Does not seem to work for me. In SU 2016 I did put the plugin under USER application Data, since I understand this is where the plugins are located now. The dialog box opens i enter all the specs but no component is drawn.

Posts

-

RE: [Plugin] Wood working rubys Update

-

RE: Align Object on a face

Thanks. I am not sure, if I know how this works, but I will try out and come back with results.

-

Align Object on a face

Hello

Is there a plugin or another method of automatically placing objects to another surface?

I want to create models of pictures as simple boxes and then place them on a wall. Normally i need to rotate the box until its aligned. Is there a way to do that automatically?Thank you very much for your help.

-

Connect access to skp generating components

Hello to everybody

I am aware that this is not the newest question. Anyway: How can I automatically generate boxes from a list of dimensions that are currently in ms access. (Like Height 800 Width 600 Depth 500).

After creating that box I would like to put a photo as texture onto one surface. The photo is included in the access database as link to a jpg. Then save this component under the name (that is of course in the access db). I mean I could simply do that manualy. But is it possible to do that automatically?

Thank you for your help. -

RE: 3d or 2d constructing

I started this tread with the question, whether to draw in 2d or 3d is more efficient and if SU is really capable of 2d.

I personally think now, that it is. There are some things that I miss. E.g. I could not find a possibility to easily define a srting point of a line in reference to another object (that is without drawing a temporary guideline) but for me SU is still a lot faster and easier to handle then (at least for me) AutoCAD. (And I think it does the job, but what about 3d in AutoCAD?) Others may find that different, that is natural but I blame it on the routines that I built up with time.

SU is mainly 3d, to quickly get a good 3d image and I think its great for that since it is so easy to handle.

I use LO daily to get good sketches as well for me as for my clients. There could be improvements (although itseems, that I have to upgrade to 8 first!)

LO is something that AutoCAD also has (or had) that is to only care about the prensentation and documentation and I think it makes a lot of sense to work first only on the construction and then on the presentation. I could not do both at the same time.

Of course I wish to have a program that gives me a perfect presentation and detailed partlist and what else from my 3d construction automatically. But if there exists one that can do the job (maybe solidedge does a good part of it) it is way more expensive. And I am impressed especially in this forum, what is possible with SU and LO, which is alot more than you could expect.

Still my question is if or when 2d is easier and more efficient than 3d. And this is meant as a question for the way that you work and not if SU is better or worse than AutoCAD or any other program. I think it is a question of the approach or organization of your work. -

RE: 3d or 2d constructing

Thanks Dave for explaining the plugin. I did not use hatching in 2d since I saw no possibilty to do it. But its great to have this oportunity. Also I never thought of drawing dashed lines in LO, this also sounds promising, I will try to use that feature. Actually dashed lines was (is?) one major defect in SU for me.

I guess there is more to LO than I was aware and using, zhanks again.

And by the way: I forgot where I put my ACAD ... -

RE: 3d or 2d constructing

hI

Thanks for your answers. Actually I am doing documents in LayOut (using Sketchup7 pro) and actually I would prefer Sketchup to Autocad. What I do in Layout is importing drawings or scenes , adding measurements and text. Is there more to LAyou? Llike actual drawing (ok there is a line tool and so forth, but I thought, this does not count as drawing tool.

Actually I am doing documents in LayOut (using Sketchup7 pro) and actually I would prefer Sketchup to Autocad. What I do in Layout is importing drawings or scenes , adding measurements and text. Is there more to LAyou? Llike actual drawing (ok there is a line tool and so forth, but I thought, this does not count as drawing tool.But I could imagine Sketchup to be a little bit easier in 2d. OK it is 3d and it is great in that, but I still find 2d sometimes much more effective than 3d. To find out measurements for production (e.g. drilling holes) 2d is just a lot faster. OK, this is true for the way I am using SU and maybe (hopefully) there is another way of using Su that avoids this.

Thanks Dave for the tip with section cut plugin, but I don´t see it´s purpose. Am I right that it creates faces instead of pure outlines of the faces in the cut? I would rather have a tool or method that creates the outlines in the cut and all the lines (hidden ones distinct from visible ones) behind the cut. I think this must be possible since there is an x-ray and a hidden line style.

Maybe I should also add to the SU wishlist a much simpler and more instantenious (?) report off components also a report generator in metric units

-

3d or 2d constructing

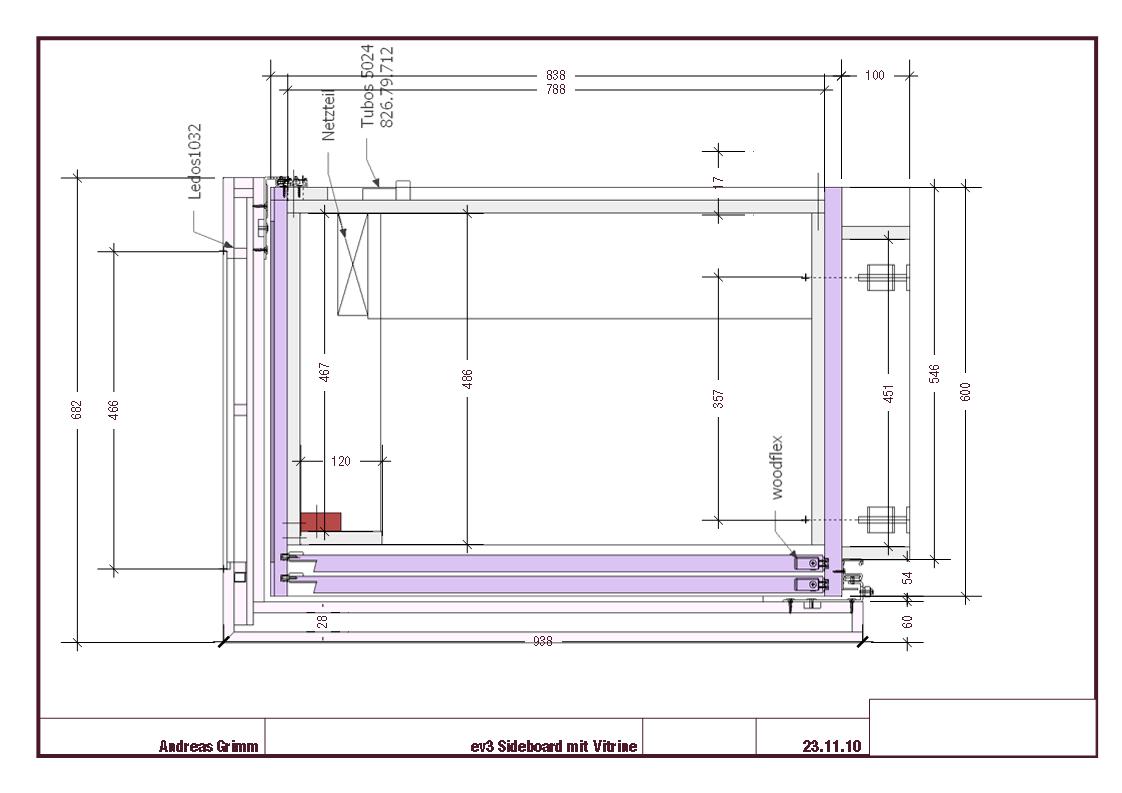

Lately I tend to drawing in 2d rather than in 3d when it comes to construction and rhater make a simpler 3d version just for the presentation to the clients. I give here an example where I did both quite complete, but you will see, what I mean when I say, that the 3d modelling of all construction details is just tiresome and not so effective. Or am I just too lazy to draw properly

? I would like to know, how much you really draw in 3d, and how much in 2d.

? I would like to know, how much you really draw in 3d, and how much in 2d.

I find it now not only slow to draw in 3d but also difficult to extracta good 2d cut or sketch from my 3d drawing. Any sugestions to that? Is there a way to make 2d and 3d drawing work together more smoothly?

And for the fun of it I add a photo of the finished piece.

-

RE: Importing sketchup files into other cad cam software

Sorry, I don´t know your ecabinets program, but on behalf of the circles: If I would export a circle into woodwop, it would create a routing routine. For drilling i have to enter a center point and not a curve. Could that be true for your situation?

-

RE: Compound curves in Sketchup

Hey vicrider

what machine are you working with and what interface or program do you use for programming?I am working with a "Weeke" and that came with woodwop 5. But I dont have a 5th axis.

-

RE: [Plugin][$] RoundCorner - v3.4a - 31 Mar 24

Hi Fredo

I desperately try to install your plugin, but I must have done something wrong: In the Sketchup 7.1 pro i put in the plugin folder:

LIBFREDO6_Dir_35

ROUNDCORNER_Dir_21

LibFredo6.rb

ZLoader__RoundCorner.rb

When starting SU it prompts:ZLoader__RoundCorner.rb

uninitialized constant Traductor::PluginWhy could that be?

Thanks for the help

-

RE: Data importer for parametric construction

Hi TIG

This is my vision

I would calculate in a spreadsheet every part of a piece of furniture. E.g. a table can very easily be calculated with little parameters. THat is of course not every thnkable table in the world, but lets say a standart model with 4 legs, given height, given thickness of the table top, offset from legs to the edge of the table top and so forth.

I entre the data in a sheet and calculate every measure of the given model. Then I generate a list with every piece and the data:

Name, length, width, thickness, material, edging material, if needed, surface material, if needed, hardware. For cabinets, tables, benches, desks and such stuff this can quite easily be done.

To import this to SU I also need to calculate the orientation ansd position of the piece inside a drawing. Generate a csv export file.

Then import this data to SU and create one object for each set.

When i create data before, it seems much easier to create a cutlist, and a calculation of the price, the material input and ... -

RE: [Plugin] ChrisP_ColorEdge

Is there anything special about the installation. I can't see the plugin in SU . I unpacked to plugins and it created a folder and a rb file ChrisP_ColorEdge_EN. Anything else? I would be very happy when I could draw dotted lines.

-

RE: Data importer for parametric construction

Thank you TIG for the quick reply. I was thinking of importing data and createobjects like boards. This is intented to be for parametric construction of different types of furniture. One could not only create cabinets but also tables, drawers, doors, desks and what not else. So I thought of calculating in excel and to export the data to SU. I also can export to an automated routine creating cnc machine programs and a cutting optimizer. Only I want to try it backwards. Not starting with the drawing but with a calcuation.

And the bad thing about it is that i have no clue about ruby and programming.

-

Data importer for parametric construction

Hi everyone

I was thinking of parametric contstruction and found it handy to have a tool that imports data from a csv file or something and produces an object from this data. Is there any tool existing that can do that? I mean it is like dynamic components, only that the interface of dcs seems very little practical to calculate complicated objects.

Thanks for your help http://forums.sketchucation.com/posting.php?mode=post&f=323&sid=fe49cb4dda69747671ed7589985f7e6b#akigrimm

-

RE: [Preview] Skabinet (make cabinets with Sketchup)

Hi NewOne

Big project you´re on.

About cutting optimization. Have you tried swiftopt or bestopt? They seem quite reasonably prized. Maybe a collaboration is possible.

If you do parametric cabinet design then it should be easy to export the cutlist in almost any format that you need. This would be almost independent from the drawing.We have a CNC machine program that does about that: It produces a partlist and the programes for each part automatically. I could send you the excel equivalent only i need to translate it. Tell me, if you ant it.

We have implemented several standards that don´t make so much difference on how the cabinet looks like, but on how it is produced. E.g. are there dozens of posibilities on how to adjust a cabinet in height. Or only think of jointers... Maybe this is not so important for a mere drawing of the boards and how the cabinet looks like as a presentation for clients etc. But still there are countless variations.

I think it would be very difficult to match all types of cabinets everywhere. So maybe start something simple and try to expand it later? Or is there a chance of designing a rather simple tool that imports parts from a csv to SU. You could calculate e.g. in excel or a mysql database and everyone could adapt that to his design. I think the more difficult part would be to define the position of each board in reference to the adjacent ones. But in this manner everyone could easily program their own cabinet and we could get a whole gallery of simple csv sheets or what ever and put them into your program. Its a bit like dc but I found dc as a interface two clumsy to handle for such a complex thing as cabinets.

Then you could add legs as dcs or from a gallery and the same with doors. Or try the same thing as before and divide the complexity in several single programs.

Maybe contrary to what you have done already.

-

RE: [Plugin] SImple wood working Tools

I've tried to translate this simple component. A simple component to draw carcasses with. Maybe you could use it. And you can use it in a report ...

-

RE: Report only in inch?

Cheers Scott

Looks like a bit of work to do, I'll surely get back to you with more questionswhen I find the time to do it.

Thanks -

RE: Woodworking tools in SketchUp

Hi

I am working on a complete furniture development system myself . I dont have really so much time for that, but I have thought of quite a bit of details and also searched existing programs for what they can do.

. I dont have really so much time for that, but I have thought of quite a bit of details and also searched existing programs for what they can do.

After my opinion there are three major goals to achief:- Create a cutlist fast and easy and use this data for all your following work.

- Connect a faktura or database programm to your drawing so you can generate easily an offer for your client.

- Make a nice and professional presentation.

What I want is a easy way to get a cutlist, since that is the base for everything else in the workshop and for my offer and a good looking presentation. May be with doord that open and all that. But dont go into details that you dont need for your work, since you know your business.

Nice would be to work in projects with all the data that dont refer to the drawing but to the project with all that a crm prog does (letters, bills, offers, adresses, deliveries, invoice, calendar) and also a calculation modul. If these all work together my work gets a lot easier.With dynamic components I think that we will reach there a lot faster than in the past. But I need to explain maybe a bit more detailed:

We're using a machine program on our CNC that lets you design standart cabinets only by parameters. That is good. But to get the cutlist we still have to write it by hand, and before that make a drawing and all the shit. And before we even start we need to write an offer for the customer and to do that we have to more or less guess or do the same work in advance. So start with parametric designing of furniture. From these dynamic drawings get the cutlist and import it in a spreadsheet or database. There you have defined times for your production(which by experience you correct) and you have easily the price of your product. If you start you printout the cutlist. Better not ones but for everymachine that you are using. For example: One list for the raw cutting of boards before planing them or as we do: we cut our boards (strandboards etc.) 10 mm bigger before formatting on the CNC. so you could have one list with final measurements and one with the raw measures.Export the rawcutlist to a optimizer for cutting boards and you willl have the exact amount of materials you have to buy. If these can be stored in a database with their price, youre there. You need to calculate the amounts of edging material and the amount of veneer and lack that youll need. To obtain that, you need to be able to tell su not only how a material should look like, but also what it really is. For example would it make no difference for SU if your cabinet is made of oak massive wood or laminated boardss with oak dekor. But you could guve that information when constructing the cabinet.

If this information can be stored it doesnt at first affect the drawing but can be very useful to have later, and when you start your cbainet entering "Material: Oak, massive" You have it in all following steps. Plus if your customer asks "How much is it in laminated boards, you change only one detail (Hopefully) and get the alternative price.So you should have quite comfortable dialogs since you have to enter a lot of data for eache piece.

Dimensions, core material, overlay material, edging material, which edges are laminated, how are the surfaces treated. And to generate a whole cabinet like that, you need even more. One thing that helps us:

Less is more

Dont create a system for every exotic kind of furniture that you will ever build but one for the 85 % average ones. You dont need to draw the joinery (my opinion) even when I deliver my furniture it doesnt seem to make a lot of difference to my customers, if the drawers have dovetails or no, as far as the price is correct.When you want to create a strechable cabinet you just use components and change these. So if you want a drawer stretched you build it in components and stretch them in their proper way. There should be no prob but dont try from the start to calculate every thinkable construction of a cabinet or table, but stick to one and then expand.

Sorry I guess this gets rather long so I better stop now. -

Report only in inch?

Hi everyone

I have experimented with dc's and did a cabinet as a dc. I did the drawing and everything in metric, also used a meztric template. SStill when I read the report, it was all in inch. Did I do something wrong or is it not posible to generate a report in metric. I ask that because I had earlier problems with exporting dxf to AutoCAD where I found everything in very strange scales. So I thought that it could be for the same reason.