[Plugin] SectionCutFace

-

TIG,

On demand working great, on my Mac. No go on the auto update, which is OK, as I usually have 10-20 cuts per model, and don't mind refreshing them to keep things running smoothly.

-Mike

-

Donation on the way!

-

Hi! ive just installed this plugin...with SU 8 pro... and it still doesnt work...and I really read all of the posts about this,and still it doesnt...please help

-

@stuczynskakatarzyna said:

Hi! ive just installed this plugin...with SU 8 pro... and it still doesnt work...and I really read all of the posts about this,and still it doesnt...please help

You report is not much use!

How doesn't it work ?

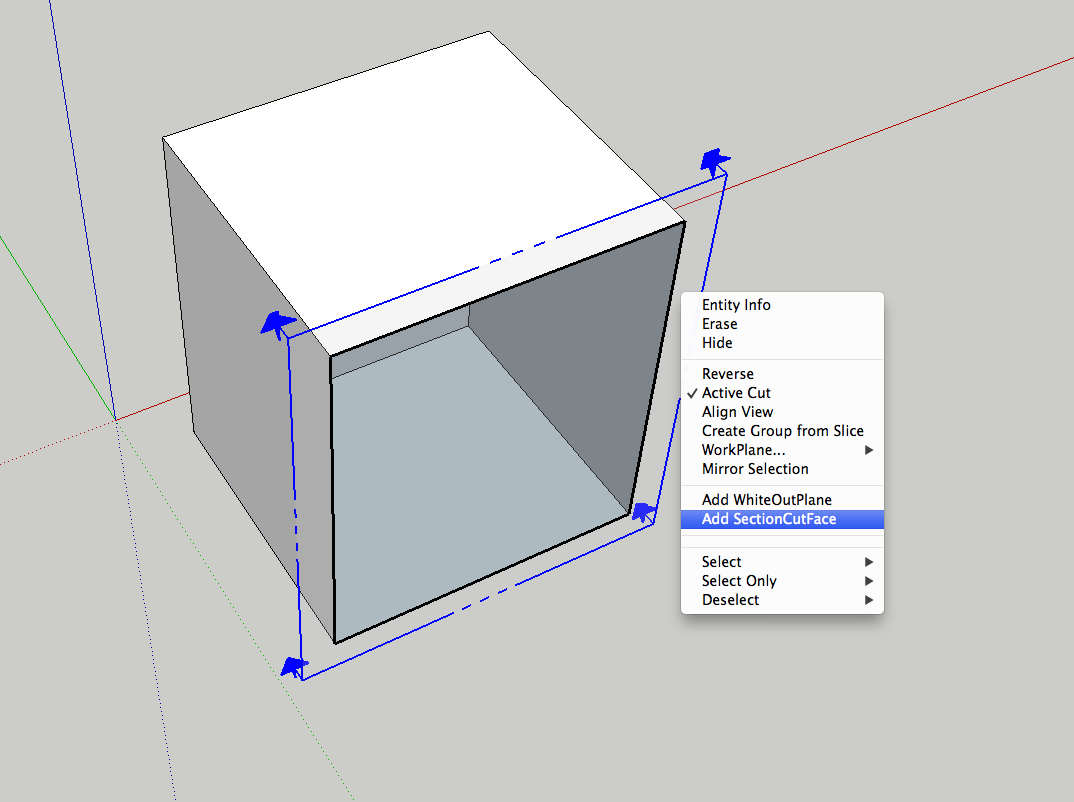

Does it appear in the right-click context-menu if you have just one SectionPlane selected ?

If so then does it open a dialog ?

If so then does it add a cut-face group on the plane ?

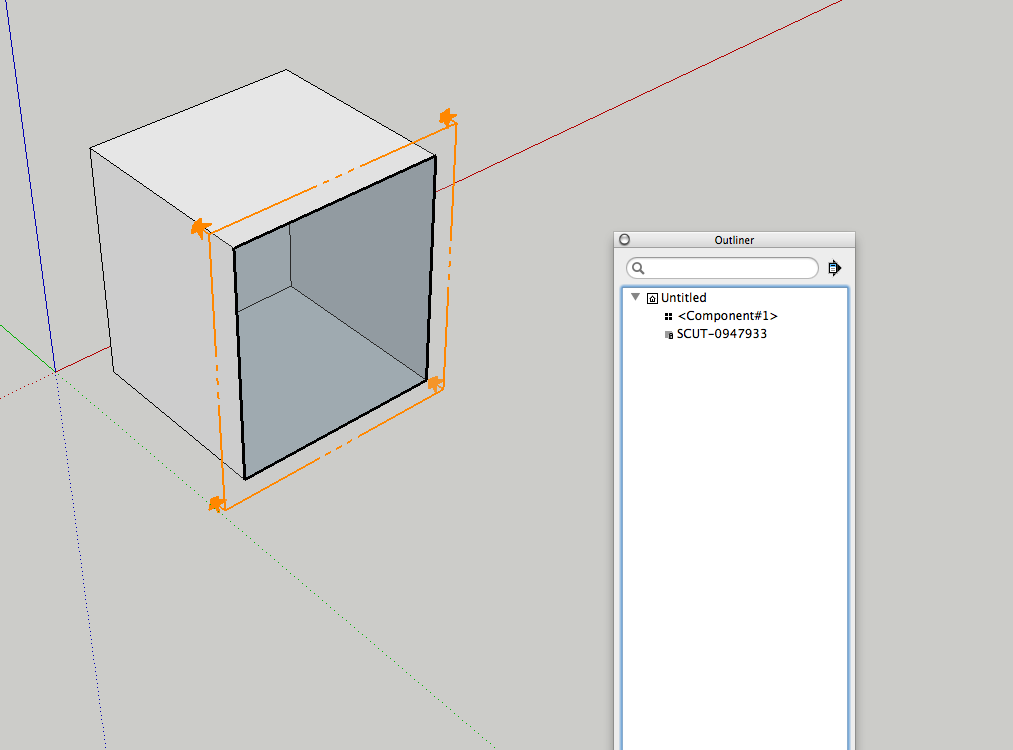

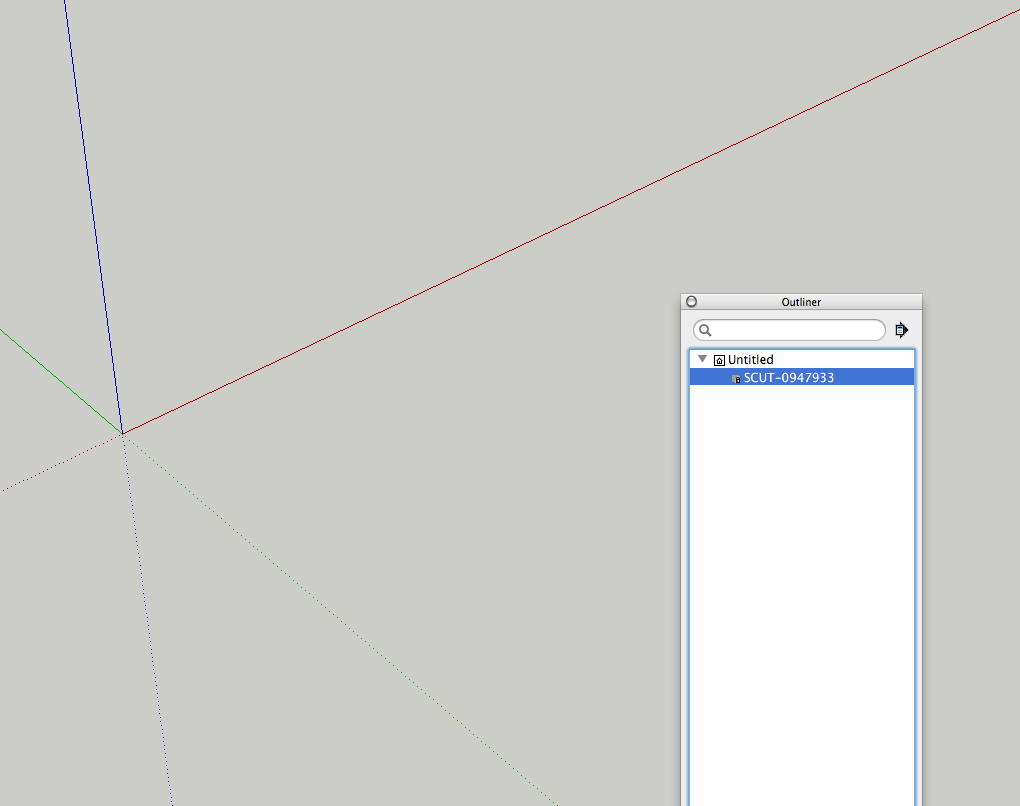

You can check this in the Outliner, it's called 'SCUT-....' on a layer of the same name.

If you set Glue to No/Yes/On_Demand you get different outcomes: No is not lined to the SectionPlane and stays unchanged where it was first made when you alter the SectionPlane or the model itself. Yes links the cut-face and the SectionPlane and it should update dynamically as the SectionPlane or model is altered [this is nor recommended for complex or multiple cuts], On_Demand does link the cut-face to the SectionPlane but it only updates if you select it and use the context-menu item to 'Redo' it when it updates [without a dialog] using the previous settings [color etc]...If you never get the context-menu it suggests that it is not installed correctly.

How did you install it ?

There are three possible ways you might have done this [you might have told us!]

You AutoInstalled the tool from the 'SkecthUcation Plugin Store' dialog's red-button, from within SketchUp itself.

You Downloaded its RBZ archive from the SCF PluginStore and used Preferences > Extensions > Install... button.

You Downloaded the RBZ, then changed its suffix to .ZIP and extracted its contents, then moved the tool's file/subfolder into the Plugins folder manually.

Restarting SketchUp to activate the tool.Can you see the tool's file and subfolder within the Plugins folder ?

Do you have a link/button on the Plugins folder's Windows Explorer window, named 'Compatibility Files...' ? If so tis suggests you have insufficient security-permissions to your Plugins folder.

You must have the security-permissions to your Plugins folder set to FULL - otherwise tools often fail to install properly [without telling you] and can even appear to be there, BUT are actually in a 'VirtualStore' as Windows protects you from yourself - the default for all files/folders in the Program Files ttree is 'read-only'. Also some tools need to write files/folders into the Plugins folder and fail if the permissions are restricted !

To fix this [with admin-powers] select the Plugins folder's icon, right-click context-menu Properties > Security > Edit and set very entry in the list to have FULL permissions.Also set SketchUp.exe to 'always run as admin' - Properties > Compatibility chec-box...

There are probably some other possible causes, but this list should give you the most common suspects...

-

nothing happens on mine, i right click, go through the choices but no result - however it may easily be my complex plugins configuration, so don't take this as a bug. shall report further when i have more time to play with it.

-

@cadfather said:

nothing happens on mine, i right click, go through the choices but no result - however it may easily be my complex plugins configuration, so don't take this as a bug. shall report further when i have more time to play with it.

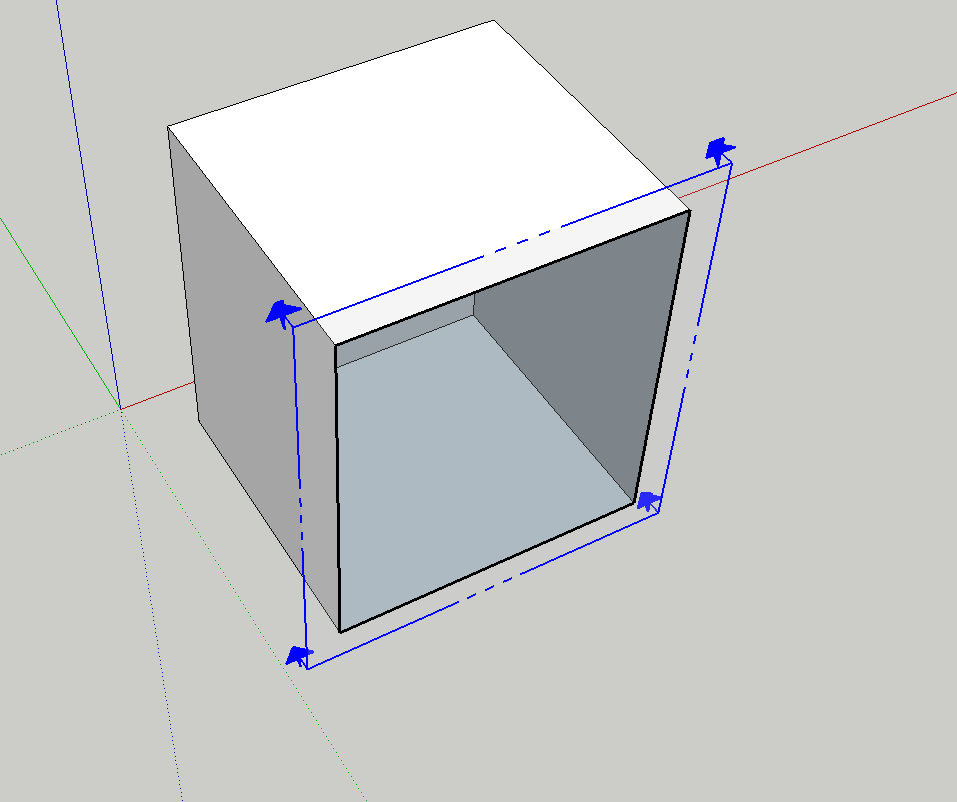

If you do a No glue version and move the SectionPlane back a little can you see the cut-face.

The cut-face can't be located on the SectionPlane because you wouldn't then see it [like if you snap a SectionPlane onto a face the face is not shown], so it's moved 0.2mm into the cut so it's then visible.

This 'offset' is a compromise between the cut-face's visibility and it looking right - obviously you don't want to see that the cut-face is not on the plane itself!

Occasionally some users setup/GC etc will still take the cut-face as being on the SectionPlane and so you don't see it, although it's there...

If that's the case there is an offset value of 0.2.mm in the code that can be adjusted slightly to see if that helps...

I can either update the tool with a value that works for you all of you [perhaps compromising the appearance slightly for many] OR add an 'Offset' option with is 0.2 and lets you enter a bigger value till you get it right for you - as an editable parameter in the loader rb file, like the others used in the dialogs...

-

Thanks TIG, that makes sense - i'll have a proper play with it later on, and 2mm sounds just fine to me.

Edit 0.2mm!!!

-

This is because when it's on a face it makes a visible 'section' BUT the cut itself intersects nothing - because the plane doesn't actually intersect with the object ! It's as if you drew a large grouped rectangle over the face then edited the contents and selected the face and used 'Intersect with model' - it has NO intersection as the two faces are 'coincident'.

I can fix this by nudging the cut say 0.2mm into the section, then it will should intersect and face...

I am about to fix another issue so I'll add that...

-

@tig said:

This is because when it's on a face it makes a visible 'section' BUT the cut itself intersects nothing - because the plane doesn't actually intersect with the object ! It's as if you drew a large grouped rectangle over the face then edited the contents and selected the face and used 'Intersect with model' - it has NO intersection as the two faces are 'coincident'.

I can fix this by nudging the cut say 0.2mm into the section, then it will should intersect and face...

I am about to fix another issue so I'll add that...

I get that. I never use this on faces, so for me this was an example of why someone might not see it working.

I should have been more clear.All good on my end.

-

Note that if you use this on a face you might not see it working.

It doesn't show up, even if I check the outliner, it is there, but not visible.

I can move the section cut fore and aft, and even delete everything, but still can't see the cut.

But as soon as I move the section cut and regenerate the cut face, it works.

Edited to clear up my intention, see below.

-

Here's v3.7

http://sketchucation.com/forums/viewtopic.php?p=172583#p172583SectionPlanes that are snapped exactly 'on-face' will now cut geometry to match the visual section, by making the cut-face 0.1mm inside the visible section.

A new option in SectionCutFace_loader.rb to change 'Inset' to > 0.1.mm, needed for a few users whose GC's leave section-cuts not showing when they are regarded as still being not 'within' the viewable section... -

Sketchup is getting better and better thanks to you guys!

The new automatic glue option made me wonder.. have you considered, besides of using a solid color, creating the possibility of using the backface material (texture) of the faces ?

Like that the front faces of the walls, window frames, slab floors etc (all solids of course) could have a 'visual' texture on the front faces and the backfaces could use their corresponding hatch textures. Especially with the new glue-option it would be amazing if the section would 'automatically' be texture mapped with all the corresponding hatches.

During the design process I manually texture the section cuts (only for the final documents I manually create real line hatches) and the above would be a great time-saver.

Anyway, just a thought.

Greetings!

Max

-

Thanks for the explanation TIG, even if I got there myself it took me some time. I was almost going to post my Locale incident as a bug in your plugin.

I made a small change in your naming of the list in the translation. Where you refer to "Glue" wich in portuguese is "Colar" I translated as "Auto-Regenerar" wich actually means "Auto-Regenerate". I hope you don't mind, but if you do, there you have the literal translation.

There could be a warning about this feature it is both powefull and dangerous...

V3.7 in such short time... you code faster that I can write!

Best regards,

JQL

-

hi TIG, i wanna know why even if i restart my sketch up, or even my laptop, the section cut plugin still isn't load in my sketchup Pro 8? i did copy and paste the plugin into my plugin folder.

-

@teresaytw said:

hi TIG, i wanna know why even if i restart my sketch up, or even my laptop, the section cut plugin still isn't load in my sketchup Pro 8? i did copy and paste the plugin into my plugin folder.

Where are you looking for it?

-

If you had read the instructions a little more carefully you might have noticed that it is a [right-click] context-menu only tool.

AND it only appears in the context-menu when you have a selection containing just one object - which must be a SectionPlane.

That is how the tool determines where to put its SectionCutFace...Where else did you expect this tool to 'appear' ?

We are of course assuming things here... that the .rb file etc was indeed in your Plugins folder and is therefore auto-loading. If you did a manual installation and you have restricted security permissions to your Plugins folder it can appear that you have installed it OK, but it's really gone into a 'VirtualStore' folder - having 'Compatibility Files...' link/button in the Plugins folder's Windows-Explorer top bars in a dead give away! Fix you permissions [Select the Plugins folder icon > right-click > context-menu > Properties > Security > Edit, set to FULL for everyone listed...] then retry installation...

Alternatively get the RBZ from the SketchUcation PluginStore page, and use the installer supplied with v8.

OR use the SketchUcation Plugin Store toolset, when you can AutoInstall the tool from a dialog within SketchUp itself...

Both of these options link via 'More Info...' to pages covering every tool's usage very comprehensively... -

Cheers TIG!!

What this plugin does is the kind of "update" many of us seculars wanted to see in SketchUp 2013... am I wrong? I mean, it doesn't even require an additional icon they (The spirituals) are said to be so afraid of...

As I have taken a long, winding and masochistic LayOut path just like many of SCF members here, your SectionCutFace plugin is already indispensable.

....donation is definitely on the way!

-

Oops.

"PayPal does not currently support Donation Payments from buyers in JP. We apologize for any inconvenience this may cause."

So is there other ways? -

@takesh h said:

Oops.

"PayPal does not currently support Donation Payments from buyers in JP. We apologize for any inconvenience this may cause."

So is there other ways?

Just save it up.

Or give a donation to another worthy recipient, on my behalf

-

Hi TIG.

@tig said:

Just save it up.

Or give a donation to another worthy recipient, on my behalf

Roger, Sir.

Advertisement