looking for a little insight on a longstanding problem.

ill back fill with details as nessecery but basically it goes like this; i do custom metal work and one off assemblies. im trying to get a new workflow in place by going from concept to SU to torchmate cad to my cnc plasma. as it stands the dxf output from SU is somehow faulty, or at least thats how it appears. all ive been able to narrow it down to is what one app thinks vs. another. its a puzzle i cant resolve.

for example take a simple 3 inch circle with a 1 inch hole in the center. (2d, no thickness)

SU shows it as what it's intended.

then exported as a dxf, tmcad shows it as a dotted outter line with a solid circle where the hole was in SU. the only thing correct bit of it is the scale matches the scale it was created at in SU. on rare occasions it can be "repaired" by using the connect path feature in tmcad, but its more a thing of luck at this point.

that same dxf imported into adobe illustrator shows up as more of a screen shot. the scale is all wrong and its in perspective (or however it appeared when i exported it). it also shows it as an outter line with a 1" circle rather than the hole. what ive noticed in ai is that it thinks the single shape is actually a collection of separate lines which are not connected, therefore they do not make a face. you can zoom into a single point and they appear connected, yet if you select that single point, you can perform a join function as though they were two separate points. i experimented on a small simple model and you can in fact glue it back together a point at a time such that ai understands its a face and it can then be exported to tmcad which also understands its a face with a hole in it and then on to the cnc cutter as usual.

so - why the difference in what constitutes a "face" or a continuous line in SU vs. the other apps and is there a fix for this ? i really want to fit SU into my process but if i cant get parts out of it its not of much use.

many thanks in advance

BUT - i cant see it in su (or any other app) yet the apps know its there and its grouped or connected somehow which explains why any path type functions dont work; because its including this bit of text info as part of the model and i cant find it so i can delete it. the tm guru has tools the average human does not so he's able to see it - delete it - and do a connect path function and wala, all is well. i suspect if the text junk wasnt there in the first place you wouldnt need to do a fix like "connect path".

BUT - i cant see it in su (or any other app) yet the apps know its there and its grouped or connected somehow which explains why any path type functions dont work; because its including this bit of text info as part of the model and i cant find it so i can delete it. the tm guru has tools the average human does not so he's able to see it - delete it - and do a connect path function and wala, all is well. i suspect if the text junk wasnt there in the first place you wouldnt need to do a fix like "connect path".

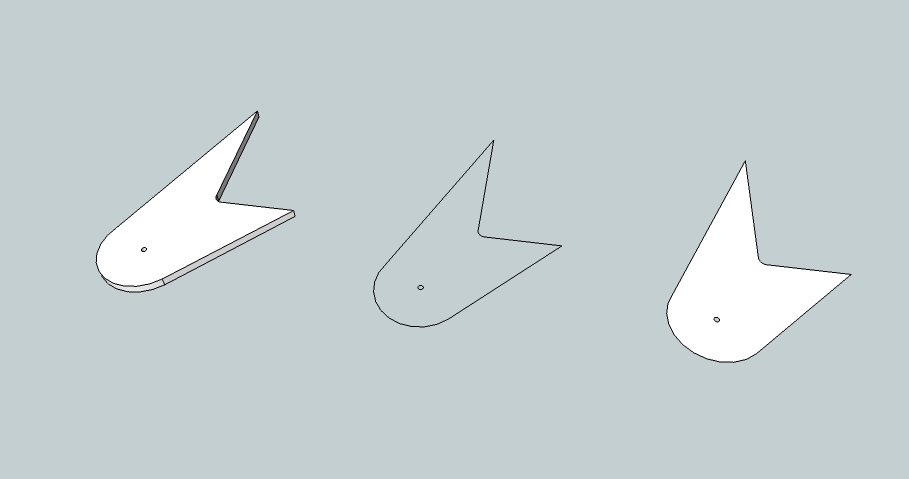

(but i managed to get some images out for a presentation)

(but i managed to get some images out for a presentation)