help with a thread

-

Aha I got you mixed up, that was the one I watched

-

I’m the problem, ha ha

I need a back to basics tutorial, I always seem to miss a certain point and nothing happens . I can see the way both of you do the threads but I’m missing something -

Ok I’ve managed a male and female thread on a 150mm diameter, with a 0.3 offset, . It’s very tight can wind it on for 2 threads , and that’s it. Tomorrow doing another female with an extra 0.3 clearance on all faces, so see how that goes. I think it’s the shrinkage on the printer that’s causing the problem

Thanks Guys for all your help -

@Leggy said in help with a thread:

I think it’s the shrinkage on the printer that’s causing the problem

That's probably it. You'll have to work that out based on the material.

-

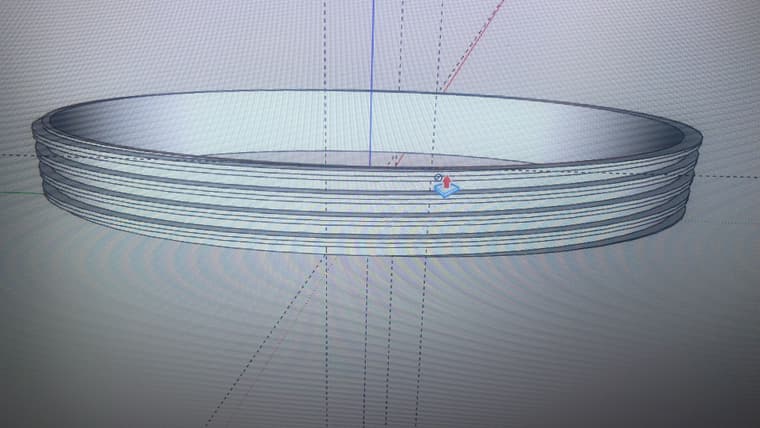

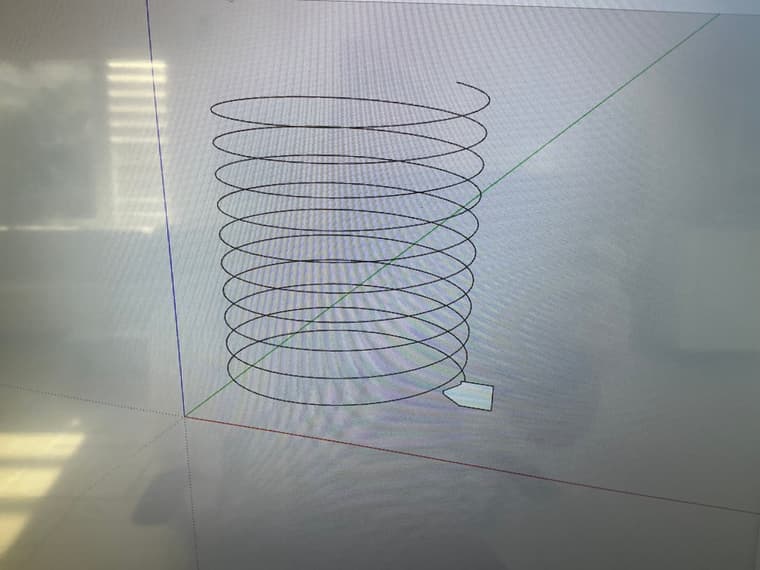

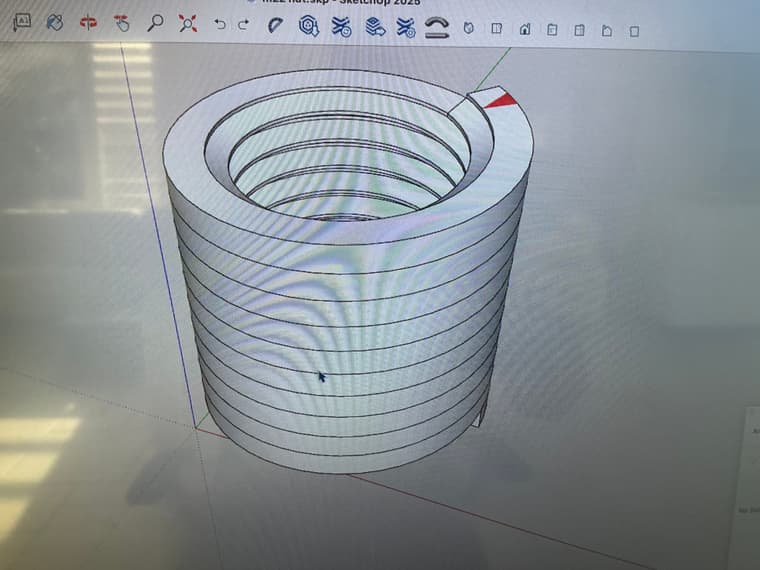

I finally got it to work , pictures to follow , thanks Guys

-

-

-

Well done @Leggy

-

Hi guys

Again thanks for all your help

Is there a chart you use to look up thread dimensions, pitch, tpi , crest etc

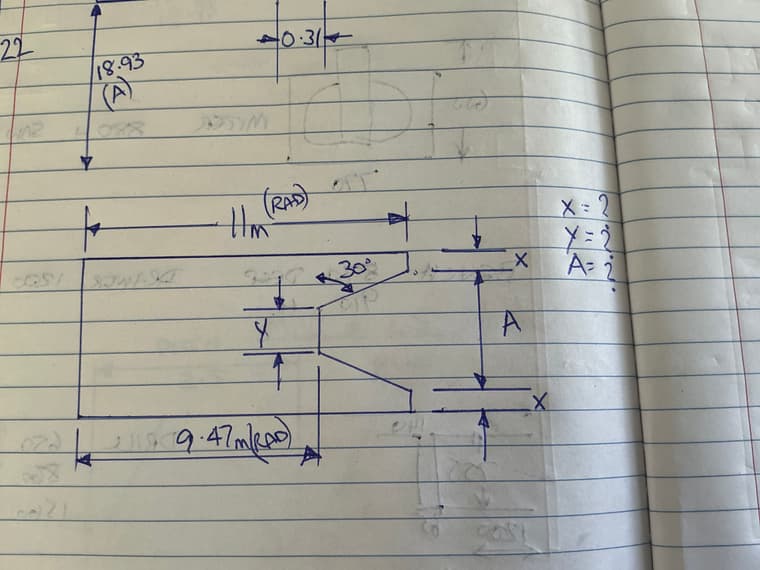

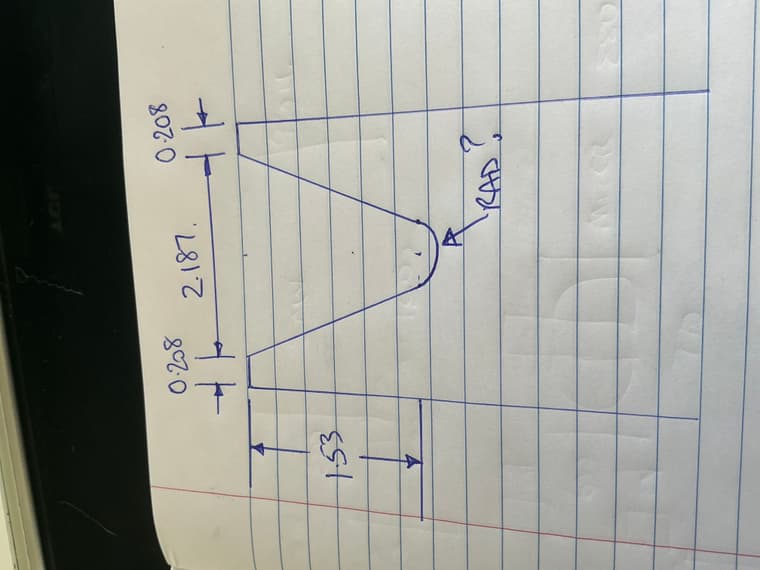

I was trying a m22 x 2.5 and got a bit confused on the chart I was following, so I asked ChatGPT

After 4 hours of me telling it, it was wrong, it finally agreed

I was drawing it in SU then asking it questions on the iPad

When I get home I’ll upload my figures and see what you think, the thread looks good on the screen, but that doesn’t mean it will fit

Thanks Dean -

-

These are what chat told me

-

@Leggy said in help with a thread:

Is there a chart you use to look up thread dimensions, pitch, tpi , crest etc

I would use the following site:

External Metric ISO Thread Table Chart Sizes M20 - M55

Metric external thread size table chart for sizes M20 to M55 Bolts and screws per. ANSI/ASME B1.13M-1995.

(www.engineersedge.com)

I wouldn't bother with the radiused corners because they'd be too small.

-

Ill check it out

-

What about tpi?

-

@Leggy said in help with a thread:

What about tpi?

What do you mean? The thread pitch is given along with the other dimensions for the threads. TPI standas for Threads Per Inch and is not used for metric threads. M22x2.5 indicates the nominal diamter is 22mm and the pitch is 2.5mm. The helix rises 2.5mm for each rotation.

-

Ah ok , I see what you mean, this is where ChatGPT was messing with me

-

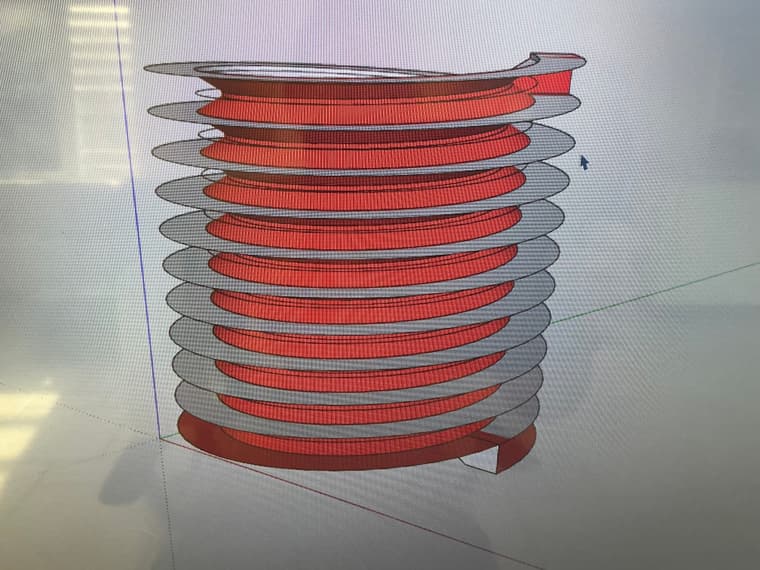

How do I get rid of the grey spiral in the last picture?

) -

Can't you just select it to highlight it and hit Delete to make it go away?

Are you modeling internal or external threads?

-

No, it seems to be in hidden sections, so would have to select every faucet on the plane and line

What I found is if I draw an arc from the top of the inner profile to the bottom, and do the helix , I can click on the curve and can delete it all

️

️

cant see the difference vwhy, but it works, the threads are great

what I found is a difference in tolerances, I printed 3 nuts with 0.1/15/2 offsets in petg and tpu, 0.1 was good in petg, but had to go to 0.2 for tpu

what a week of RND -

@Leggy said in help with a thread:

it seems to be in hidden sections, so would have to select every faucet on the plane and line

Likely you need to weld some edges first.

@Leggy said in help with a thread:

what I found is a difference in tolerances, I printed 3 nuts with 0.1/15/2 offsets in petg and tpu, 0.1 was good in petg, but had to go to 0.2 for tpu

Not surprising. They have different shrink rates.

-

D Dave R referenced this topic on

D Dave R referenced this topic on

Advertisement