A Recent 3D Printing Project

-

@Rich-O-Brien I'm not open sourcing the print files yet but we'll see. This is going to a friend to test to see if it's even going to be useful.

Cool story about the sock remover. Maybe something like that would happen for me.

-

can i have the stl file please

-

@fransko what stl file? If you are referring to the one for the clips I showed in my first post, no, I don't give away my model files. Sorry.

-

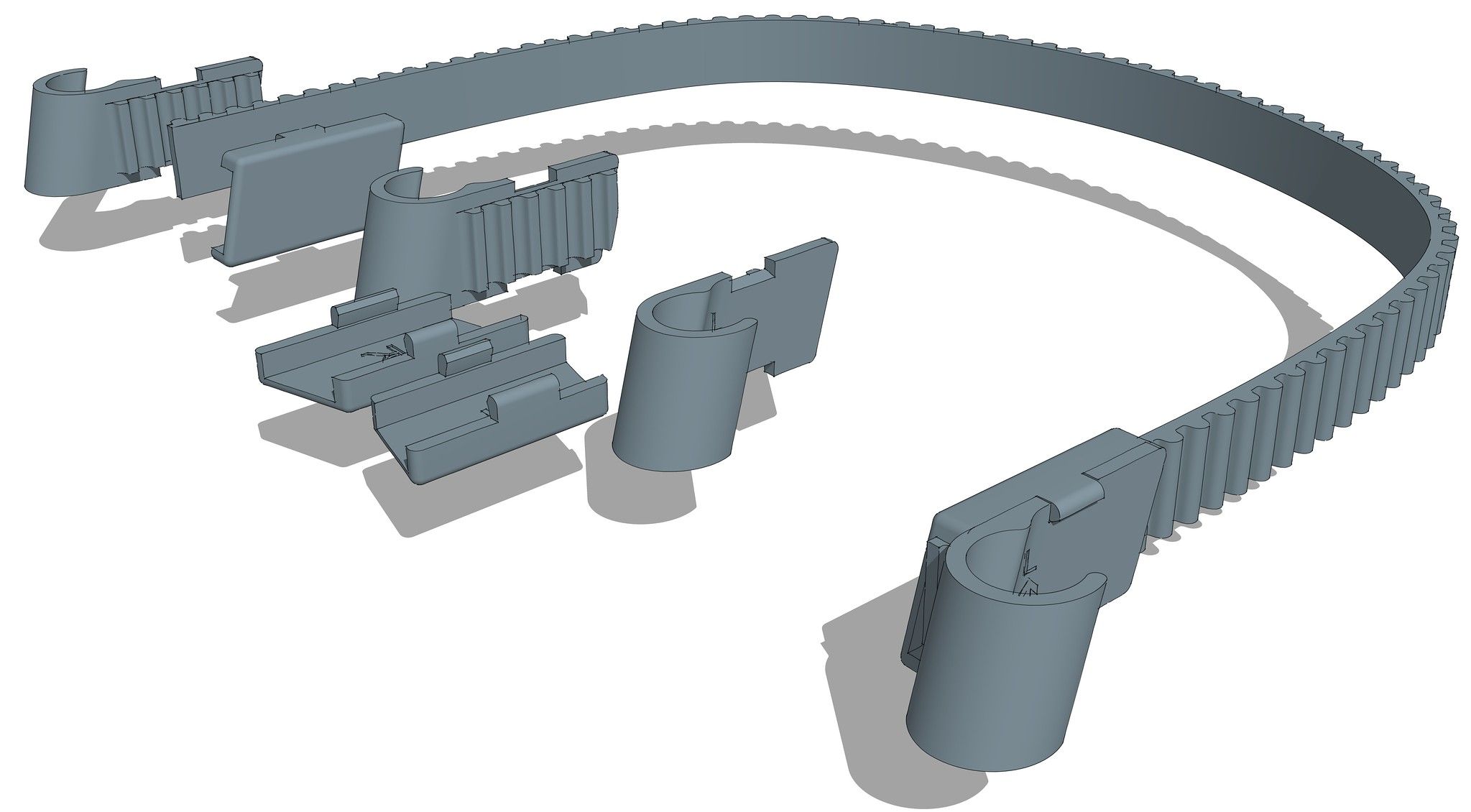

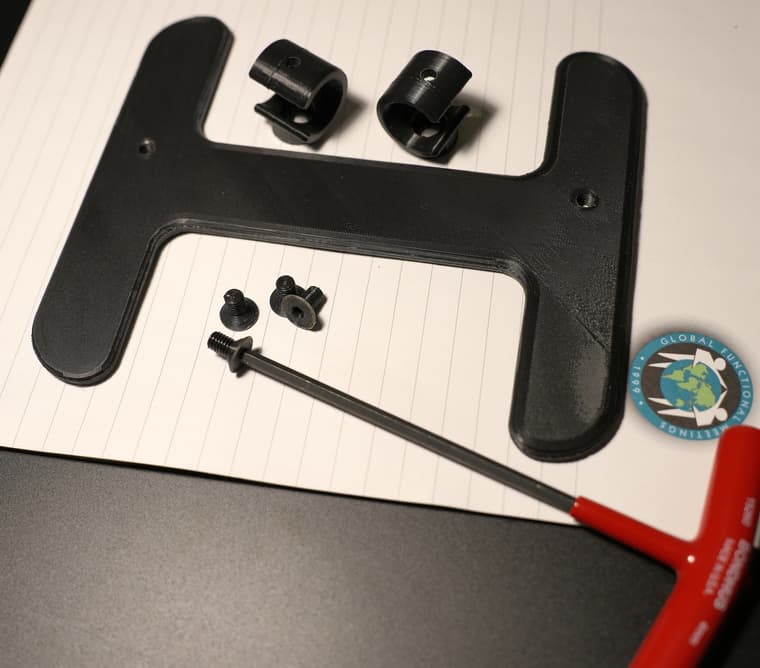

A few more 3D printed things.

The H-shaped thing fits into the back pocket of a waist pack style camera bag and the C-shaped clips attach to it through the fabric with M6 screws. I printed some temporary ones while waiting for proper metal ones to show up. The 3D printed screws worked fine as long as they weren't torqued too tight.

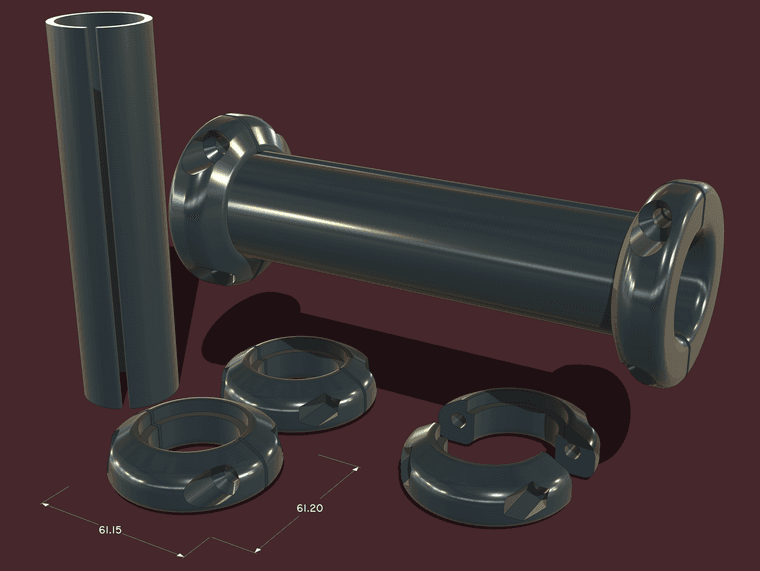

This is a sort of adaptor for attaching the bag on a new chair. The new chair's cross tube is farther back and larger diameter than on the old chair.

And here's the bag in place on the adapter on the new chair.

This is an auxilliary footplate with side guards to keep feet from falling off the sides. Temporarily installed for the picture. Waiting for screws and lock nuts to come.

-

VERY nicely done, SIr.

-

These are great examples of using 3D printing to much needed customised elements to disability aids. In particular personalised elements.

Probably at a fraction of the cost if you asked a supplier to create custom pieces.

-

@Rich-O-Brien thanks Rich. You're right. The bag adapter thing wouldn't be available off the shelf anywhere.

There are alternatives for the footplate thing but as you say, they are much more expensive. A friend had ones made of HDPE installed on her chair.

I think the price was about $250 or $300. My version has less than $3 worth of filament in it and I can't charge for the development time.

My version weighs about a third of the one she has.

My version weighs about a third of the one she has.@Mike-Amos thank you.

-

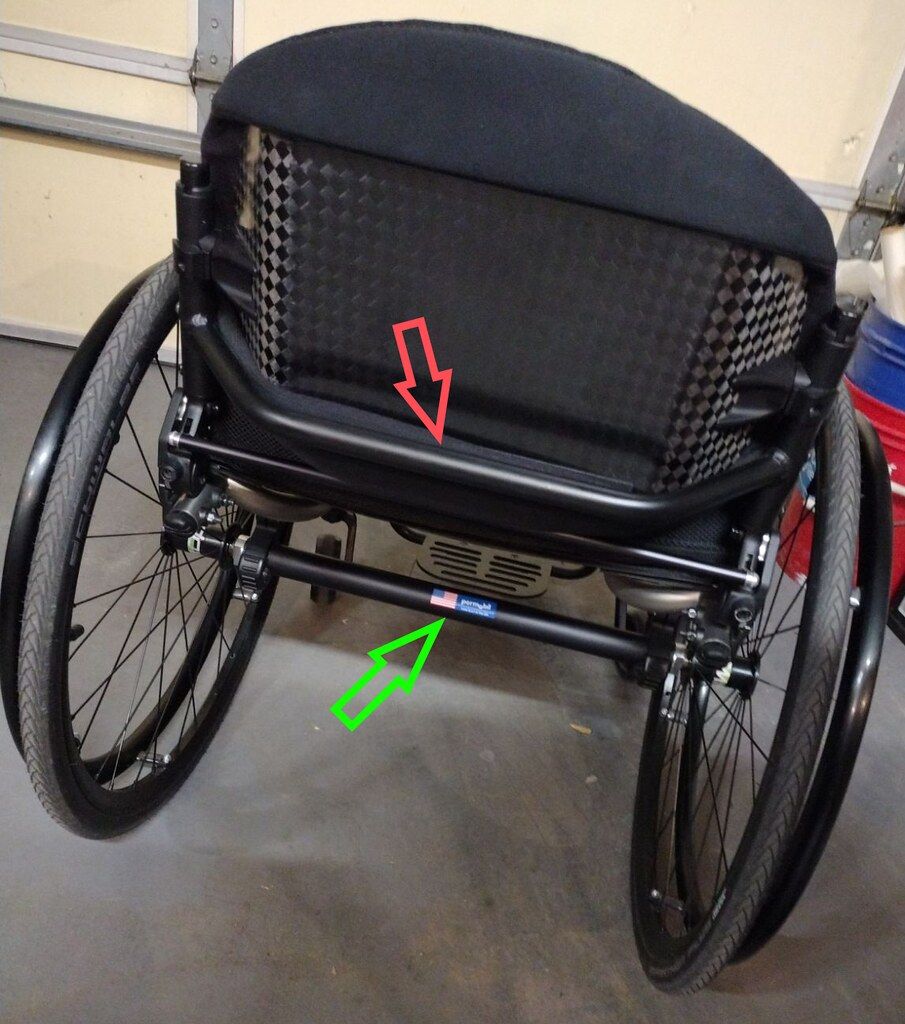

Another 3D printing project for a wheelchair. The tube was made of TPU and fits on the axle tube of a wheelchair to provide padding and protection from where a wheelchair lift picks the chair up. The rings clamp on either end of the tube and prevent the chair from shifting side to side. They were made of PETG.

The axle tube is indicated with the green arrow.

-

Is it to prevent wear and tear on the lift or to prevent the vehicle getting damaged?

Or is it a case that lift manufacturers and wheelchair manufacturers are not making compatible equipment?

-

It's to prevent wear and damage to the anodizing on the chair's axle tube. The lift is designed to be very generic and so it's not really an incompatibility thing. The lift is intended to pick the chair up by the 19mm aluminum cross tube on the backrest but that's not a real strong part to hang the entire weight of the chair from, especially on rough roads. I designed and printed some hooks to lift and support the weight of the chair by the axle tube. In the picture here https://flic.kr/p/2peh56W, there's some white foam tape that was used temporarily. It's not very durable, though.

Advertisement