@dave r said:

Hi Tim,

Long time, no see. I hope you're doing well.

Hi Dave; yup, all ok over here. After the fun and excitement of building the house I got pulled into the Raspberry Pi world to develop and improve the Scratch program (anyone who has kids that are interested in tech things should at least look at http://www.raspberrypi.org) and pretty much haven't had time to do anything else for the last couple of years.

Now at last I have a little time to try to repair a large and beautiful model plane I crashed three years ago...

@dave r said:

So are you trying to take the skin (with thickness) off the wing structure? Are the ribs and spars already in there? Or is your goal to be able to create the shapes of the ribs and such? If it is the latter, what about slicing the wing shape--maybe TIG's Slicer plugin or manually placed cutting planes?

Good question.

What I have is an original dxf file of the design by Fred Guillfoyle that I imported and started working on. I noticed that when I 'assembled' the wing ribs they didn't seem to fit terribly well, as if the import had just been a bit vague.

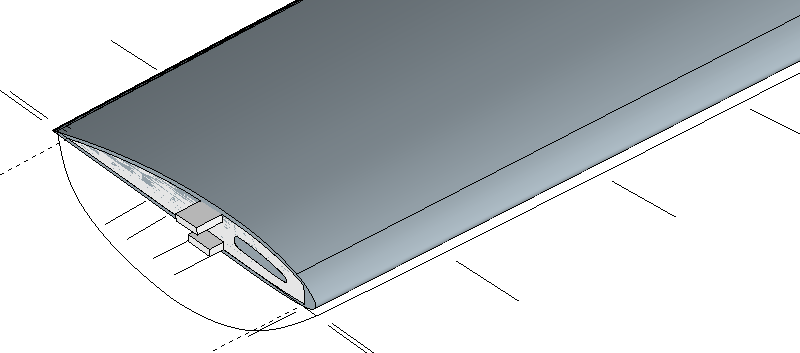

So, I used a nice little importer (https://github.com/elliottt/sketchup-airfoil) to read in the standard coordinates of a the ClarkY airfoil it uses (no jokes about the choice please, not my decision) and compared the rib shapes to that. It took a while before I realised that I had to scale the airfoil to the full outside dimension of the wing and then offset inwards by the sheeting thickness, but the ribs are reasonably close once you do that.

Clearly, at this point I could just accept the data and move on but where would the fun be in doing that? So, I started wondering how to derive wing rib shapes in SU, given a root and tip profile. Note that the profiles may well be fairly different in many wings - we often use a lower camber tip profile to reduce the likelihood of tip stalling.

I can see two basic ways of doing the job (and an opportunity for an extension to automate!).

a) (probably only good when the root & tip profiles are the same even if scaled) extrude from the full root profile, select the tip face, scale it down. Use a tool that does something like jointpushpull to offset the surfaces inwards by the thickness of the desired skin - typically anything from 1/32 to 3/32. Then place 'sheets' of balsa where the ribs need to go, intersect and remove the unneeded stuff. Add slots for spars etc and off we go.

b) place the root and tip profiles where needed. Offset inwards on each one by the skin thickness. Remove the outer profile. Use a tool that will skin over them, hopefully coping with an shape changes due to different profiles. Then place the ribs, intersect etc as above.

I guess there is a third way where the outer profile is made solid, the ribs placed and cut and the offset done to each individual rib.

I'm sure I've seen one or more tools to do this kind of thing but simply can't remember what they were called even well enough to get any sense from searching! It wouldn't surprise me at all to find that some modeller had written an extension to do all this and lay out the result ready for cmc or laser cutting.