@Dave-R would it be the amount of segments in the corners?

Posts

-

RE: adding thickness

-

RE: adding thickness

I tried the skin technique , looks better , I have one little area that is showing through , but ill print it and see how it looks

-

RE: adding thickness

@Dave-R yes joint P/P , not playing nicely , I select the whole surface but only a part of pulls out

, the inner skin seems to be coming through the outer one

I used the first curviloft , the head that's split in slices

ill try your idea with the lines -

RE: adding thickness

hi Dave

I've been trying what you said , and I'm getting some weird results with P/P. I also tried another way by selecting the outer circle and rectangle then curviloft, then the same with the inner circle and rectangle, but got a conflict on the inner and outer skins -

adding thickness

downpipe square to round.skp

hi is there a simple way to make bits with a 1.2 mm wall thickness? -

RE: Strange corners

Overhang is 45 so no support needed, support at ideamaker gave me a gcode for xy and it worked good

To be honest the raise 3d machines can’t compete with the bambus -

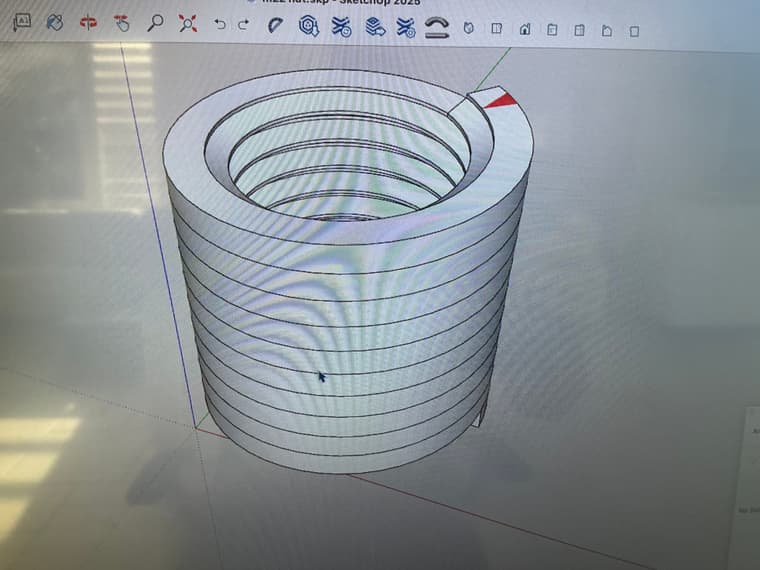

RE: help with a thread

No, it seems to be in hidden sections, so would have to select every faucet on the plane and line

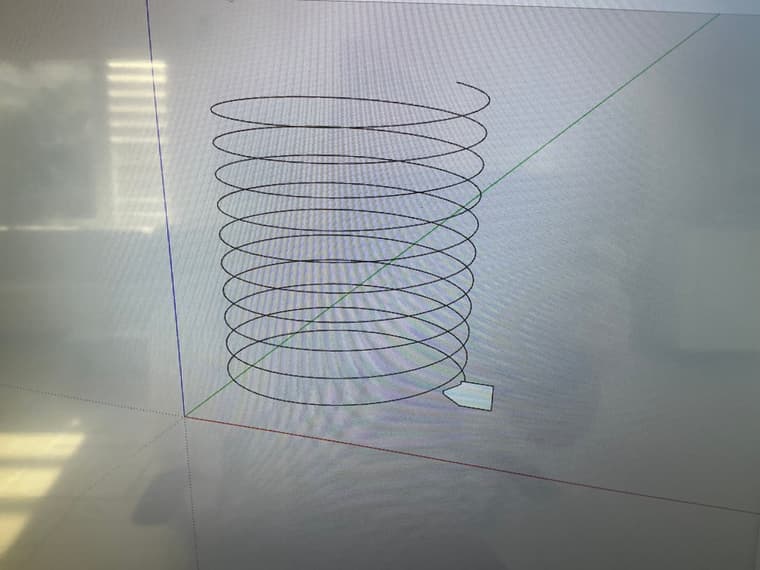

What I found is if I draw an arc from the top of the inner profile to the bottom, and do the helix , I can click on the curve and can delete it all

️

️

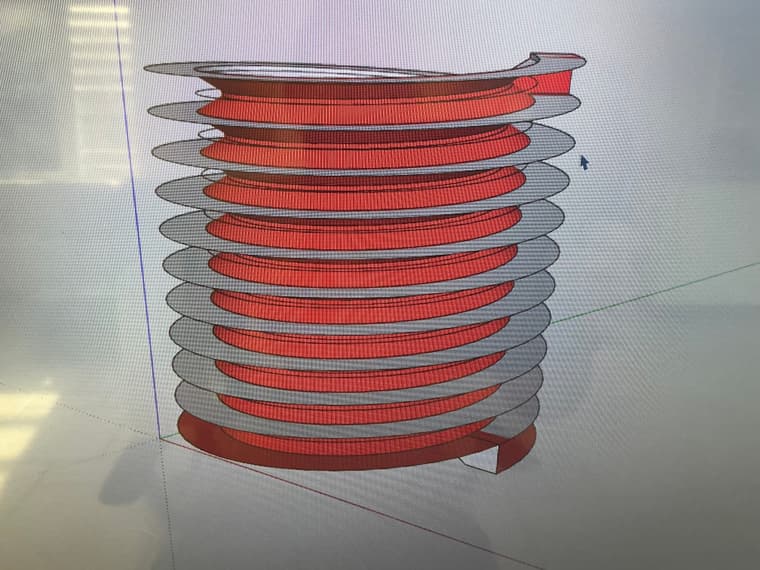

cant see the difference vwhy, but it works, the threads are great

what I found is a difference in tolerances, I printed 3 nuts with 0.1/15/2 offsets in petg and tpu, 0.1 was good in petg, but had to go to 0.2 for tpu

what a week of RND -

RE: help with a thread

How do I get rid of the grey spiral in the last picture?

) -

RE: help with a thread

Ah ok , I see what you mean, this is where ChatGPT was messing with me

-

RE: help with a thread

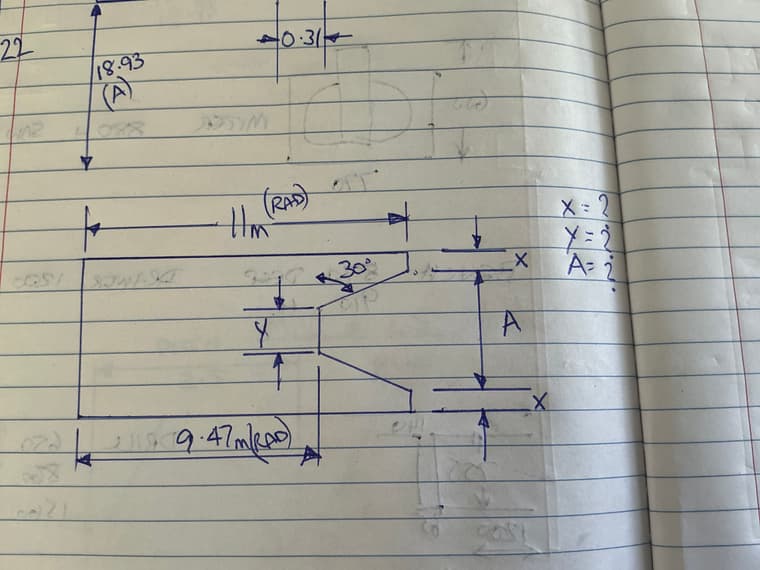

Hi guys

Again thanks for all your help

Is there a chart you use to look up thread dimensions, pitch, tpi , crest etc

I was trying a m22 x 2.5 and got a bit confused on the chart I was following, so I asked ChatGPT

After 4 hours of me telling it, it was wrong, it finally agreed

I was drawing it in SU then asking it questions on the iPad

When I get home I’ll upload my figures and see what you think, the thread looks good on the screen, but that doesn’t mean it will fit

Thanks Dean -

RE: help with a thread

I finally got it to work , pictures to follow , thanks Guys

-

RE: Strange corners

The base is where my finger is, so the layer lines go up from there

-

RE: help with a thread

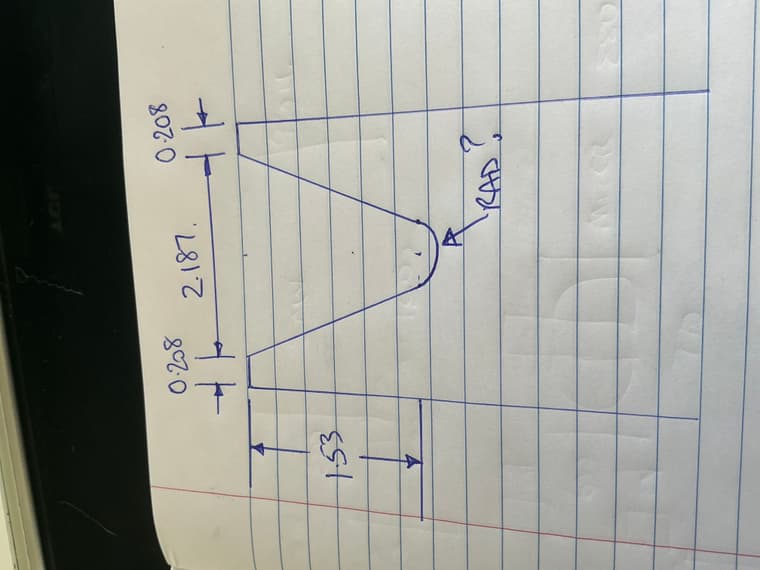

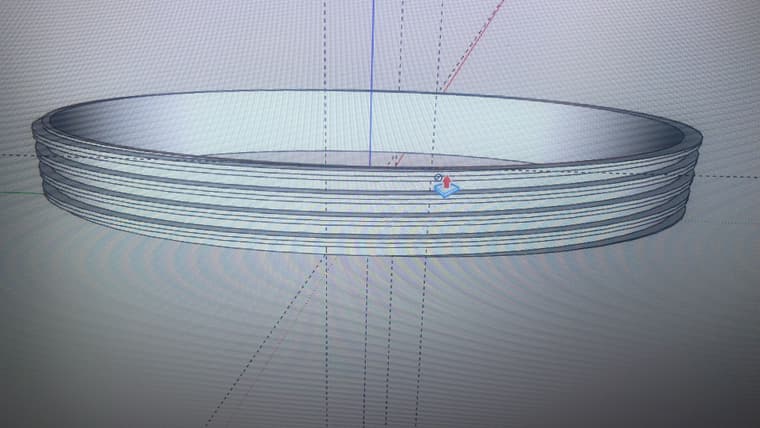

Ok I’ve managed a male and female thread on a 150mm diameter, with a 0.3 offset, . It’s very tight can wind it on for 2 threads , and that’s it. Tomorrow doing another female with an extra 0.3 clearance on all faces, so see how that goes. I think it’s the shrinkage on the printer that’s causing the problem

Thanks Guys for all your help