How would you model this?

-

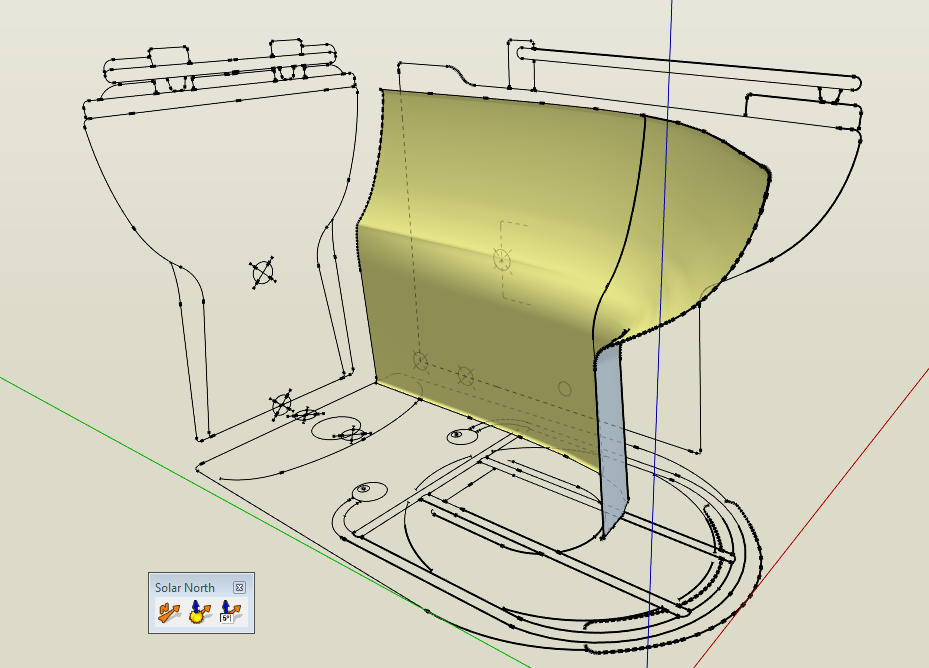

Hi guys, I've toyed with the idea of someday when i get a freetime I'd build a library of models I use commonly on projects. I thought I'd start with a slophopper, simple cleaner sink.

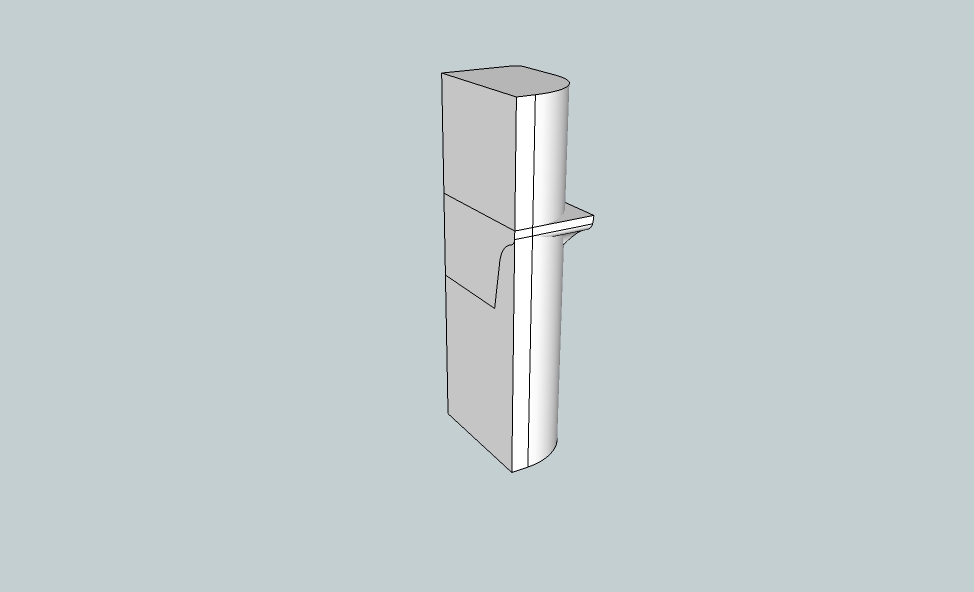

But do you think I can get it to look anything like the acual DWG files I was sent?

Can anyone be so kind as to give me a kick along. I've started using Fredo's Curviloft tools but not really sure if it is the best way to go....

-

-

thanks mac1, I was hoping to stick with SU rather than use another program.....

-

I don't think he's pointing to the other program, more so pointing to Tig's answer of using Boolean Tools.

I would suggest section modeling but I'm not one to give advice on organic modeling.

-

Andrew,

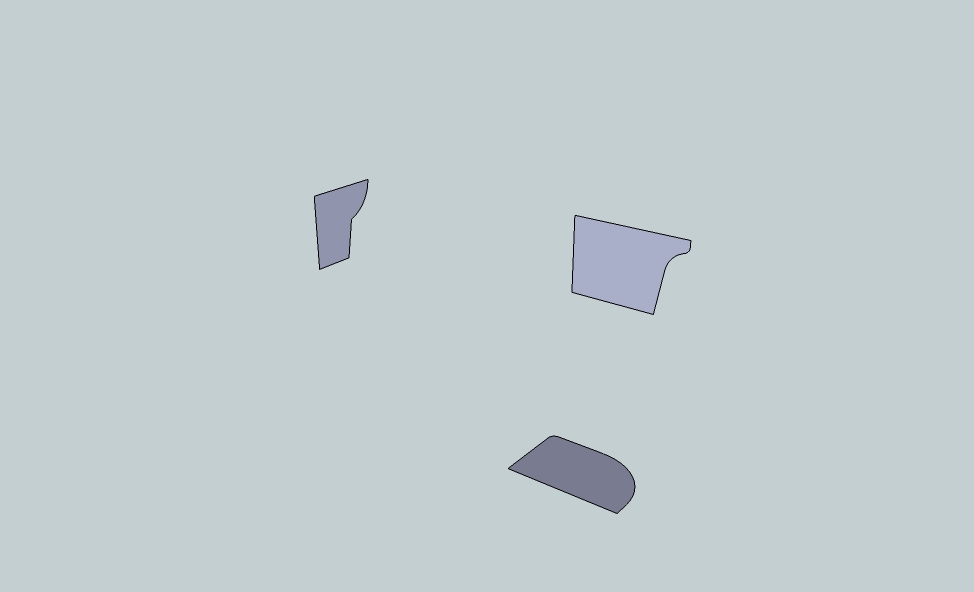

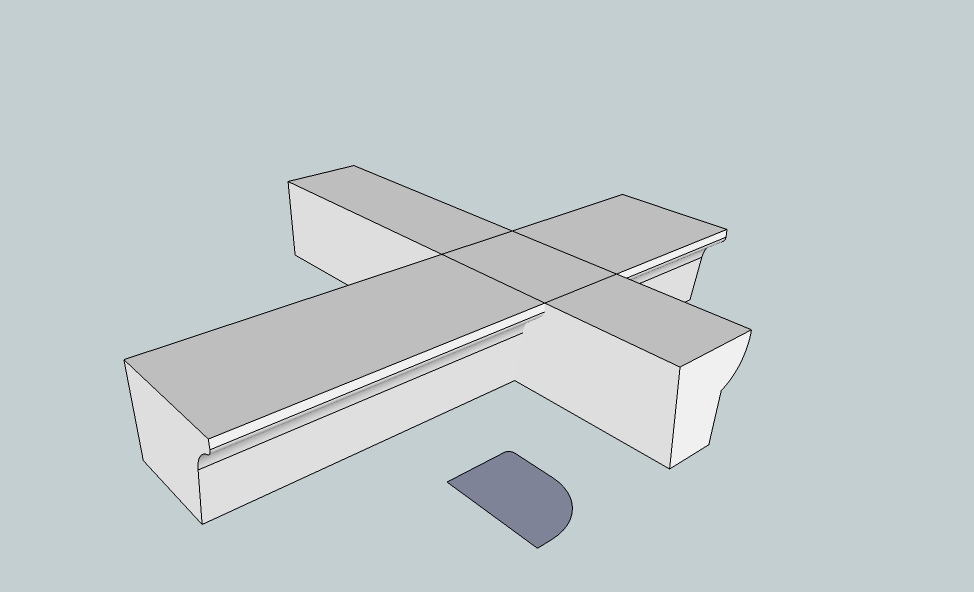

See attached.

Should get you started.

........

Extrude your CAD sections and use Bool Tools or new SU8 Solid Tools.

Use Intesect or Difference Tool

........

Hope this HelpsHoward L'

-

Push profiles, 2 at a time. Use Intersect Faces. Get rid of parts you do not want.

Good luck.

-

Those drawings are missing an element in the design...i think?

The transition from the bowl to the back. I'd imagine it would curve inwards? Have you a real photo?

-

Its hard to tell you all the steps to modeling a sink, but honestly, I found that you can model anything with Sketchup.

Even an animal or person.

I would suggest doing one piece at a time.

Try the "revolve" tool and the "follow-me" tool to create organic shapes.

I usually create a geometric shape first and then use the "M" tool and "S" tool to tweak it into an organic one.Also, sandbox has a lot of capabilities to create organic meshes. Its harder to use, but I created a Grotto (Pool cave with waterfall/slide) with the sandbox tools and it came out pretty good.

Takes a lot of patience but once you learn all the advanced capabilities of Sketchup... anything is possible -

Thanks to you all taking the time and chiming in.

Kris - I see what you mean... sorry for the misunderstanding, mac1!

Don & Howard - Both methods were how I tried at first however the look is not the same.... [see attached photo image] you'll see that the underside of the rim is moulded consistent with the top rather than squared. I was thinking it may be an ExtrudeBy____ process or curviloft.

What do you think?

-

@unknownuser said:

Those drawings are missing an element in the design...i think?

The transition from the bowl to the back. I'd imagine it would curve inwards? Have you a real photo?

you read my mind, Rich! see above...

-

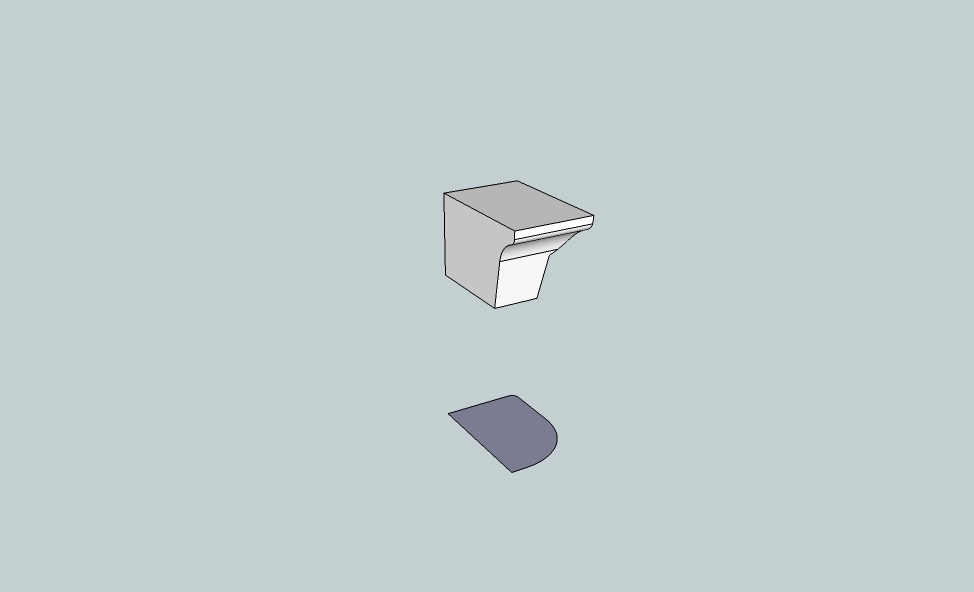

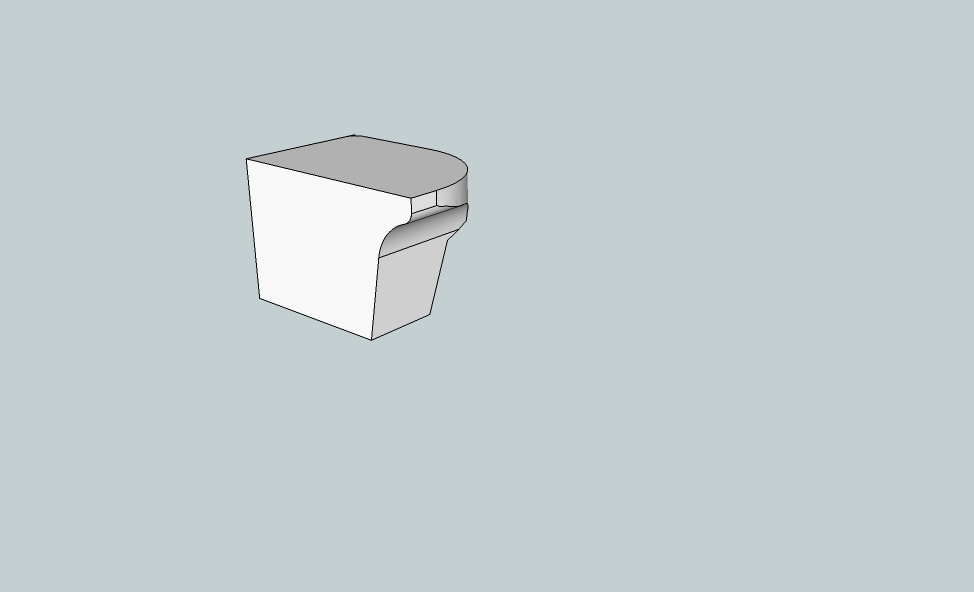

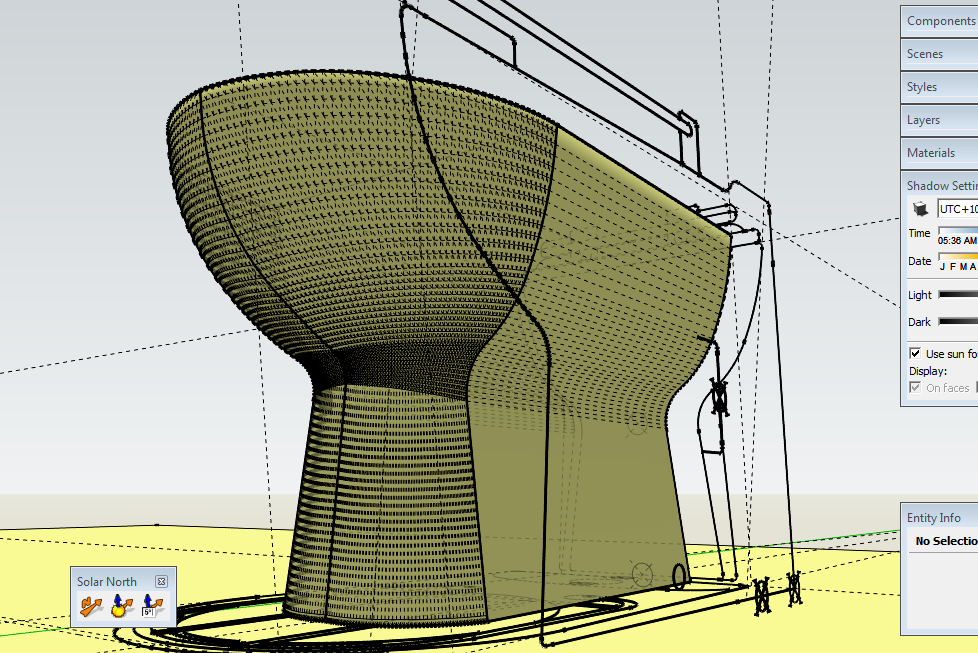

Here's the start.....

Andrew_Shitter.skp -

Rich

It's a sluice for washing away 'dirty stuff' - NOT for 'number twos' directly produced over it...

BUT the principle of its modeling remains the same........ -

Don't invite me round for a party then

-

That's pretty close, Rich!

so what did you do to get it?

so what did you do to get it?And yes TIG's right; that stainless steel rack on it's lid might make for an iteresting experience....

-

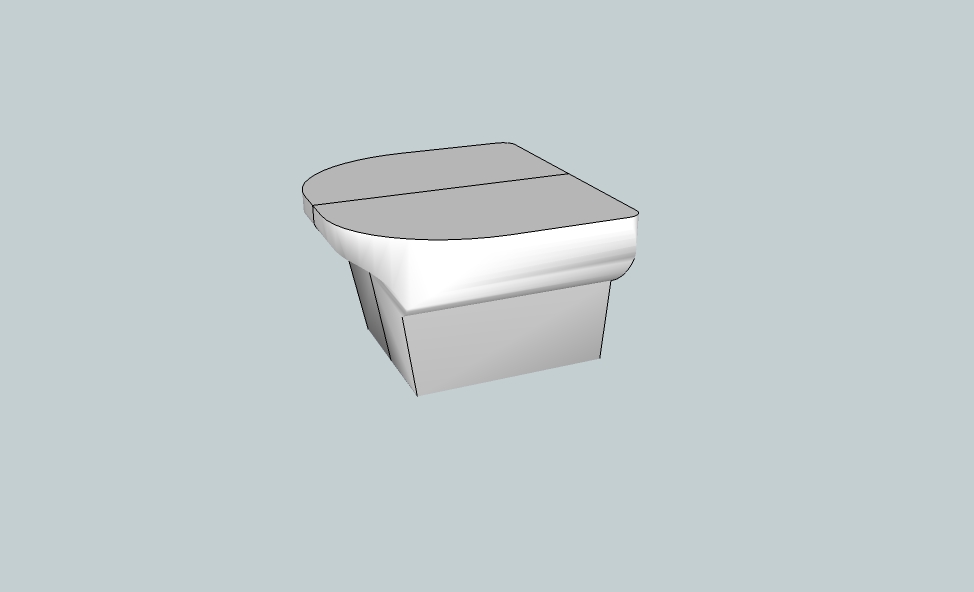

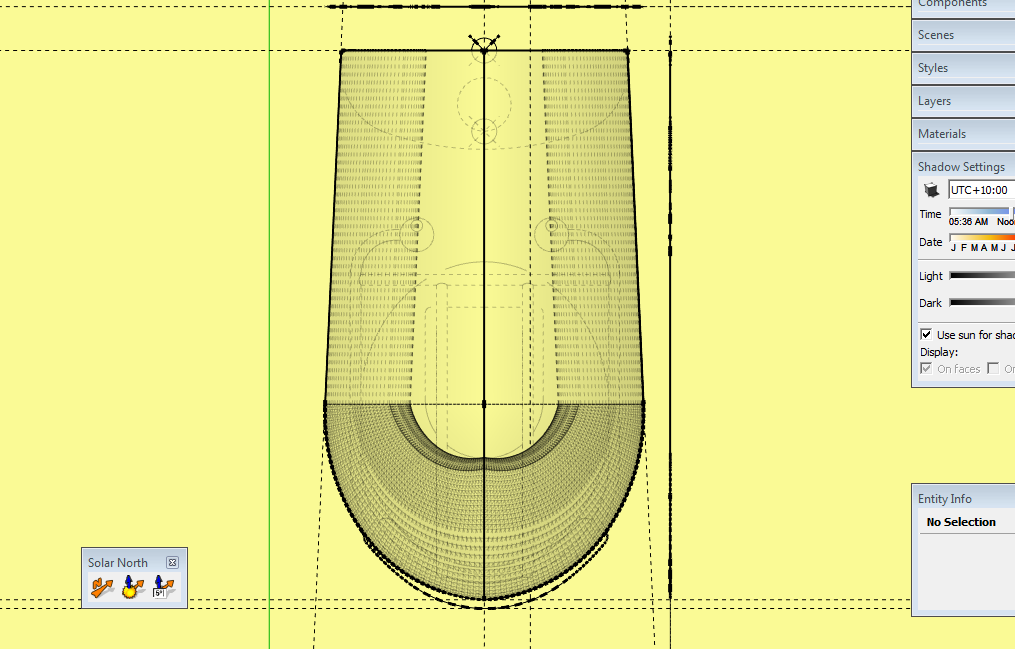

Here's a play.

When you look closely the profiles of front to side are not the same as well as the side walls deminish as it moves to the back. I tried EEByRails but the bottom curve is a questions which you'll see in the plan view....I just copied the CAD lines so segments are high and hence many facets so I would need to cut them down. How would I do that considering the welded profile may be made up of differing lines lengths?

-

Very nice, looking good

-

Late to this party, but I'd use Artisan and these video tutes:

-

@tig said:

Rich

It's a sluice for washing away 'dirty stuff' - NOT for 'number twos' directly produced over it...

BUT the principle of its modeling remains the same........@unknownuser said:

Don't invite me round for a party then

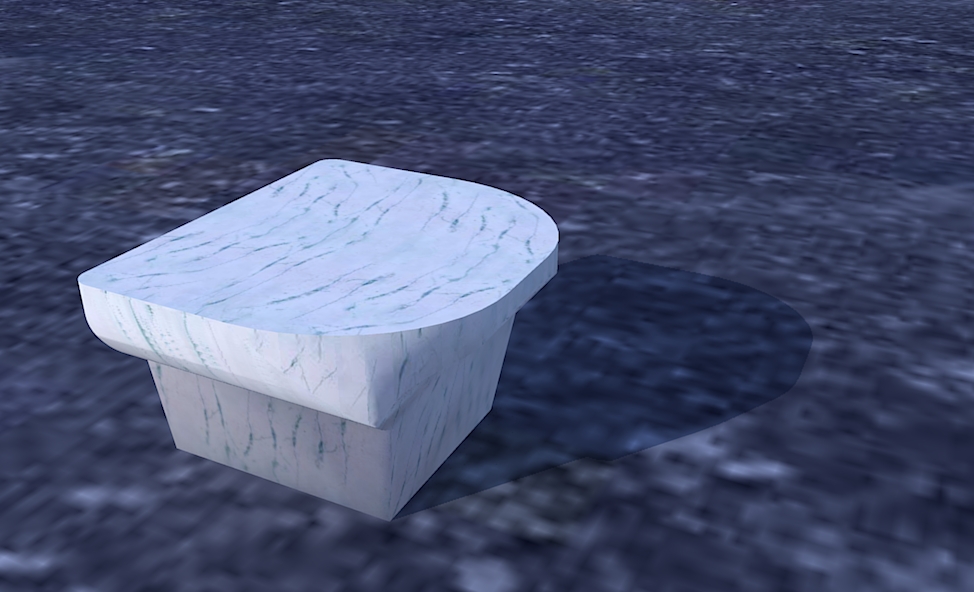

Andrew, sorry I did not see this earlier.

There are obviously many different ways to go about it, here is my starting stab...

(I find it useful to use Subdivide & Smooth to create a profile that will later be Subdivided & Smoothed, wait, what? )

)

[flash=853,505:5722dj61]http://www.youtube.com/v/C3g_oktqBiY&fs=1[/flash:5722dj61] -

nice Boo...

-

Some people here make things seem so easy!

Advertisement