Hello Majid,

Good to hear that you are doing well.

And congratulations on the birth of your son.

Bep

Hello Majid,

Good to hear that you are doing well.

And congratulations on the birth of your son.

Bep

Try the tool Sandbox, but I don't know if the ruby code is open.

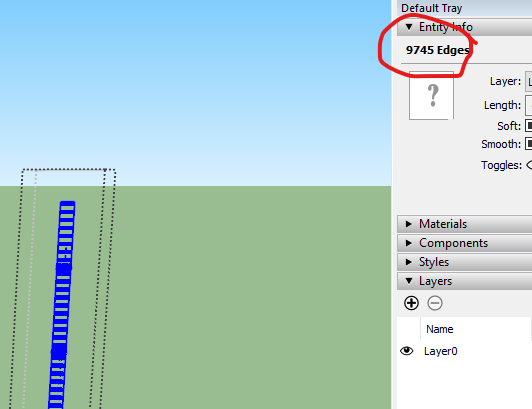

Try to get the number of entities per segment down

Make a component of segments that are the same.

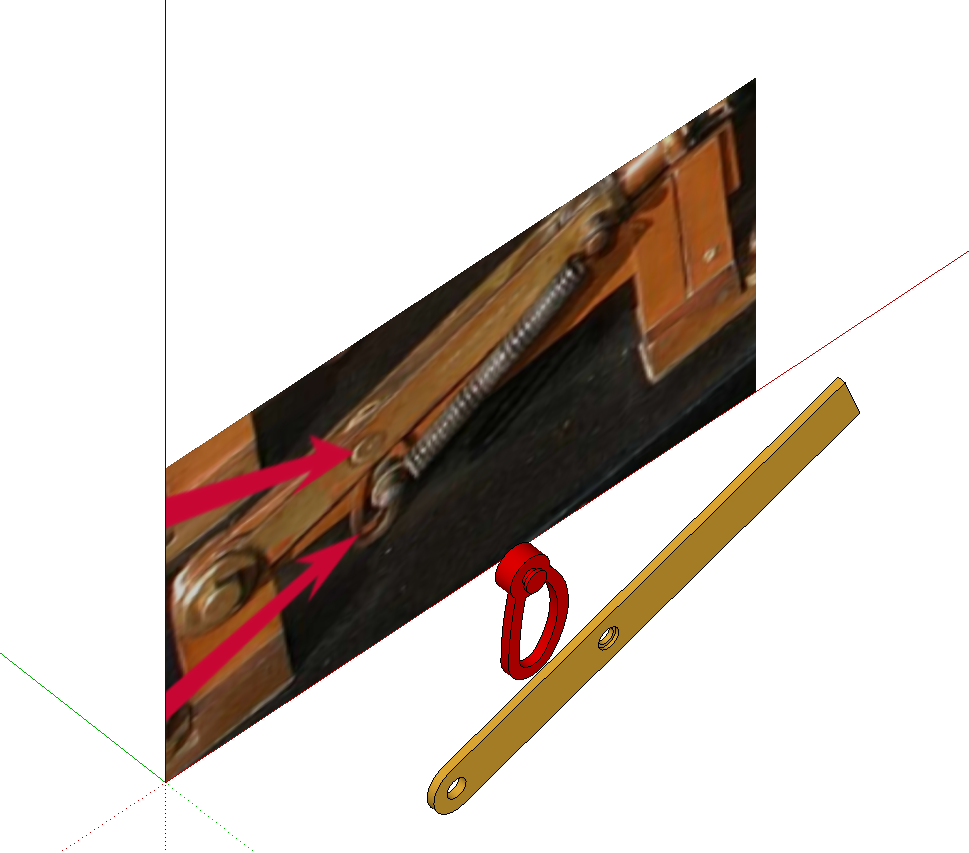

"So, at this point the spring has tension and the red part has made contact with the pin, and further movement of the handle will begin to slide the blade out of its contact. Right?"

[highlight=#ff4040:doulhaql]Yes![/highlight:doulhaql]

"But, just to keep my reputation as a royal pain-in-the-butt alive, I do have a question -- To keep the spring from just raising the blade with the arm, there would have to be tension, or pressure, that holds the blade in place until the arm raises the blade far enuf that it can break free and snap up, right?"

[highlight=#ff4040:doulhaql]Yes!, the pressure should ensure for enough friction wen the spring gets loaded to prevent the blade from sliding out of the contact fingers

Whit this design the "red part" slides the blade out off the contact fingers.

Then at some point the blade snaps away from the contact fingers[/highlight:doulhaql]

But, while every blade switch that I have found uses a contact that is formed into a sort of spring shape to ensure good contact with the blade this beast seems to have relatively thick "arms" that stick straight up, and I don't see how they can provide the spring action to ensure good contact, let alone provide enuf pressure against the blade to prevent it from just moving up with arm.

[highlight=#ff4040:doulhaql]They somehow can get enough contact pressure wih this design, without enough contact pressure the contact resistance would be to high, and the switch could burn/melt at that place.[/highlight:doulhaql]

"Also can't figure out why they would go to the trouble of cutting the contact down the middle like that. Does that have something to do with it?"

[highlight=#ff4040:doulhaql]Yes, this is done to ensure a big enough good contact area, to keep the contact resistance as low as possible

Wider fingers would be more difficult to get them plane to the switch blade[/highlight:doulhaql]

About your drawing.

A part of the blade and the top of the fingers should be slightly rounded, to let the blade slide in easier.

Some things to read up on the switch topic:

https://phasetophase.nl/kalenders/kalender_2009.html (translate with google)

https://ecprops.com/products/knife_switches/knife_switches.html

http://0330de8.netsolhost.com/test/html/products/knife-switch.php

Together we have 4 active brain cells

Hopefully the move to your new home goes very well.

@andybot said:

Ah - that would make the most sense - it has to do with how you open or close the switch and prevent arcing. The separate handle allows you to move your hand away from the switch, and the spring flicks the switch open once it gets a certain amount of tension on it.

The sole purpose off this design is to prevent as far as much the current from arching.

The switch blade and contact would otherwise burn fast.

This design makes the contact of the switch open at a fast speed, undependable off the speed with witch the operator opens the switch.

Its a single blade switch

The springs and the red parts are essential parts of the designs of the switch.

The red parts are probable riveted to the handle.

Wen you open the switch, you first load the spring to some tension.

Then the red part hooks under the pin in the switch blade.

Wen moving the handle further the switch blade starts sliding out off its contact.

At some point the loaded spring will with great speed pull the blade out off, and further away from its contact.

The sparking is minimized by speed with witch the blade moves away from its contact.

Now the switch can be fully opened.

Wen closing the switch, the blade is pushed in between its contact by the round brass part just under the handle.

red part.skp

The springs and A and B are used to open the switch quick after some preload on the spring.

This should prevent serious arcing at the contact points.

Don't make this mistake.

I unfolded a cilinder/ring, and measured its area (cm²) with the tekst tool, with hidden lines turned off in view. (bottom strip of fig 1)

The strip at the top drawn with the rectangle tool shows the correct area.

although the face, when selected looks undivided, the square cm² turn out to be only for a part of the ring.(fig 2)

I notest, that drawn with the rectangle tool, entity-info identify's the rectangle as a face, and the unfolded rectangle as a surface.

fig 1

fig 2

@joe wood said:

yeah I figured that but I can't block emails from my contact us form!

just wondering why the text is so messed up, but not really important, just curious.

It becomes garbled be course the Cyrillic script is not decoded the right way.

Sketch3d.de wrote:

@unknownuser said:

I know, giving an inch but expecting a yard is common these days.

This sounds very much as a somebody who is a reseller of SU-pro.

I know that you can't make any money on SU-make.

But then remember the many SU-Make users that are involved in helping others in these forums.

And don't forget the Plugin developers that make and made all the free Plugins.

This community of helping and giving people are the ones who made Sketchup such a successful program.

Probably this on will fulfill your needs.

http://sketchucation.com/forums/viewtopic.php?p=274199#p274199

Sadly the author of this plugin has past away (rip, Honoluludesktop!).

So this plugin is also not supported anymore.

Then there is https://pcon-planner.com/en/download/

It can convert your dxf to a v14 .skp

William,

I think your cad program has somehow changed your .dxf file.

In your .dxf the arcs have more segments, there are elements moved, and crossing lines.

Which cad program are you using.

Bep

Hallo William,

I don't now what you did different than I did.

Bep

Hekwerk met bogen in su2018pro test.skp

Give the geometry "faces" by drawing over one line.

Then try to export again.

Bep

You will find the download here:

https://sketchucation.com/plugin/2106-sb_trilateration

Of course i am interested!

I wasn't even aware it was missing from the standard tools.

But then, nobody will know which tool they miss until they need it.