"click the underside as you would pull the down-light to change"

have moved the onclick to the whole not the lens area so as to make it easier to operate

"click the underside as you would pull the down-light to change"

have moved the onclick to the whole not the lens area so as to make it easier to operate

Make all the parts then place their axis at their point of rotation, then place each component within any component if they share the same action, so a finger is within the hand, which in turn within wrist, then the wrist in the arm..so nesting depending the number of joints or detail required.

You will find it easy to place and change nesting using drag and drop in outliner,

With animation it depends on what you want, how much interaction. The example has one onclick to drive 3 movements, for transferred, nested elements its difficult to have separate onclicks as the parent will always proceed any nested ones. you would have to create 3 button areas in the parent to achieve this.

click the underside as you would pull the down-light to change

If you post your model, or a simple concept and how you want it to operate, then can be more specific on the best approach

I am using 2018. however can see problem when referencing in a formula, a suggestion is to put the pages in the value section of the options list

My take on this,

Make solids, place, rotate as you want, then outer shell

see

formula used:

did not see your post until today, after a bit of research on cams, (not my field, I'm carpenter and estimator)

need only the rotation and the formula does the rest

the more you stare at it the more you see, like kind of getting night vision, or coming into a darkroom from sunlight

Copying groups with attributes creates groups that are connected, you would need to make them unique via a script

It may be best to make components, then right click make unique, you could experiment with reset scale or scale definition, which ever is best suited for the situation.

You can use find with the item to be found included in the text to avoid the error , and test if the result is within the length of the original text

Note that semi is placed before in the conditional statements otherwise will not be selected

Further to this, you will notice that on animation of the bottom drawer, all move. To correct this the animation must be moved to inside the copy. Hence another level is created.

My reason to ask about your interest in DCs is to guide you in your development. Although internal copies has its merit it also has many drawbacks, in that it greatly increases file size and becomes more complicated in structure, as are becoming aware. So if this is a basic project then okay, but if its a development toward a kitchen design system with quantity lists, materials... then I suggest looking at

https://sketchucation.com/plugin/1613-gkware_cabmaker

If you still wish to pursue your own, then I can help, but the DCs need to be simple and have the ability to swap, plus incorporate some simple ruby scripts to make it easier to handle.

The drawer and face has to be within the component that is copied, most likely you need a handle too. So place all within a "opening" component and copy this as needed.

May I know if this is a one / two off project or are you hoping to create a collection?

create a separate attribute and reference that

Hi Forum, I’m working on a pair of gears meshing and I want to animate them. The gears are identical and I can animate them - but only one at a time. Is it possible to animate them both together so that they remain in me…

SketchUp Community (forums.sketchup.com)

Si besoin je peux partager mon composant dynamique afin que vous puissiez naviguer dedans.

can do

The condition is either true or false, 0 or any negative number is read as false whereas any positive number is true.

A bit of a short cut in logic.

The space is not required for mathematical functions, just there for my own readability

Hi

To work out the number divide the opening by the whole door size and convert to integer

To get the remainder take this number times the size from opening

For door lenx, use condition if remainder then the last copy (= copies) is to be remainder

There were some issues with the geometry and scaling, first applied lenX to two faces, then had to make a group of the edges so that it obeyed the formula rather than its natural scale

made outline to size to opening, added some copy function to the support

Instance names are automatic updated in outliner, DC option and attribute dialog, also labels in layout. So my recommendation is to use component names for generic terms like panel, board, box...then their #numbers are somewhat redundant. And specific for instance names

The attached file contains a DC, select one of the instance name for any of the generic panels in outliner. Change this instance in Entity info and you will see that its updated in the option and attribute DC dialog. There is a report attached to the file and this is reference to the instance name too.

The parts are made from one DC panel that is placed using a version of the rotation rectangle script, to place, orientate and scale as require, plus excess to the options.

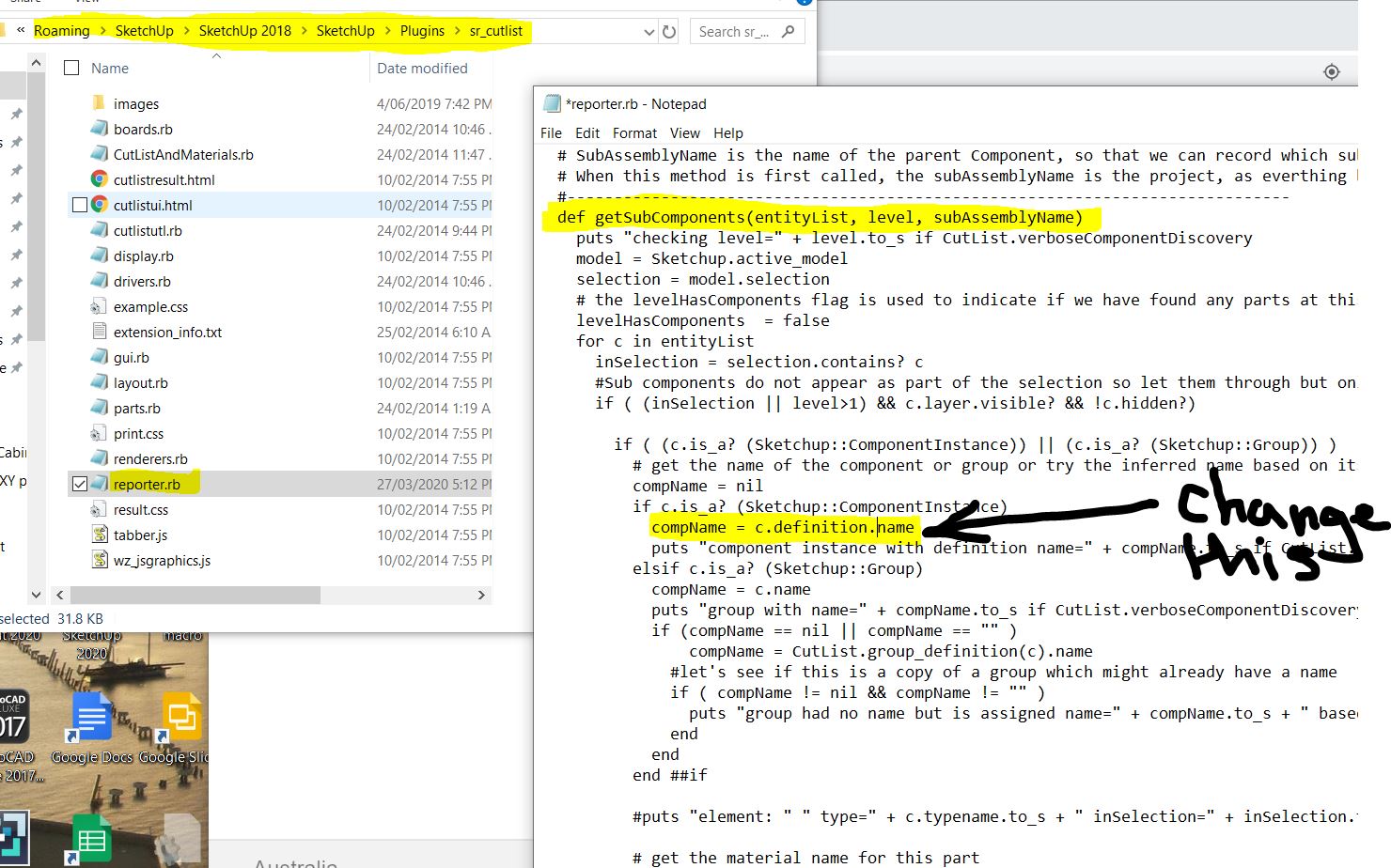

As you would be aware, cutlist 4.1 reports component definition names. However you can change the cutlist script to use the instant names if available otherwise the component name by going into the ruby file and replacing compName = c.definition.name in the reporter

if c.name == "" then compName = c.definition.name else compName = c.name end

save, if sketchup open, close and reopen for the script to reload,

Note if you do decide to use the "power" of instance names for your DCs, then you cannot use the "Name" attribute in the component info section as this disables this function, plus when first creating a DC this does not work, until you have "saveas" it to a folder and inserted an instance.

(You can use _name in the value section to reference the existing definition name if require for an attribute like description = _name & " " & lenx & "x" & leny )

If you wish to create the DC placing script, please ask, then will show what I use, but note the ruby,though works is still at a basic level, I am still learning and do not have the expertise of some of the others on this forum.

Hi Franz,

DCs involving more than one level will become unique if internal sizes or positions are changed, its unusual for animation to trigger this, unless the operation changes the original size or position of a part. So please upload the DC so can offer some explanation or solution.

Rather than relying on the definition name, I suggest using the instance name to document your project.

https://sketchucation.com/forums/viewtopic.php?f=289&t=70511&start=30

Simplification using ruby scripts is another approach, also consider some developed ruby solutions like FlexTools extension

Philip

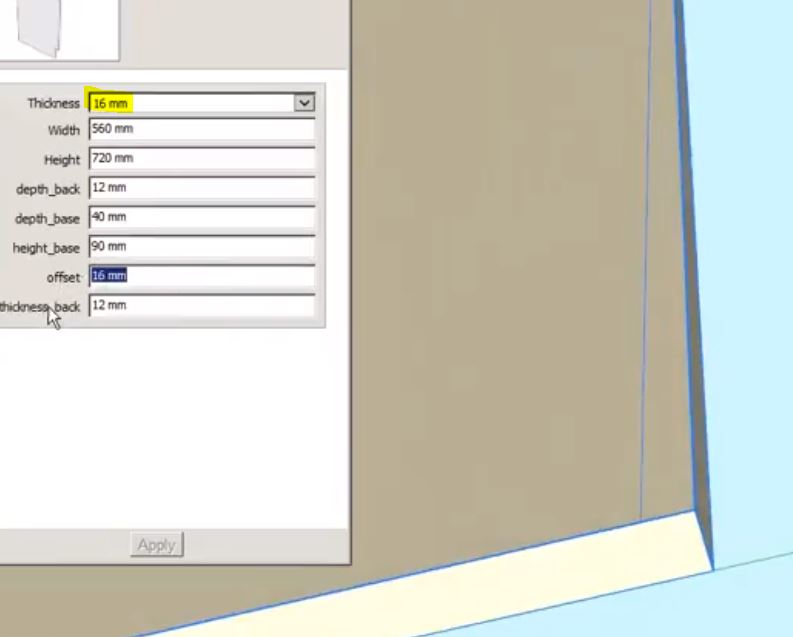

There are two ways to create this, one is to use parts and hide the common edges and faces, the other is to use cutting components

In this case its parts and hidden faces/edges as shown @ 2.04 on video

you can see the outline of the end face/component when the offset is matched to the thickness with a given back thickness,

When you create such. I recommend you use solids then can outer-shell the subs to create a whole (retaining the parent for data and ability to reinstate with swap with its definition)

cutting components work if the edges are hidden (outlines can be added as dynamic groups or components)

Either way, it involves making sub components or (I prefer) groups to suit your purpose