help with a thread

-

I’m the problem, ha ha

I need a back to basics tutorial, I always seem to miss a certain point and nothing happens . I can see the way both of you do the threads but I’m missing something -

with a 150mm diameter

-

ok , after watching Rich's video about 8 times I'm making progress. I was missing the upright extension

what's curve origin? I set it to -1.5 as in the video, so that made the male thread , now to make the female which ill offset by 0.3 -

@Leggy said in help with a thread:

I'm making progress.

OK. So you don't need the video tutorial I did? Good enough.

-

@Dave-R where is it?

-

@Leggy said in help with a thread:

watching Rich's video about 8 times I'm making progress

I did a video?

-

-

Aha I got you mixed up, that was the one I watched

-

I’m the problem, ha ha

I need a back to basics tutorial, I always seem to miss a certain point and nothing happens . I can see the way both of you do the threads but I’m missing something -

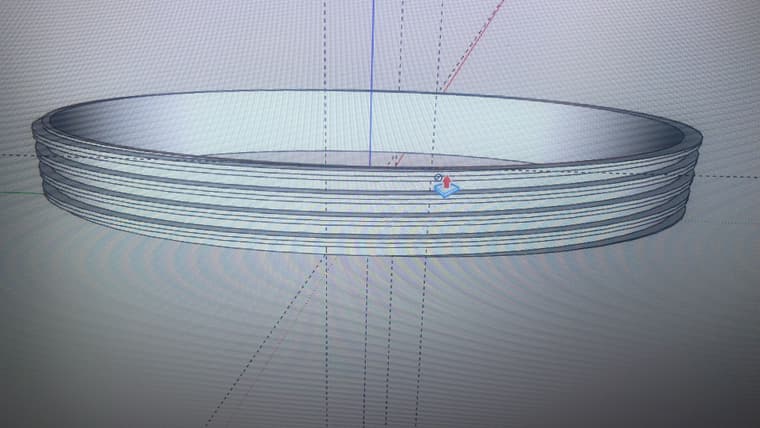

Ok I’ve managed a male and female thread on a 150mm diameter, with a 0.3 offset, . It’s very tight can wind it on for 2 threads , and that’s it. Tomorrow doing another female with an extra 0.3 clearance on all faces, so see how that goes. I think it’s the shrinkage on the printer that’s causing the problem

Thanks Guys for all your help -

@Leggy said in help with a thread:

I think it’s the shrinkage on the printer that’s causing the problem

That's probably it. You'll have to work that out based on the material.

-

I finally got it to work , pictures to follow , thanks Guys

-

-

-

Well done @Leggy

-

Hi guys

Again thanks for all your help

Is there a chart you use to look up thread dimensions, pitch, tpi , crest etc

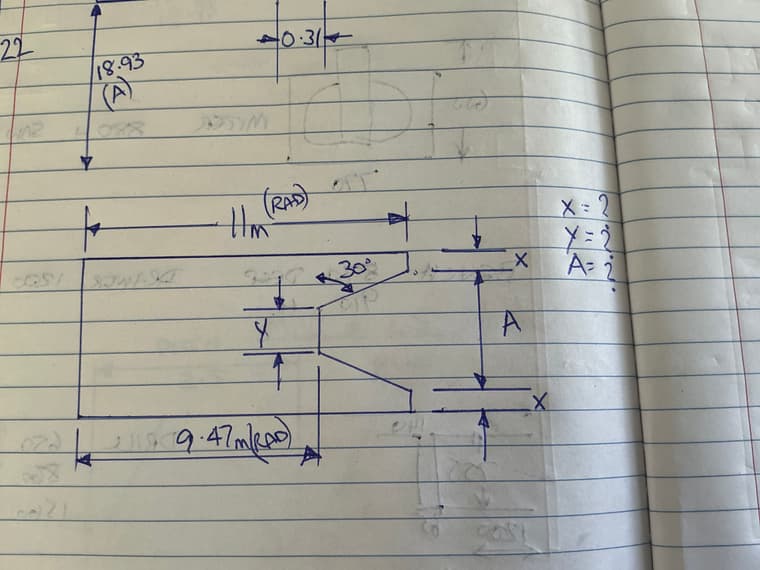

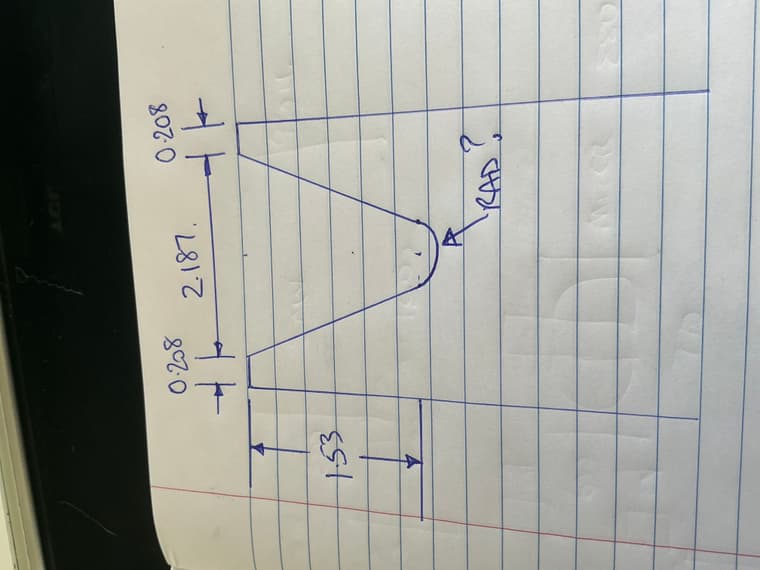

I was trying a m22 x 2.5 and got a bit confused on the chart I was following, so I asked ChatGPT

After 4 hours of me telling it, it was wrong, it finally agreed

I was drawing it in SU then asking it questions on the iPad

When I get home I’ll upload my figures and see what you think, the thread looks good on the screen, but that doesn’t mean it will fit

Thanks Dean -

-

These are what chat told me

-

@Leggy said in help with a thread:

Is there a chart you use to look up thread dimensions, pitch, tpi , crest etc

I would use the following site:

External Metric ISO Thread Table Chart Sizes M20 - M55

Metric external thread size table chart for sizes M20 to M55 Bolts and screws per. ANSI/ASME B1.13M-1995.

(www.engineersedge.com)

I wouldn't bother with the radiused corners because they'd be too small.

-

Ill check it out

Advertisement