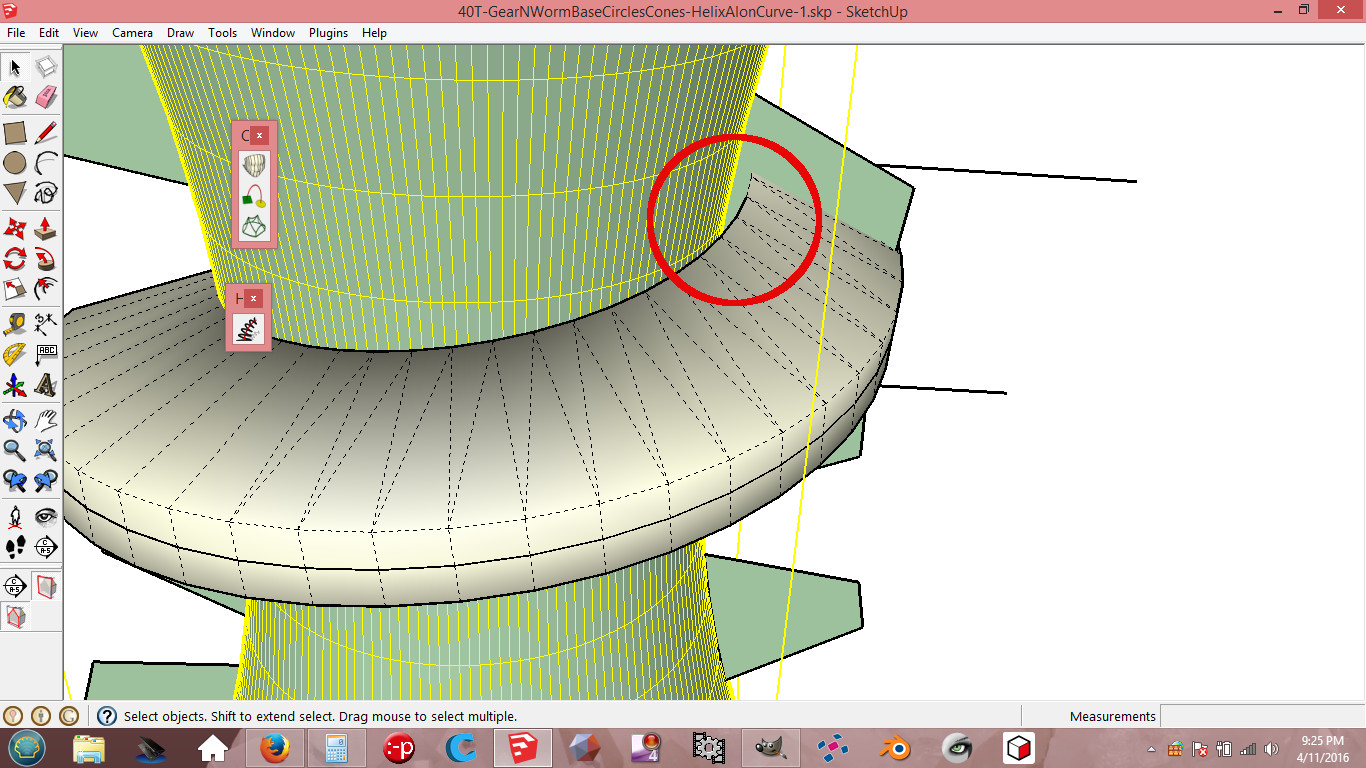

Hourglass Helix?

-

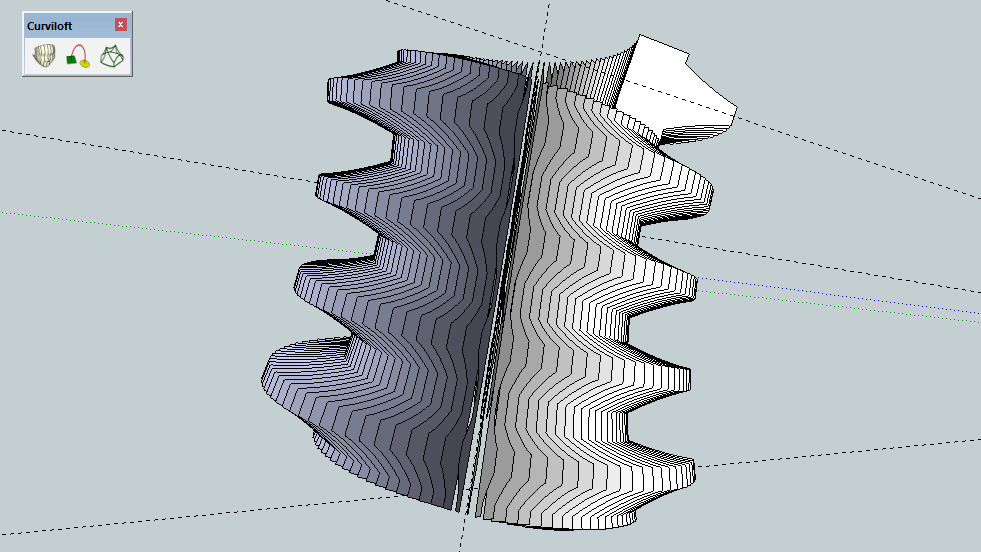

Edit: Uh! I was fool or too tired. I do not need to make the cut. The helix path is already ok hourglass shape and pitch growing and valid for curviloft.

Now thinking how to get the the path or shape helix turn tighter or more along the hourglass body, perhaps just more sections? I have to learn better this helix along curve plug-in.

-

Maybe this can help you!

Loft along a Vector by the genious Projection By Didier Burr

Joint PushPull Interactive by Fredo

...or Curviloft!

-

-

Thanks! I check them. I still have about 0.2mm "error" on radius with curviloft.

-

Maybe Flowify can be of help here.

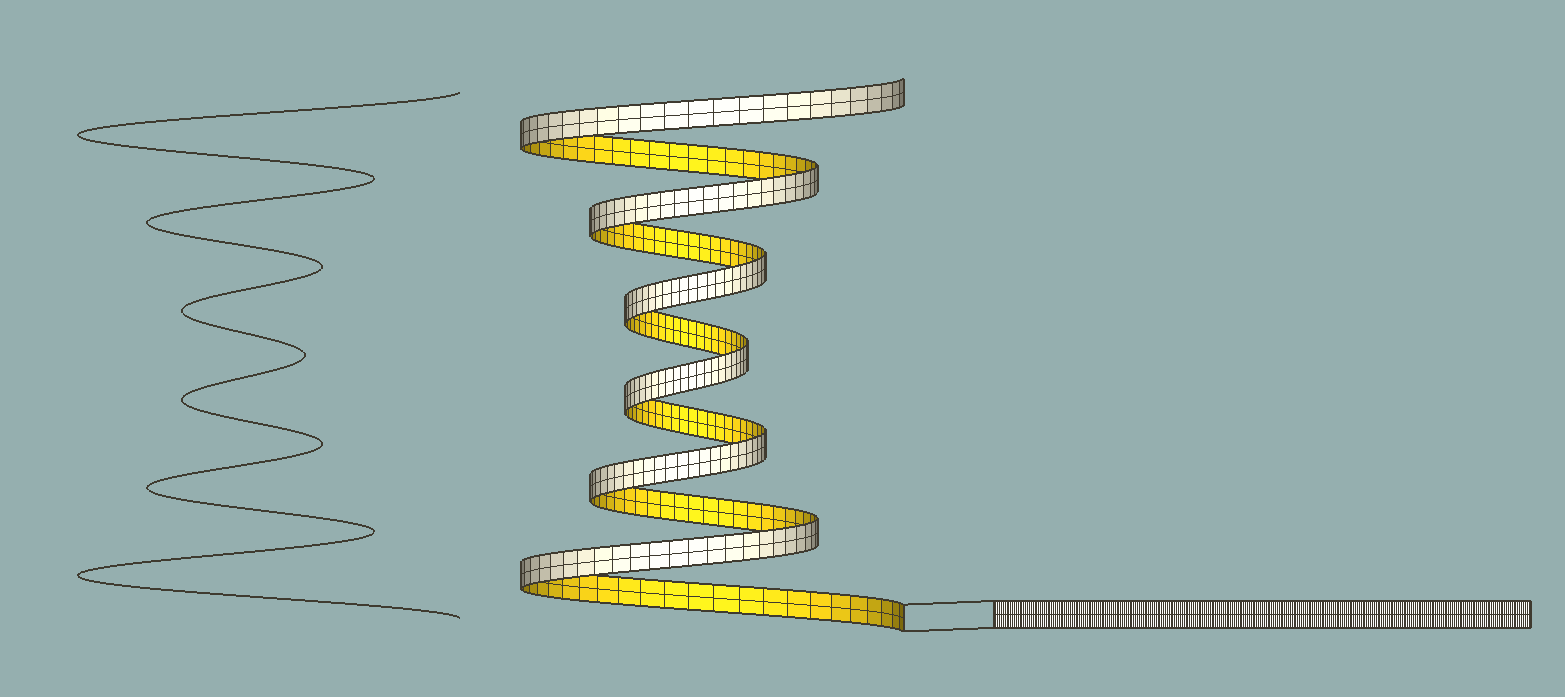

The spiral can be turned into a quad surface with "Extrude Edges by Vector" from TIG's extrusion tools. Just extrude the spiral edges along the blue axis up and down. After that the worm can be mapped onto the quad surface using Flowify.

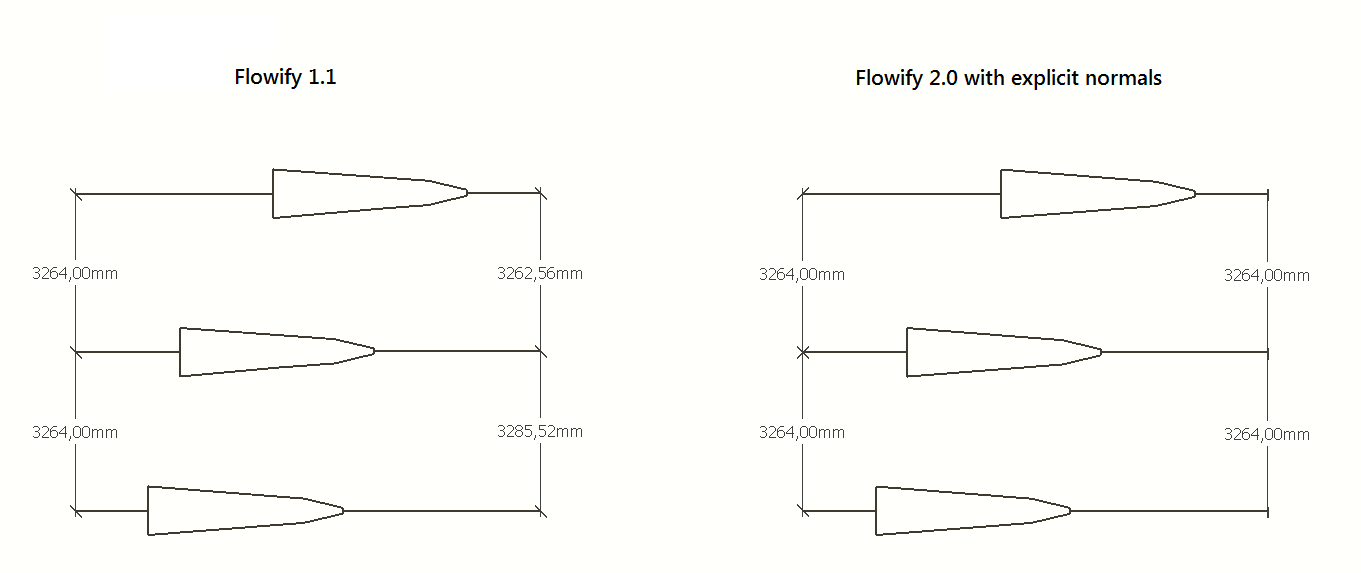

A problem here is that since the spiral's radius is variable the vertex normals in the quad surface does not extend radially from the spirals center. This means that the distance between two revolutions in the spiral is not retained at the tip. The difference in this case is <1%.

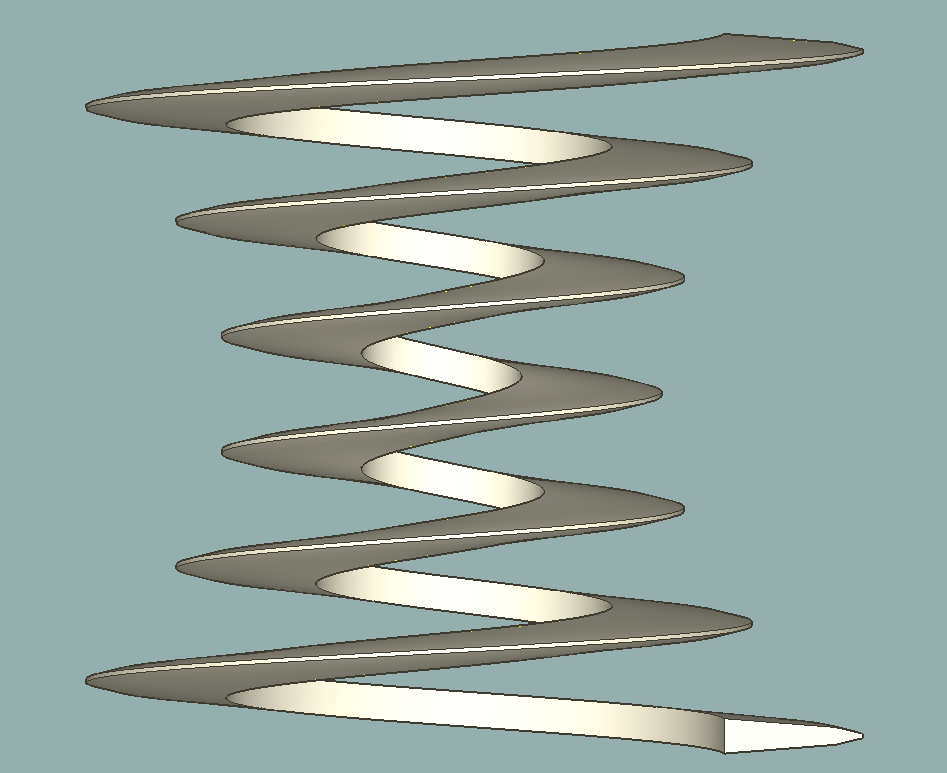

In the upcoming version of Flowify (2.0) it will be possible to explicitly set the normals at each vertex. The image below shows the setup. All normals extend radially from the spirals center and this aligns the geometry at the tip with the geometry at the base between revolutions. The last image shows the difference in a section cut for three consecutive revolutions.

-

There's another thing too. The tooth has to point to the center of the worm wheel. So I have tried curviloft follow spiral path and tooth faces oriented to the center. No success yet. So the path is not correct then.

-

This is an intriguing problem. Here's another take.

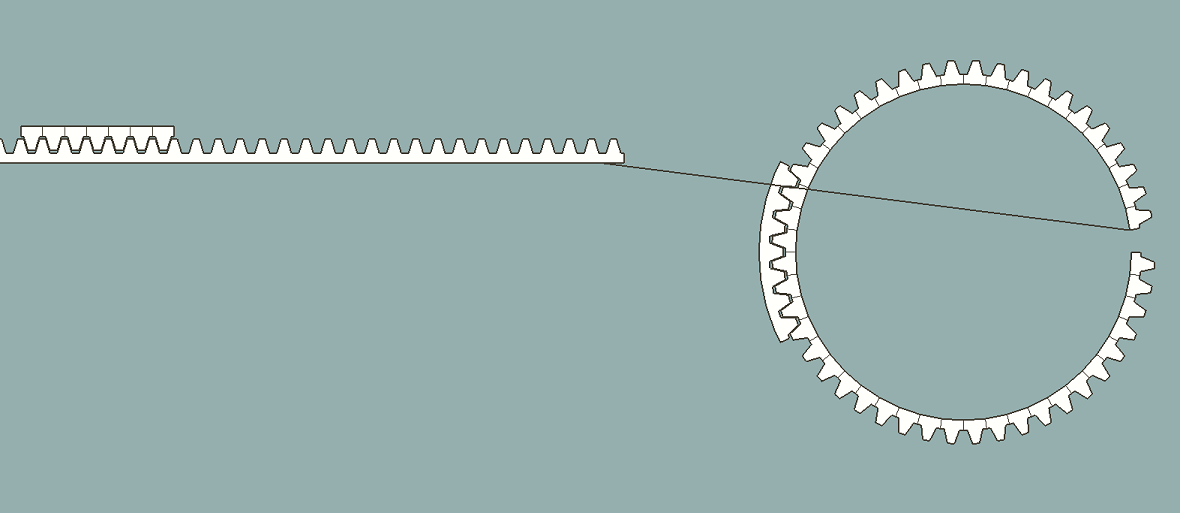

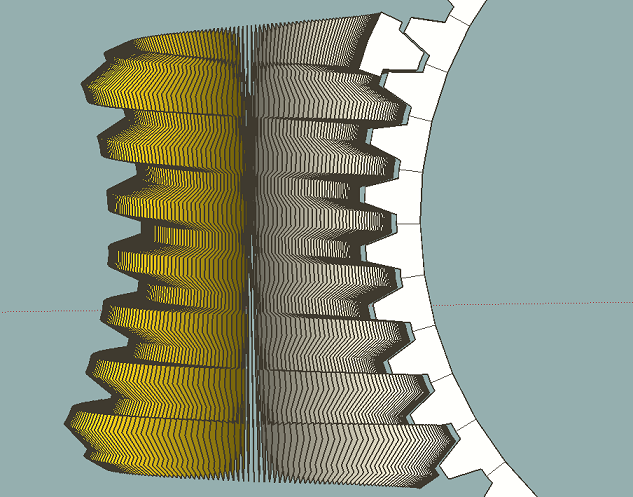

The first image is a flat setup for flowify and a flowify output which is a gear and a profile for the worm.

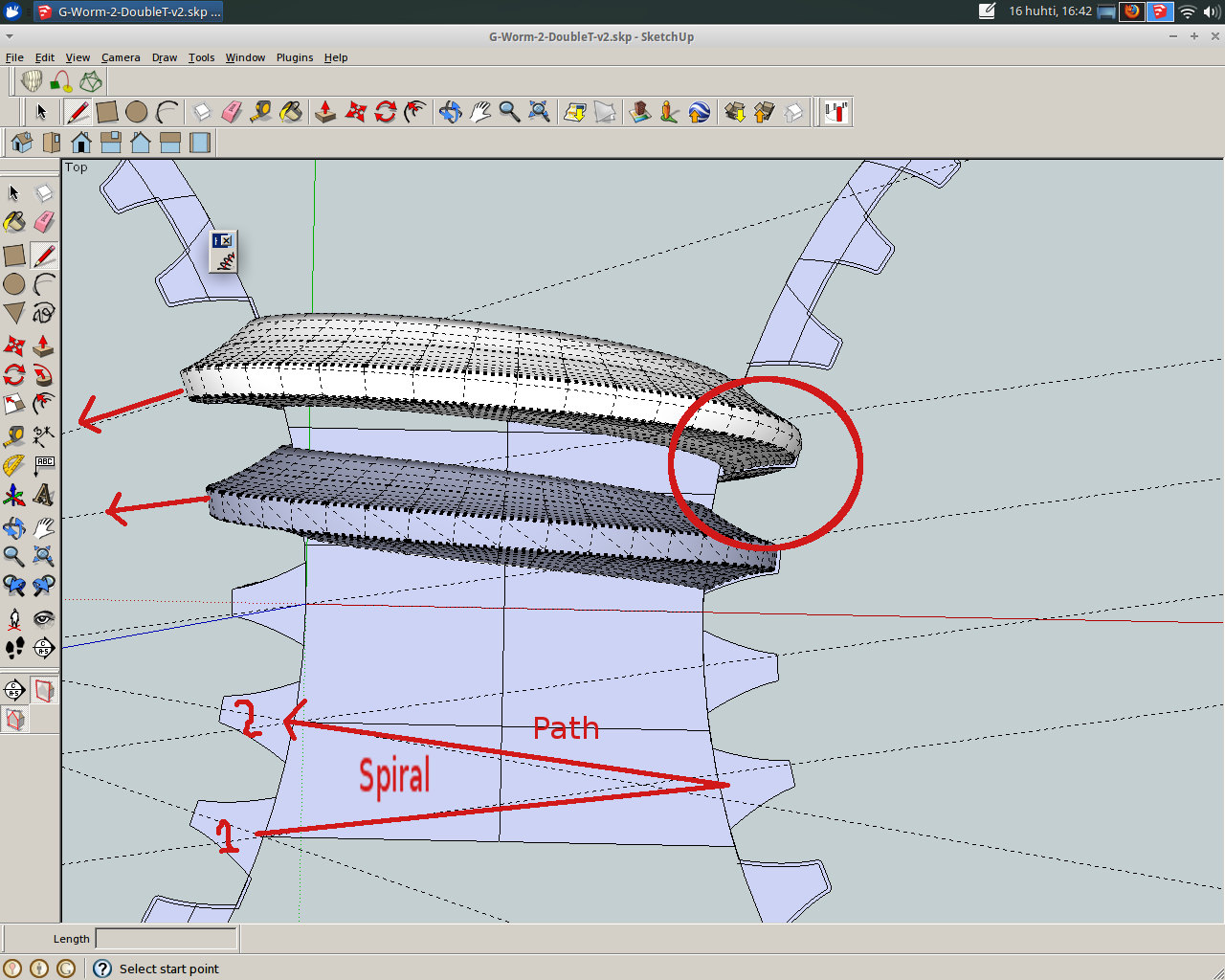

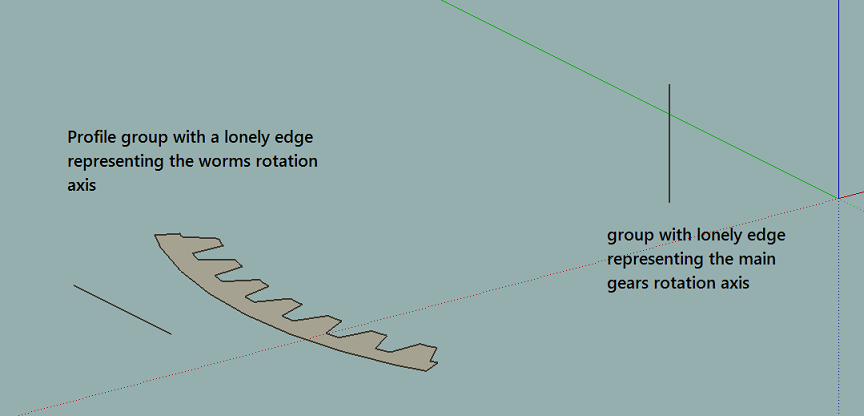

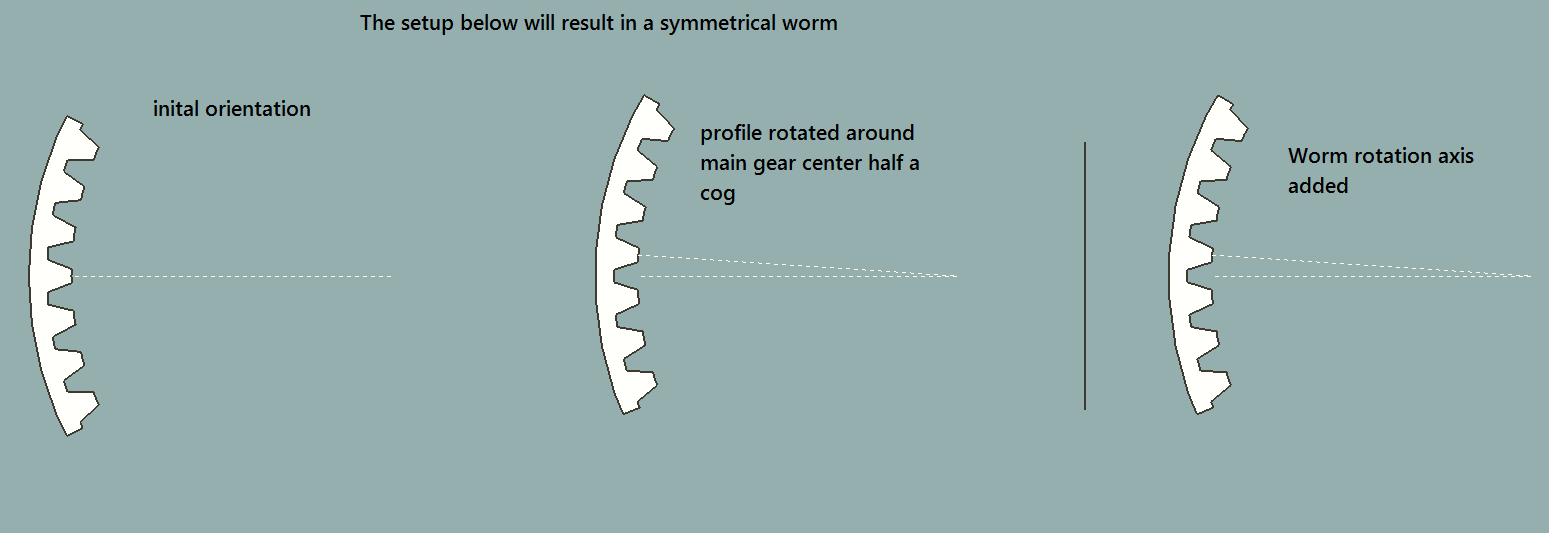

The next image shows a setup for a tiny custom script (attached below). The script takes two groups as input:

1) A group with a single edge representing the rotation axis of the

main gear.2) A group containing the worm profile AND a lonely edge representing the worms rotation axis.

The script itself has two internal parameters at lines 49 and 50. Those are the number of cogs on the main gear and the number of circle segments for the worm.

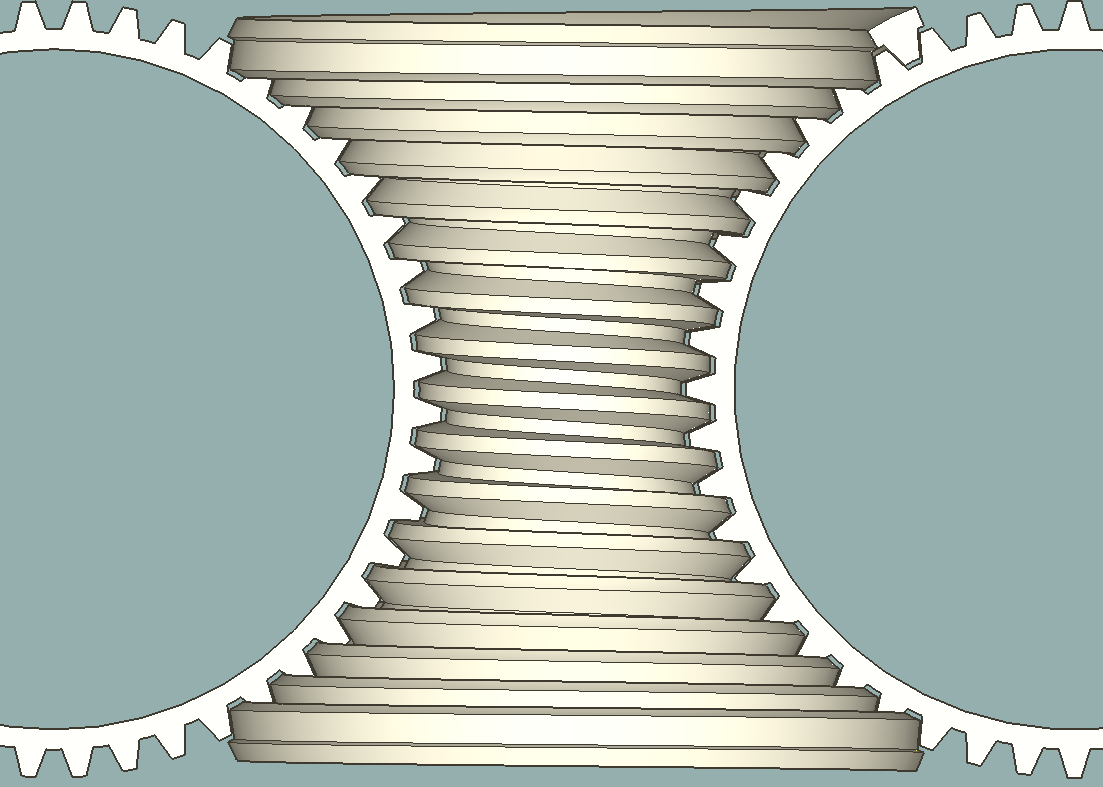

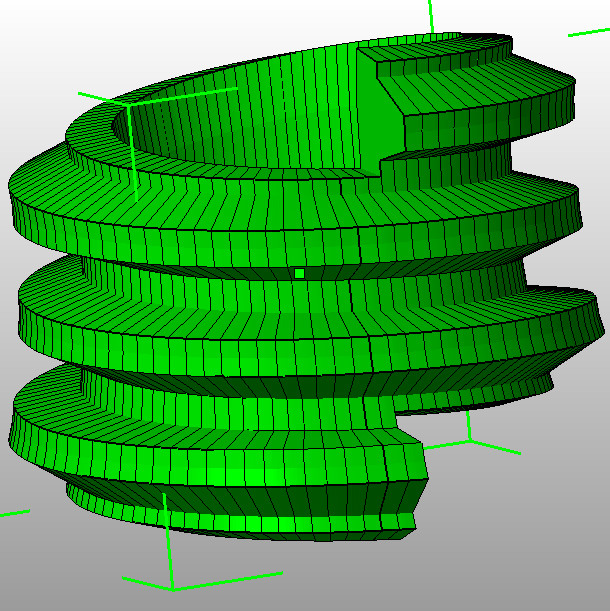

To run the script, open it in a text editor, set the parameters and save. Then select the two input groups, copy and paste the code into the ruby console and press enter. The result for 48 cogs on the main gear and 192 segments in the worm can be seen in the last image. The output is just profiles that have to be merged manually with Curviloft.

-

Some final observations and additions.

A skinning method is added to the script so most faces are created automatically. However, since adding geometry with the internal add_face method does not merge stuff properly the resultant group needs to be exploded and regrouped. This will ensure a proper merge. Some holes need to be filled manually. Also, the worm profile must consist of exactly one face for the skinning to work.

When creating a worm the profile will rotate one cog around the main gear center. So, a symmetrical helix requires the profile to be rotated around the main gear center half a cog in the opposite direction. The rotation axis for the worm should be added after this procedure.

-

Very nice script! Something like this, I thought, but would be painful to do "manually". So the profile has to be rotated. 40 tooth gear 4.5 (9/2) degrees etc. That's perhaps because my own profile test went horizontal and crazy mess?

Naturally the worm wheel has a helix angle. Now to think where and how to cut the ends... I got the holes fixed with just automatic settings in NetFabb. There's many globoid worm tutorials in the web that seem to be erroneous, Solid works etc. Perhaps this script etc. is one quite correct way... Very nice!

-

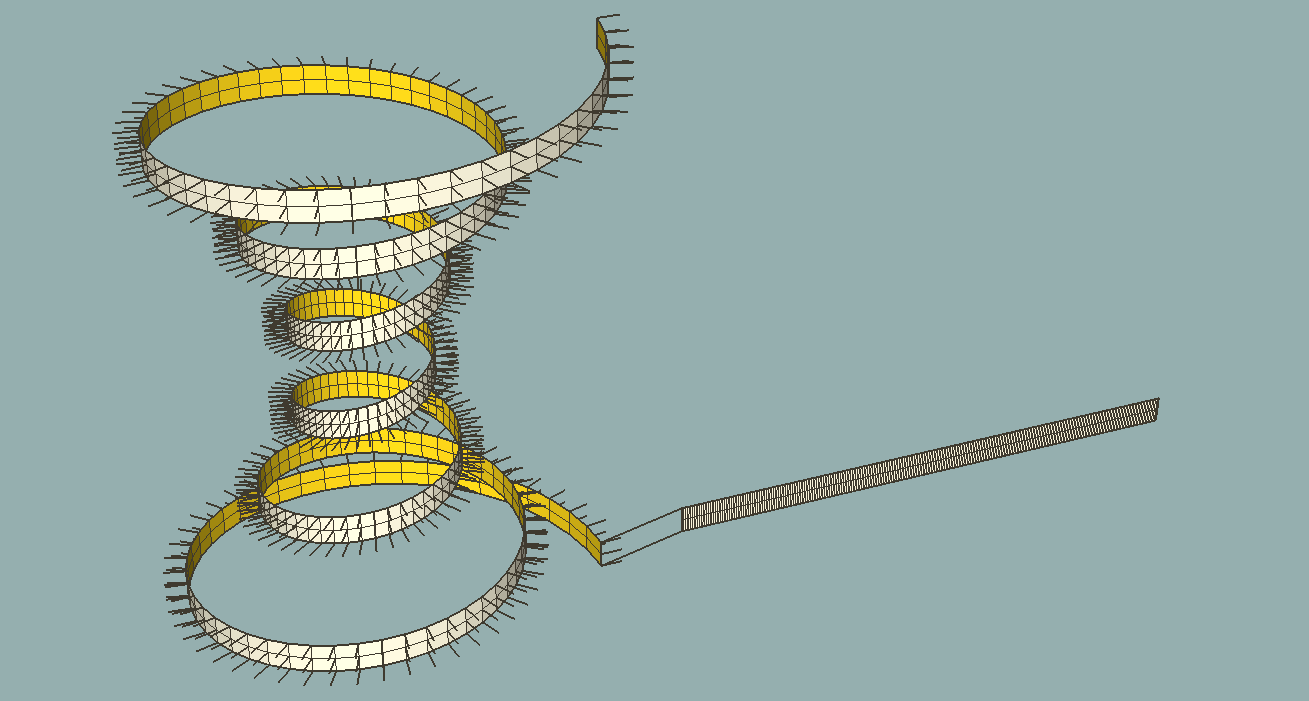

This came out from involute gear plug-in profile (60 Tooth). Thanks CAUL! I hope that I can soon proceed to a 3D printed piece & real world test.

Advertisement