How do I model this into a 3d cone?

-

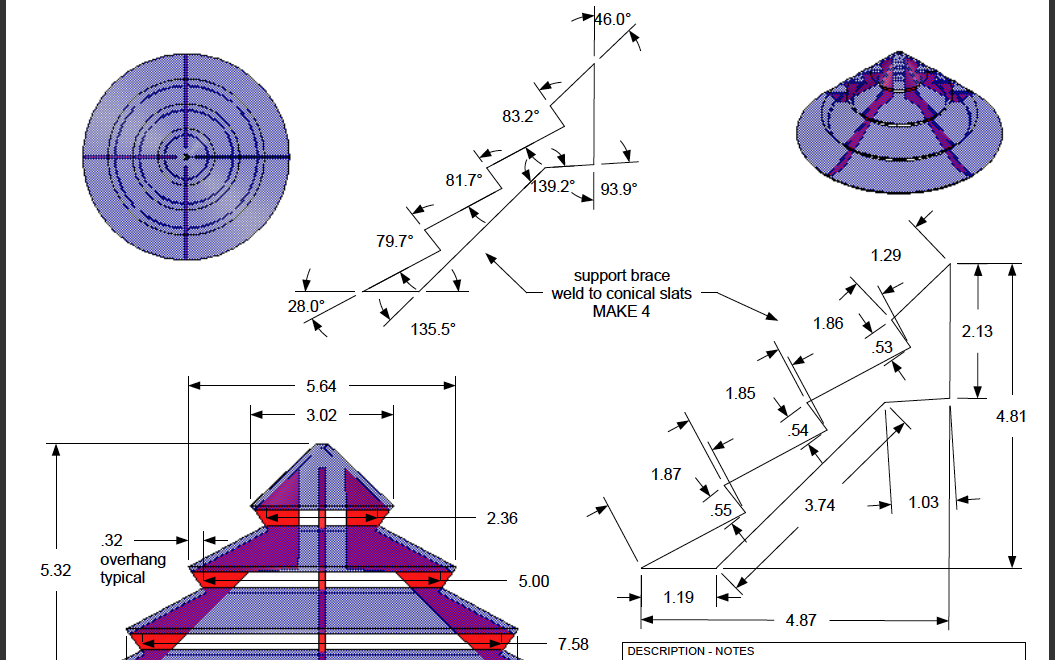

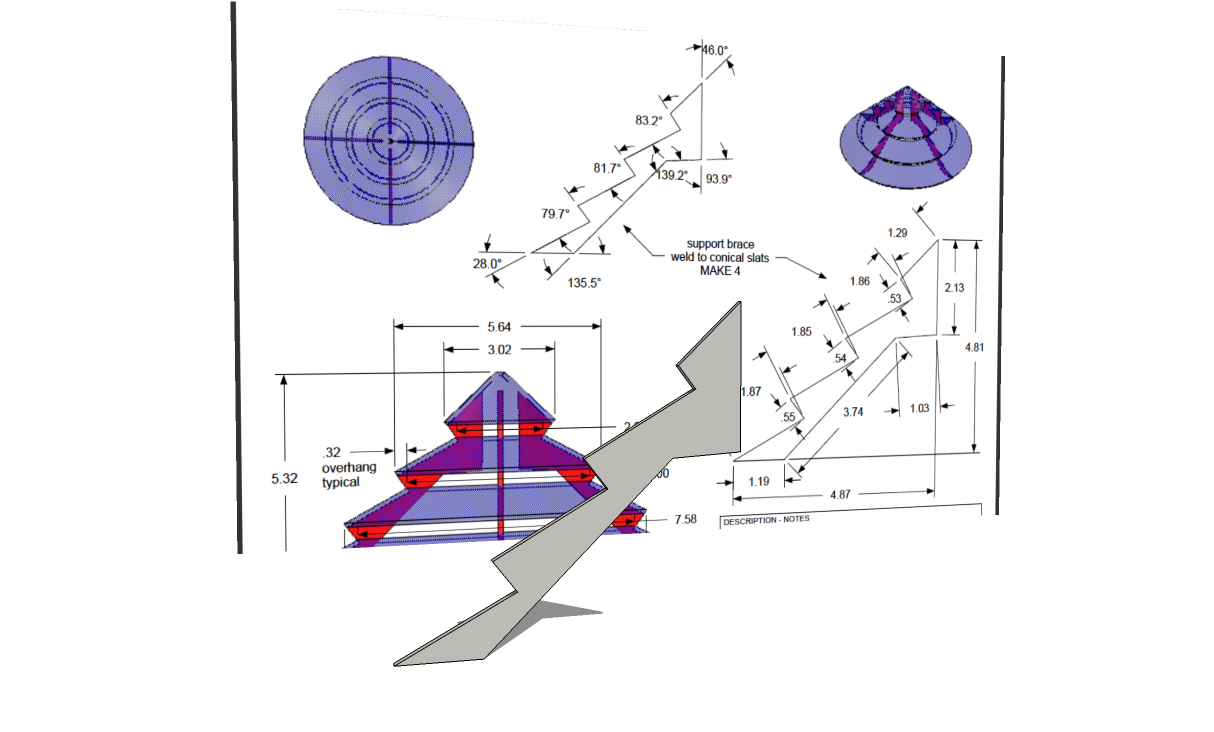

It looks to me as if page 2 shows all the angles you need to construct the supports for the cones. If there are any missing you can pick them off the drawing in SketchUp.

-

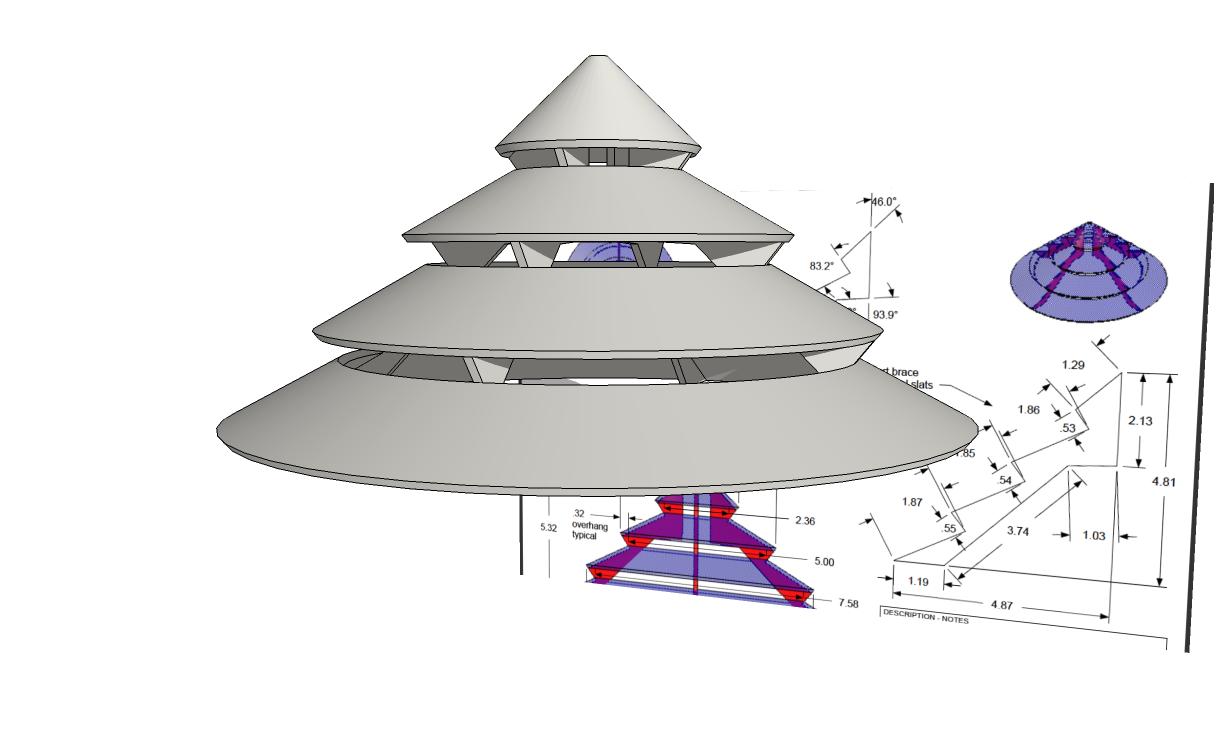

Construct the cones to fit onto the supports.

-

@dave r said:

[attachment=1:3azqxhjm]<!-- ia1 -->support.png<!-- ia1 -->[/attachment:3azqxhjm]

Construct the cones to fit onto the supports.

[attachment=0:3azqxhjm]<!-- ia0 -->cones.png<!-- ia0 -->[/attachment:3azqxhjm]

That is exactly what I was trying to do but I couldn't get the bracket to form the slopes you have without guessing the middle step outside corner angle. Such as the 87.1 degrees is an inside corner of the second step what is the outside corner angle to get to that step, because it ia the angle of the cone. If I match the cone to the bracket after ASSUMING an angle then the drawing on the cut sheet would be wrong.

I found the equations to figure out the complete proper dimensions of the folded cone. So I can use Cotty's method to set the proper angle

Thanks guys

-

You can measure the angles off the drawing. That's how I did it. You could also download the CAD files from the guy's website and import the one(s) you need and be done with it.

-

@dave r said:

You can measure the angles off the drawing. That's how I did it. You could also download the CAD files from the guy's website and import the one(s) you need and be done with it.

Actually Dave I didn't think about measuring the drawing lol. And of couse that drawing is the one he didn't include a cad of!

Thanks

-

Figures he wouldn't include it. Still, the drawing in the PDF file was made from his CAD file so you should be able to measure accurately enough from it right in SketchUp.

If you're off by 0.05 degrees will it matter in the SketchUp model?

It looks like he might have modeled this thing in SketchUp. It's too bad he doesn't make that model available.

-

@dave r said:

Figures he wouldn't include it. Still, the drawing in the PDF file was made from his CAD file so you should be able to measure accurately enough from it right in SketchUp.

If you're off by 0.05 degrees will it matter in the SketchUp model?

It looks like he might have modeled this thing in SketchUp. It's too bad he doesn't make that model available.

You are right about that! But this is why I like to model something before I start a build... to find little errors now, not later!

This unit is supposed to power a 10kw generator, which for me is enough to power my shop, burn my scrap wood, and give me heat through the winter, so I really do want to try and build it

-

Interesting, I did not know wood gasification was used in Europe during WW2.

FYI after doing some search and finding https://bioenergy.ornl.gov/papers/misc/energy_conv.html: For the 10KW generator operating 3 months @ 12 hours /day with air dried wood (2% moisture content) about 2.6 tons of wood needed. -

Mac1, I make a lot of scrap in my woodworking shop but not that much.

I expect most woodworkers would need that 10Kw from the generator for less than 6 hours a day even if they are working 12 hour days.

I expect most woodworkers would need that 10Kw from the generator for less than 6 hours a day even if they are working 12 hour days. -

@mac1 said:

Interesting, I did not know wood gasification was used in Europe during WW2.

FYI after doing some search and finding https://bioenergy.ornl.gov/papers/misc/energy_conv.html: For the 10KW generator operating 3 months @ 12 hours /day with air dried wood (2% moisture content) about 2.6 tons of wood needed.This unit, and most of the newer ones can use fuel at a higher moisture content and it works out to 3 pounds of wood per hour and 30 minutes, and that's hard wood, chips, scraps,pellets, any thing that is bios.

-

Can you cite a link to back that claim.

The link I gave you is independent of design but the actual energy content of what is used unless they are BSing. Unless I used the data wrong then that should be the bottom limit

If you are going to spend $ to build the system you want to use the same approach you cited for design and understand first.

I would not rely on what the designer states now until he has proof.

BTW FMEA demo project, somewhat old now, stated 20# wood is equivalent to 1 gal of gasoline. -

Look this isn't a forum about the merits of burning wood. I have already looked through various studies. In fact check out Utube there are enough people in there swearing by them.

-

I could care less about that. If you are comfortable with your " design" spend all the money you want on it.

-

Is this dwg file any help. It's translated from the pdf.

and I made this SU file from that. I did nothing to check the scale. Scale from a pdf is probably suspect. You can rescale.

ADJUSTABLE GRATE MEC#4EBC00.dwg

-

@pbacot said:

Is this dwg file any help. It's translated from the pdf.

and I made this SU file from that. I did nothing to check the scale. Scale from a pdf is probably suspect. You can rescale.

Thanks for the input. I went ahead and did one myself and then matched yours to mine and they were the same except one step had an angle difference of .1 degrees lol and like Dave said .2 doesn't even mater. I called my friend who has a cnc plasma cutter in his business and he says that it is only accurate to .5 degrees on a small part like this just because of the slag burn off!

Advertisement