Sketchup is Inacurrate???

-

The USA is already quite 'metric'...

You have had 'decimal' money forever.

You buy coke/pop in 'liters'.

Your cars have 'cc' engine data.

The US Army measure horizontal distances in 'meters' [but then heights in 'feet' - as do aircraft the world over!].

Most complex science in conducted in 'metric'.

So I expect that much of the US space-program is 'metric' too...Now if only we can get you into using a few 'metric lengths'...

I find it surprising that given the US's break with the UK just as the French were pushing their newfangled 'metric' system, that the US didn't adopt it too, much of the rest of the world did...

We are not trying to get you to adopt a decimal time or calendar system

-

Remember the Mars Climat Orbiter

Some millions $ in smoking vapors for error between unities in translation!

-

@tig said:

So I expect that much of the US space-program is 'metric' too...

:right. much of it is. unfortunately, not all of it.

we crashed a probe into mars by accident due to some imperial/metric conflicts

re:length.

all of our official land surveys etc are metric as well.. it's just the tradesmen that won't switch. I think most of us would be into switching but most of our materials are still sold imperial only.it's pretty much the govt and manufacturers of building materials that need to lead the way.

Edit. well, I see frenchy has beaten me to the mars thing

-

@unknownuser said:

That's a very good example Jeff

maybe one of these days I'll get the point across that I've been trying to

-

@arcad-uk said:

I can see the argument from both sides for arc offsets because in the past I've wanted both results. Ideally SU will be given true arcs at some point. But from this thread I now understand why things are the way they are and on balance from an architectural perspective I prefer to have any offset from an arc create a consistent (wall) thickness which is what happens now rather than tapering the arc section to maintain a vertex offset.

I guess I'm now flogging a dead horse but the way it works now doesn't give a consistent wall thickness. see my last upload in this thread which shows an example using an actual wall.

-

Hey, what's better than a dead horse to beat! Anyhoo, wouldn't you use follow-me in a case such as the one you show? That way you are certain to have a consistent profile along the path.

-

@andybot said:

Hey, what's better than a dead horse to beat! Anyhoo, wouldn't you use follow-me in a case such as the one you show? That way you are certain to have a consistent profile along the path.

it would be nice if I could. but if I were to put a 2x6 profile at the end of one of those perimeter edges (in my latest example skp) then run follow me, it would produce the exact same (bad) geometry as offsetting the perimeter then push/pulling the face upwards.

these two tools (offset/followme)use the same brain..

-

oh. learn something new every day... I guess this one is a dead horse of the highest order. Oh well, back to ACAD.

Edit: oh hell, I'm back for more. The profile width is absolutely correct with follow me, but why is it not correct in your example? (5.489")

-

@unknownuser said:

@unknownuser said:

That's a very good example Jeff

maybe one of these days I'll get the point across that I've been trying to

Your first example, the one that you think is correct, doesn't have a constant wall thickness.

The other one (by your standards being incorrect) does indeed have a constant wall thickness.I can see the occasional need for offsetting an arc to get predictable new arcs instead of curves with unpredictable radii. But here in your example the wall thickness is correct by using SketchUp's basic 'Offset' tool.

Why do you measure/dimension its thickness not perpendicular to its surface?

-

@wo3dan said:

...Why do you measure/dimension its thickness not perpendicular to its surface?

Let me put it this way: you use 2x6 for the base plate. It's not a 2x6 anymore in your correct example. It is in the incorrect one at the right, (scene 4).

Due to the correct offset method SU correctly calculate the (inside) lengths, etc. that you marked in red. This is exactly what you'll get when you cut the 2x6 to match the outside frame perimeter. -

@wo3dan said:

@wo3dan said:

...Why do you measure/dimension its thickness not perpendicular to its surface?

Let me put it this way: you use 2x6 for the base plate. It's not a 2x6 anymore in your correct example. It is in the incorrect one at the right, (scene 4).

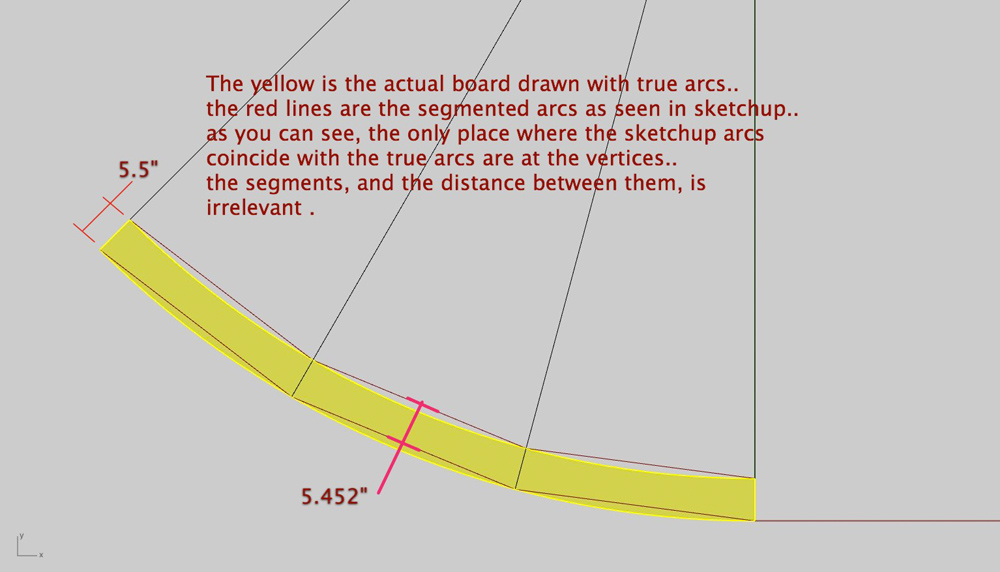

Due to the correct offset method SU correctly calculate the (inside) lengths, etc. that you marked in red. This is exactly what you'll get when you cut the 2x6 to match the outside frame perimeter.it's an arc.. the only point(s) on the arc that are true are the vertices.. the straight segments in between have nothing to do with it..

draw an arc with 2 segments… there are exactly three points that are going to be true.. those are the endpoints and the one vertex in the middle.. those three point will be the only place to accurately measure the radius.. these are also the only points where you can measure the thickness of an arced wall.

for all intents and purposes, i could do the same drawing using only guide points to represent the geometry.. the lines connecting the guide points do not matter at all..

notice for this wall, i have original arc with segments spaced at 12" (arc length.. not segment length).. the reason for that is because i also want the studs to be on 12" centers and they must be placed on the vertices to be true.. the can't be placed on the straight segments because things won't line up..

-

@unknownuser said:

there are exactly three points that are going to be true

It's better than a broken watch who give the good true time twice a day!

-

maybe this helps? (rhino)

.

-

Why does this matter? Is the project going to be build with a CNC machine or by a carpenter? The carpenter will read and cut to the correct dimension. A CNC machine the will facet the curve incorrectly. How many buildings are built with CNC machines. This is an honest quest as I don't know if it really matters. For a machine designer it would be critical if CNC is used in manufacturing. If the plans are meant to be read by a human and are annotated properly I don't see the problem.

-

@roger said:

Why does this matter? Is the project going to be build with a CNC machine or by a carpenter? The carpenter will read and cut to the correct dimension. A CNC machine the will facet the curve incorrectly. How many buildings are built with CNC machines. This is an honest quest as I don't know if it really matters. For a machine designer it would be critical if CNC is used in manufacturing. If the plans are meant to be read by a human and are annotated properly I don't see the problem.

lol.. you're right.. the carpenter will read and cut the dimension given.. only it's the wrong freaking dimension

-

@andybot said:

oh. learn something new every day... I guess this one is a dead horse of the highest order. Oh well, back to ACAD.

Edit: oh hell, I'm back for more. The profile width is absolutely correct with follow me, but why is it not correct in your example? (5.489")

it's because you're measuring the arc wall at the wrong point.. i want to build a curved wall -- not one consisting of a bunch of straight 2x6s mitered together (in which case yes, the 5.5" width would be proper)..

but it's an arc -- and theonly place an arc is accurate in sketchup is the vertices.. you have to measure your arcs/circles etc from there..

edit.. for instance.. draw a circle in sketchup then draw a few diameter lines across it… the only place where the lines will be the true length are at the vertices.. if you draw a line connecting a segment to a segment, it's going to be shorter than the actual diameter

-

Are you beating your head against a wall there?

-

It's for that is not very cautious to build an atomic Plant from Su but no problem for draw it!

-

@unknownuser said:

@roger said:

Why does this matter? Is the project going to be build with a CNC machine or by a carpenter? The carpenter will read and cut to the correct dimension. A CNC machine the will facet the curve incorrectly. How many buildings are built with CNC machines. This is an honest quest as I don't know if it really matters. For a machine designer it would be critical if CNC is used in manufacturing. If the plans are meant to be read by a human and are annotated properly I don't see the problem.

lol.. you're right.. the carpenter will read and cut the dimension given.. only it's the wrong freaking dimension

I would say the problem is with the architect who inserted his dimensioning at the wrong point on the drawing. In this case wouldn't you insert your dimension at the vertice where the measurement is correct? Or manually change the dimensioning if it MUST be inserted at another point? Not arguing, just filling gaps in my knowledge.

-

@roger said:

I would say the problem is with the architect who inserted his dimensioning at the wrong point on the drawing. In this case wouldn't you insert your dimension at the vertice where the measurement is correct? Or manually change the dimensioning if it MUST be inserted at another point? Not arguing, just filling gaps in my knowledge.

the real solution is to draw it accurately in the first place. that way, the drawing is accurate and the dimensions are accurate... and any subsequent geometry in the model will be accurate and so will those dimensions.. and so on and so forth.

drawing sloppy then editing dimension is both hack and inefficient..and again, you can draw this wall accurately in sketchup and obtain proper dimensions etc. it's just that you can't use certain tools (which should be the right ones for certain situations) to obtain the true dimensions.

Advertisement