Hourglass Helix?

-

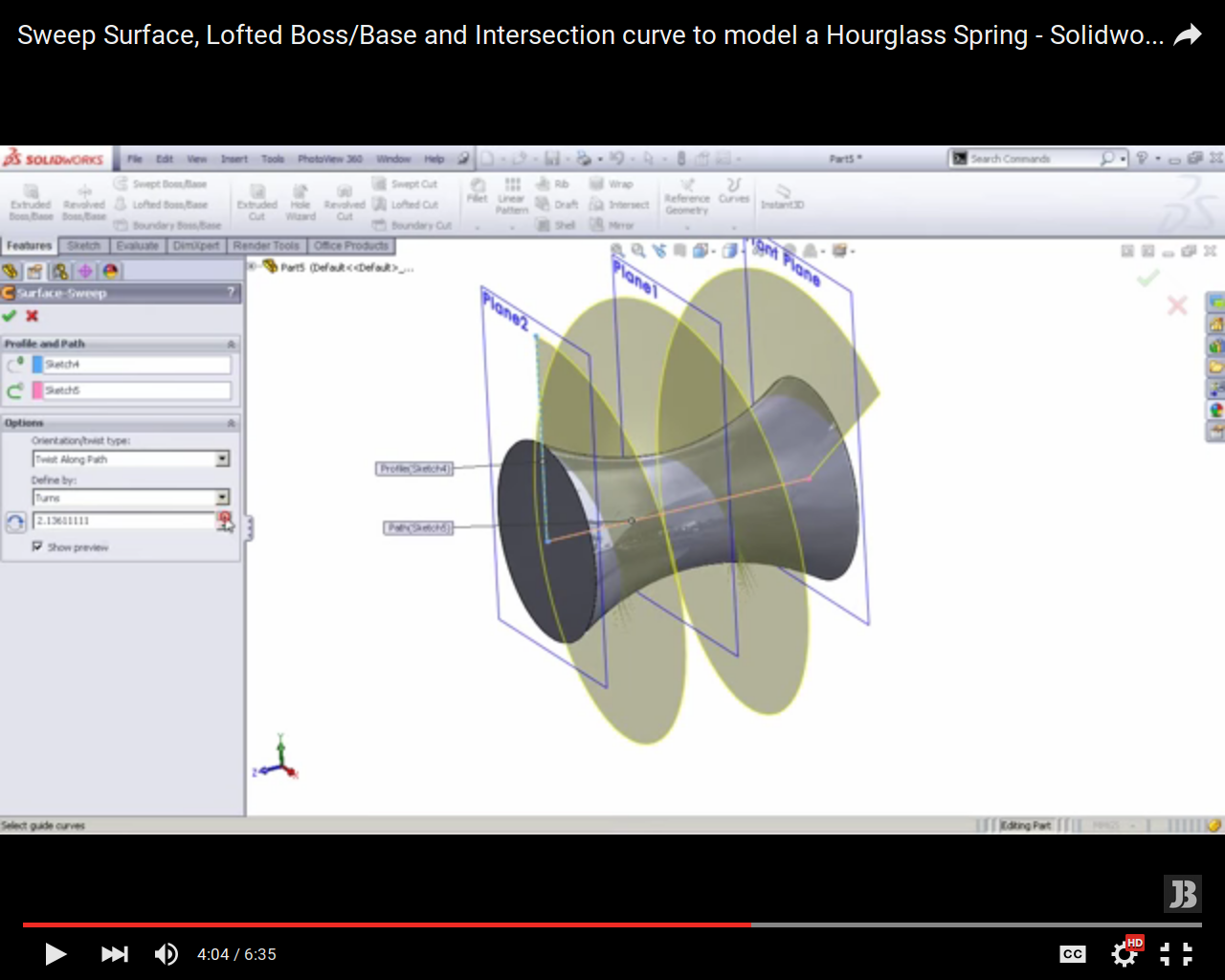

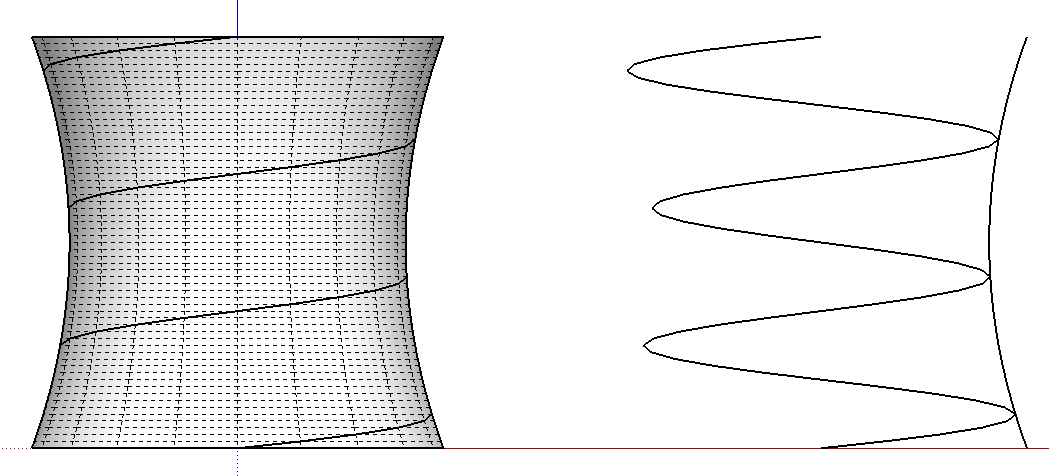

How I make this helix sweep cut to the hourglass to make paths (intersection)? Hourglass helix path. Helix and ?.

-

Ok! I think I made it with the Curviloft.

-

-

I'm a bit lost, are you asking a question?

Could you explain your question better with some images perhaps.

Pilou has given you a great helix tut.

I'll add mine in case it is of interest.

-

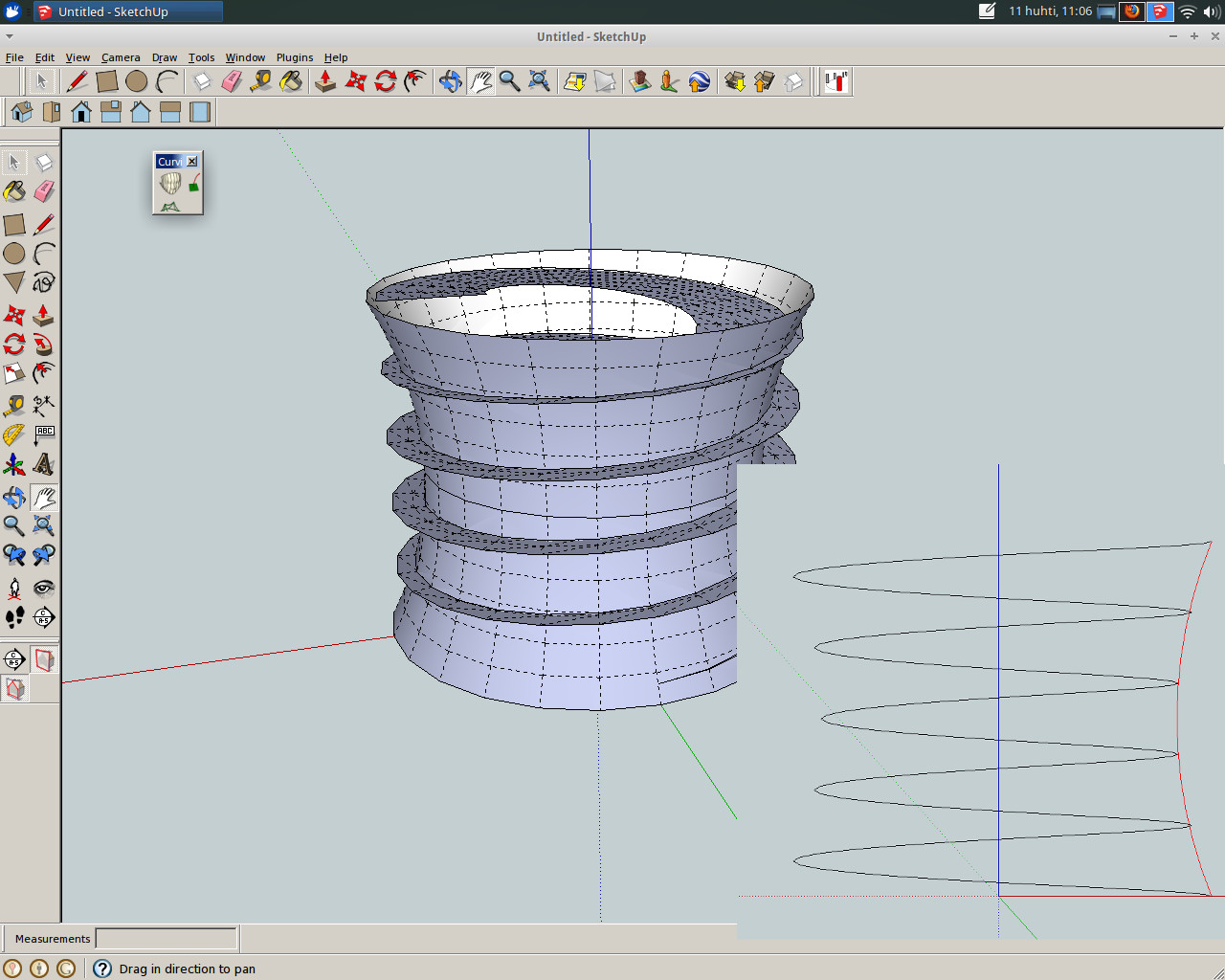

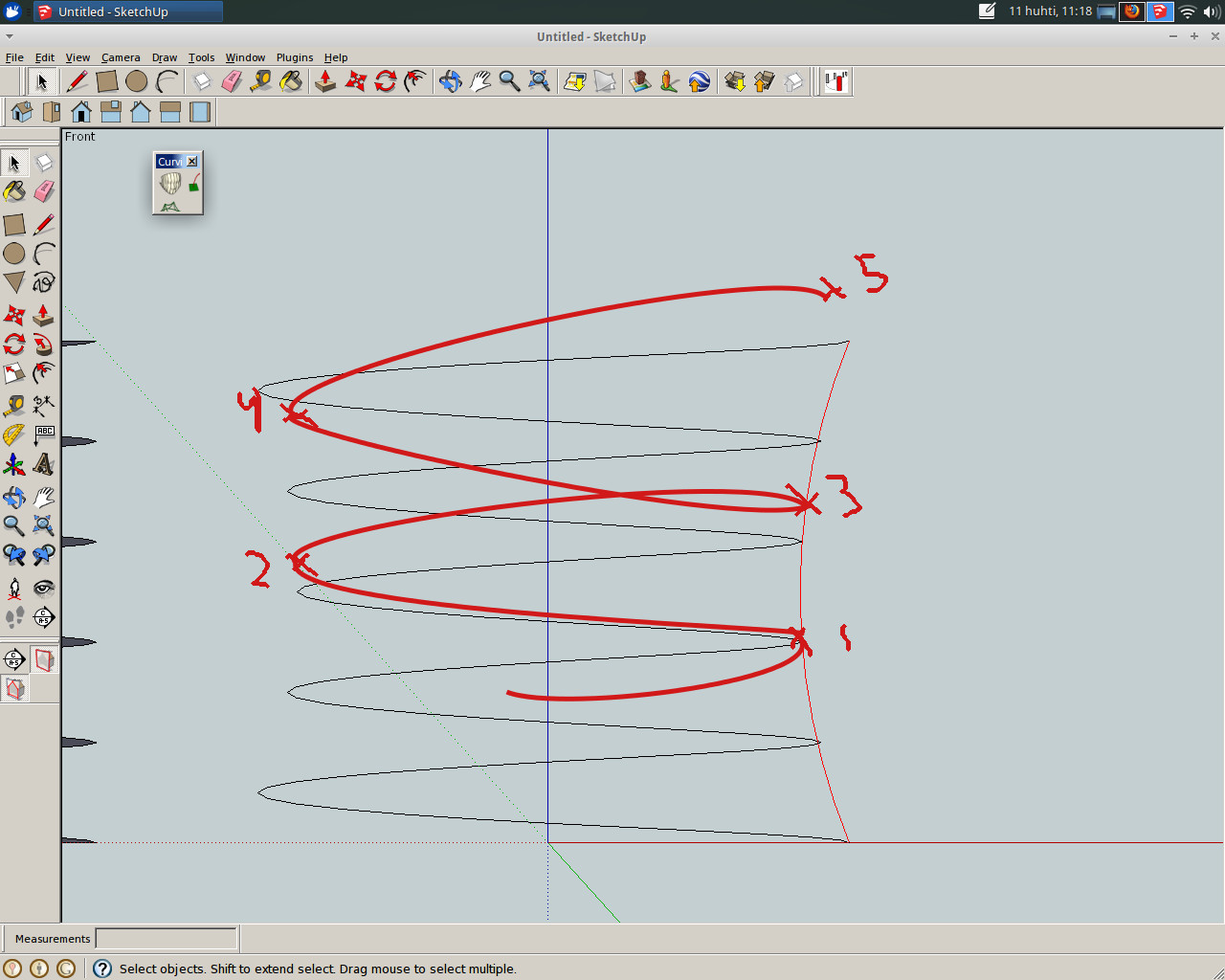

Perhaps this image explains what I wanted and managed to make, with two normal helices + faces made with Curviloft cutting a path to a hourglass shape (or two curved cones). Sadly this is not enough what I need. I need helix going and growing up through the certain points (second image). Is there a way to make helix go using certain points or first pitch, second pitch etc.? Or I'm not sure if stitching helices with different pitch one over other makes a continuous grow? Like that half circle helices do not grow up correctly.

-

This isn't really all that difficult. Draw a lathed shape with the curve you're after. I used a Bezier curve and Follow Me. Make the shape a component or group and show hidden geometry. Then use the Line tool to draw the helix. Draw from intersection to intersection.

The number of turns and the smoothness of the helix will determine the numbers you use for the sides of the circular path and the segments in the Bezier curve. In the interest of time, I used 20 sides onthe circle and 60 segments on the Bezier curve. This gives 3 turns in the helix. -

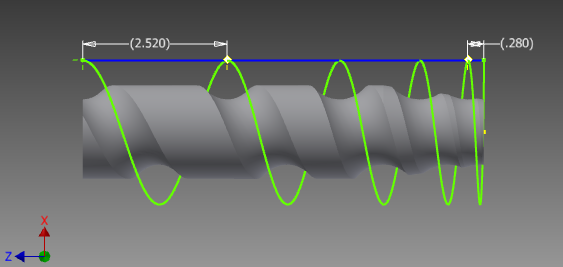

Hmmm. That's a nice way from point to point. But I need a variable pitch helix, so I cannot easily use intersections. 73.2mm -> 74mm etc. If there exists something like img.2 here down...? Points and pitch between them .

-

Why didn't you ask for a varying pitch in the first place? Do you want BOTH varying pitch AND the "hour glass" shape?

Give real specific dimensions.

-

-

See my previous old post for draw your curve!

Some tricks inside!

http://sketchucation.com/forums/viewtopic.php?f=79%26amp;t=49558#p445823 -

http://www.drawmetal.com/download

Build the Volume first then deform it by Fredo Tool!- Fredo Scale Box Scaling (+SHIFT No Uniform) + Box Tapering + Box Stretching (+ F4) and you can draw any sort of volume helicoidal!

-

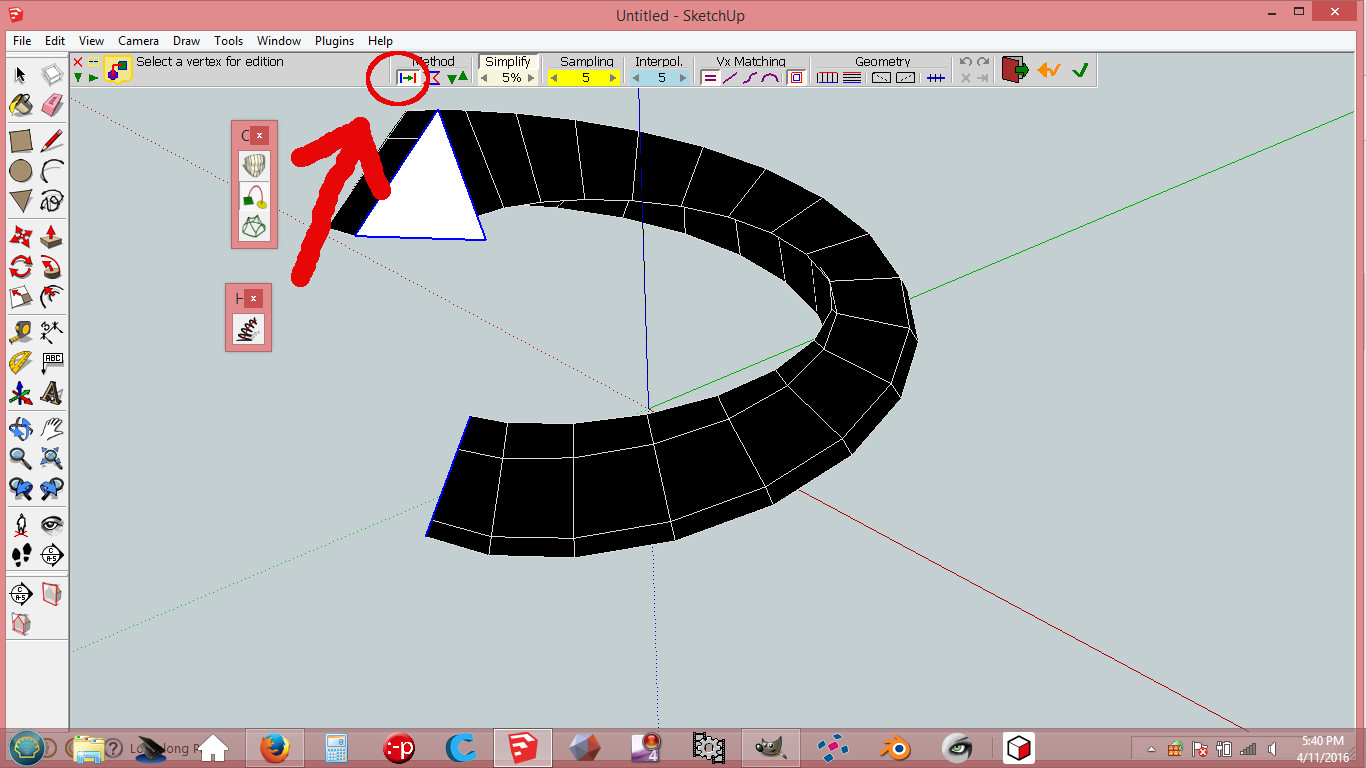

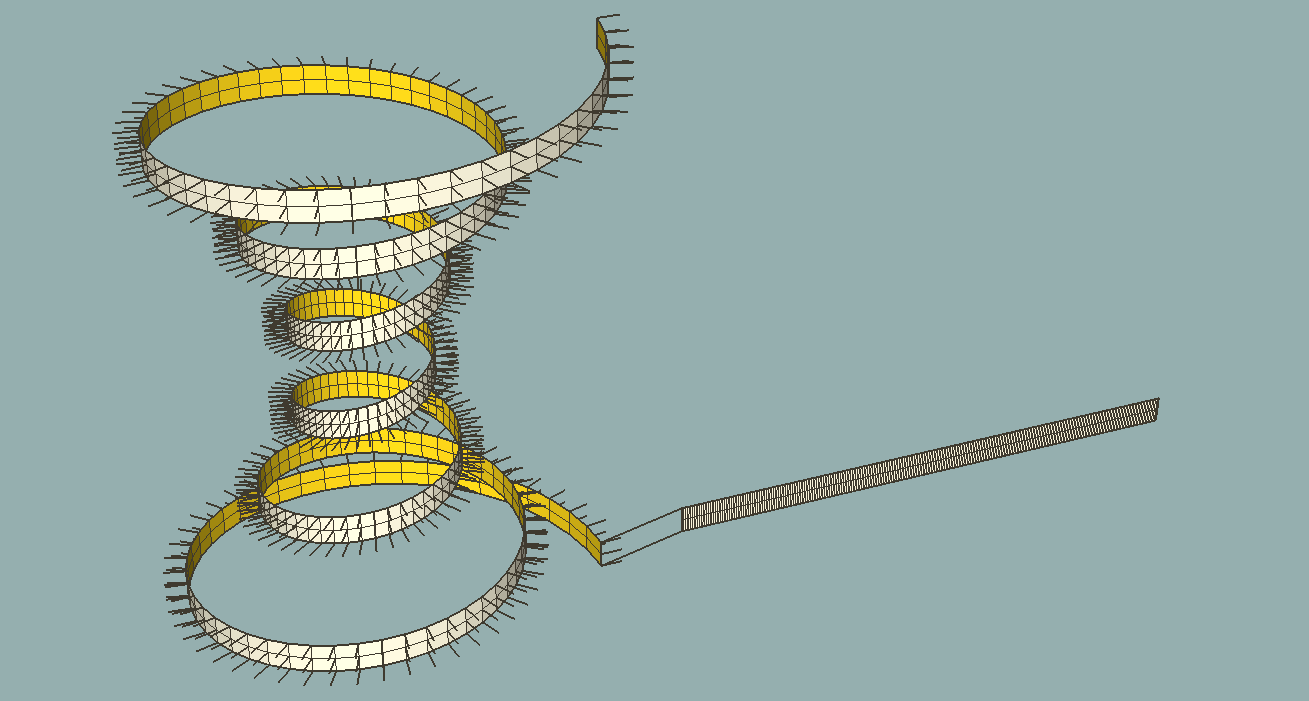

Perhaps I managed to make the correct helix, but sadly now I cannot get it to work with the curviloft correctly. First image helix. Second helix made of half circles. Not good, but the closest what I have.

-

Perhaps I found the correct option for curviloft. I have to think and try more...

-

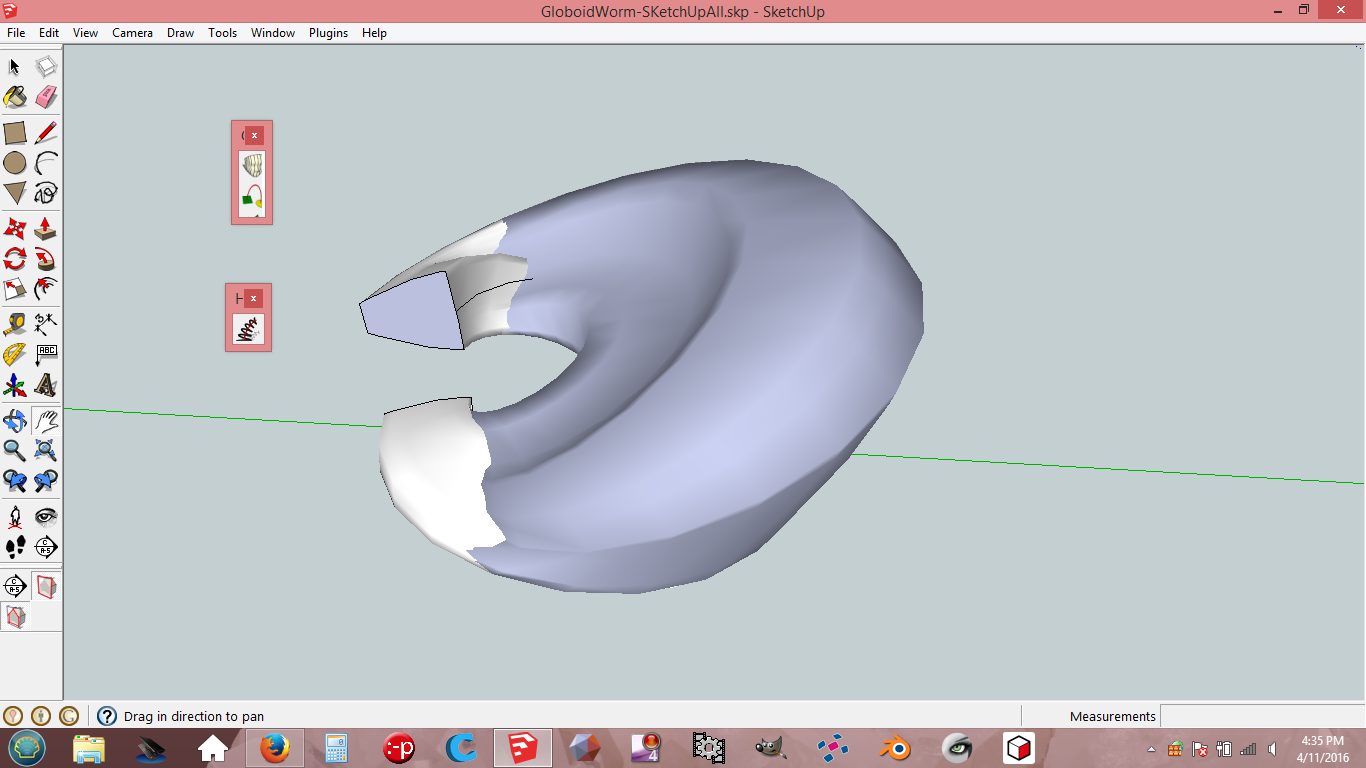

Edit: Uh! I was fool or too tired. I do not need to make the cut. The helix path is already hourglass shape and pitch growing and valid for curviloft.

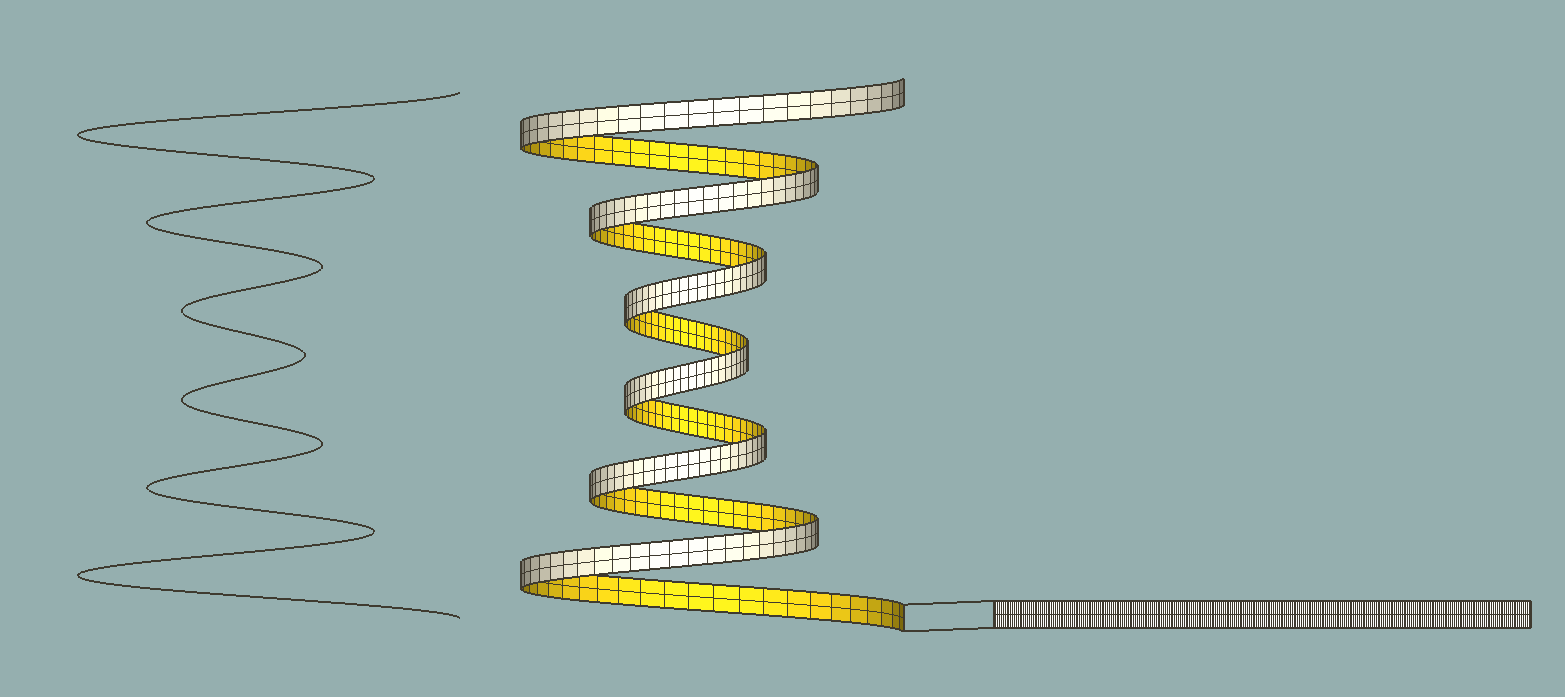

Sorry! First I needed just the hourglass helix and then I found that I need variable pitch also. Yes I need both. Thank you pointing to the Helix along curve! At first it looks like that plug-in can do the thing If I do a one variable pitch helix using different length lines, then copy and scale it down 0.5 red&green axis. And then make curviloft faces along the paths cutting the hourglass and leaving a path which is a helix with hourglass shape and variable pitch.. I will try.

hmm what is the degrees option in Helix along curve plug-in...?

-

Edit: Uh! I was fool or too tired. I do not need to make the cut. The helix path is already ok hourglass shape and pitch growing and valid for curviloft.

Now thinking how to get the the path or shape helix turn tighter or more along the hourglass body, perhaps just more sections? I have to learn better this helix along curve plug-in.

-

Maybe this can help you!

Loft along a Vector by the genious Projection By Didier Burr

Joint PushPull Interactive by Fredo

...or Curviloft!

-

-

Thanks! I check them. I still have about 0.2mm "error" on radius with curviloft.

-

Maybe Flowify can be of help here.

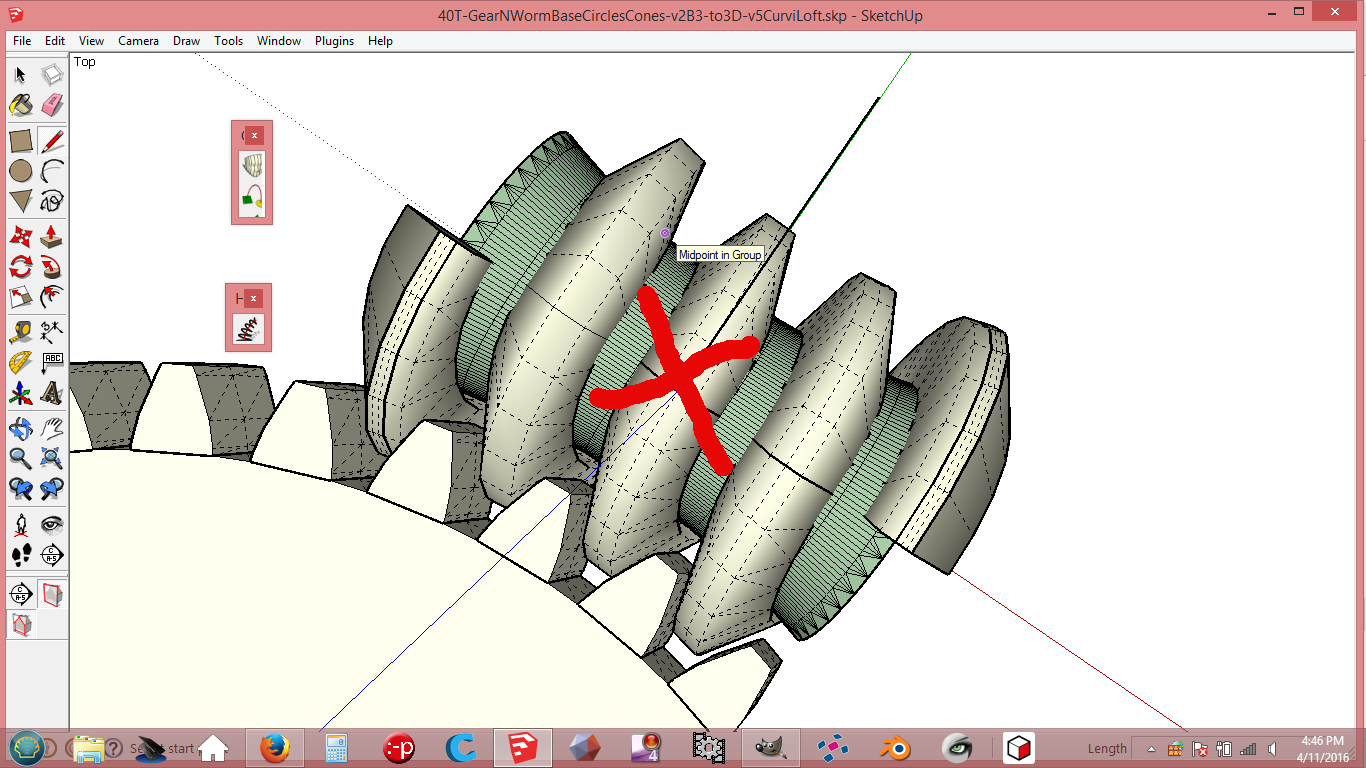

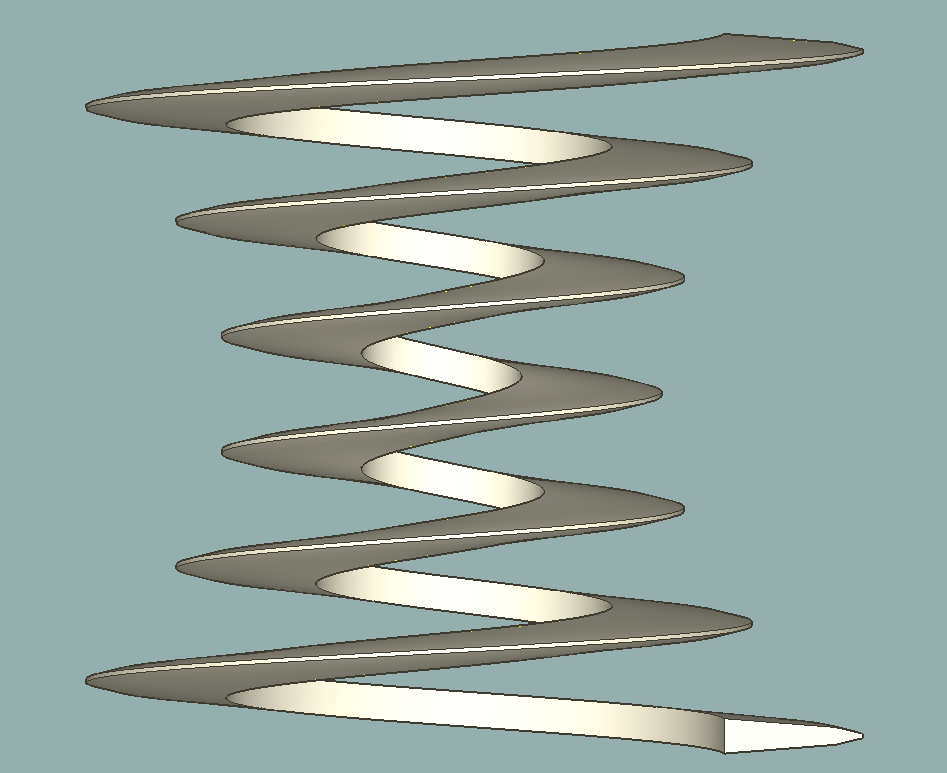

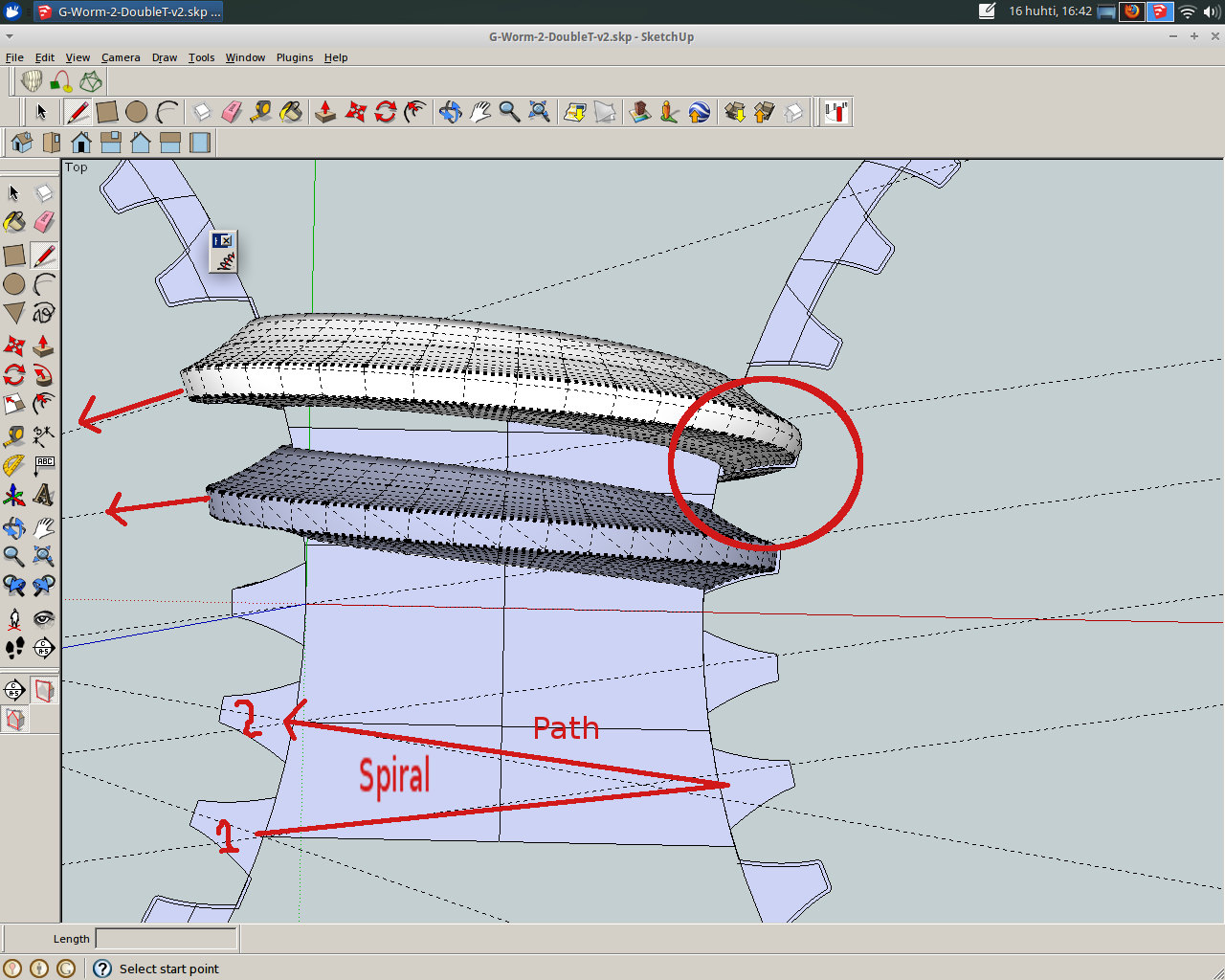

The spiral can be turned into a quad surface with "Extrude Edges by Vector" from TIG's extrusion tools. Just extrude the spiral edges along the blue axis up and down. After that the worm can be mapped onto the quad surface using Flowify.

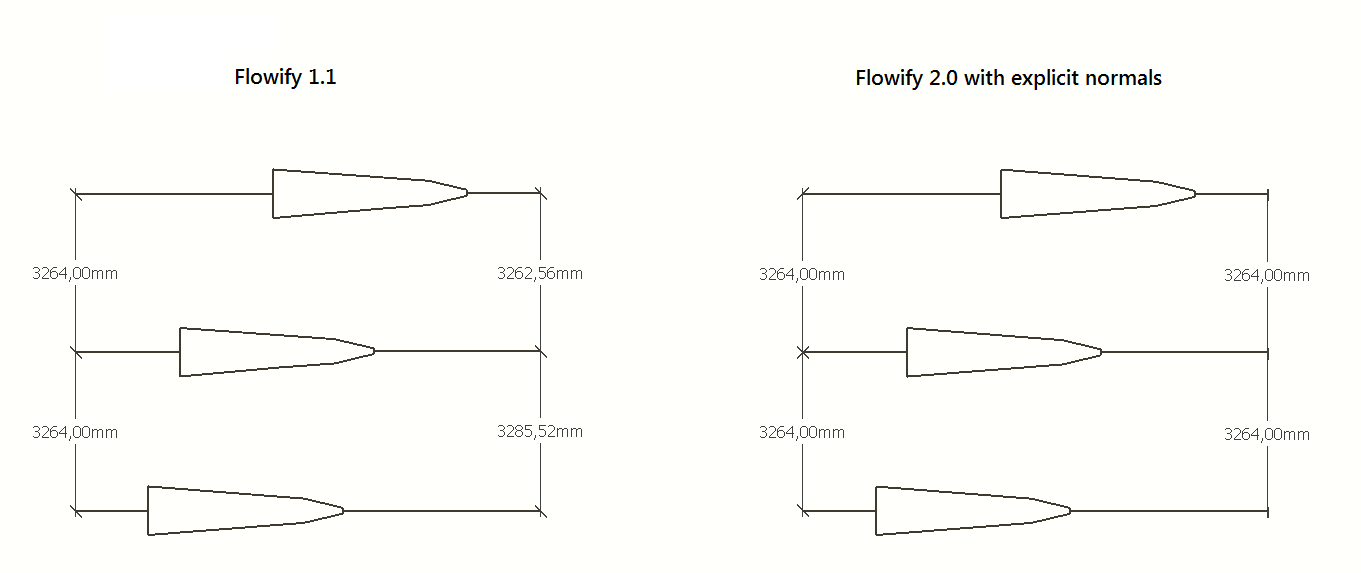

A problem here is that since the spiral's radius is variable the vertex normals in the quad surface does not extend radially from the spirals center. This means that the distance between two revolutions in the spiral is not retained at the tip. The difference in this case is <1%.

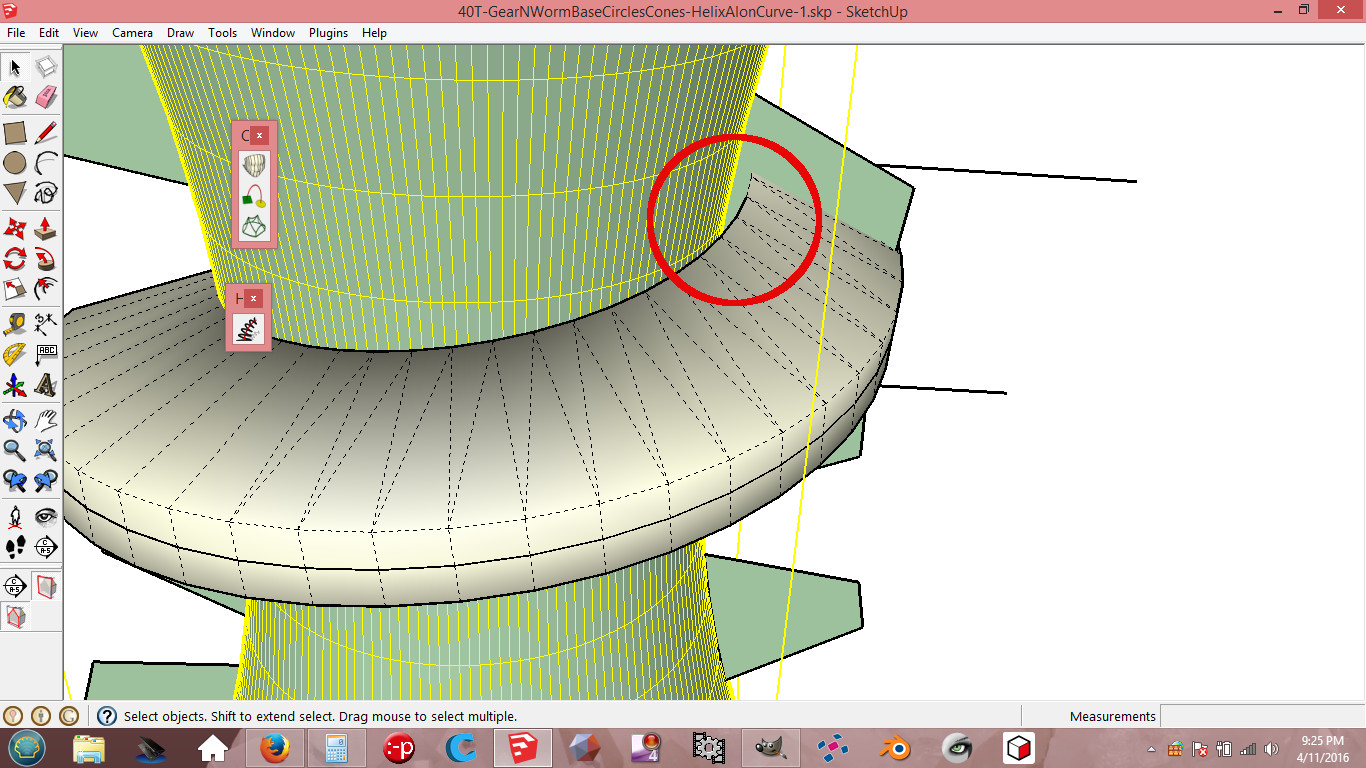

In the upcoming version of Flowify (2.0) it will be possible to explicitly set the normals at each vertex. The image below shows the setup. All normals extend radially from the spirals center and this aligns the geometry at the tip with the geometry at the base between revolutions. The last image shows the difference in a section cut for three consecutive revolutions.

-

There's another thing too. The tooth has to point to the center of the worm wheel. So I have tried curviloft follow spiral path and tooth faces oriented to the center. No success yet. So the path is not correct then.

Advertisement