@ely862me said:

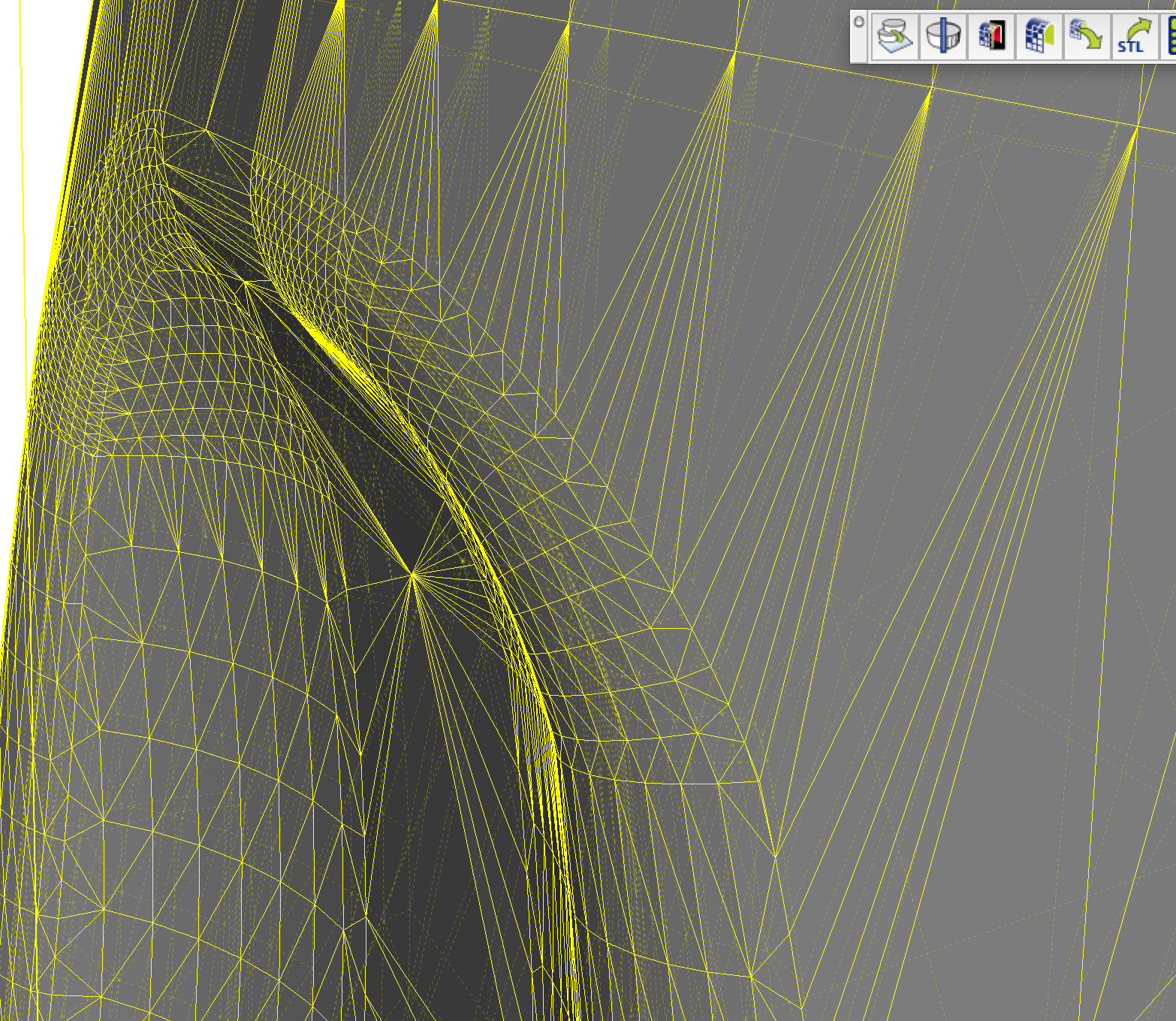

Yep, you just have to wait a bit, about 3-4 minutes, for each intersection to be made.

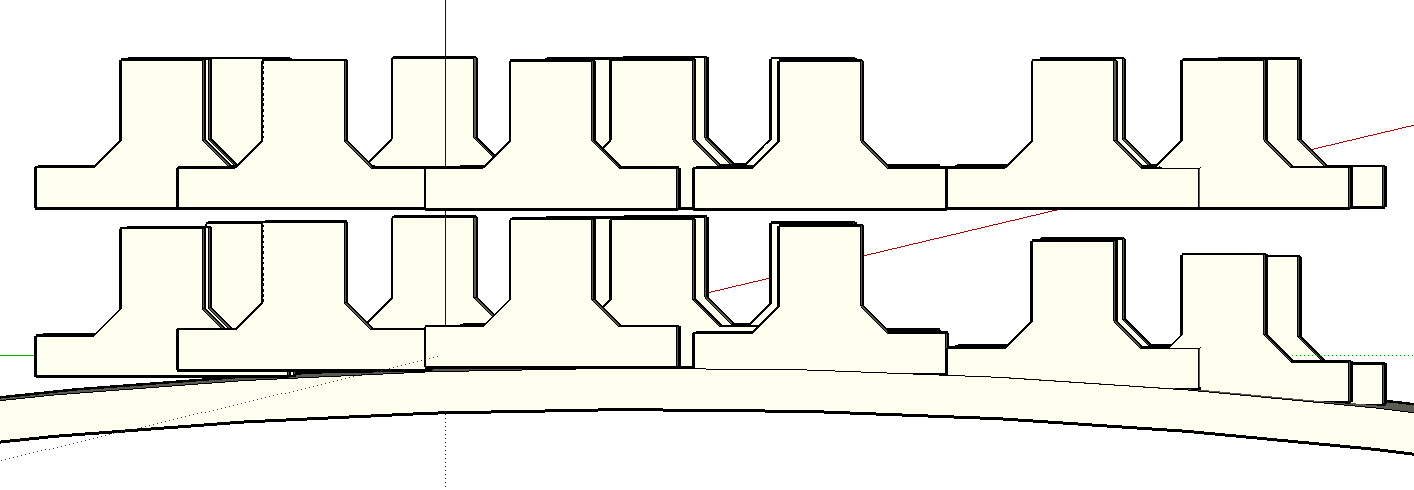

In the middle I opted to make the middle line coplanar and just cut the inside part which has no middle line. Then you just unsmooth it and you have the cut.

Keep in mind to intersect each plane separately to have faster response with the intersection. In my case I worked the middle line then each end .

I also scaled it up 10 times more, then down again.

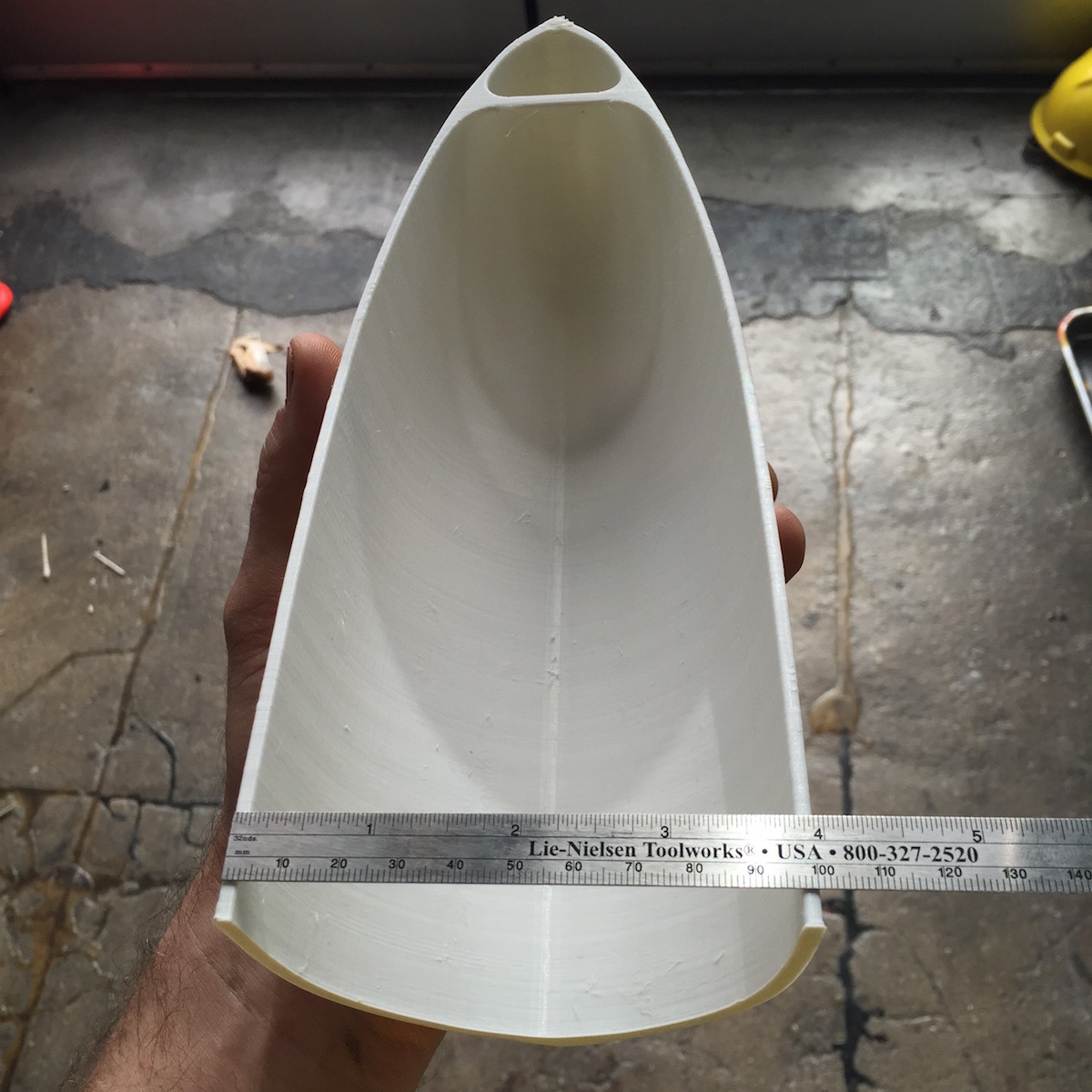

That is very impressive to me, I am missing something in my approach. However Netfabb was a breeze, and I'm up and running! First part is being printed.

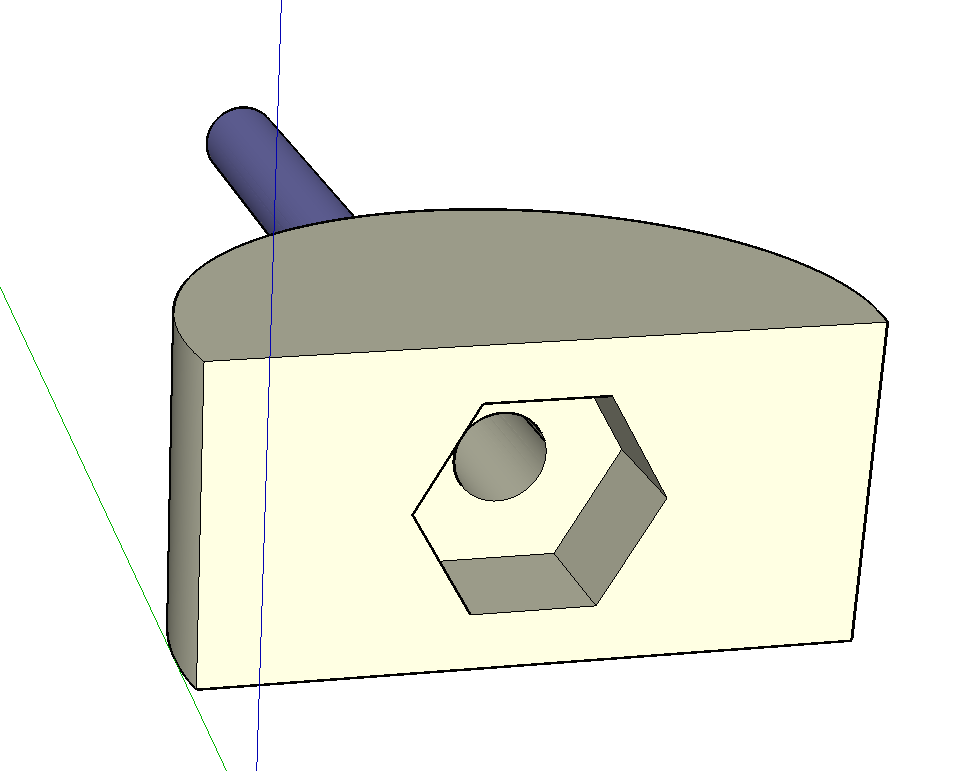

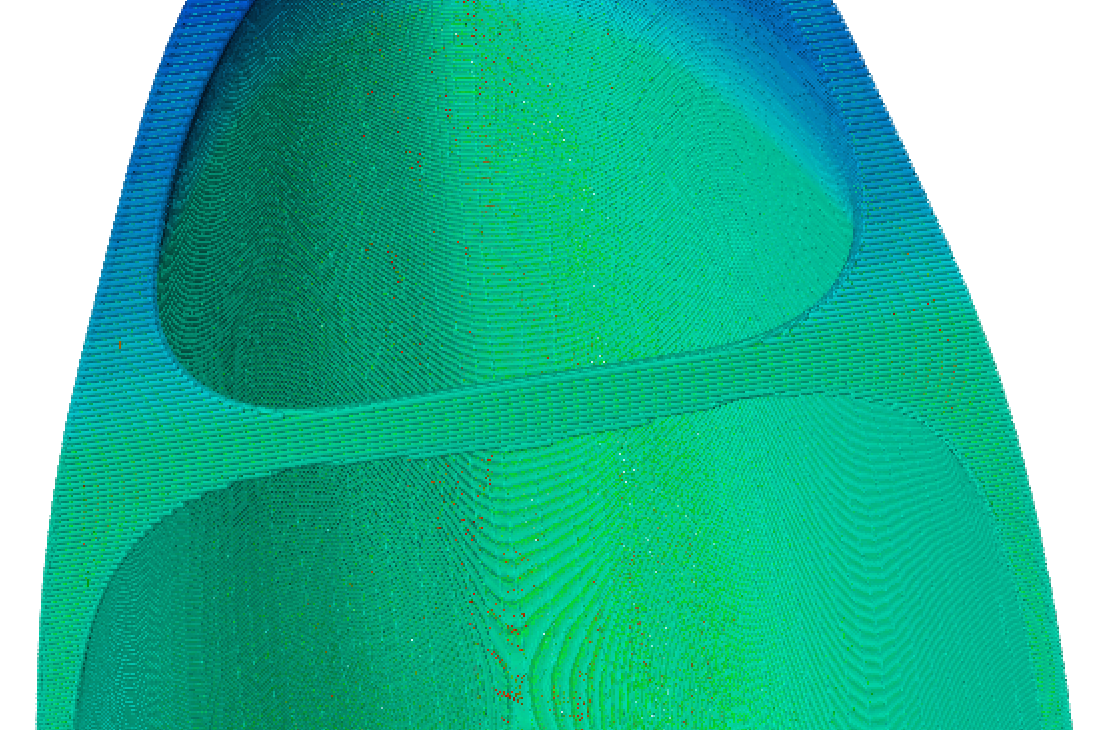

Some details on the parameters:

Extruder temp: 218 C

bed temp: 60 C

Layer height: .2mm

1st layer: .3

Perimeters: 2

Layers on top and bottom: 3

fill density: .3

Speed:

infill: 40mm/s

inside perimeters:45 mm/s

outside perimeters: 35 mm/s

bridge: 60 mm/s

non print speed: 300 mm/s

These numbers are not based on anything other than my experience, which is fairly minimal. If anyone has any pointers in this department, please let me know!

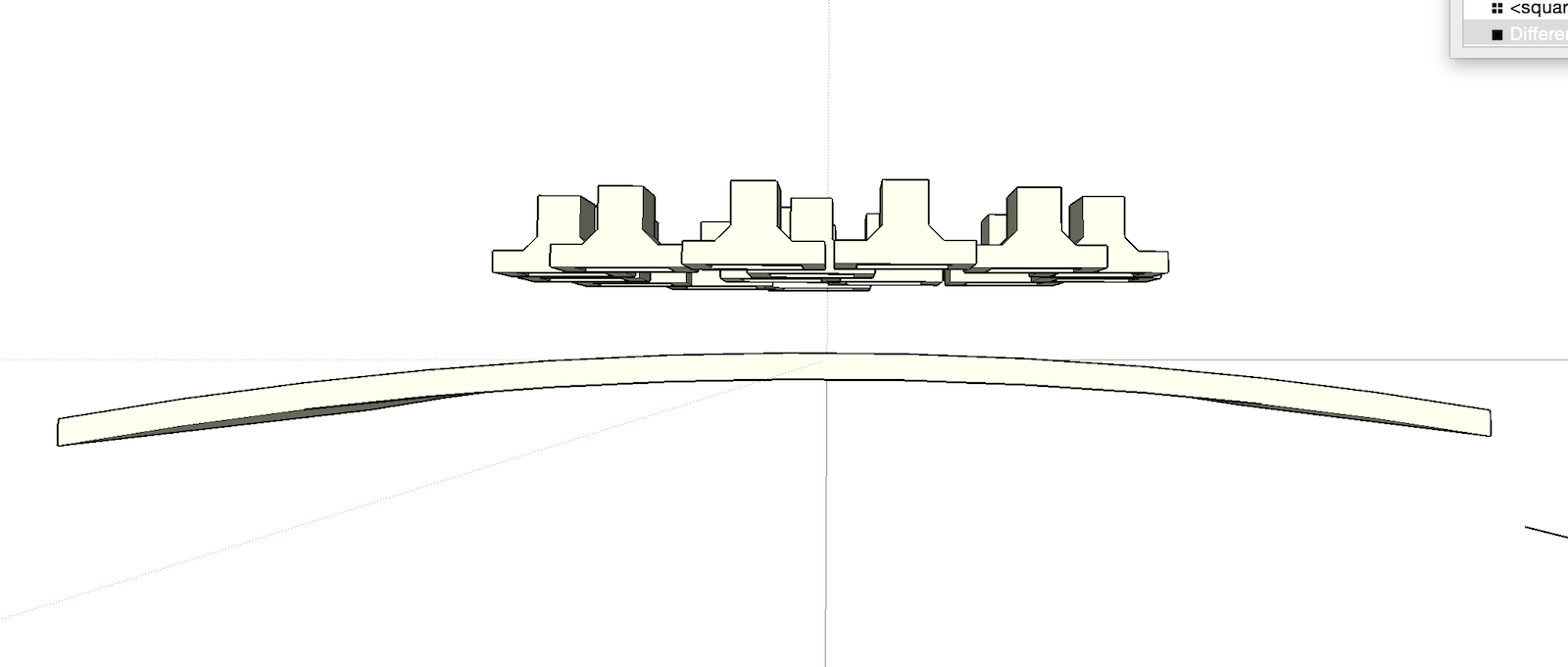

I could probably push the speed a bit, but I figured I would play it safe for this first one. I am printing half of the boat hull vertically which is about 25cm tall, 9.85". Originally I had planned on printing it horizontally upside down, but it barely fits on the bed, and would necessitate a lot more bridging. I've found a good rule of thumb with Rostocks is to stay away from the very edge of the bed as you will lose resolution. With the Rostock design, if you have a choice and good bed adhesion etc, go vertical!

EDIT: I just realized that when I cut this up, i had been thinking i would print the hull parts upside down, the advantage being that I would have a clean seam on the upper lip to glue to. So, I sliced it wrong, as evidenced in the pic below-- there is a belly in the bridge. I would need to slice it a little lower on the Z axis to avoid this... or go back to printing it upside down. Impending Fail? we'll see. I'm 6 hr into the print so I think I'll let it run its course.