Looking good so far, now I'm looking forward to the finished print!

Posts

-

RE: Rule no.1 in Sketchup for 3d printing

@voljanko said:

Example: If I draw an 1mm3 cube and export the STL file choosing mm as the unit ,the STL file will be exactly the same like I draw an 1m3 cube and export the STL choosing m for unit.

This makes sense! Good explanation

-

RE: Rule no.1 in Sketchup for 3d printing

That will work for some cases where you can specify the print units, but my 3D printer assumes models are in mm by default, so it's easier to have it in mm before importing.

-

RE: Rule no.1 in Sketchup for 3d printing

Definitely a good practice, David!

My favorite way to scale a model is to draw a reference line near the origin, say 10 mm long. Immediately use the Text tool (not 3D Text) and click on the midpoint of the line. The length of the line is entered by default, click in empty space to save it. This is a reference line.

To scale the model up, use the Tape Measure tool. Click on one end of the line, then the other end, and type 10000, and click enter. Sketchup asks if you want to resize the model, click yes. Do your work, then use the same process in reverse to scale the model back to printing size.

This way is nice because the reference line is marked so you always can tell what the life size of the model should be.

-

RE: Where to get your models 3D printed

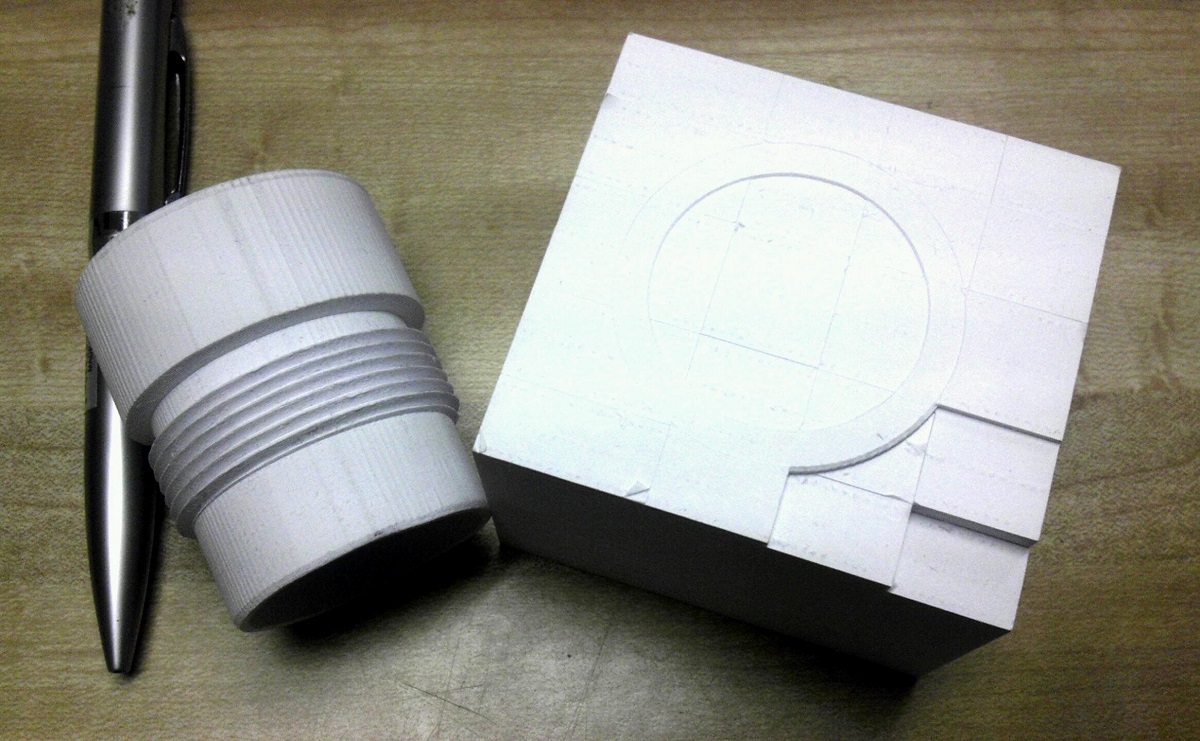

Mcor has a very interesting printer. Here's one of my models made in paper on their machine. Feels almost like wood.

They are expanding their presence like you mention, but as yet there are few services that offer Mcor printing to the public.

-

RE: Adventures in 3D printing Sketchup models

I'm guessing model units are getting mixed up in the process. Do you know about the STL exporter? If you use that, it's just one step and there shouldn't be any trouble! Protip - you can ZIP the file before uploading to speed the process.

-

RE: Adventures in 3D printing Sketchup models

@solo said:

What I really want to know is the price if you have your own machine, I'm contemplating buying one, but do not know which one or what material yet.

Pete, the best way to get a feel for these printers is to see one in person. There are local makerspaces in nearly all major cities that will let you come and take a look for free, or pay a monthly fee join to use the tools.

I looked up one in Dallas called the Dallas Makerspace: http://dallasmakerspace.org/

From their calendar, they have an Open House every Thursday night where you can pop in, get a tour, and ask questions. I have found the folks that frequent makerspaces are very receptive to questions and helping others get started in 3D printing and other useful skills. They can help you understand the different kinds of 3D printers and help you choose one that'll work for you.

For anyone else wanting to learn more about 3D printing, finding a makerspace (also called hackerspace) to see a printer in action and ask the regulars questions is an excellent way to get started. Here are a few ways to find groups with 3D printers:

-

Where to get your models 3D printed

There are many options to get your Sketchup model 3D printed. Owning your own printer is the most convenient and cheapest way. With your own printer, you are limited to only a handful of materials, usually some kind of plastic, and you'll need to learn 3D printer operation and perform maintenance when it breaks down.

Using a print service is another way to get things printed, and is perhaps a better choice when starting out, or just when you want better print quality. You'll get a wide variety of materials, and someone else takes care of the actual printing. Here's a list of the materials available from one print service, Shapeways:

Print services come in several flavors

There are a few varieties of print services, listed loosely in order from cheapest to most expensive.- Crowdsourced - where you work directly with the printer owner

- Print service with optional shop platform - automated system to order professional parts and/or sell your designs to the public

- Specialty print service - professional engineers assist you printing your design on their pro machines

Many desktop printer owners are available through crowdsourced services. The service helps you find a printer, you email them a file, and then meet them to get your part or have them ship the part to you. The benefits are working locally and usually at good prices. Some crowdsourced services include:

Print services with a shop platform are going to be your best price for professionally made parts. These automated systems allow you to upload a model to the service, choose a material, and order the part. Making & shipping the finished item takes anywhere from a few days to a few weeks. If you wish to sell the printed part to the public, you can add a markup to your cost, and the print service will take care of order fulfillment and pay your markup for each item sold. You do need to know the materials and respective design guidelines well to get the most out of the system. Some of these services include:

Specialty print services have professional machines and will give you the most personal help throughout the process. They'll often have specialty machines and printing materials not available on the cheaper services. Some of these print services can be found via the crowdsourcing sites linked to above.

- GPI Prototype

- Solid Concepts - these are the guys that 3D printed the all metal 1911 pistol

- Google search "Rapid Prototyping" to find more

Minimizing costs

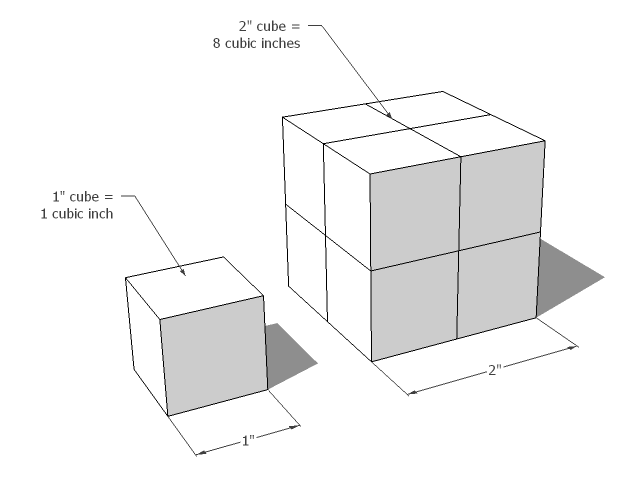

Something to keep in mind is that prices are generally charged by model volume. Realize that doubling print size actually increases the volume by 8x (see following image), so you'll want to optimize the model for the material you're printing in.

High detail plastic has different requirements than laser sintered nylon, which is modeled differently than ceramic or stainless steel. Too much material and you'll pay more than necessary - too thin of walls and the part will crumble.

One way to optimize the model is to punch holes in the model, making the model just a skeletal structure. With 3D printing, model complexity is free, which is just the opposite in other types of manufacturing where complex models increase machine time and are expensive to make. Here's an example of a complex lattice structure that is relatively cheap to 3D print.

Participate!

I encourage folks to add your favorite places to get things printed, especially local services that others may benefit from. 3D printing newbies are welcome to ask questions!

-

RE: Adventures in 3D printing Sketchup models

I was seriously impressed with that big 14K gold pendant. Shapeways just started offering gold a month ago, and that was the first thing I ordered. They sent it out in that nice case (for free!), which is a really nice bonus. I had it in hand in just 7 business days!

I don't sell the chains, but have been thinking to add them. It's one more thing to have on hand and keep track of, but it may well be worth it.

-

RE: Adventures in 3D printing Sketchup models

3D Printing is for - Jewelry!

These are pieces that I designed in Sketchup, printed via Shapeways and i.materilise, and sell to medical professionals online. The parts are not 3D printed directly, but rather a wax model is 3D printed, then placed in a plaster mold, and finished using lost-wax casting and hand polishing of the parts. The best thing is that the print services take care of all the work, sending my customers or myself the perfect finished part.

The pendants sell from $69 for the smallest silver one to $450 for the big gold pendant.

Sterling Silver

Solid 14K Gold

Solid 14K Gold

Solid 14K Gold

Sterling Silver

-

RE: Designing 3D printable Screw Threads

DMLS is usually used to make parts for rockets and high end cars where the cost can be justified, but they wanted to show on a smaller set of intricate parts what the capabilities are. Guns have to be manufactured to high tolerances, and those parts came out of the printer ready to use - no hand finishing required! To me, that really shows the power of 3D printing.

I'd love to see what you get printed.

-

RE: Designing 3D printable Screw Threads

Actually, there is an 'experimental' stainless steel material, now that you mention metal. From i.materilise, right here: http://i.materialise.com/materials/high-detailed-stainless-steel

There is other 3D printed metal available, but VERY expensive. Some folks in Texas printed a working 1911 pistol using Direct Metal Laser Sintering (DMLS), but the parts cost $10,000!

-

RE: Autodesk to launch its own 3D printer this year!

I'm excited about this, since most of the open source printers are made by a few smart people in their spare time, while Autodesk has the resources to put behind this and really make it work. Most open source printers feel incomplete, and are often hard to use, so a better platform will be a welcome addition.

They mention following the Android model for phones - if Autodesk is half as successful as Google was, this will be a really big deal.

-

RE: Designing 3D printable Screw Threads

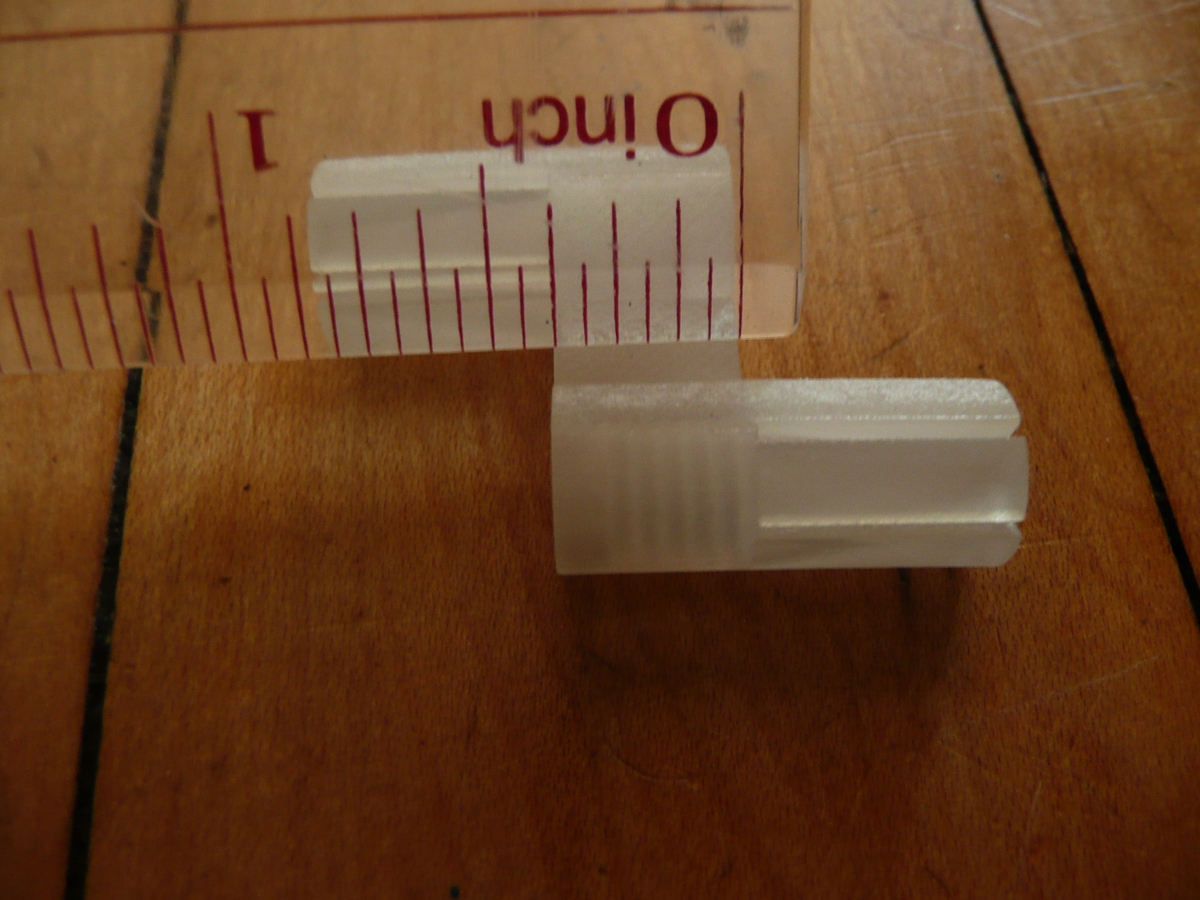

Oli, I have successfully used Shapeways Frosted Ultra Detail(FUD) material for screw threads on a 1/4" bolt. I used FUD because it is the highest resolution material available at a decent price that I know of.

A photo of the part. It worked perfectly with a 1/4" bolt from the hardware store.

You can probably go smaller. To figure out how small you can go, you can look at the design guidelines for the material, available here. For FUD, the minimum detail is 0.1mm, so as long as your thinnest thread thickness is greater than 0.1mm, you'll be fine.

Edited to add...

In this image, the Crest thickness would be the minimum detail in the model, so that tiny line would have to be 0.1mm long or greater.

-

RE: Adventures in 3D printing Sketchup models

Pete, a part made on a home printer will cost roughly 1-5% of a professionally printed part, but you also have a lot more work involved and will get a much lower quality product.

This cabin was printed on a pro printer (Full Color Sandstone from Shapeways) for ~$150:

The same cabin printed in ABS plastic on my home printer for $2.25, not including the 3 failed prints - and the model doesn't look nearly as good.

If I knew how to operate the printer better, I could get better prints. I've had it for 6 months now, and have had 1 major problem where I had to tear apart the extruder to clean out jammed filament, and several smaller problems that took a few hours of troubleshooting to correct. Home 3D printers are NOT plug and play yet, and it really depends on your needs and skill level if you want to buy a printer.

An analogy of using a print service vs your own printer would be sending a Sketchup model to a professional render guy and getting back a nice polished render made with Thea, vs. trying to figure out how to use Kerkythea on your own with no prior knowledge of rendering.

-

RE: Designing 3D printable Screw Threads

Just to keep in mind, since designing and printing are two very different animals, you'd need to match the resolution of the printer to the detail on the threads. Meaning that if you wanted to print these fine threads, you'll want to use a high resolution printer or else the threads will come out looking like blobs.

-

Designing 3D printable Screw Threads

Our local Woodworking master (Dave R) shows how to design 3D printable screw threads in this article:

Screw Threads in SketchUp

-

RE: Adventures in 3D printing Sketchup models

3D Printing is for - Scale Models!

While making a custom hook is no reason to go out and buy a printer, this following example may hit closer to home for the architects on the forum.

A project I posted a few weeks ago, this scale model of a tiny cabin is useful for helping customers understand the layout of the home, and for marketing to potential customers.

3D Printed teeny tiny cabin in color

-

RE: Adventures in 3D printing Sketchup models

@cotty said:

One older example: Repair of a roller of an office chair

great use of Sketchup and 3D printing to solve a problem in daily life

great use of Sketchup and 3D printing to solve a problem in daily life@cotty said:

... and it's still rolling

you did a good job!

you did a good job!That ceramic vase turned out very well. I have my first ceramic model arriving in a couple of weeks

@kaas said:

Did a 3d print job recently for a former client (I remodeled his house a few years ago). Can't share too much details but will share my process and tips.

...

Max

Excellent tips, Max...especially this one:

@kaas said:

in Sketchup I set up a sort of assembly line: I modeled the splines at the origin, copied those a short distance next to the splines and started lofting there. Copied the result a short distance next to it and mirrored the loft and welded into a volume. Copied all the volumes next to it and did the booleans there, copied the end result next to it and did the final cleanup there. By doing so, you can easily switch back to the original shapes without destroying any of them.

That's the exact same process that I use, and is shown in effect in the Sketchup screenshot of my car hook above.

@kaas said:

I think I have covered most of it. First time I saw the 3d printed object after looking at it at a screen for a day is a strange but nice experience I must say.

Agreed - the scale of an object can be hard to judge on screen, since you can zoom up as close as you want. I'm often surprised how small my 3D prints turn out, even though I know what scale they're modeled at.