[Plugin][$] Curviloft 2.0a - 31 Mar 24 (Loft & Skinning)

-

Interestingly, this file skins fine for me, but what you're describing is exactly like the problem I was having above.

-

@jgb said:

It was great before, but with Quads it is absolutely great. No more tiny surface fragments to clean up (so far as I see). And way FASTER to boot

i wish i could use Quads too

i agree that this plugin is really kind of wizard thing

-

FYI for what it is worth:

Using the skinning mode and selecting the closed loop, by left to right in context select or double click on one, then selecting the green check mark skins ok each time. If I try to select one edge, right click to bring up the context menu and select extend selection to all connected I have some problems but maybe an operator error? Note: At the steep part of the curve some triangulation is none by program to get face formation. -

@irwanwr said:

i wish i could use Quads too

I don't understand what you mean. Quads are just a better method to calculate and display faces on a surface. You don't actually "use" quads specifically. The pluggins (JPP, Curviloft, etc) use them when activated.

-

Mac1

Neither method you suggest works for me.

I've noticed that Curviloft tends to fail when I want to form a totally or very nearly flat surface.

It also seems to be overwhelmed by large complex surfaces. It goes all rainbow on me but if I just select smaller portions without any edits, the smaller surfaces form nicely. When I then explode all the subsections, it forms 1 complete surface. A bit more work, but less aggravating than trying to find the non-existent "problem".

But all said, it is a plugin I simply CANNOT live without.

-

@jgb said:

@irwanwr said:

i wish i could use Quads too

I don't understand what you mean. Quads are just a better method to calculate and display faces on a surface. You don't actually "use" quads specifically. The pluggins (JPP, Curviloft, etc) use them when activated.

i meant the TT Quad Face tool, it seems so good so sophisticated.

-

@jgb said:

Fredo - We have A problem

The attached model is an extracted edge of a fairing. It should be a single face and all flat.

When I loft it, I get either a black face then just an empty group (thought that was fixed

) or nothing happens, but an empty group forms anyway. If I manually join verticies it will form a flat face.

) or nothing happens, but an empty group forms anyway. If I manually join verticies it will form a flat face.There are no edge fragments, or gaps. The faces perpendicular are all properly formed, as well as the opposite edge to this one.

There are also no "errors" (colored lines) appearing, so I cannot find the problem.

I've had a few like this and it was easier to manually face them, but I figured you shold take a look at it.

[attachment=3:22uctz0e]<!-- ia3 -->C-Loft Problem.skp<!-- ia3 -->[/attachment:22uctz0e]

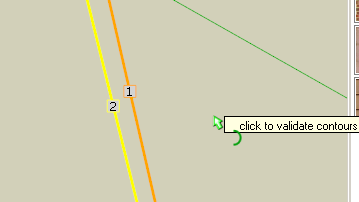

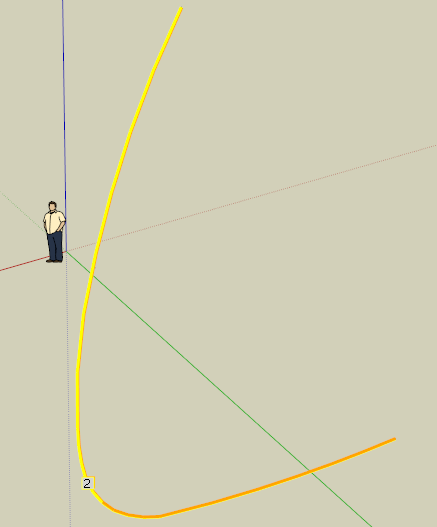

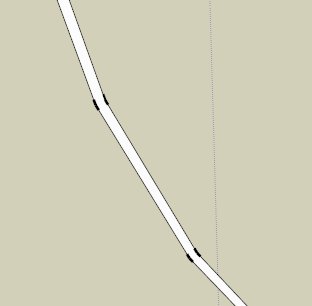

Not sure I understand the problem.

You have too identical boomerang-like profiles placed very close each other. If you select them and use the Loft by Spline tool, you get the fin skin between the two profiles.

[attachment=2:22uctz0e]<!-- ia2 -->Cloft problem small.png<!-- ia2 -->[/attachment:22uctz0e][attachment=1:22uctz0e]<!-- ia1 -->Cloft problem big.png<!-- ia1 -->[/attachment:22uctz0e][attachment=0:22uctz0e]<!-- ia0 -->Cloft problem filled.png<!-- ia0 -->[/attachment:22uctz0e]

What else do you want?Fredo

PS: When you select, make sure that you do not select the same segments twice. Curviloft does not trap all situations yet. THis is why you have a numbering for the profiles.

-

I checked and I only have 1 set of lines, so I don't understand why you see 2 sets.

And, when I do select any of the 3 modes, none form a skin.But when I select "skinning" it will give me a full black pre-skin. Hitting enter or green check leaves an empty group. If there was even a tiny gap or fragment, or double line in the selection, C-Loft would usually say so.

If you (and others) don't get the same result, the only reason I can think of is some other script in my pluggin set that you don't have is causing, let's call it, interference.

When I manually connected the opposing verticies, the skin formed, section by section, and most, but not all, the added lines could be removed without losing the skin.

Like I said above, this usually happens when I try to skin a flat or nearly flat surface.

I use "skinning" most of the time. When it doesn't work, I try the other 2 modes. When they don't work I go through the lines to find any anomalies (gaps, fragments or double lines), fix them and try again. If it is a complex or very large set of lines, I will then try to sub-divide it into several sections. Invariably the sub-sections form when the whole did not using the exact same set of lines.

I've just finished all the main fairings on my big airplane project, but over the next few weeks, I'll have a whole bunch of complex skins to create, for the aircraft's interior skins. If I do encounter any problem that persists after I fix as much as I can find, I'll post it here, not so much looking for a solution, but for you (Fredo) to analyze. Maybe there is a very subtle bug that only surfaces (no pun intended) in specific circumstances. I've been there, and that's why most of my hair has gone.

And I am not implying that I may not be doing something wrong.

-

I get the two lines also and is the reason I used the skinning option and get the same result as Fredo. BTW I measure 0.5 in apart and looks like by design ???

If this is not by design you may want to find the reason before going to a large project??

BTW I noted in the above post the tool triangulates and if you delete those faces are lost. Sounds like same result you are getting. My work flow is double click to get in context of the curve, select the skin tool, left click and select the total curve, select the green check and once the black is formed you need to click in space to complete the surface. Use outliner to see that a group is formed within your group and explode unless you want to keep as a nested group. -

@irwanwr said:

i meant the TT Quad Face tool, it seems so good so sophisticated.

Are you having problems in getting QuadFace Tools to work?

-

I did a test too without having any trouble either.

As Fredo and mac1 -

@thomthom said:

Are you having problems in getting QuadFace Tools to work?

yes, a big problem actually. it's me, myself. still unable to understand "how to", "the way", etc. Quad Face works.

as Gaieus once told me (and it does make sense), "learn to walk before you run". i might need to slow down a little bit. at least just to get back what i got from SU6 when i left it.

in the other hand i can see that others can use the Quad Face very well

.

.

from the description and clips, it is an amazing tool. i hope i'll find something to practice with and learn the Quad Face.cheers thomthom

PS: i'm able to learn and use your other tools though. material, cleanup and guide tools. tyvm for those tools.

-

@mac1 said:

I get the two lines also and is the reason I used the skinning option and get the same result as Fredo. BTW I measure 0.5 in apart and looks like by design ???

The 2 lines you refer to are the inner and outer edges of a very large 1/2 inch thick panel which is part of a fairing made of several adjoining panels. The 1st master panel itself (outer skin) was originally formed by C-Loft, then thickened with JPP to 1/2 inch. It formed all 4 edges. All the panels are rectangular (4 distinct corners) with that similar pronounced curve.

Then I selected 1 edge to become the curve control for this adjacent panel, which had a different overall shape at the top, but shared an edge. I formed that panel the same way, but had to modify it for the design. In doing so, I lost the 2 side edge faces and 1 top edge face (expected). I then closed the top 2 corners. One edge immediately skinned, but this edge and the top did not. I expected the top not to skin as it had a slightly irregular profile, but this edge should have auto skinned because it was skinned prior to the mod, and the top end was redrawn. I used C-Loft to re-skin the top edge (worked 1st time) but this edge persistently refused. I have since manually skinned it in the model.

If you want I can post the complete panel here, in its present state, but I doubt it will contribute anything to this discussion.

-

@mac1 said:

My work flow is double click to get in context of the curve, select the skin tool, left click and select the total curve, select the green check and once the black is formed you need to click in space to complete the surface. Use outliner to see that a group is formed within your group and explode unless you want to keep as a nested group.

Mac1; To keep the perspective, I'm replying separately to your 2 parts.

I do exactly that, and get a correct black face. BUT when I click to finish, I get an empty group. I've said this several times. In a previous post I highlighted this to Fredo, and he replied by acknowledging then fixing the problem. Like I said before, this seems most likely to happen when facing a very nearly flat surface.

And using SU8 Free, I don't use Outliner. To get at the empty group (to delete it) I use TT's Selection Tools.

-

Humm

Let's see. Fredo and I both get the same result. Hope others respond but that looks to me like problem was corrected. I guess there are two issues from my view point:- Why our models have two lines and yours has only one. I guess that means we are trying to skin different entities. Until that is resolved further work is fruitless. In my experience base of aerospace engineering a faring is usually a thin shell that encapsulates a payload and is the reason I thought the 0.5" thickness is correct. If I delete one of the lines what do I then try and skin? If I simply draw a cord from end to end the whole thing skins

I guess I need some type of definition of the actual shell or do I miss something??

I guess I need some type of definition of the actual shell or do I miss something?? - How many more confirmations do you need?????

- Why our models have two lines and yours has only one. I guess that means we are trying to skin different entities. Until that is resolved further work is fruitless. In my experience base of aerospace engineering a faring is usually a thin shell that encapsulates a payload and is the reason I thought the 0.5" thickness is correct. If I delete one of the lines what do I then try and skin? If I simply draw a cord from end to end the whole thing skins

-

@jgb said:

@mac1 said:

I get the two lines also and is the reason I used the skinning option and get the same result as Fredo. BTW I measure 0.5 in apart and looks like by design ???

The 2 lines you refer to are the inner and outer edges of a very large 1/2 inch thick panel which is part of a fairing made of several adjoining panels. The 1st master panel itself (outer skin) was originally formed by C-Loft, then thickened with JPP to 1/2 inch. It formed all 4 edges. All the panels are rectangular (4 distinct corners) with that similar pronounced curve.

Then I selected 1 edge to become the curve control for this adjacent panel, which had a different overall shape at the top, but shared an edge. I formed that panel the same way, but had to modify it for the design. In doing so, I lost the 2 side edge faces and 1 top edge face (expected). I then closed the top 2 corners. One edge immediately skinned, but this edge and the top did not. I expected the top not to skin as it had a slightly irregular profile, but this edge should have auto skinned because it was skinned prior to the mod, and the top end was redrawn. I used C-Loft to re-skin the top edge (worked 1st time) but this edge persistently refused. I have since manually skinned it in the model.

If you want I can post the complete panel here, in its present state, but I doubt it will contribute anything to this discussion.

Please do.

I think we are working at cross purpose withoout seeing the whole picture

-

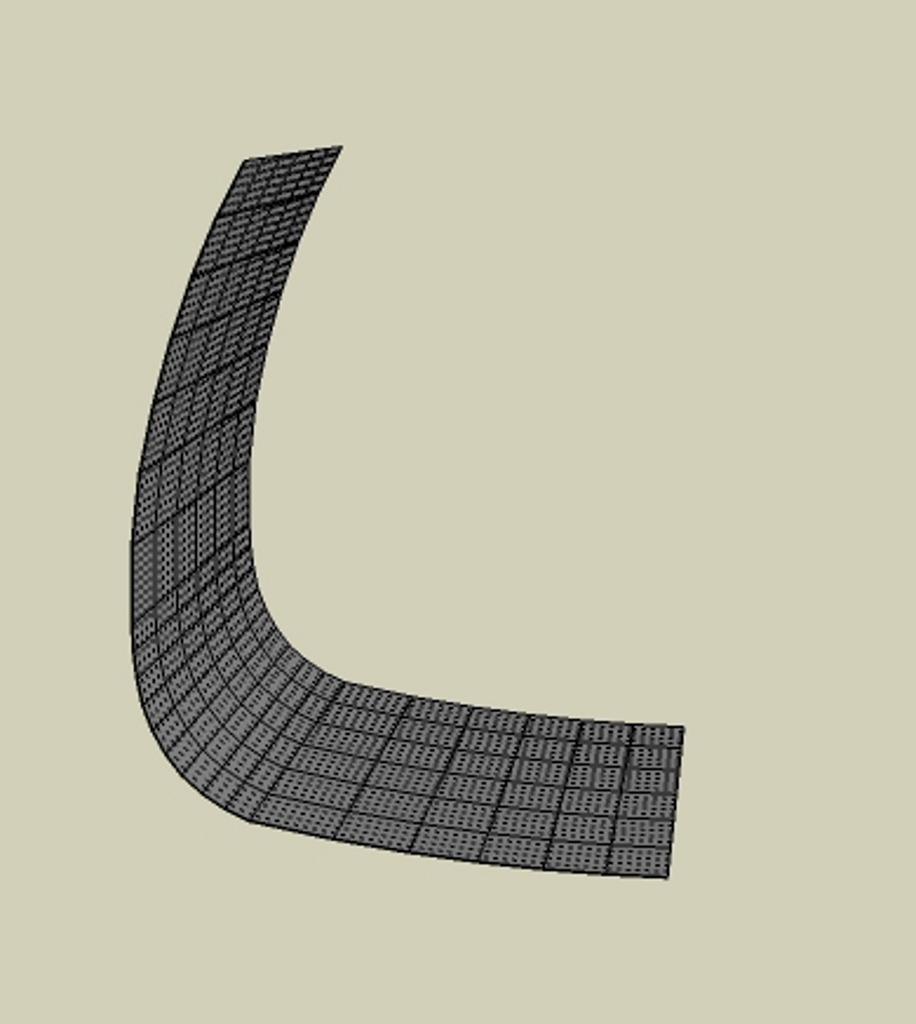

Is this some what the goal?

Is this some what the goal?

As I noted the 1/2" face is not flat so you cannot push pull a soften or curved face. TIGs extrude tools maybe better for this problem but need to see the total issue.

This was done loft by spline but just one side of the surface. To get the thickness it will require two steps and then reconnect the ends.

-

Mac1; You are very close to the actual panel, except for a curve that you could not know of.

Please note; I am not looking for a solution. I have it. The original post was for Fredo to investigate why I get a black face but an empty group.

I've attached copies of the actual problem panel and the adjacent panel with notes. A 2nd copy has the problem face deleted and a C-Loft empty group attached.

FYI, these panels are carbon fiber composite honeycomb sandwich, 1/2 in thick. At this point in the design development, the stiffeners and structural attachments are not yet incorporated. To all you aero engineers, these panels are NOT primary structure, and are subject only to aerodynamic loads. Even so, they are stronger than they have to be, considering the planned stiffeners/internal structure that attaches them to the primary a/c structure. As such, they are considered fairings.

-

@jgb said:

Please note; I am not looking for a solution. I have it. The original post was for Fredo to investigate why I get a black face but an empty group.

I will have a look at it and come back

Fredo

PS: do not forget that Skin works on coons, that is 3 or 4 profiles in loop

-

@unknownuser said:

PS: do not forget that Skin works on coons, that is 3 or 4 profiles in loop

In Canada a coon is a smart thieving mammal.

In Canada a coon is a smart thieving mammal.  (Racoon)

(Racoon)

Advertisement