Designing 3D printable Screw Threads

-

Our local Woodworking master (Dave R) shows how to design 3D printable screw threads in this article:

Screw Threads in SketchUp

-

This is great news!

-

Just to keep in mind, since designing and printing are two very different animals, you'd need to match the resolution of the printer to the detail on the threads. Meaning that if you wanted to print these fine threads, you'll want to use a high resolution printer or else the threads will come out looking like blobs.

-

How small can this possibly be Marcus?

-

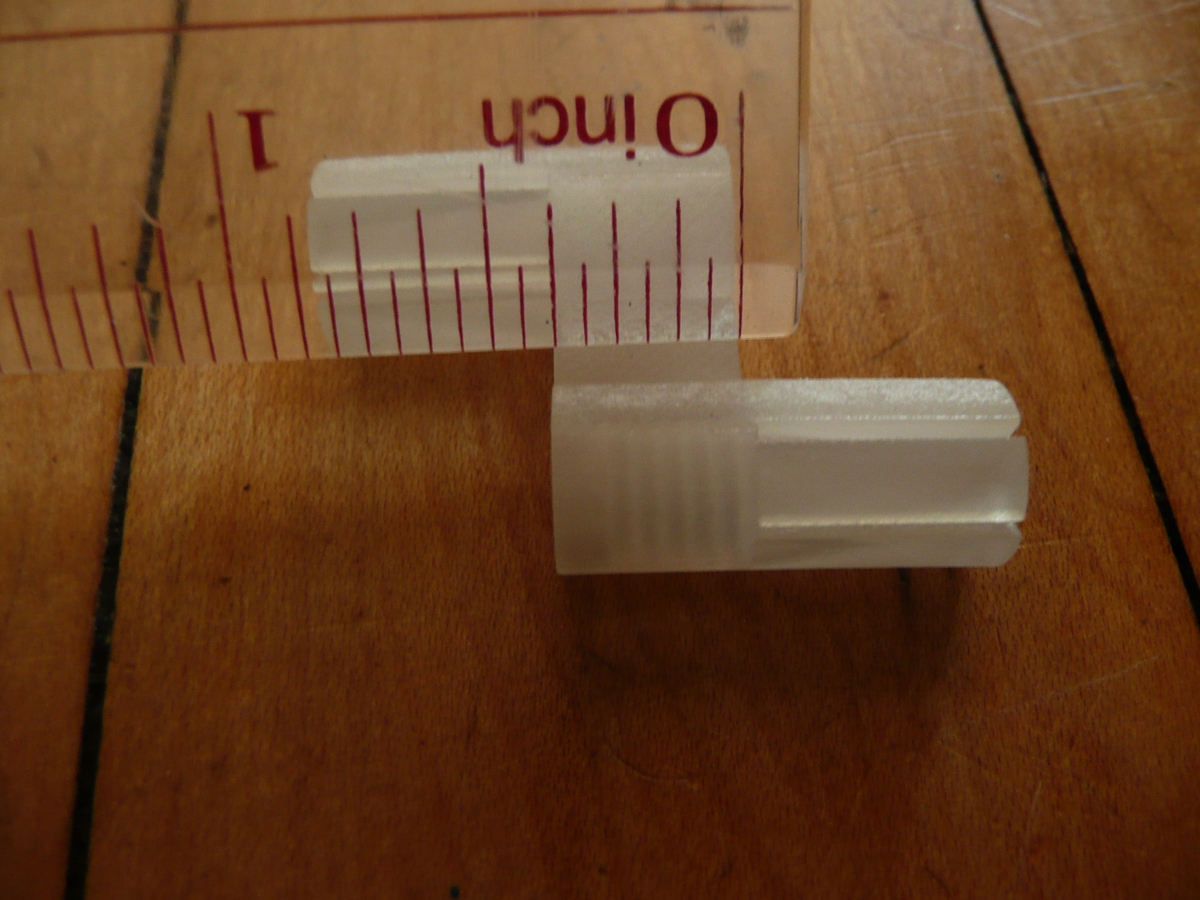

Oli, I have successfully used Shapeways Frosted Ultra Detail(FUD) material for screw threads on a 1/4" bolt. I used FUD because it is the highest resolution material available at a decent price that I know of.

A photo of the part. It worked perfectly with a 1/4" bolt from the hardware store.

You can probably go smaller. To figure out how small you can go, you can look at the design guidelines for the material, available here. For FUD, the minimum detail is 0.1mm, so as long as your thinnest thread thickness is greater than 0.1mm, you'll be fine.

Edited to add...

In this image, the Crest thickness would be the minimum detail in the model, so that tiny line would have to be 0.1mm long or greater.

-

Great information! That was my next question too...how does it marry with a standard part from a shop, thanks for the clarification. Shame there is no metal printing process able to work at such high detail. 0.1mm is awesome, 3D printing is coming on very quickly!

-

Actually, there is an 'experimental' stainless steel material, now that you mention metal. From i.materilise, right here: http://i.materialise.com/materials/high-detailed-stainless-steel

There is other 3D printed metal available, but VERY expensive. Some folks in Texas printed a working 1911 pistol using Direct Metal Laser Sintering (DMLS), but the parts cost $10,000!

-

Oh wow. Begs the question why they didn't just buy a 1911! haha Thanks again for the info, I'm loving this 3D Printing forum!

I was going to price up some prints in ceramic and stainless versions, I guess the stainless will be significantly more expensive! i.materialise did say they'd offer bulk discount though. When I get a sample I'll post the photos on here.

I was going to price up some prints in ceramic and stainless versions, I guess the stainless will be significantly more expensive! i.materialise did say they'd offer bulk discount though. When I get a sample I'll post the photos on here.

-

DMLS is usually used to make parts for rockets and high end cars where the cost can be justified, but they wanted to show on a smaller set of intricate parts what the capabilities are. Guns have to be manufactured to high tolerances, and those parts came out of the printer ready to use - no hand finishing required! To me, that really shows the power of 3D printing.

I'd love to see what you get printed.

Advertisement