Chidori furniture joint

-

Is anybody familiar with this system. I'm looking for details of the joints. The system apparently consists of 12 sticks with different junction details which connect without the aid of glues, nails or screws. I've checked out Amazon but with no joy. Any leads would be greatly appreciated. Many thanks in advance.

-

Some graphics at the bottom but no dimensions.

-

Estimating from the length of the guy's thumb and the chisel width I'd say it's made from ~38mm HW [~1½"] - perhaps PAR to that size?

The half-laps etc are then based on the cross-section size.

The length of the 'bars' is modular - so as long as the mid-section is twice the ends' length it should all fit together.

Perhaps something like 300/150mm [12/6"].

Given it's traditional Japanese it's probably based on tatami-mat sizes which are around 3x6' ? The size module depends on area 955x1910mm around Kyoto, 910x1820mm around Nagoya and 880x1160mm around Tokyo - so chances are the size is base on something like a '300/150mm module'...

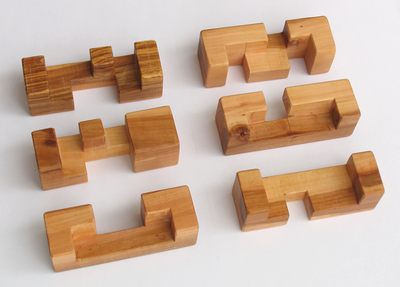

Note that there are three bar types with different notching to ensure interlocking in 3d - just like a wooden puzzle-box.

The ends need dowels to allow stacking/side-linking or rubber inserts for feet or over-sailing table-tops.

Any shelves are sized and notched to the module too.

Should be relatively easy to make as SKP parts... and then in reality by using some good quality planed HW, and a trusty table-saw/router-table/hand-chisel/drill-press etc...It's a very clever and inspiring idea.

I might have a go making something... I need some shelves...

It even got me thinking about a simple 3d cross 300mm module with dowel-hole ends that add up in a similar way... -

Try this link, too. http://e-j-p.org/collection/02/

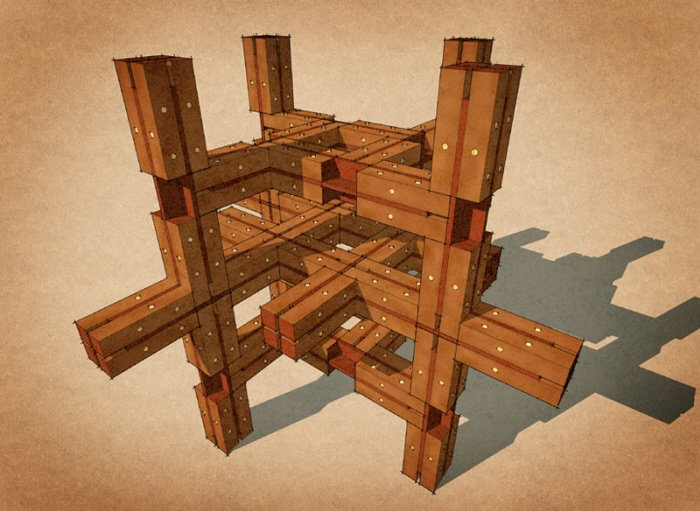

It reminds me of burr puzzles.

-

Here's my take on it (

).

).

My version only needs one type of hardwood 'stick'.

The notch has an offset cylindrical post allowing the pieces to twist into place and interlock to form a 300mm 'cross'.

The form lends itself to 'mass-production' on a table-saw/router-table/drill-press etc with some jigs/stops set.

These then connect together with hw dowels etc to make cubes etc, with added shelves/tops etc.

-

Here's my second take on it (

).

).

My mark-2 version only needs one type of hardwood 'stick', and the notch has an offset angled square post _19mm on the diagonal, allowing the pieces to twist into place and interlock to form a 300mm 'cross'.

The form lends itself to easier 'mass-production' on a table-saw/router-table/drill-press etc with some jigs/stops set. The square/ 45-degree cuts are easier that mark-1 with its rounded post and they still rotate into place satisfactorily if made tight enough...

These then connect together with hw dowels etc to make cubes etc, with added shelves/tops etc.

-

Excellent.

-

Hi TIG just seen your modified version. Looks much easier to fabricate, will give it a try when I get the chance. Thanks for that.

-

One of the burr puzzles I referred to.

-

-

Even you find a solution in 3D that want not to say that is the solution in the reality!

A very difficult one!

-

Pilou, I'm not sure what you just said. I had one of those puzzles when I was a child. That one isn't too bad to figure out.

-

If I had the wooden one I could probably do it with my eyes closed. When I have some time I'll put yours together.

-

You must several days of try before to find the solution by hands (if you find it !

I know only one person who i said to test it who find it!

All the others give up!

It's a vicious solution!

-

Muscle memory.

-

Impossible to make it eyes closed!

Carreful there are variations as shown here

It's not mine!

or

etc...

[flash=420,315:1nd228mp]http://www.youtube.com/v/dTGO_NR6YiA[/flash:1nd228mp]

-

And I am very curious to know how

they build in wood because you must make some very little decrease/ decrease measures against a computer 3D model!

(for easy sliding)

If you don't know the solution i don't see how that is possible

-

@woodarc said:Is anybody familiar with this system. I'm looking for details of the joints. The system apparently consists of 12 sticks with different junction details which connect without the aid of glues, nails or screws. I've checked out Amazon but with no joy. Any leads would be greatly appreciated. Many thanks in advance.

Reminds me of a system that I came up with in architecture school.

-

@unknownuser said:

And I am very curious to know how

they build in wood because you must make some very little decrease/ decrease measures against a computer 3D model!

(for easy sliding)

If you don't know the solution i don't see how that is possible

You can hardly make it exactly right in the Model because the 'cutting' has so many variables...

You make some 'clamped on jigs' on your table-saw or router-table [these depend what you are using to make the cuts!] for the max/min extents of the various cuts. You make some test cuts and see how they fit together. The jigs can be 'fine tuned' by adding thin paper shims between its parts to reduce the amount cut off [or by removing them to increase the amount that is cut off] ... until the test cuts fit snuggly together - if it's a dry fit you want a tighter fit that if it were to be glued as you have to leave space for the glue! Of course if you had one of the clever [but expensive] Incra jigs [ http://www.incrementaltools.com/ ] you could input 1000th of an inch adjustments until your cuts were perfect... -

Roger - that looks similar to a coffee-table I made over 35 years ago - remodeled in Sketchup...

Advertisement