What's this?

-

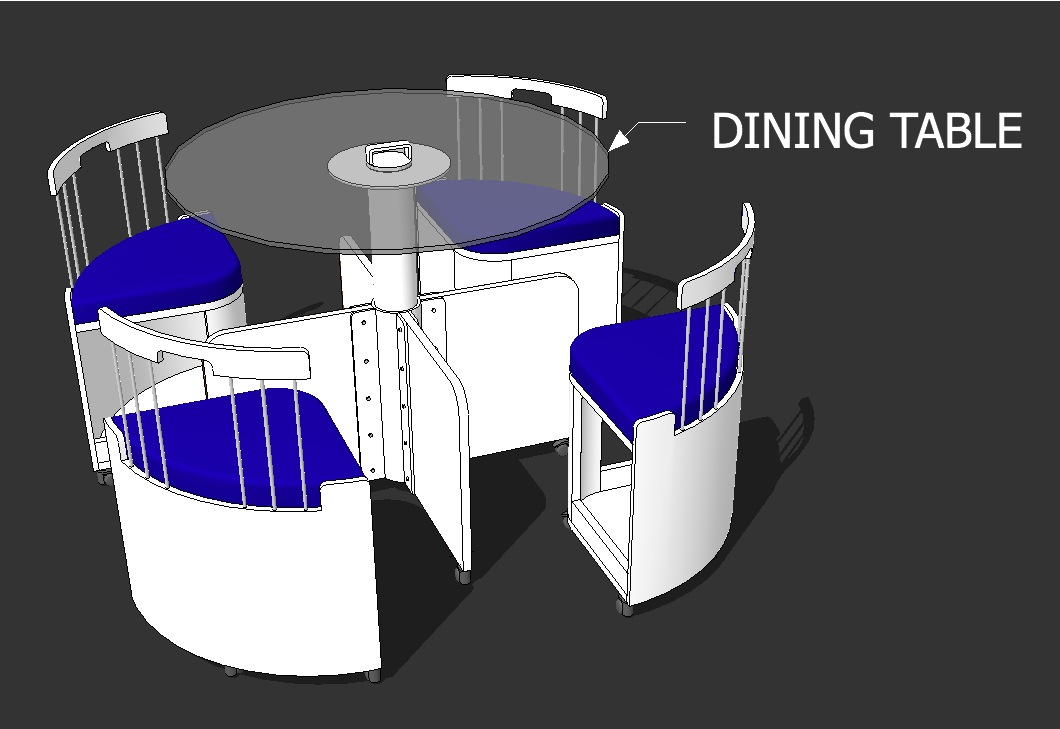

I agree with Ken, it looks like 4 chairs and a table. The chairs appear to have retractable back rests.

But I have no idea what the handle in the middle does

-

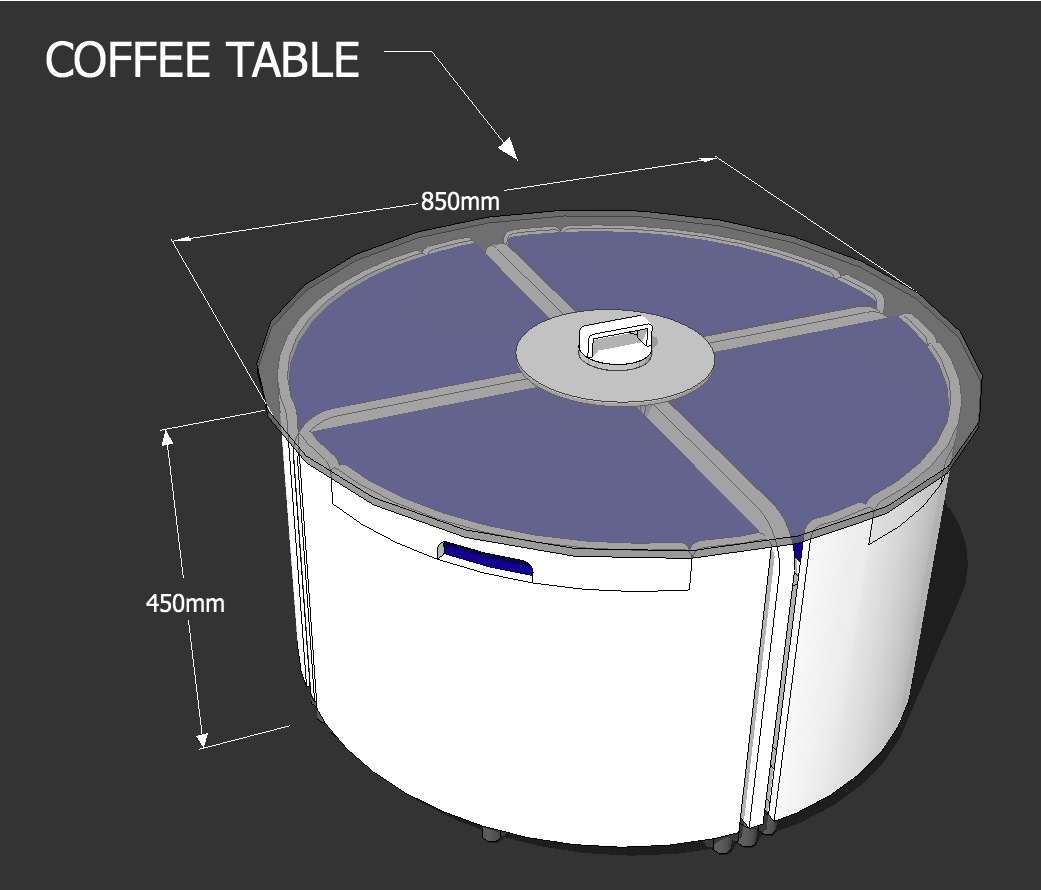

I agree - it's a coffee-table that changes into a table and four chairs.

The chairs' backs lift/popup by ~400mm... and the 'central handle' lifts up the circular glass-top on a telescopic central leg by ~300mm, so it's a decent height to sit at...The only change I'd make is to the handle as it detracts from the four-fold symmetry of the form... Could it be normally recessed into the center and then itself pop/flip-out when pressed in so you can 'lift' the rest ?

I have this much less clever version in my kitchen...

-

Or do this [flash=560,350:1s6j9vzy]http://www.youtube.com/v/VQ_AwFSWIPU[/flash:1s6j9vzy] only a little more complex

-

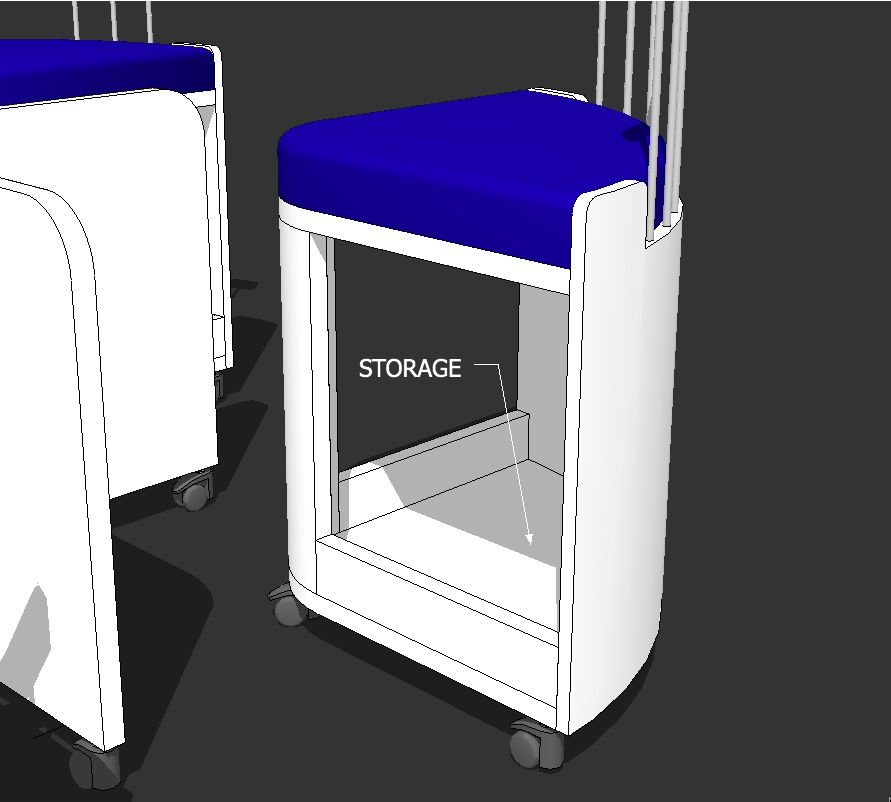

Yep, its a table and chairs, with a little difference. I am playing around with a dual use coffee table / dining table. Also some storage area. It might suit small apartments.

This is the Mark I and I have started on Mark II which is going to be more simplified and include a clipping / holding mechanism to hold the chairs in the closed position, also playing around with the storage areas, top / side loading etc.

I am trying to figure out how this can be built exclusively in timber as the aluminum parts would tend to make it expensive and possibly out of reach for DIYer. Also the 'lifting' system needs looking at.

TIG, I also have the Fusion Dining set from IKEA. Liked it the first time I saw it. I am always fascinated with dual function furniture ...... suppose its the 'gadget' lover coming out in me. BTW, that Capstan table is way cool!

-

Hey, great concept, and challenge.

Here is a pavilion designed as a project by a team of the students at M.I.T architecture school. It uses a system of Kerf cutting, which is not new in woodworking by any means, but the technology available to accurately execute it is.

Here is their brief:This pavilion is the culmination of a semester's research into a novel digital fabrication technique by a team of graduate students in the MIT Department of Architecture. The design of the pavilion is the result of an old technique reinvented using digital strategies and tools. Kerfing, the cutting of wood to add flexibility, has a long history in wood working. Our research combined the material logic of kerfing with the flexibility of parametric modeling and the accuracy of a CNC router. Our parametric model integrated all the digital steps in the modeling and fabrication process, from initial control over the global form to the unrolling and generation of the cut patterns required to make each unit. The patterns allow the plywood to be bent into a predictable shape without the use of additional tools or techniques.The pavilion is a manifestation of new possibilities for design and construction.

This looks like a plywood based system, but the Haida, the aboriginal natives to Haida Gwaii have been employing it for centuries using solid woods (cedar in particular), kerf cut and bent from a single piece of wood.

I wouldn't hesitate to try and contact the MIT folks. Maybe an arrangement can be worked out.

Good luck with this one

-

-

TIG, you would need some power supply. Isn't it?

or one battery 9V

or one battery 9V

-

Really nice design, very imaginative

One observation - it looks like the chair backs would maybe be weak (I'm assuming you would use wooden dowels, since you mentioned you wanted to use all timber)

-

Nice idea Mike, I'm working on some compact living projects and it's the sort of solution the end user might like. Obviously this is probably personal preference but if you can sit on a bar stool at a breakfast bar then why do you need to provide a back support.

I'd agree with TIG the table lift needs some work maybe an office chair type gas strut.

-

I like it, but perhaps you might consider the flanges that are the supports for the base of table. Myself being rather tall and occasionally clumsy, I view those as knee-banging table rattlers. I would waste no time in scooting my seat forward and capsizing a beverage with a well placed knee-shot to the support. A flat, wide, bar-like support that rests directly on the floor or uses slightly recessed wheels would eliminated those bruises and toppled glasses of wine. Low enough to slide beneath the chair base, obviously.

Just a thought.

-

@Rich

You have not studied the concept. The design is primarily a coffee table then an occasional dining table.While the küre looks funky, it becomes a big useless blob sitting in the middle of the room taking up valuable space when not being used as a dining table

@ Steve

Yep, you are right. the chair backs are weak. I have to work on that. Maybe even drop the backs.@ArCAD-UK / Trevor B

TIG is right. Lifting the glass table top would require a fair amount of muscle work. I am thinking of going with a lighter wood (ply) top and a very simple way of having two heights - coffee table - dining table.@Jeff

I'm designing for normal humans! Just kidding

I take your point. I now think there is no need for casters on either the table or chairs, just some gliders (very short ones) like on sofas, but much smaller. -

The table-top could have a concealed hydraulic ram - like a hatchback car's door, or even some 'springs to assist you in lifting it up easily. To lower it you'd release the 'catch' and it is damped as it settles down too...

OR 'Ratchet' strips could also allow an incremental lift and lower using a simple sprung 'catch' [that could all be wooden]

OR how about a 'lever' system in one of the legs [with a flip down/up pedal that is accessed when a chair is slid out] - that can then 'jack' the table up [like a car bottle-jack?] and when released it lets the top slowly settle back down...

-

Great suggestions TIG. I will play around with those.

-

Hey Mike, I got to thinking about the seat back problem, and this is something I came up with.

Adding the extra layer would let you increase the thickness of the seat back. This could also work with the wooden dowels.

Probably not the look you were going for, with all the curves, I just started having fun with it

But you get the idea

But you get the ideaAnyhow, just an idea.

-

That works Steve, well done

I am moving towards doing even a more straightforward design that doesn't involve curved plywood.

This is great as it turning into a collaboration

-

@mike lucey said:

That works Steve, well done

I am moving towards doing even a more straightforward design that doesn't involve curved plywood.

This is great as it turning into a collaboration

A square table and 4 square chairs ?

-

Now there's an idea

-

The Sqhair

Economical on material too.

Simply table-sawn and router rounded-corners etc as needed etc.

The table can use a simple foot-operated bottle-jack mechanism to lift it up and on release lower down.

The storage under the seats is set back a little to avoid heel-clashes.

The seat-back half 'L' slides up/down on dado friction glides [à la draw-slides] with a catch to it lock 'up' ?

When the seats are removed from the assembly they are set around the table at 45 degrees on the sides of the square. The seats are on castors.

-

Nice, but those seat-backs don't look very comfortable

-

Now we are getting places.

TIG, would that table have a bit of wobble potential? Also I think Steve might be right about the backs not being too comfy.

Have you a pic of a 'foot-operated bottle-jack mechanism'? I'm curious about that.

I'm not so sure about the seats being on casters but they could be lockable. I think slides might work better.

Advertisement