Cutting a large model for 3D printing (revisited!)

-

Hi guys-

You all really helped me with a large 50 cm tall print I did back in June I believe it was. http://sketchucation.com/forums/viewtopic.php?f=388%26amp;t=62325

I am here to request some more help with a big print. the biggest component is attached. it is barely bigger than my build platform, which is 11" diameter (circular) by 17" tall. there are going to have to be some slices through the front of it, I see no way around it. so the question really is: what are some good ways to attach / weld PLA plastic seamlessly? As I'm writing this I am realizing that this is sort of outside of the purview of this forum since it doesn't specifically relate to sketchup...

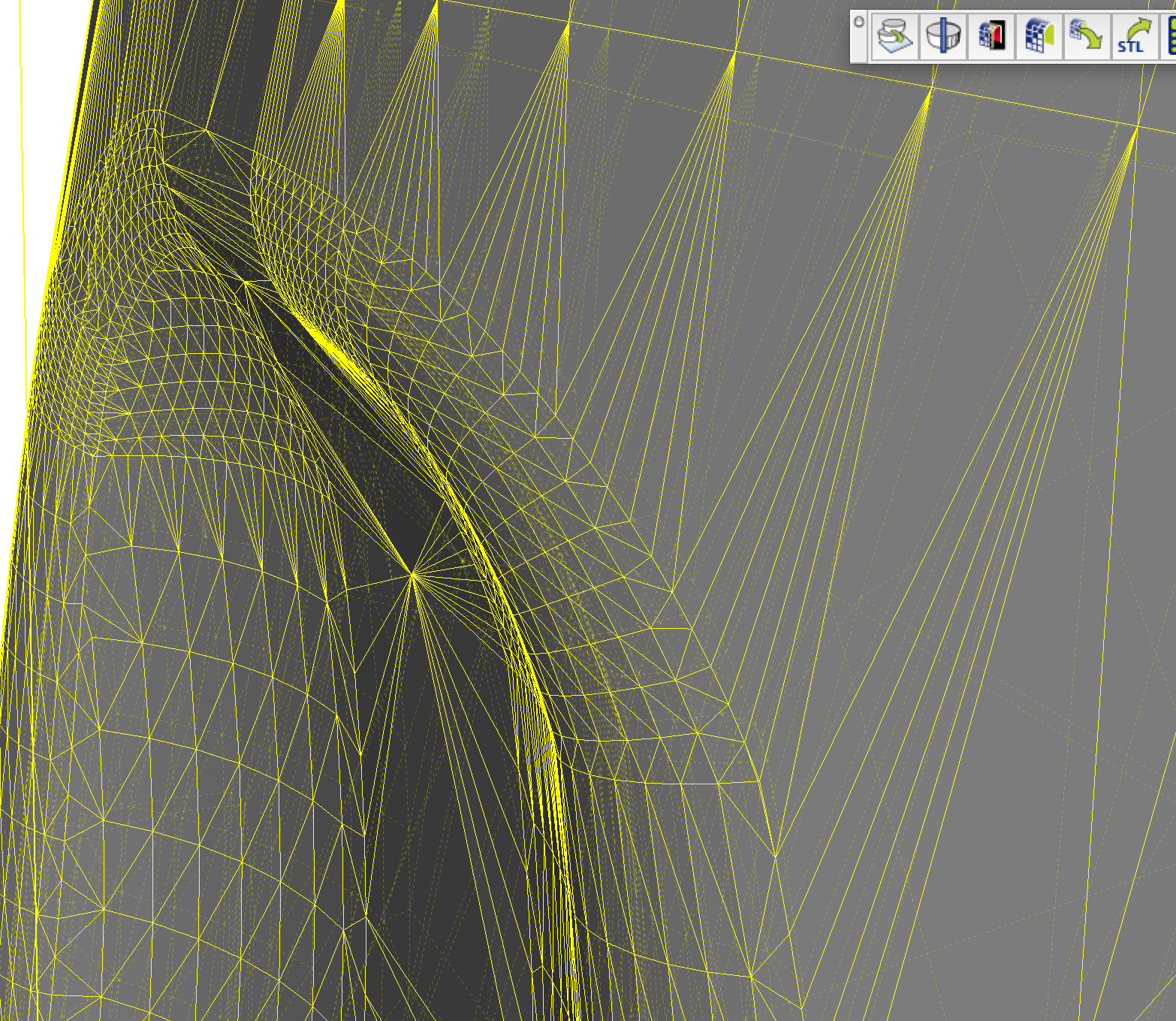

but while I'm here I guess I have another question that is pertinent to the forum: I noticed that when I converted this model from NURBS to a mesh in Rhino that there were some clusters of long skinny polygons which I understand are not desirable for 3D printing. Is there a way to change this within sketchup? or better to do this in rhino? please see attached photo and file.

-Rev

-

Hi Rev, superglue and hot glue are commonly used to attach 3D printed parts together. For some novel ways including friction welding the parts together, you may check out this piece on Makezine.

Regarding the long skinny triangles, I wouldn't worry about them unless you are experiencing trouble while printing. While they aren't ideal, I've never personally had trouble printing them. That said, increasing the polycount while exporting is likely the best way to avoid the long triangles, but then you can run into overly heavy models that take longer to process and can also make for a lower quality print.

Advertisement