@honoluludesktop said:

bmike, your drawings are great, but they are still not production drawings. At least not in the manner that I am accustomed to seeing.

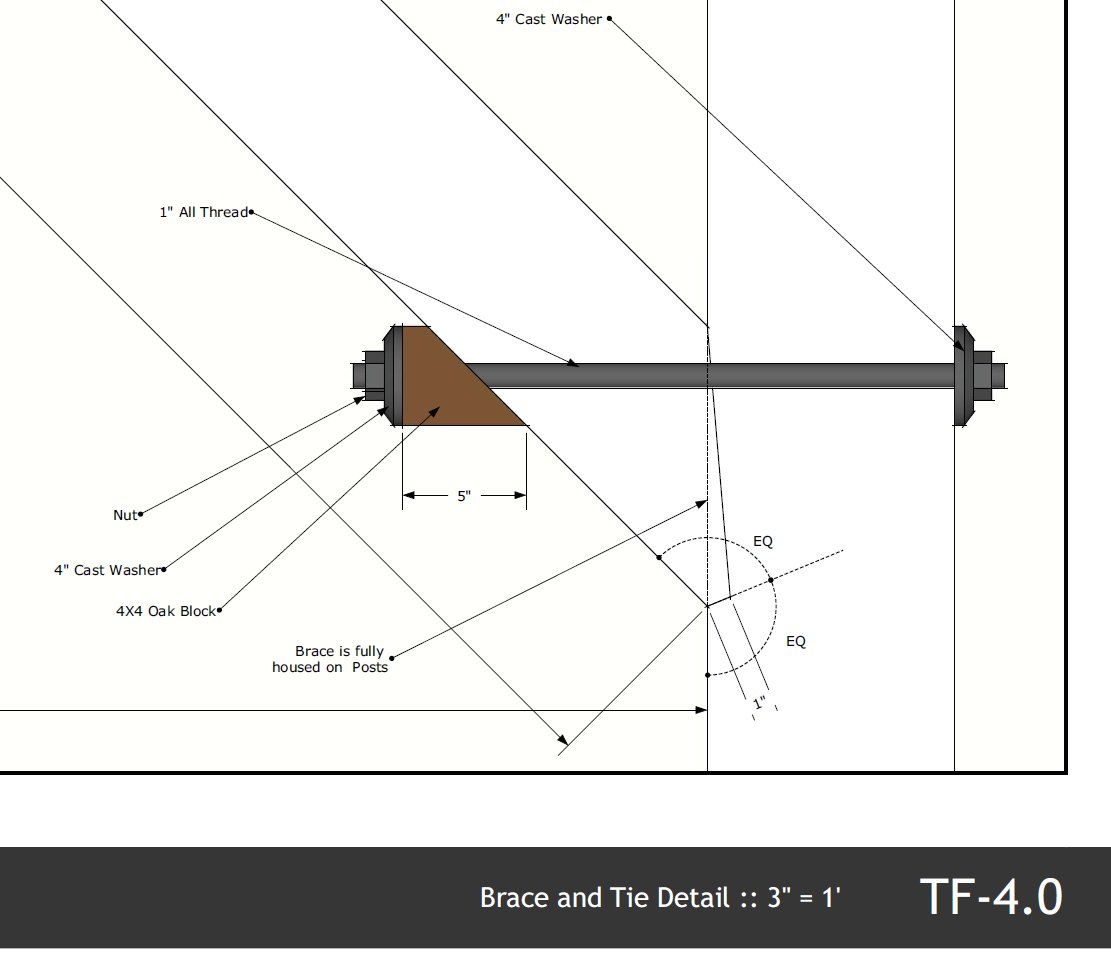

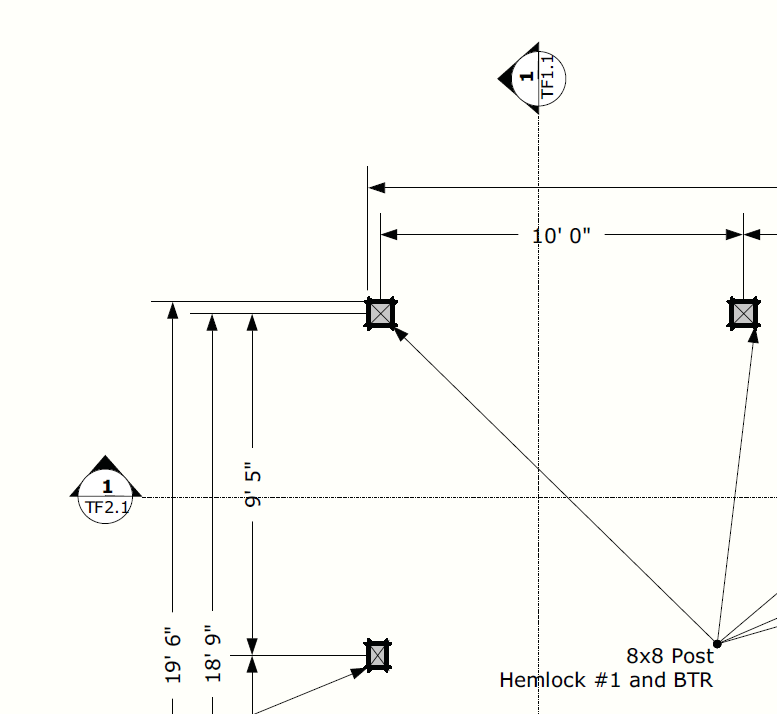

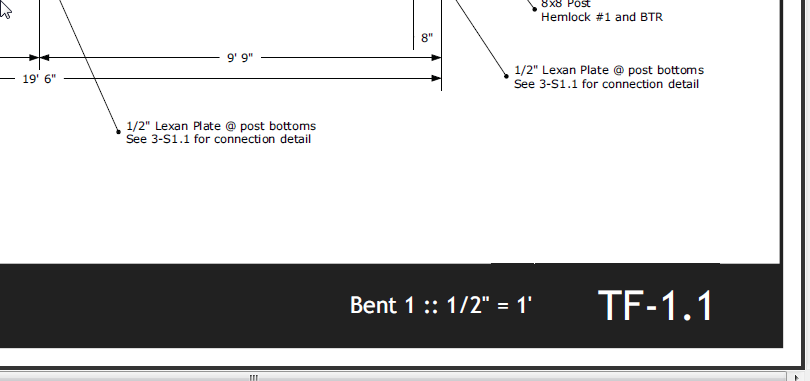

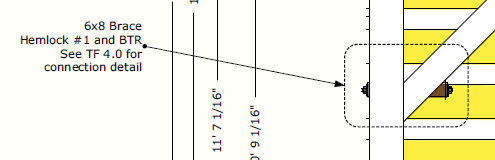

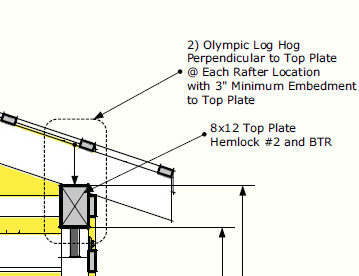

One of those buildings (the lumber shed example) is a PE stamped set of drawings including all connection details, call outs for sheathing, piers, fasteners, strapping, etc. etc.

It has been submitted to the building department, PE stamped and calculated and engineered, and went out to bid.

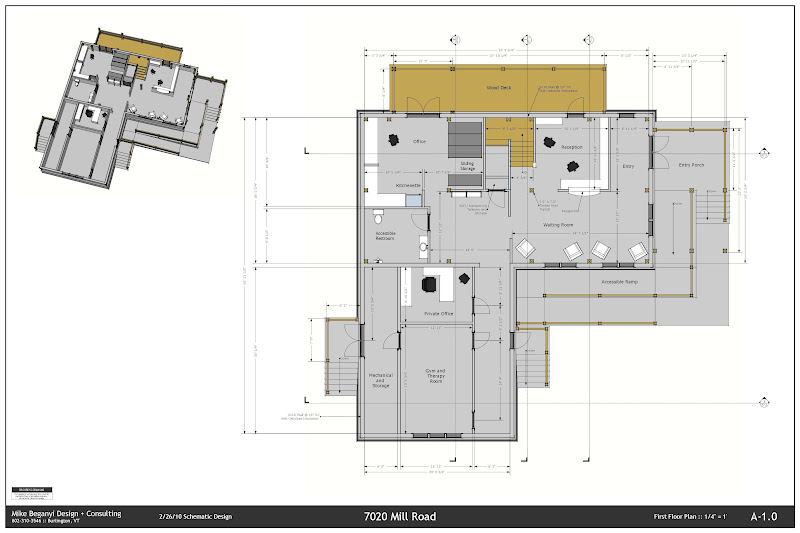

The other (the full building with interiors, etc.) has just moved out of the development phase. That particular set of drawings was used for presentation to the planning commission and to solicit bids. It has been turned over to an architect very local to the project for construction documents, as it is in a very unique site and requires lots of attention from local engineers (foundation) and the architect to fit it into the town's planning / zoning.

I have a house in the works that I am doing in the same method as the above pics. It will be a full set of build documents, likely PE stamped.

If we stray from SketchUp, I use an AutoCAD overlay specifically for heavy timber work (3d modeling, primarily of joinery, etc. that lets us talk to our CNC machine) - these drawings exist as machine language, 3d model, and full 2d printed shop drawings. We include your typical plan / section / etc. of the timber elements - but also incorporate 2d representations of the 3d structure - either details or full assemblies. The craftsmen in the shop (the structure is pre-cut) have access to a PC with the same software the designers use - so they can inspect the model, clarify how things fit, etc. etc.

It would be cumbersome to do what I've done on a very large commercial project (the full TF building depicted in my examples is a small medical therapy office)- but this brings us back to the whole BIM / representation discussion too... so... its a bit of a catch 22 - too much information would bog down simple software and make it unusable for the types of things SketchUp is good at, and it would need to be tailored to individual industries as the language and methods vary from an airport project to a small custom residence. I really like that its pretty easy for me to place 3d details / sections / etc. into my sections / elevations / etc. It brings a greater awareness to non-3d thinkers of how thing fit together, turn corners, and relate to each other. This has been especially powerful for me as I work with timber structures - and its nice to show how this very visible (and sometimes dramatic) part of the building relates to people / furniture / layout / windows / etc.