Edge bevel question

-

that's pretty tough to do in sketchup.. how accurate does it need to be and if accuracy is important, do you want the same radius all the way around with a fluctuating offset or the same amount of offset with a fluctuating radius?

-

try using intersect with model and then delete the unwanted geometry

edit: nvm misread the question

-

Well, I'm for a simple bevel, like the one at the top of the nested shape.

By the way after some tests I believe is not possible to achieve it in SketchUp.

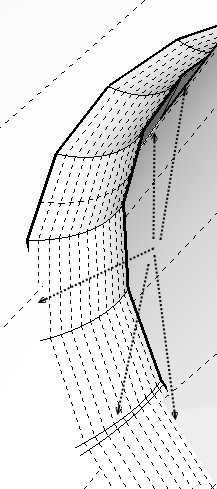

It looks like the problem is the base of the cylinder is curved in two ways: as a circle and as laying over the underlying curved surface. -

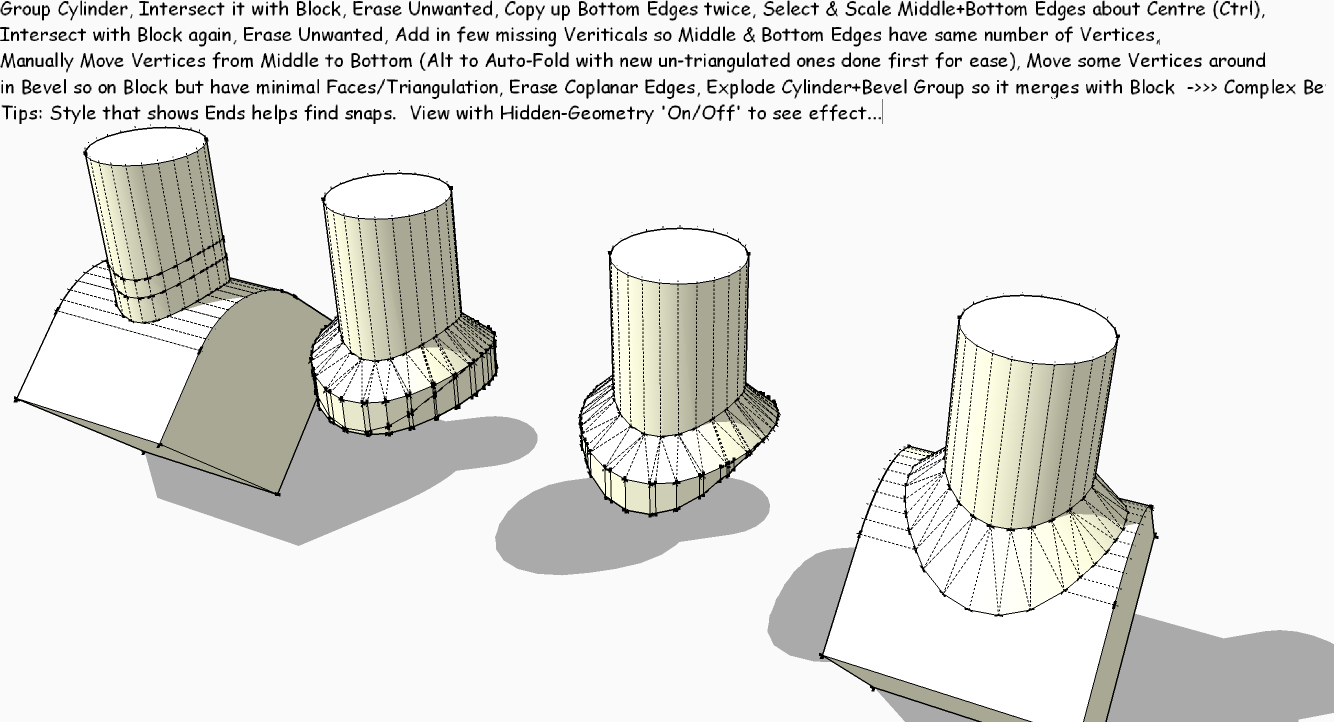

See the attachment. It's not a perfect way, but you can experiment with it.

-

-

I wonder, could Chris' Bend plugin be used here?

-

Thanks for your help, guys!

I like TIG solution best, but man! That's a crazy workflow to bevel an edge!

OK, we'll survive, gonna play around that...

-

the problem is that the angle between the tube and it's mating surface changes..(in the original post's picture, the area near your arrow is an obtuse angle and changes to 90deg at the sides).. that drawing also shows that you're not wanting a simple bevel rather a radius..

TIG's drawing makes more sense of what i was getting at in my first post in that the amount of offset grows as it nears the top/bottom of the joint.. you could also do it where that amount stays the same and the angle changes..i put in a feature request for the subdivide&smooth plugin that would handle this nicely.

http://www.sketchucation.com/forums/scf/viewtopic.php?p=149839#p149839 -

In my version the offset stays the same and the bevel's angle changes the further down the curving block it is. Of course you could try having a constant angle bevel and then the offset would be variable... but against a curved surface that falls away there's a chance that it's never meet it...

You have to think how this might be done in 'real life' - after all, we are only modelling it as an approximation - chances are it would be a bit of both - on 'professional bodge'... -

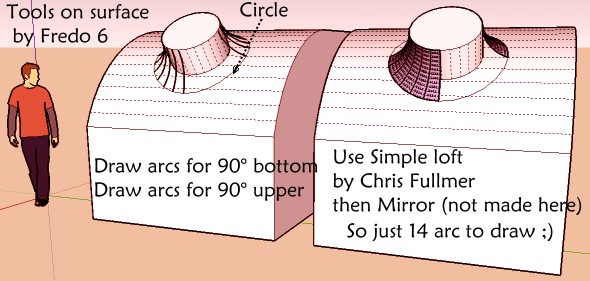

Pilou - great ideas...

-

I have forgotten to say : Mirror 3 points by TIG

-

Another solution

So it's a variable fillet (the best fillet but depending of what is needing

(the best fillet but depending of what is needing

Mirror by TIG

-

I was praising your thinking, I wasn't criticising you not mentioning my Mirror-tool !

[J'ai été en louant votre réflexion, je ne chante pas la critique de ne pas mentionner mon outil 'Mirror'!]

-

Of course yes, but the funny thing is that I did'nt remember the author of the Mirror plug, so when I saw that was the "Tiger", I could'nt resist

A cool thing will be a "sweep 2 rails" in SU so here Arc is the profil, Rail 1 = "circle 1" (curve 3D) , rail 2 = circle 2

So just draw one arc, one circle on surface and 2 clicks

-

@unknownuser said:

.it is just a follow-me with the bevel profile and then intersect

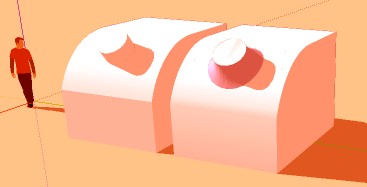

That will be wonderful but you can't

At some place upper profil can't "past" to the cylinder!

Result gives some crack fissures!

-

right, with a simple angled bevel, you could do it as modelhead is saying.. the 'bevel' shown in Carrozza's original picture will cause the problem that frenchy is showing.. the joint's intersecting angle doesn't remain consistent so something has to give when you try putting another radius in there. blending 3 curves together like that is always going to pose a problem because there are so many variables at play.

-

Yes it's a tricky edge to deal with.

To date Pilou's solution is the most clean and customizable.

Advertisement