Barley Twist Spirals

-

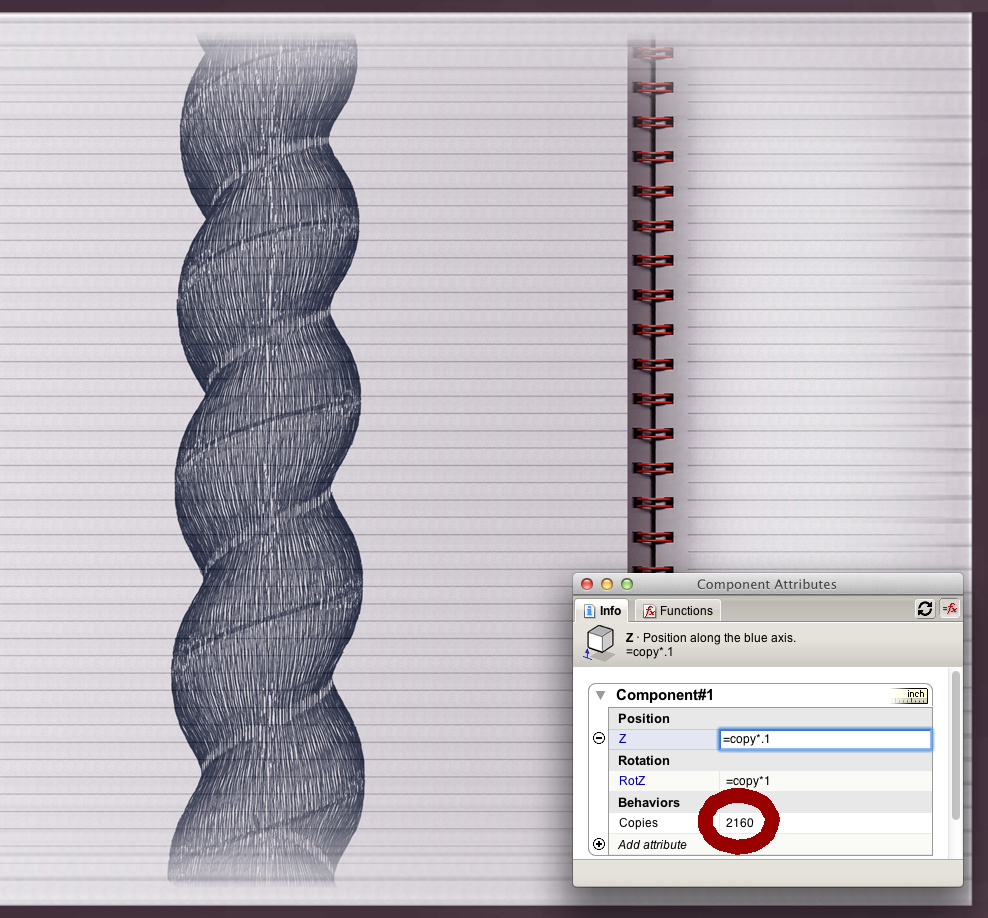

archturn, you could use the method I showed and create the transitions when you've finished. There isn't any reason you couldn't fit it to the rest of the turning. I did on the table legs. The transitions are similar to creating the pommels which I've showed in several other blog posts so I didn't bother with them in that one. The Screw plugin is nice, too. although you can do multiple starts the way Gilles shows, I would still make a single turn as a component and copy it as I did in the blog to keep file size down and make it easier to adjust the length.

-

@dave r said:

archturn, you could use the method I showed and create the transitions when you've finished. There isn't any reason you couldn't fit it to the rest of the turning. I did on the table legs. The transitions are similar to creating the pommels which I've showed in several other blog posts so I didn't bother with them in that one. The Screw plugin is nice, too. although you can do multiple starts the way Gilles shows, I would still make a single turn as a component and copy it as I did in the blog to keep file size down and make it easier to adjust the length.

Totally agree with this.

-

Hi,

here are two more options

-

I can see that I should have been visiting the forum more frequently instead of pulling my hair out. Awesome!!!

-

Yes. You should have.

And as I wrote before, there's more than one way to arrive at the final result in SketchUp. This is a great example.

And as I wrote before, there's more than one way to arrive at the final result in SketchUp. This is a great example. -

@charly2008 said:

Hi,

here are two more optionsCharly

I'm wondering how to use the "follow me keep" plugin". I installed it and though it shows up in my plugin menu nothing seems to happen when I click it. -

You have first to select both the path and the face and then run the plugin.

-

Just a question: why use two plugins instead of one which does very well the job?

-

@gilles said:

Just a question: why use two plugins instead of one which does very well the job?

I'm going to try them all. I remeber some time back trying the "draw helix" without the "follow me keep" tool. That was one of the times I gave up. The result from using the native "follow me" is pretty ugly so I thought I would see what this tool was all about.

Again, I wasted a lot of time by not coming here first. -

@gilles said:

screw1_5.rb.

select 3 profiles (in the following case), set start point, set end point, enter n steps n turn and go.

Could you elaborate on using screw1_5??

-

Will do later, its late here in France and I should sleep.

-

use a whole bunch of profile curves then apply wonky style?

-

Just a quick question. In reality, can you turn a Barley Twist, or is it more of a carving exercise?

-

Dale, barley twists can be turned, sort of. There's a machine that combines a router with a lathe and gears them together for creating barley twists and other ornamental milling. Check out this link. I used to have one of their machines and used it a lot. Of course now with CNC-driven equipment, it gets even more sophisticated. I can't say I would recommend dealing with the company but the idea was interesting.

-

Thanks Dave, really interesting machine. I often wish I was a machinist, boy there would be trouble then.

-

@dale said:

Just a quick question. In reality, can you turn a Barley Twist, or is it more of a carving exercise?

Here are two videos of turning a barley twist and then a rope twist on my machine.

http://www.youtube.com/watch?v=LcjVLg0ql7c

Barley Twisthttp://www.youtube.com/watch?v=0zVD22NqgSc>

Rope Twist -

That's Great. So can you directly import from SketchUp to you machine?

( Oh and, I guess I'm still living in the past, as I was thinking of how difficult if not impossible to turn it by hand. )

) -

@dale said:

That's Great. So can you directly import from SketchUp to you machine?

( Oh and, I guess I'm still living in the past, as I was thinking of how difficult if not impossible to turn it by hand. )

)My machine is not a full CNC but a step below it. It is a hydraulic copier so it traces a profile. The indexing function (used for the twisting) however is computer controlled so the setting up of gears and indexing pins that Dave R referred is not necessary. The templates I use for the turning profile are drawn in CAD and sent to a machine shop with a laser CNC so I can get a pretty fine template for tracing

-

-

Archturn, I was just looking at an old book on turning from the Gutenberg Project and toward the end they spend some time talking about doing various spiral turning by hand. They show some pretty cool examples in the photos. I'm sure you're getting them done in a lot less time.

Talk to you tonight with live demo.

Advertisement