3D Printed Screw Threads

-

-

Nice work Dave - thanks for sharing images of the “printed” products.

-

Thanks.

I need to get some gray filament for these things. This white PLA came with the printer and I've got some black but they are both difficult to photograph well.

-

That's nuts

I'd be interested to know the lifespan of these. Plus the file size of the skp as that knurling is gnarly!

-

...I always love this facet cut(?)! great work, both in SkUp and in print

-

@rich o brien said:

I'd be interested to know the lifespan of these. Plus the file size of the skp as that knurling is gnarly!

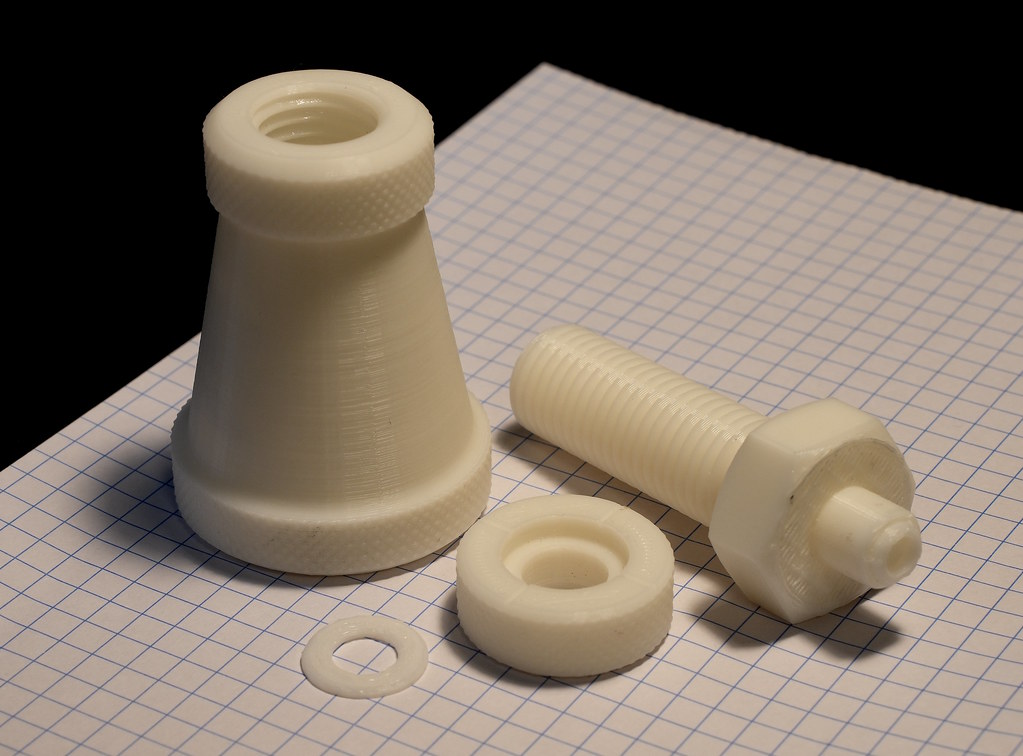

Thank you. Lifespan is suspect at least in use. In this print there's only 10% infill on the base unit so I'd expect it wouldn't be durable in a shop.

The SketchUp model file for all four parts is 1.5 Mb.

Thank you, too, HornOxx.

-

Great job

-

-

-

Dave , your mechanical bits never cease to amaze and delight me.

-

Thank you sir.

-

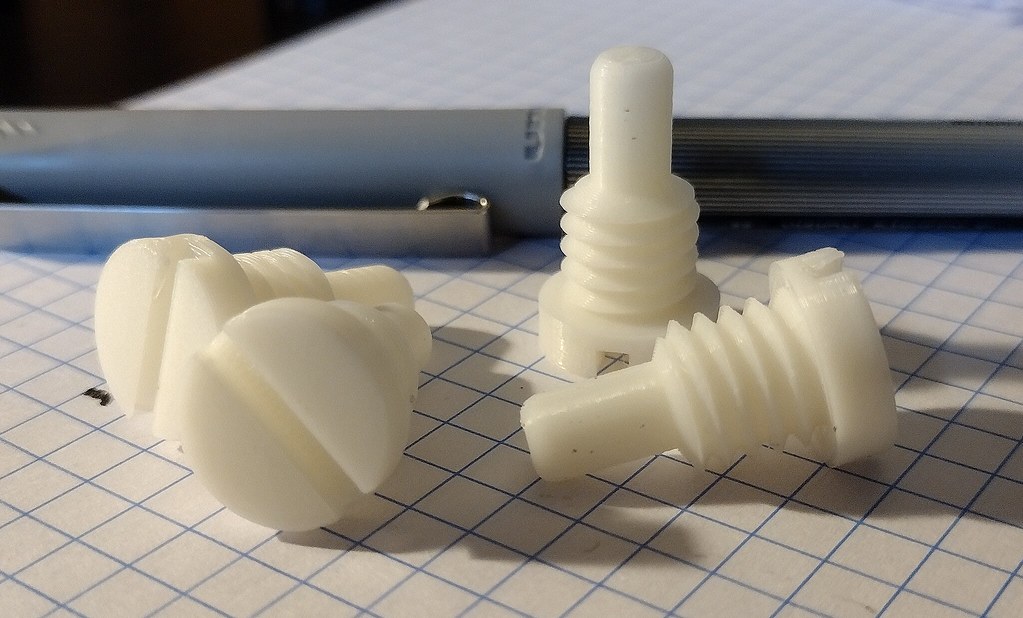

More screw threads. These are 23mm long.

They are for a model of a U-joint from around 1900.

The center ball and short pieces of the shafts have been printed. Yokes are printing now. Looks like I managed to get the screws dirty fitting them into the holes in the ball. I haven't decided it I'll print the tapered pins or make them a different way.

-

@tuna1957 said:

Dave , your mechanical bits never cease to amaze and delight me.

I agree with tuna57 completely.

-

Thank you.

-

-

Nice

-

klasse!

-

Hey this is awesome, just a quick question. What do you typically use for tolerances between the nut and bolt? I know it depends on the printer but just wanted to get a baseline idea.

Robert

-

Thanks.

@rspierenburg said:

What do you typically use for tolerances between the nut and bolt?

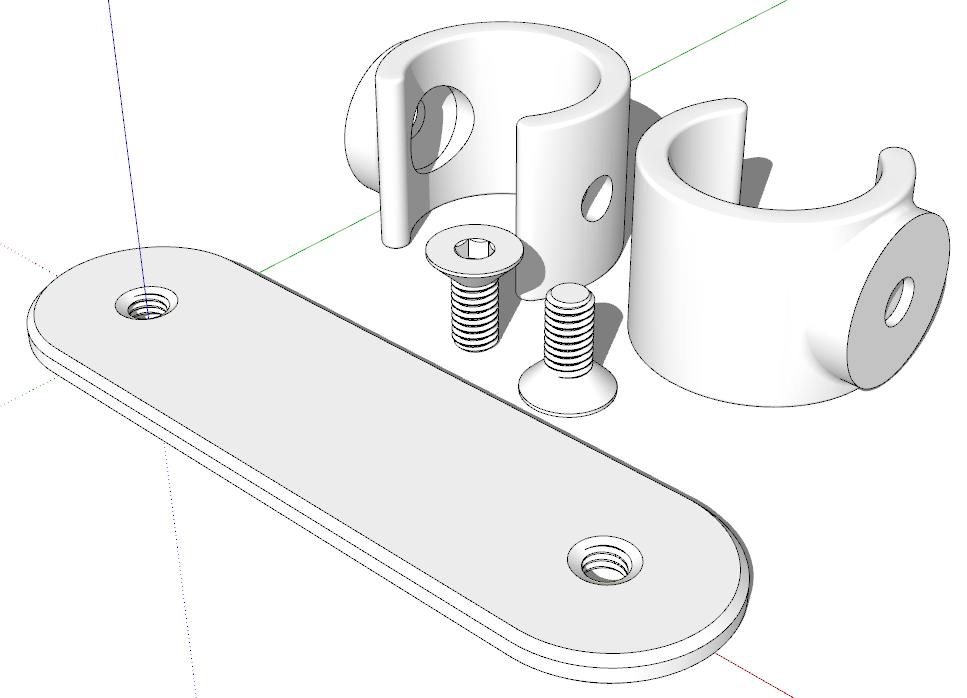

I nrmally model the internal and external threads to the specifications given for the thread type and class. In some cases if I'm feeling lazy, I just scale up the internal threads by 1.02 or 1.03 in X and Y without scaling Z. I've found I can't be lazy with Acme and square threads, though. Scaling doesn't work for them. They have to be modeled correctly.

-

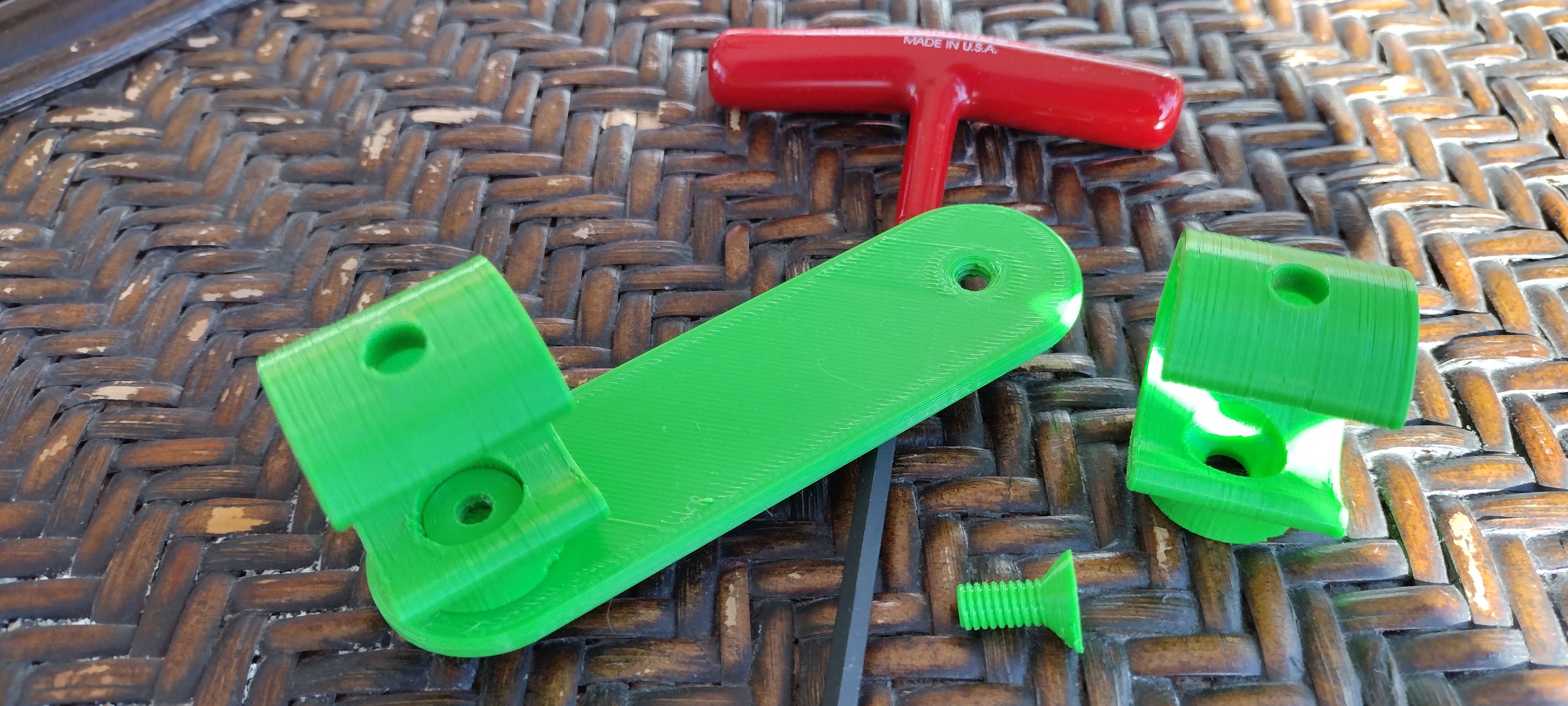

M6 x 1.0 screws. I didn't have any short enough metal ones on hand and it was faster to print a couple than go to buy some for this proof of concept thing.

Advertisement