Working with wrought iron

-

I'm modeling a car from a 60's TV show, and it has some wrought iron scrollwork. I thought it would be pretty easy to do the scollwork, but apparently I was on drugs when I had that thought. Maybe there's a plugin that would make the whole process a snap, but there are so many plugins available, and their names often have little to do with their true function, that I gave up going thru the list.

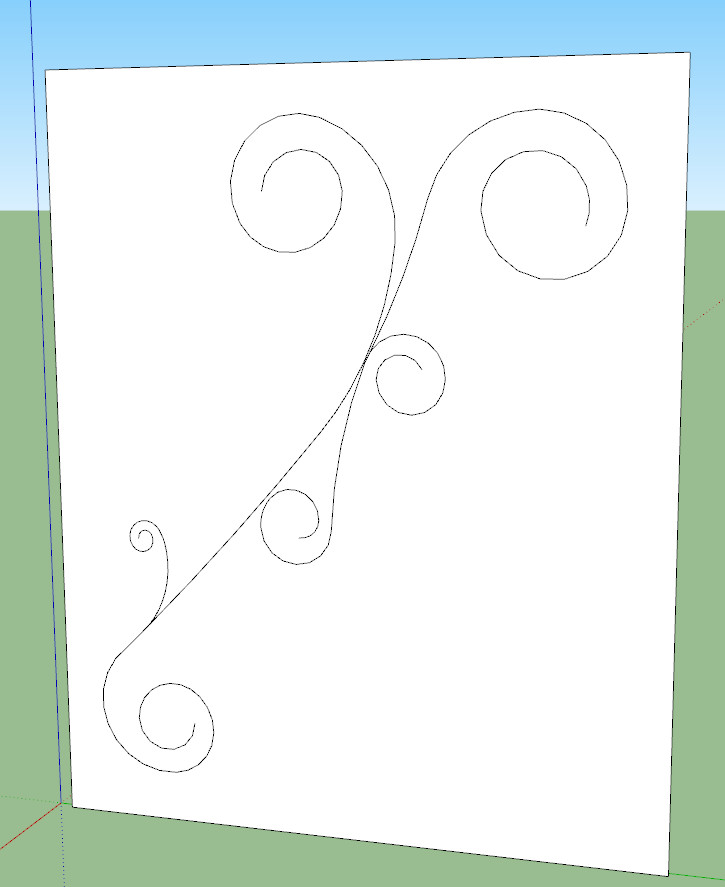

I need this

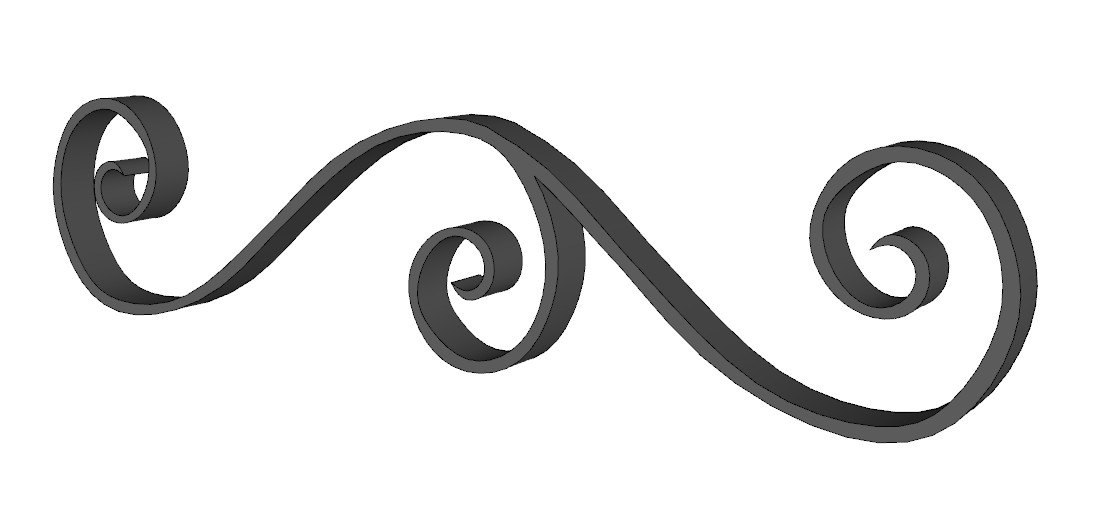

to look something like this

I've attached the skp file, but I don't want someone to just do it for me, I need to know how to do this.

Any suggestions would be greatly appreciated.

-

Curve maker will do it.

-

how about extrude line and then joint push-pull on the resulting surface?

-

@andybot said:

how about extrude line and then joint push-pull on the resulting surface?

Yeah, I had joint push/pull in mind from the start, but all it did was make some very weird shapes. Just doesn't seem to work with this shape at all.

-

Sorry, didn't realise it was the thickness you wanted, Follow me as a native tool or Profile builder, http://www.smustard.com/script/ProfileBuilder might help.

-

maybe?

-

Have you tried ShapeBender?

-

@unknownuser said:

maybe?

Thanks, there are several pgms there that look very promising. How the heck do you keep track of all the stuff available out there for SU?

-

Thanks for all the fast responses, I will check out each suggestion and see what they can do. Maybe they won't work for this particular problem but will come in handy for other things. Thanks again

-

-

@dave r said:

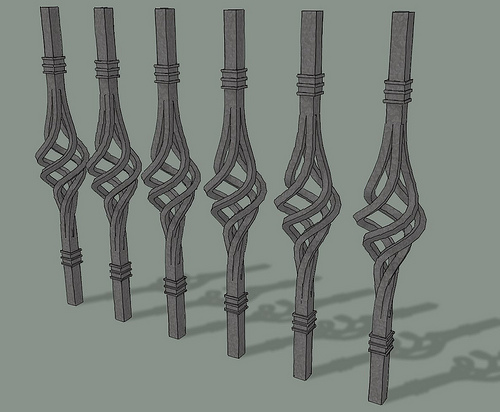

Once you get that wrought iron work down you can work on something like this:

Yeah right, as soon as I get that brain implant I've been saving up for

-

Christmas is just around the corner. Maybe Santa will leave you one in your stocking.

-

you have the hard part done which is drawing all those curves

see this sketchup for the rest:

that's all done with regular sketchup tools..

i would recommend one plugin for this stuff and it's called recurve.rb.. it has an option for you to select one of the line segments then it will select all the connecting segments to it and join them into one curve.

[edit] here's a link to recurve.rb:

http://forums.sketchucation.com/viewtopic.php?t=36822[edit2] just noticed your desired output has sharp ends instead of the square ones in my drawing.. i think you can figure that bit out yourself

-

@unknownuser said:

Dave R wrote:

Once you get that wrought iron work down you can work on something like this:

And the way to make it for real:

http://www.youtube.com/watch?feature=player_detailpage&v=l1_tF67B9CA -

Cool! Thanks for that link. I made something similar in silver and in copper when I was in fine art school many moons ago. I used them for handles on some small vessels I made. It was fun to watch one being made in iron, though.

-

That really was cool. So tell me, I assume the bar was made up of four bars, so how was it made "solid" except for the section that was twisted?

-

It's welded together at the ends.

-

@unknownuser said:

[edit2] just noticed your desired output has sharp ends instead of the square ones in my drawing.. i think you can figure that bit out yourself

Actually the scroll work on my model does need the square ends. The pointy ends just happened to be on the example I pulled from the warehouse.

Thanks for the skp file, it's so tempting to just use it (not that I would do anything like that

)but this weird model is gonna need a fair amount of this stuff so I just gotta buckle down and get it done. Probably the only time I'll ever need anything like this since I only work with car models, but what the hey.

)but this weird model is gonna need a fair amount of this stuff so I just gotta buckle down and get it done. Probably the only time I'll ever need anything like this since I only work with car models, but what the hey. -

@dave r said:

It's welded together at the ends.

Oh. I was hoping there was some magical secret to it

-

They're welded together by black dwarfs in underground caves.

Advertisement