profile (60 Tooth). Thanks CAUL! I hope that I can soon proceed to a 3D printed piece & real world test.

-

RE: Hourglass Helix?

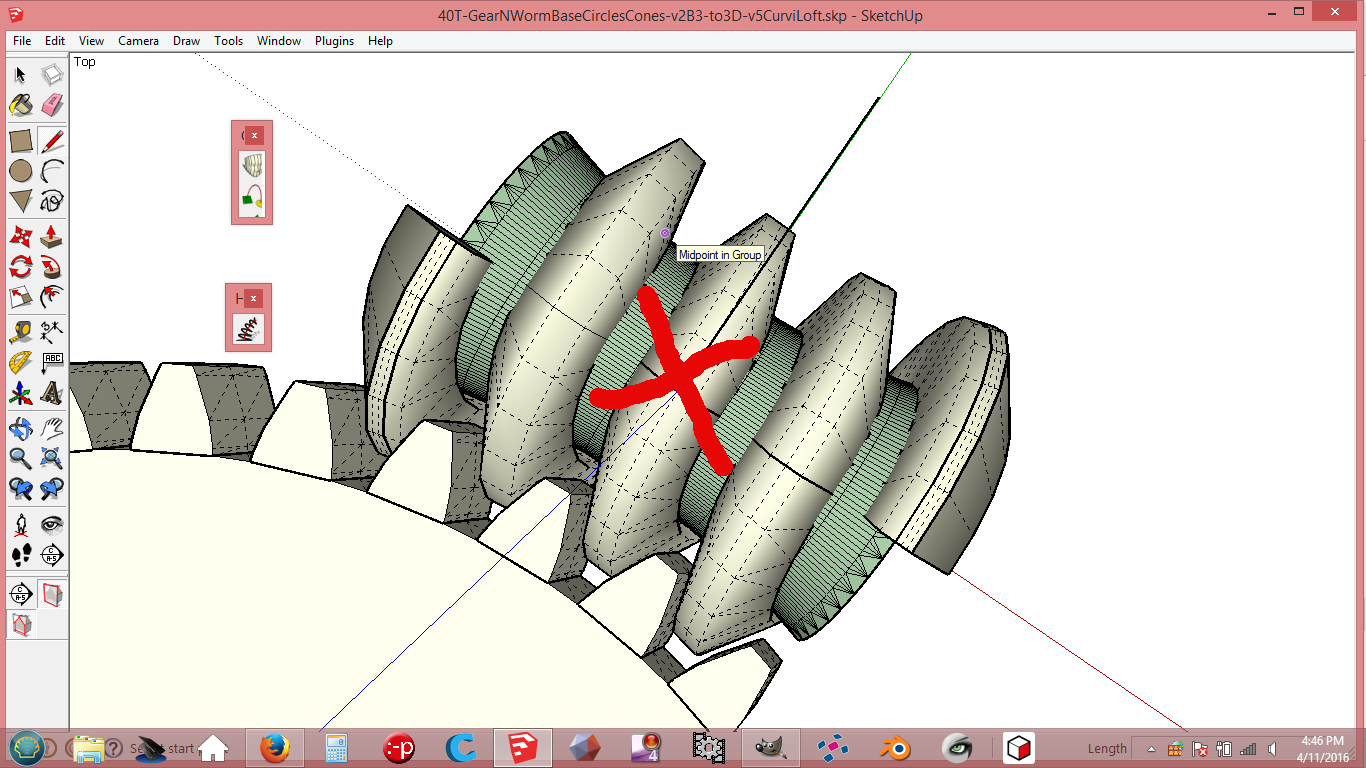

Very nice script! Something like this, I thought, but would be painful to do "manually". So the profile has to be rotated. 40 tooth gear 4.5 (9/2) degrees etc. That's perhaps because my own profile test went horizontal and crazy mess?

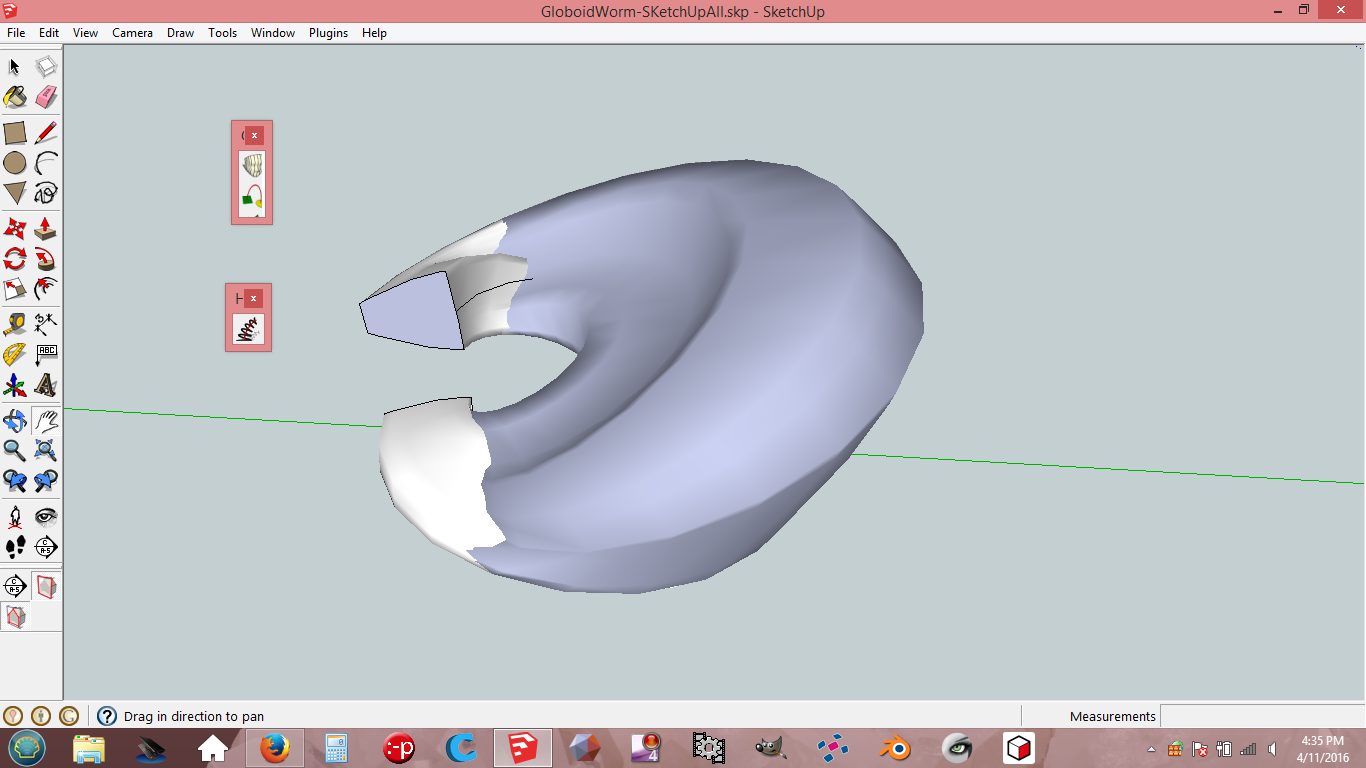

Naturally the worm wheel has a helix angle. Now to think where and how to cut the ends... I got the holes fixed with just automatic settings in NetFabb. There's many globoid worm tutorials in the web that seem to be erroneous, Solid works etc. Perhaps this script etc. is one quite correct way... Very nice!

-

RE: Hourglass Helix?

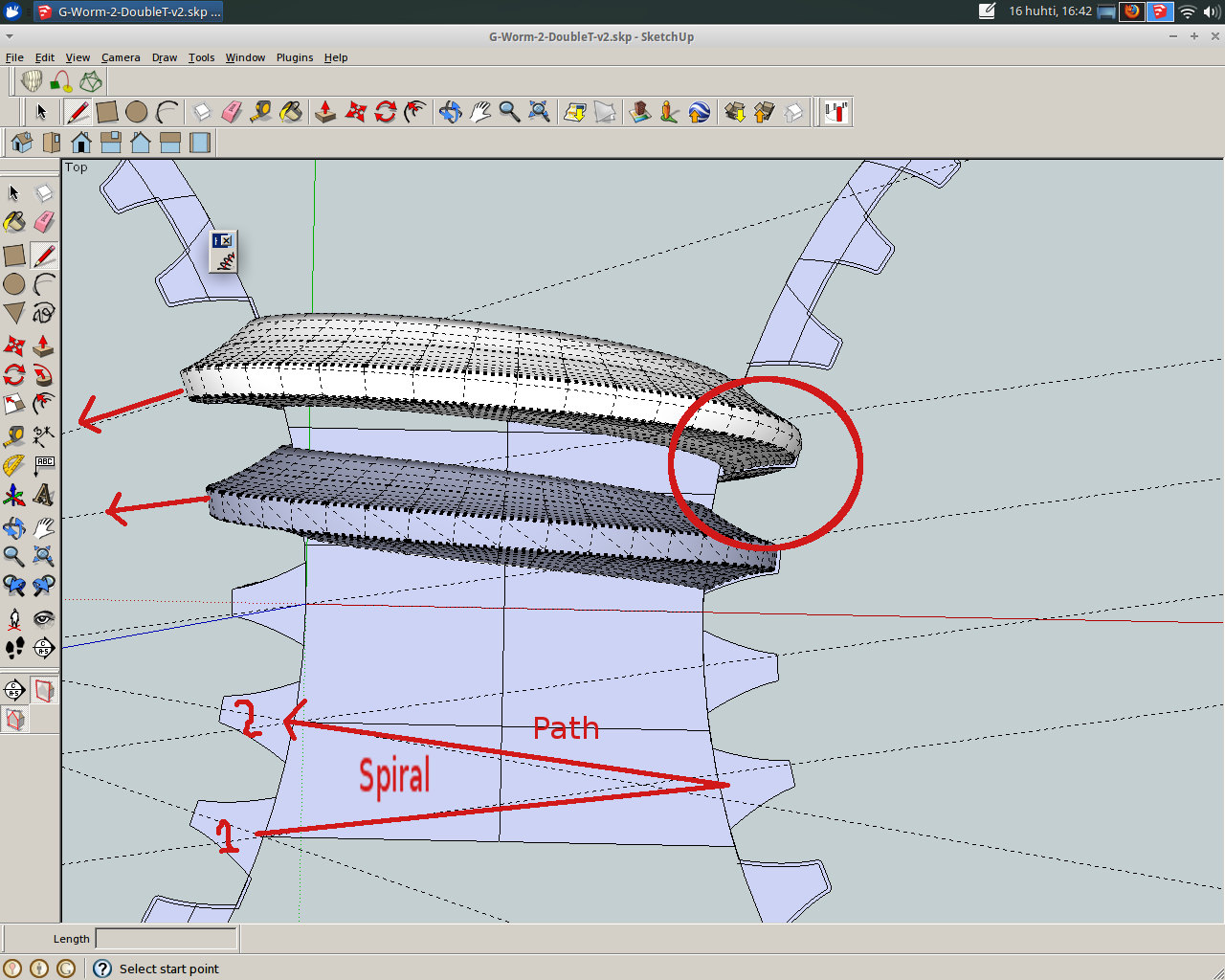

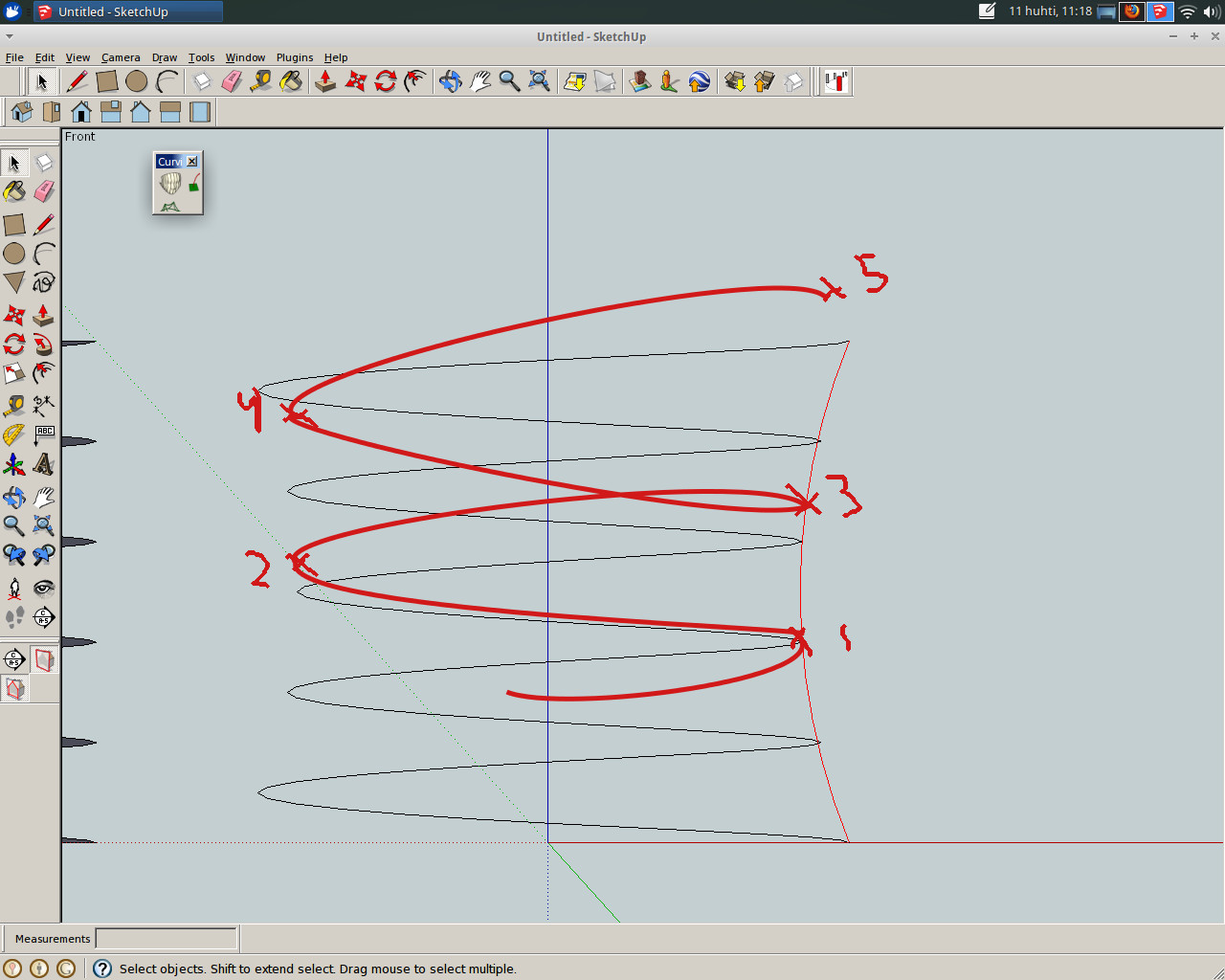

There's another thing too. The tooth has to point to the center of the worm wheel. So I have tried curviloft follow spiral path and tooth faces oriented to the center. No success yet. So the path is not correct then.

-

RE: Hourglass Helix?

Thanks! I check them. I still have about 0.2mm "error" on radius with curviloft.

-

RE: Hourglass Helix?

Edit: Uh! I was fool or too tired. I do not need to make the cut. The helix path is already ok hourglass shape and pitch growing and valid for curviloft.

Now thinking how to get the the path or shape helix turn tighter or more along the hourglass body, perhaps just more sections? I have to learn better this helix along curve plug-in.

-

RE: Hourglass Helix?

Edit: Uh! I was fool or too tired. I do not need to make the cut. The helix path is already hourglass shape and pitch growing and valid for curviloft.

Sorry! First I needed just the hourglass helix and then I found that I need variable pitch also. Yes I need both. Thank you pointing to the Helix along curve! At first it looks like that plug-in can do the thing If I do a one variable pitch helix using different length lines, then copy and scale it down 0.5 red&green axis. And then make curviloft faces along the paths cutting the hourglass and leaving a path which is a helix with hourglass shape and variable pitch.. I will try.

hmm what is the degrees option in Helix along curve plug-in...?

-

RE: Hourglass Helix?

Perhaps I found the correct option for curviloft. I have to think and try more...

-

RE: Hourglass Helix?

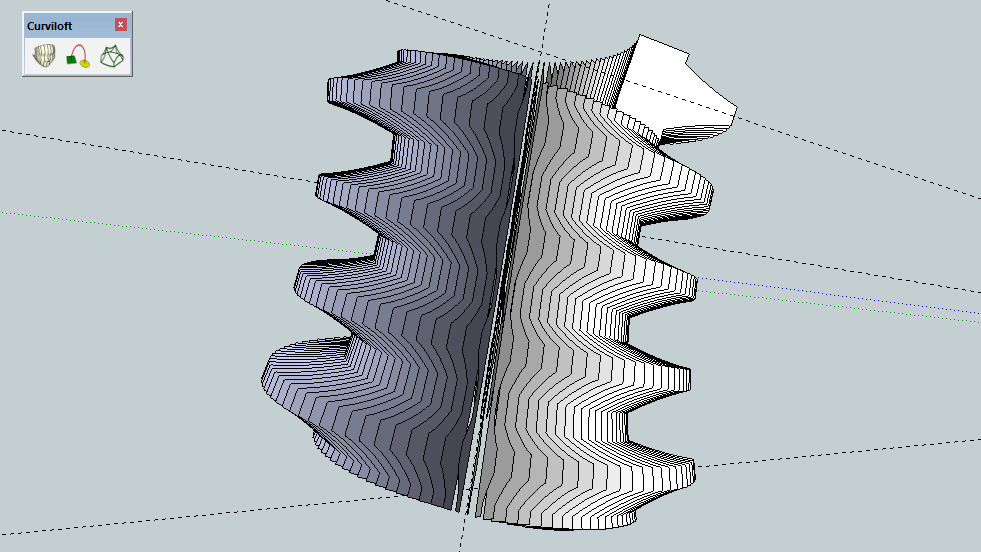

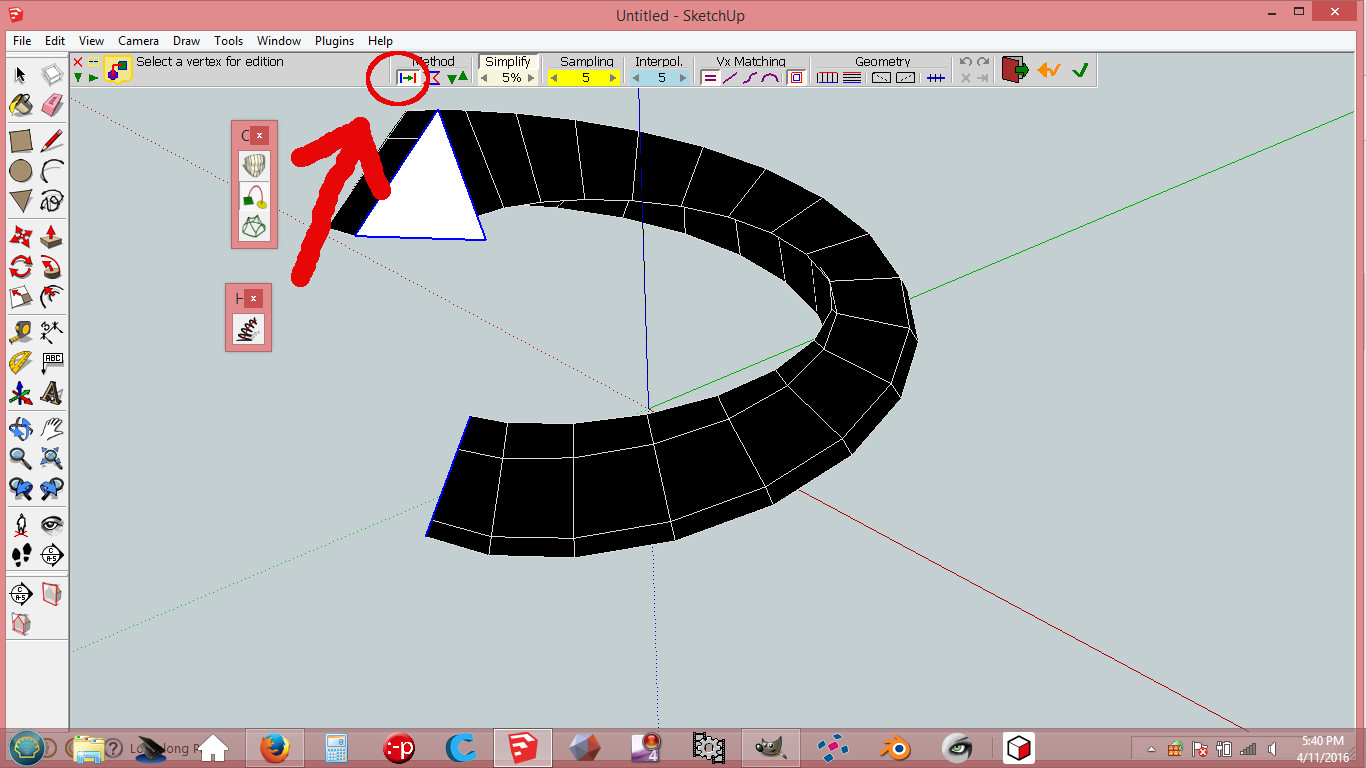

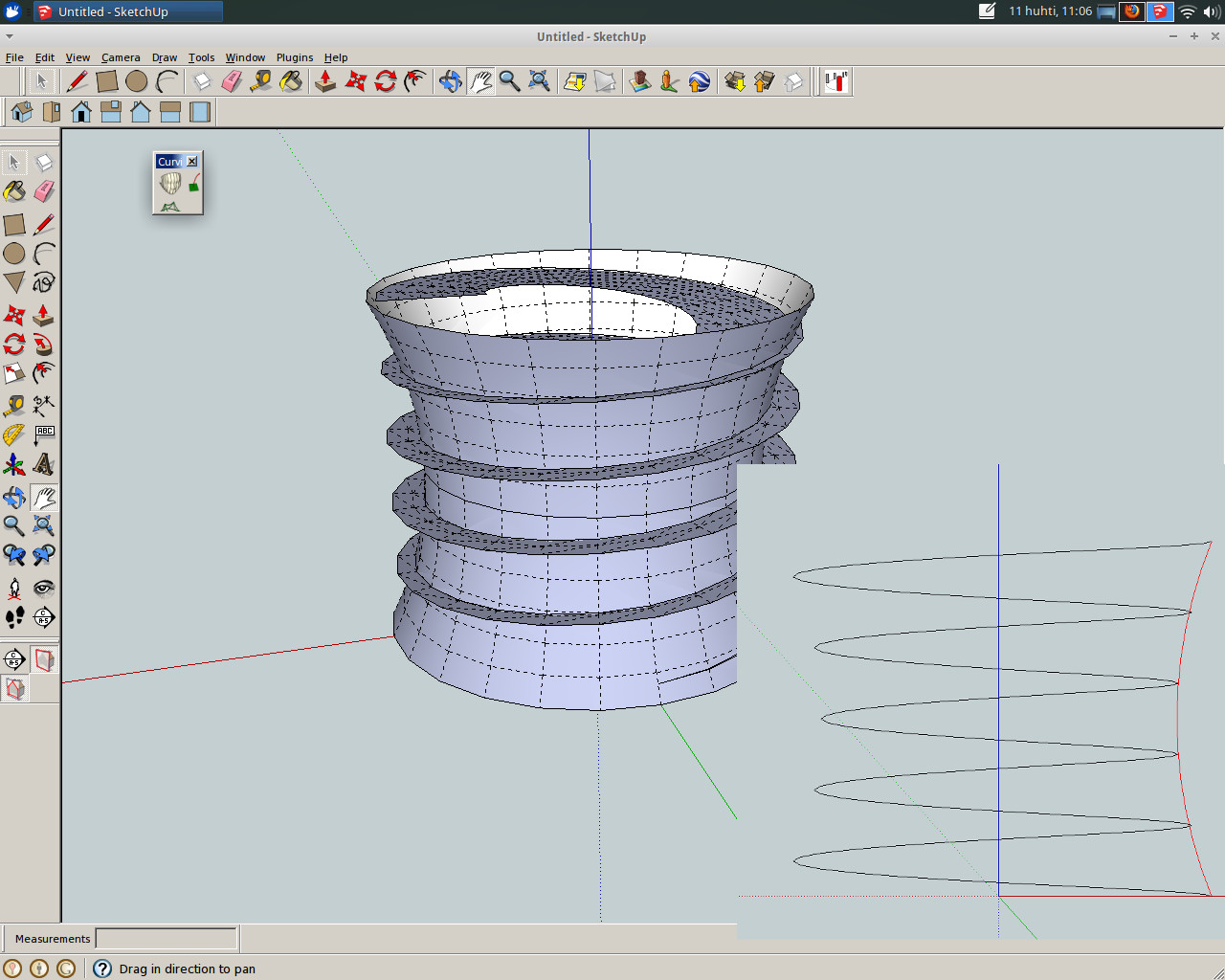

Perhaps I managed to make the correct helix, but sadly now I cannot get it to work with the curviloft correctly. First image helix. Second helix made of half circles. Not good, but the closest what I have.

-

RE: Hourglass Helix?

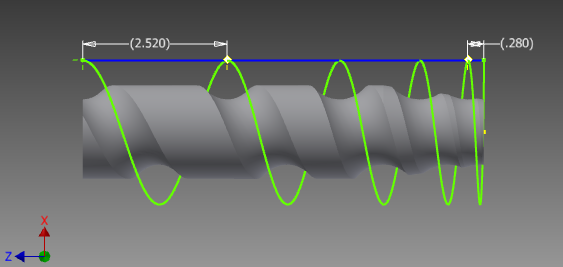

Hmmm. That's a nice way from point to point. But I need a variable pitch helix, so I cannot easily use intersections. 73.2mm -> 74mm etc. If there exists something like img.2 here down...? Points and pitch between them .

-

RE: Hourglass Helix?

Perhaps this image explains what I wanted and managed to make, with two normal helices + faces made with Curviloft cutting a path to a hourglass shape (or two curved cones). Sadly this is not enough what I need. I need helix going and growing up through the certain points (second image). Is there a way to make helix go using certain points or first pitch, second pitch etc.? Or I'm not sure if stitching helices with different pitch one over other makes a continuous grow? Like that half circle helices do not grow up correctly.

-

Hourglass Helix?

How I make this helix sweep cut to the hourglass to make paths (intersection)? Hourglass helix path. Helix and ?.

-

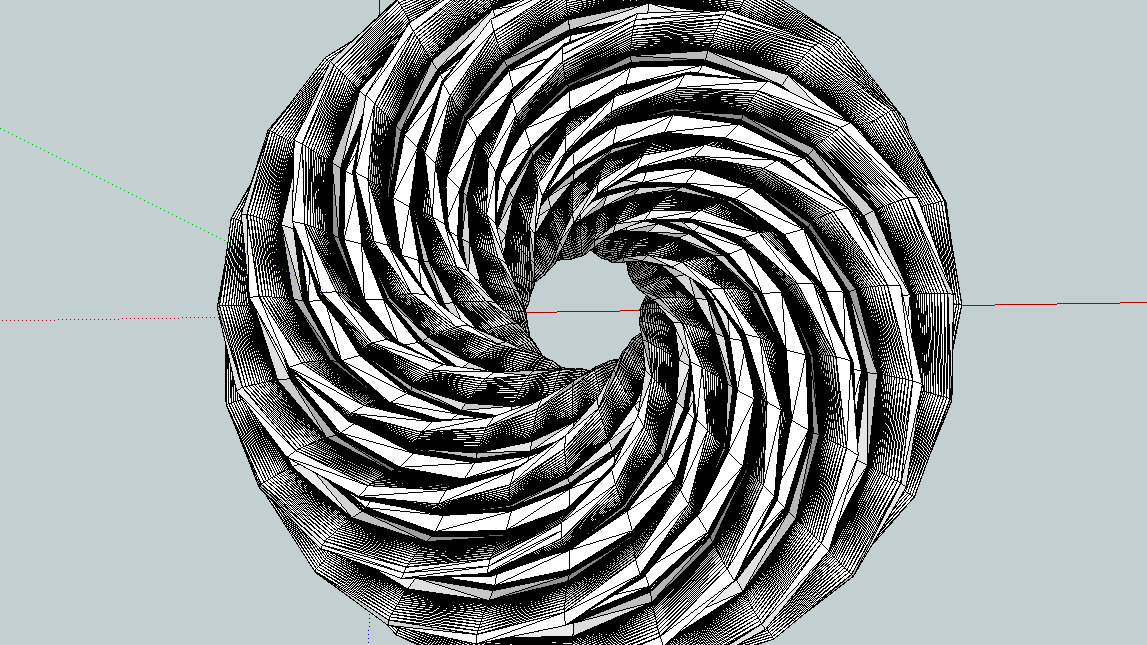

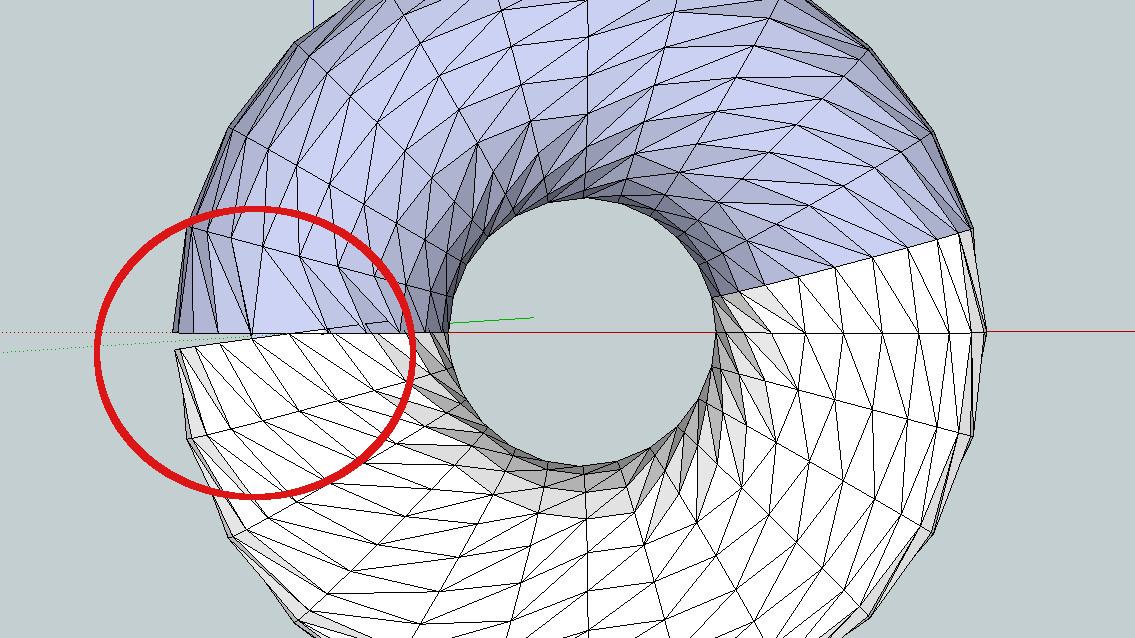

Unique Twisted Torus Shapes / 3D Printable

Using the Follow And Rotate plug-in you can create unique twisted torus shapes. FAR wants to behave a little bit badly sometimes, but with few extra steps you can create your own solid, 3D printable design. Be careful with very complex shapes, it can take hours to complete. This example just few minutes.

-

RE: FollowAndRotate Not Closing The Circle Path?

The last section extrudes turning less. Overlapping etc. Well the plug-in is still very useful when I can cut and join the halves = solid object. This was (the last twisted torus) extruded from an involute gear. 12 tooth. A quite heavy task.

-

RE: FollowAndRotate Not Closing The Circle Path?

Here is the reason. It has to rotate:

-

FollowAndRotate Not Closing The Circle Path?

I can overcome this and cut the model to halves and make flips & join the "good" halves.

I have 24S circle * 15 degrees = 360 deg. Perhaps I'm on a wrong way...

The photo clarifies the question:

-

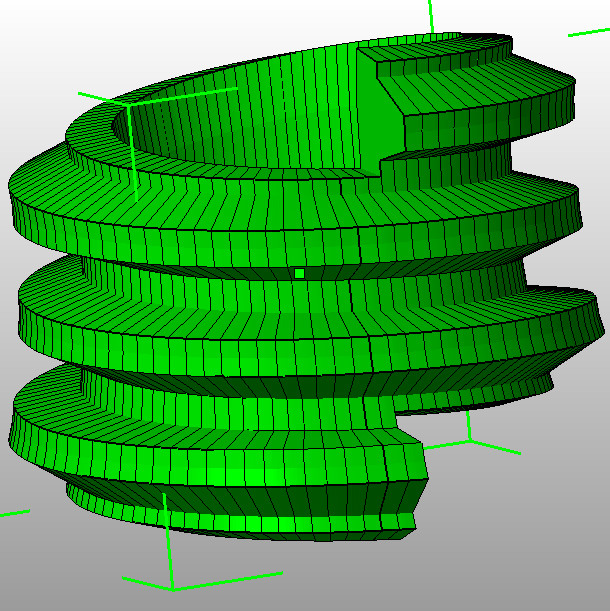

Worm Gear In SketchUp (3D Printable)

There is some things that could be done better and more exact, but the gears were tested to roll quite well. Except if you are making a swiss clock. Where is the "face width fixed" SPgears plug-in download location (I fixed it as shown on Sketchucation Forum)? It's very late... more tomorrow.

So, again. These are non-enveloping gears. Perhaps it's not hard to make double throat/double globoid? The worm wheel I had to fix in NetFabb basic (free version), but it's very easy, shown at the end of the video. The worm itself is done quite fast and solid.

Make a better shaft for your needs if you want. I used just M5 bolt as an axle.I started calculations from: http://www.mechguru.com/worm_gear_basic.htm