@chrisglasier said:

Here is an explanation I posted on Three.js forum.

... and a link to the new web workshop

@chrisglasier said:

Here is an explanation I posted on Three.js forum.

... and a link to the new web workshop

Here is an explanation I posted on Three.js forum.

Quote ...

My first post here; may I ask members what you think about marrying Three.js to Trail, Branch and Aspect interface?

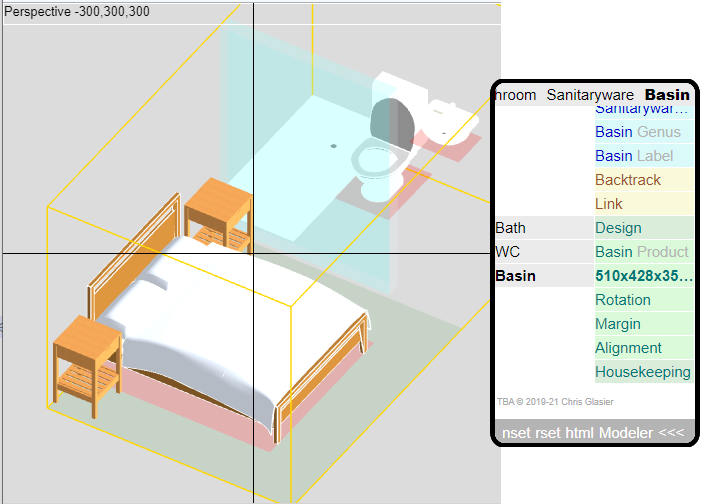

Small Three.js sampler scene created from selections in TBA interface

Though small, this work in progress illustrates how a hierarchy of ideas, assembled with TBA selections, is made into empty Groups and Objects, and then expanded with selected 3D models and manipulations from bottom up. I have used Collada models, TBA identities and link tools, and custom design tools for margins, rotations, x-axis positioning, y and z axis alignment, footprint, and division elements; setting up for more manipulations like handing, grouping, cloning, layering, animation and so on.

The main point of my post is that this is a completely different approach, in this case to building design processes, based on selection rather than drafting. I am hoping those who appreciate that, will contribute to one or more of its multiple facets, to help push the experiment forward.

... unquote

A long time ago I tried to promote something similar here. Now, I think there is greater awareness of the need for different ways of working since online productivity is more widely recognised. So I would like to re-introduce the idea of using models as the basis for such a new way of working.

As with Three.js, I am sure this forum's involvement will also help push the experiment forward.

@builder54 said:

Possibly a rivet joining to 2 clamps together.

Thanks for your input but my problem is really how to model a path that binds one tube to another at right angles when extruded as a tape or wire. Actually, I am thinking of trying plastic coated electrical wire as a durable and readily available material. It needs to have a waist to really tighten the binding; the salt-laden tropical winds can be really vicious.

@jean lemire said:

Hi Chris, hi folks.

What do you intend to use for banding ?

Can you post a picture or is it like shown with dry vegetal fibres (bamboo ?).

This is a better picture

It is very strong; sold in 600mm lengths. Not sure I can get in Sri Lanka, but other material will look similar.

@jean lemire said:

Hi Chris, hi folks.

See this SU file for ideas.

Thanks Jean,

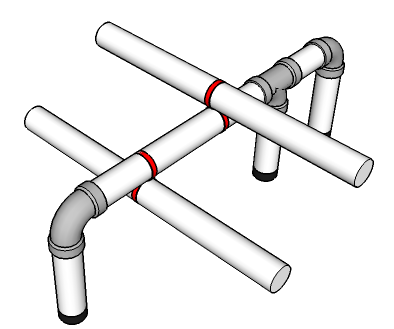

I am trying to show how the finished joint will look ... there are many ... a neater version of this type of thing.

The pipe runs are on a roof that is on the shore of the Indian Ocean, so I am proposing using PVC pipes for the gantries and some kind of PE banding to bind the existing PVC water pipes to replace this mess:

So I need to present the final new look to compare.

The installer creates a band like you have modelled but with a waist both to tighten and tie off the banding (hence figure of eight).

I tried but found that too much for me ... that is why I am back here!

Cheers

On the ear'ol again I am afraid.

I am looking for a model of a figure of eight with the top loop 90 degrees to the bottom. It is to strap two 25mm pipes that cross each other together.

@aikibrown said:

...Building Regulations have become more onerous.

Ah yes I remember them ... But here in Sri Lanka we can trip the light fantastic with homegrown teak and a wish and a prayer. Public liability insurance ... what ho!

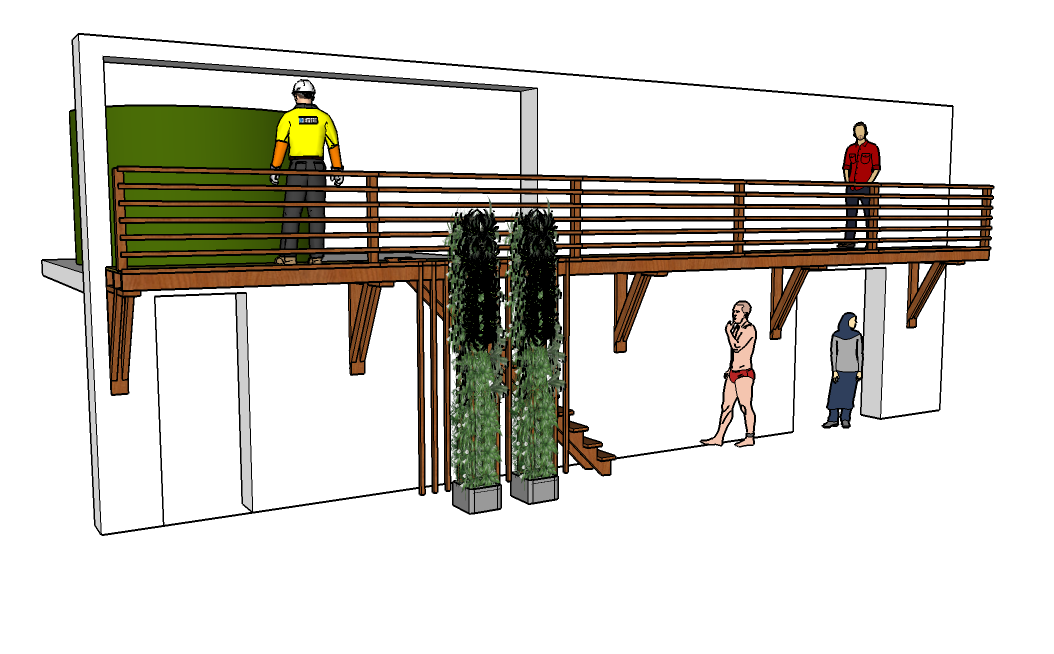

With people, water tank and Triffid

With people, water tank and Triffid

@baz said:

My two bobs worth: I would bring the brackets by the double opening as close together as possible, the span at present seems too wide. And possibly add another.

Thanks, I am just providing the concept and major components; another guy is creating the model from the cad drawings. An engineer will be involved. But your comments are noted as they say around these parts.

@baz said:

I would beef up the right angle corners of the brackets as well, there will be a large amount of lateral force on that joint.

Noted.

@baz said:

The access stairs worry me, are they removable? I wouldn't like to see a party up there

They are just for maintenance staff and Triffid pruner. It will have a hatch at the top. It is next to a small pool, so it is also a kind of drinks stand, clothes horse, poolside thing.Thinks, maybe extend some treads though the vertical trellis.

@dave r said:

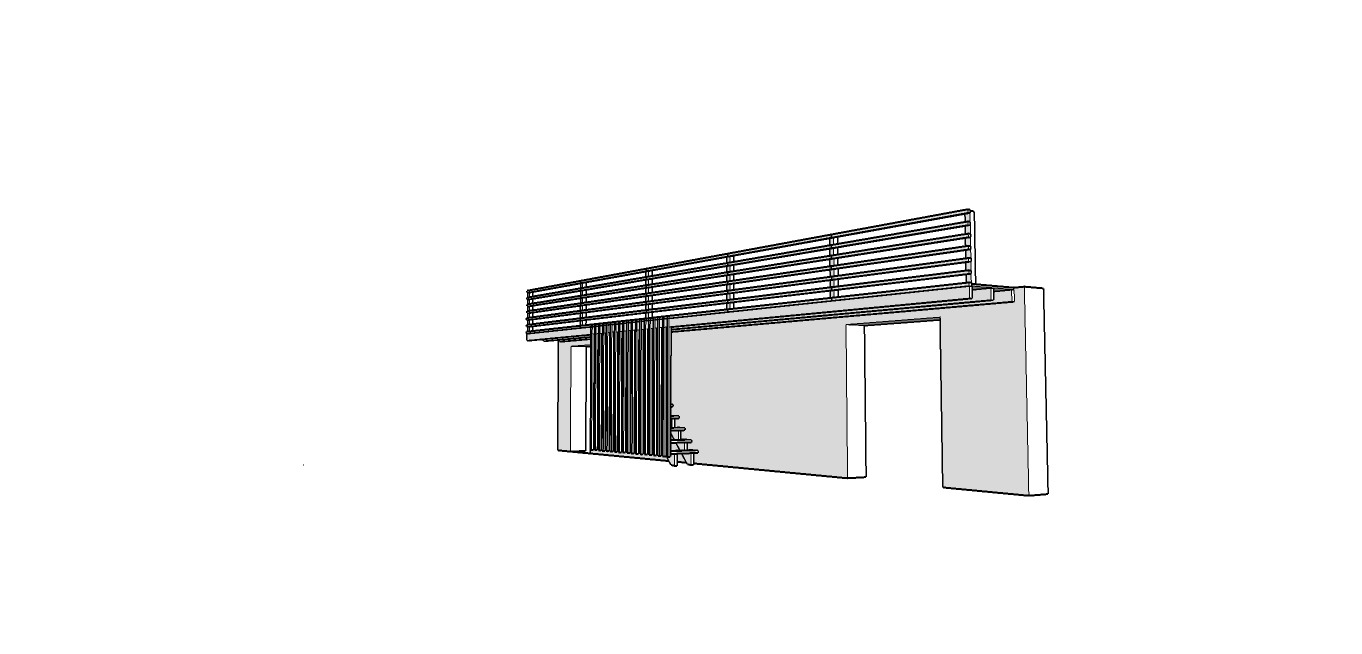

.... My guess is that the scantlings should be heavier and/or you will need more of them.

I think we will use Sri Lankan teak; so generally, like doors and windows here, section sizes are real slim. The one on the left rather picks up on that. I will model it and see what the locals think.

If there is a structural engineer reading this, would be most grateful for informal advice.

And thanks again Dave; always good to prey on your kindness!

Chris

@dave r said:

I don't have anything on hand but if you were to show images of the sort of thing you're after I expect they'd be easy enough to model.

Something simple like these but a little less chunky if possible. I know you know about sizes!

Please move the post to proper place if possible.

Cheers

Chris

@dave r said:

Out of curiosity,why did you put this in the SketchUp Bugs category?

Old age and late nights. Will send some ideas this weekend; thanks for the offer.

Dave R or anyone, if you happen to have a model of a bracket to support this walkway, my residents' committee would be most grateful. It is to access a water tank room, but also serves as a framework for Wisteria or somesuch climber. It is 800mm deep. It needs only to take the weight of a single gardener pruning the Triffid.

@dave r said:

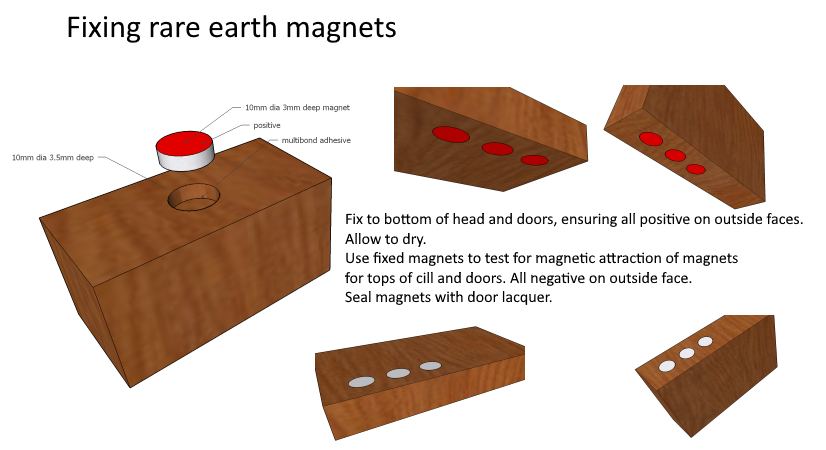

Can the magnets be set into the door a little farther and covered with a plug or a veneer of some sort?

Yes I did think of that. What I have shown is the fallback position. I might be able to source black plastic discs. They will do it on site despite the fact they have a big workshop - such is the way around here in Sri Lanka. Will post a pic when (if it ever) it comes to fruition. Your advice always appreciated.

@dave r said:

When you do get a model set up you can show it.

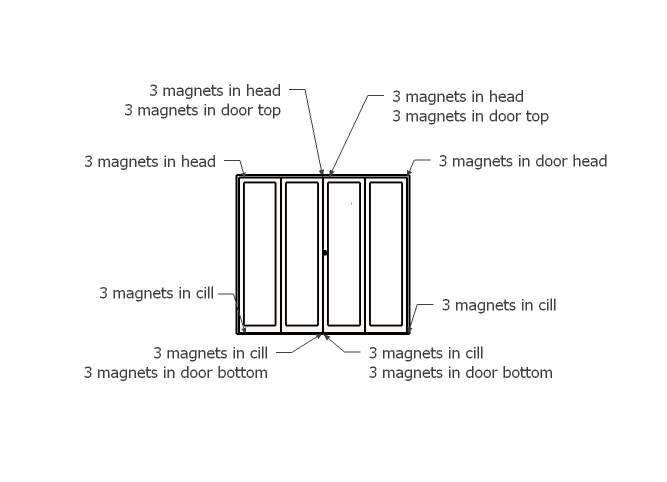

I did try as you suggested but the magnets are just too small and the screen too big. Also the procedure to get the polarity correct is probably the most important aspect. (I thought of painting the positive side but they are uncontrollable and can only be separated by sliding I did not at first realise just how strong they are.). So I just did this to help explain on site.

@dave r said:

.... transparent material on the doors if you want to do it in one image. ...

Thanks Dave. I will try that as I want to do a little bit of animation and allow the Singhalese-speaking woodworker to orbit to see what's what. The french doors fold back 180 degs against fixed counterparts and their magnetics are attracted to different magnets in the frame head and cell in open and closed positions. If I had a working model I could show you!

Nice steam engine by the way ...

I am want to show the location of sets of 10 dia x 3 mm rare earth magnets let into tops and bottoms of timber doors and frames. I would like the magnets to show up with coloured faces. Is this possible? I am getting too old to think how.

@moot said:

Also, I'd like to be able to clear the list when starting a new project...

May I ask if you found out how to clear it? If so, please tell!

@tuna1957 said:

Explode it and your back to the original, see if that makes a difference in behavior.

Makes sense (works) thanks! Any tips how to anchor, for example, the horse to the center of the shelf?