@box said:

It's also incredibly small. You will have problems creating faces that tiny.

It's just weird that the two lines are so far apart in the arcs.....

@box said:

It's also incredibly small. You will have problems creating faces that tiny.

It's just weird that the two lines are so far apart in the arcs.....

@dave r said:

You say you transferred the points to the rear face. How did you do that?

To be honest, I wouldn't cut the corner off the way you're doing it. You method will require you to create the faces on the edge of the metal because they won't be there when you've finished. Instead, I would draw a "cutter" to extrude through both surfaces, run Intersect and delete the waste.

I didn't think of that....and I have done that many times!

I have a curved sheet of sheetmetel I want cut off the corner. So I used line on surface on the outside face and deleted that face. I transferred my points to the rear face. I then used the tool again on the rear face but as you can see the Arc is WAY different, why is that? the 2 surfaces aren't that far apart.

@pbacot said:

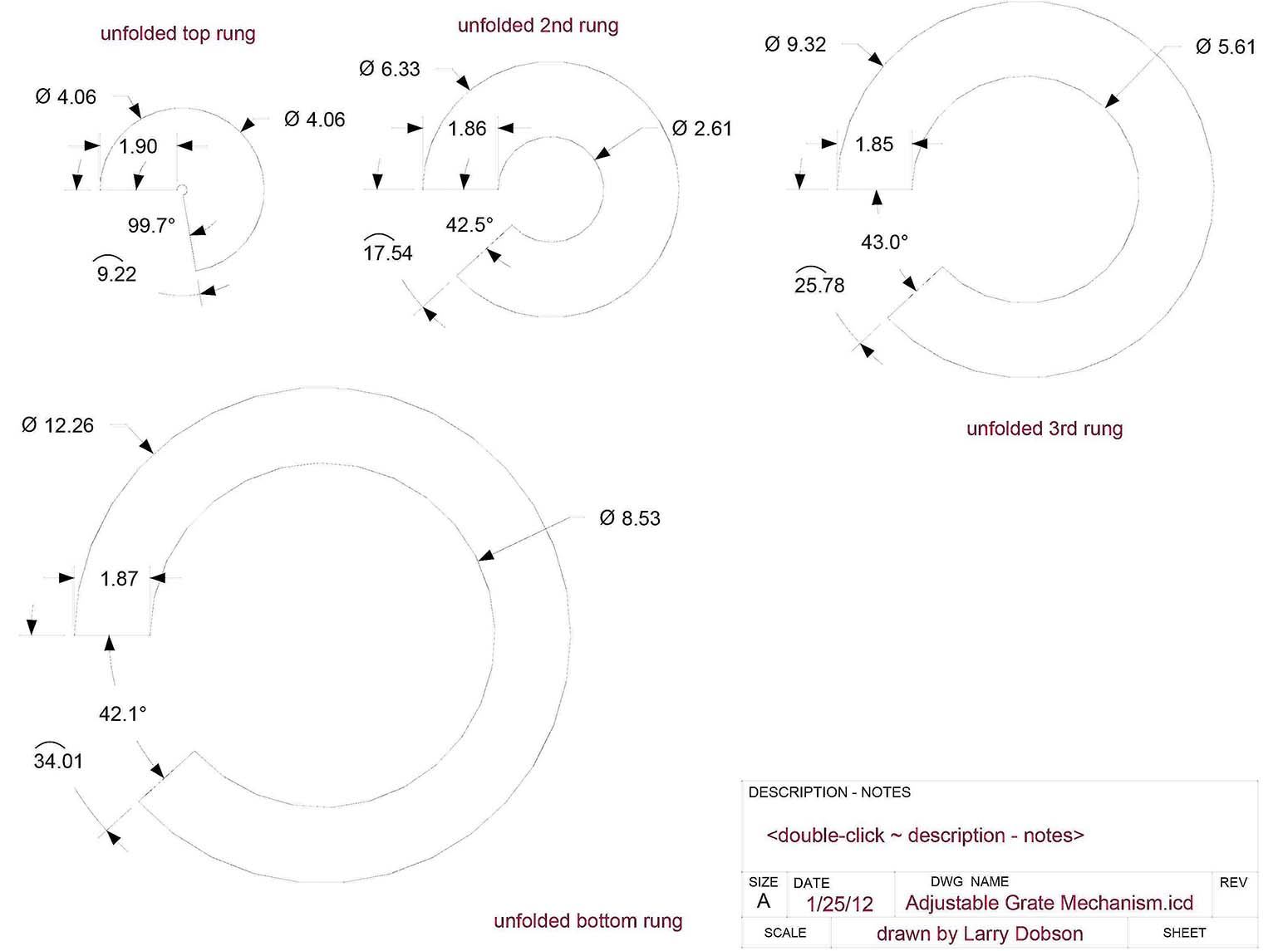

Is this dwg file any help. It's translated from the pdf.

and I made this SU file from that. I did nothing to check the scale. Scale from a pdf is probably suspect. You can rescale.

Thanks for the input. I went ahead and did one myself and then matched yours to mine and they were the same except one step had an angle difference of .1 degrees lol and like Dave said .2 doesn't even mater. I called my friend who has a cnc plasma cutter in his business and he says that it is only accurate to .5 degrees on a small part like this just because of the slag burn off!

Look this isn't a forum about the merits of burning wood. I have already looked through various studies. In fact check out Utube there are enough people in there swearing by them.

@mac1 said:

Interesting, I did not know wood gasification was used in Europe during WW2.

FYI after doing some search and finding https://bioenergy.ornl.gov/papers/misc/energy_conv.html: For the 10KW generator operating 3 months @ 12 hours /day with air dried wood (2% moisture content) about 2.6 tons of wood needed.

This unit, and most of the newer ones can use fuel at a higher moisture content and it works out to 3 pounds of wood per hour and 30 minutes, and that's hard wood, chips, scraps,pellets, any thing that is bios.

@dave r said:

Figures he wouldn't include it. Still, the drawing in the PDF file was made from his CAD file so you should be able to measure accurately enough from it right in SketchUp.

If you're off by 0.05 degrees will it matter in the SketchUp model?

It looks like he might have modeled this thing in SketchUp. It's too bad he doesn't make that model available.

You are right about that! But this is why I like to model something before I start a build... to find little errors now, not later!

This unit is supposed to power a 10kw generator, which for me is enough to power my shop, burn my scrap wood, and give me heat through the winter, so I really do want to try and build it

@dave r said:

You can measure the angles off the drawing. That's how I did it. You could also download the CAD files from the guy's website and import the one(s) you need and be done with it.

Actually Dave I didn't think about measuring the drawing lol. And of couse that drawing is the one he didn't include a cad of!

Thanks

@dave r said:

[attachment=1:3azqxhjm]<!-- ia1 -->support.png<!-- ia1 -->[/attachment:3azqxhjm]

Construct the cones to fit onto the supports.

[attachment=0:3azqxhjm]<!-- ia0 -->cones.png<!-- ia0 -->[/attachment:3azqxhjm]

That is exactly what I was trying to do but I couldn't get the bracket to form the slopes you have without guessing the middle step outside corner angle. Such as the 87.1 degrees is an inside corner of the second step what is the outside corner angle to get to that step, because it ia the angle of the cone. If I match the cone to the bracket after ASSUMING an angle then the drawing on the cut sheet would be wrong.

I found the equations to figure out the complete proper dimensions of the folded cone. So I can use Cotty's method to set the proper angle

Thanks guys

I have all his drawings. He has 2 sets. 1 set is all PDFs and one set are DXFs but neither has ALL the dimensions and or angles. Look at page 2 of the PDF listed are inside corner angles but not the outside angles to draw the support brackets. Unless I'm missing something, I need the angle each of the cones is at to get the angle of the step on the support bracket.

I am trying to model a wood gasifier from a set of pdf plans but have no idea how to come up with the angles of what the finished cone would be. I am not good at math. Any ideas?

Yes it does feel good. Before I joined here I never did anything on a computer but game and check my Email. It wasn't till I went to Woodcrafters and overheard some guys talking about Sketchup that I got interested. That was a year ago, and I have had quite the learning curve based on the above and that I'm now 60 trying what I should have done years ago, and I still work full time......If I can do it ANYONE can

By the way if you turn on layers you see more....

The file has every mistake in it you can have, I think. Layers are messed up. Not all solids. etc, etc. But, I drew everything in one day, exported as a series of jpgs and sold the job of building the cabs for $12 grand. The wainscot walls and coffered ceiling are there but he got to see what it would all look like! Gotta love it!  Just wait till I'm not a newbe!

Just wait till I'm not a newbe!

Ok got it fixed. I made the mistake of referencing the door Z value instead of just referencing the bottom style lol everytime I moved the door up the rails went to the moon! Still have improvements to make... but it has been interesting lol

I did as you suggested and hide those ends looks much better!

but did discover an error I have to fix when I move the door lol Post yours when done am interested in seeing finished formulas

you did a great job of explaining it!!!! Last night I did finish the thing, but not quite like you did.... mines sloppy in comparison but you can see how I bungled through it. I just go in and group the 2 miters and center pieces after I set the door size and then it exports to cut list fine,(it only goes done 2 layers)then I can explode the group to edit it if need be.

I know that if I group the miter cuts and center pieces AFTER I pick a size, then cut list will give me the stick length. So If I import separate copies into my drawing and mod them individually, I'm thinking it's a "little" faster to go to cut list...am I wrong? But still having problems getting all the pieces to align properly.

EDIT Well after messing with this all day, I have come to the conclusion that unless they can get this to go down one more tier (Grand parent to Grand child) this is just a "movement" or for "show and tell" tool and not good for cutlist import at all.

I see where you are going with this... the angles have to be treated separate so they don't "distort" when changing the panel to another size that isn't perfectly square. But now, how would this export to Cutlist?

I have been trying to make a DC of this door in which I can change the height and width. But every attempt has been one in which the joints don't fit, or the trim doesn't position correctly, or something else goes wrong. Can anyone show me how to do it?

Don't know if anyone can use this but I put together a PDF of functions, definitions, and the links to examples so I don't have to keep going online and digging the info up.