Designing my new mower stand

-

As always truly masterful modeling and fine pure sketchup rendering!

-

Pretty darn cool..... could very well make some $$$ with this sort of thing if you were so inclined. Curious if you can find pre-made metal ramps that are long enough to allow the mower deck to clear on the way up. Most of the ones I've seen for sale would be to steep.

-

You must put that in the free Twinmotion 2019 (if you have loaded it) !

-

Pilou, is it a piano running here instead of a mower ?

Pilou, is it a piano running here instead of a mower ? -

@hornoxx said:

:shock:

wow! - what an unusual but even more cool and real project this is!! Excelent!

wow! - what an unusual but even more cool and real project this is!! Excelent!Much appreciated!

-

@HornOxx

Of course yes, (can be anything) because you can change personnage (above a building worker as pianist) and their Tools (Piano as mower) and their movements here following Building Workers can dance or make any movements of an existing animated personnages- Amazing!

Of course path is just limited by drawing basic step line (in x,y,z yellow bases) but it's better than nothing and largely enough for funny results!

Here only on (x,y) you see leaves moving just a little because strength of wind is too small !

but on z is possible too

And you can even modelize the terrain like the SU Sand box (but more easy) if you want !

A terrific free program!

May little animation above (the Pianist mowering) take me less 3 minutes to make! Terrain vegetation flowers etc...from zero!

-

@jenujacob said:

@hellnbak said:

...but when I'm having fun with a model I just can't seem to back off. And I did learn a LOT about my mower while researching everything....

I can totally understand this... glad to know that I am not the only one!

cool project though! keep us posted here!

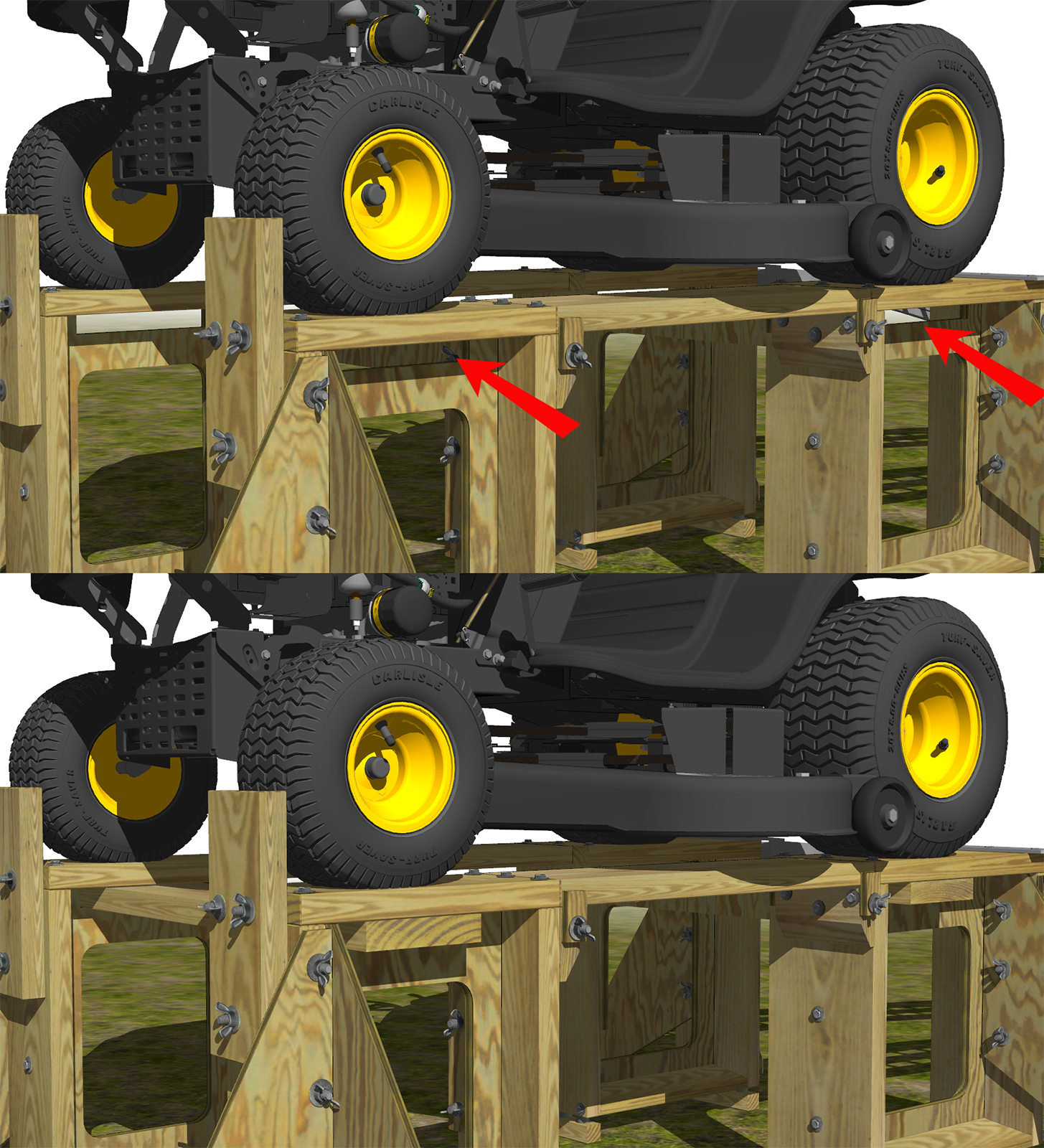

Thanks. It's still in the develpment stage. For example, I've decided to add some slots to let me slip in a plank in case I need to use a scissor jack to let me remove a wheel, or whatever

-

@pbacot said:

As always truly masterful modeling and fine pure sketchup rendering!

I appreciate the kind words (keep 'em coming)

-

Very cool and clever design!

-

@tuna1957 said:

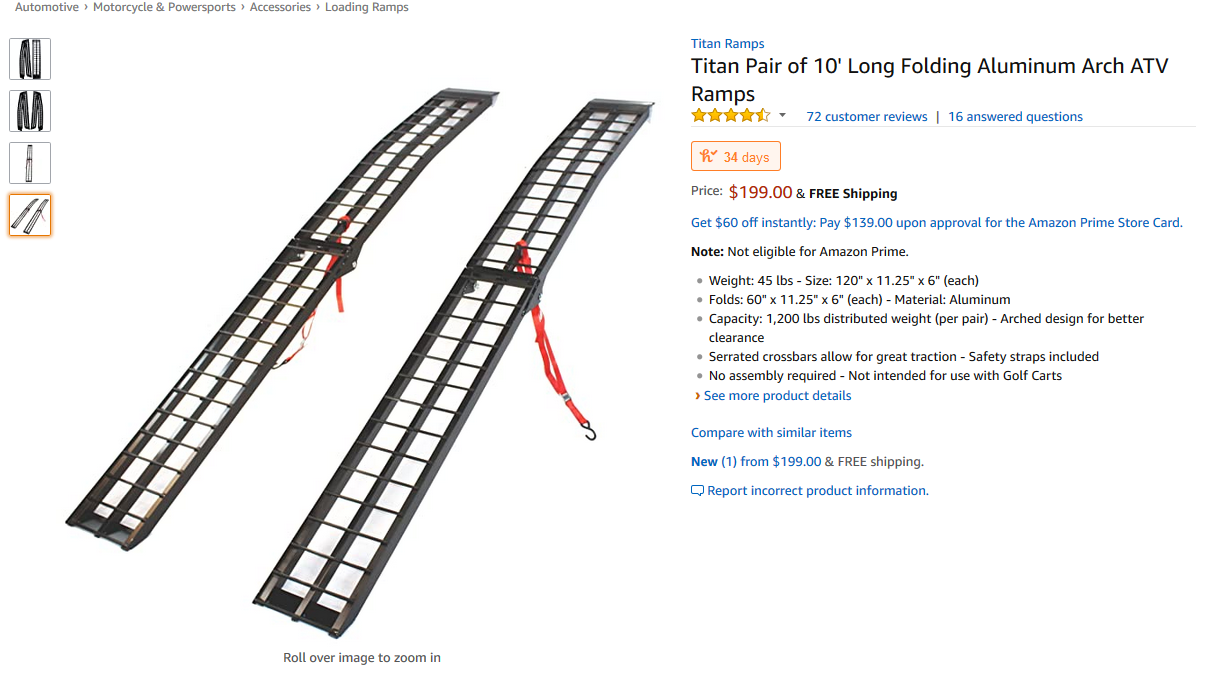

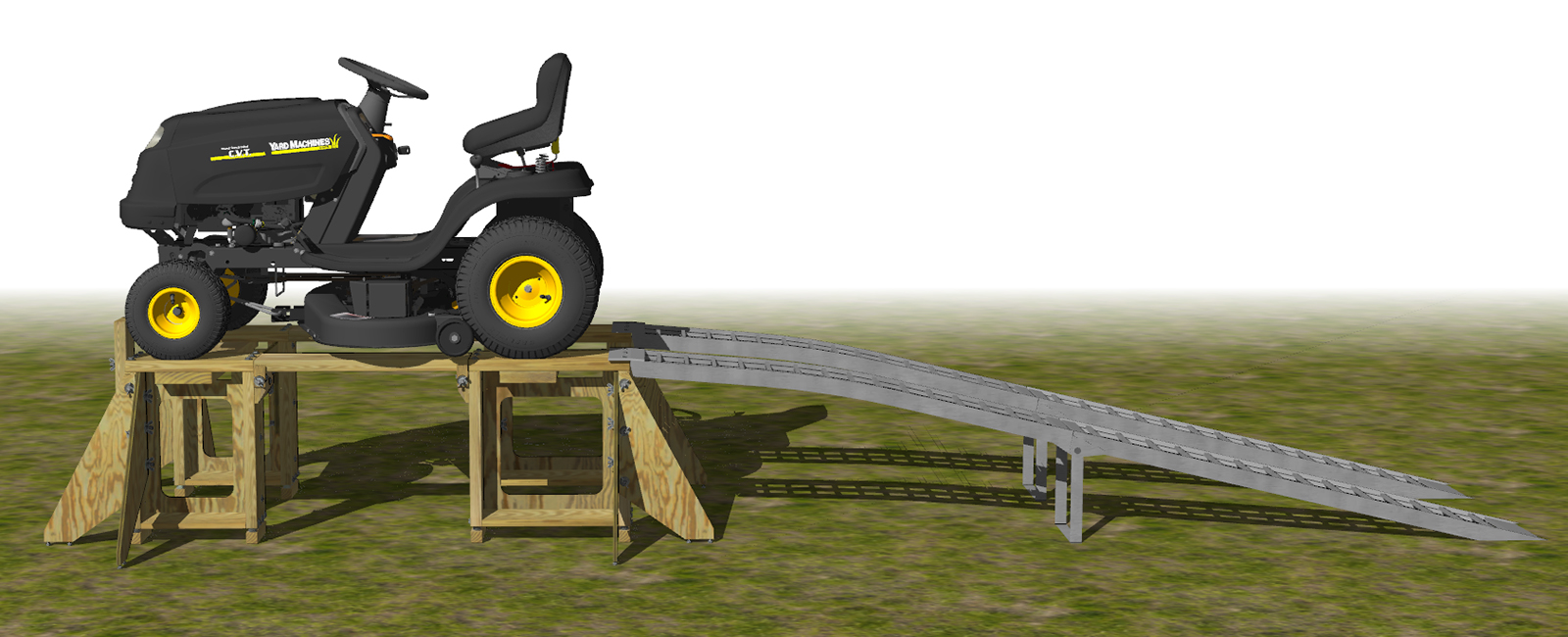

Pretty darn cool..... could very well make some $$$ with this sort of thing if you were so inclined. Curious if you can find pre-made metal ramps that are long enough to allow the mower deck to clear on the way up. Most of the ones I've seen for sale would be to steep.

Thanks, but won't be making any $$$ with this, it's just something to make life a little easier for me.

As far as the ramps go, I too was concerned with the deck clearing the ramps. I considered all my options and decided that a foldable ramp at least 10 feet long would do the trick. All of the ramps I'm considering are the longest I could find, keeping in mind that for strength and dependability adding a brace at the fold point is a must. This is one of the top contenders -

I think the deck would clear ok with these

-

@pilou said:

:fro:

You must put that in the free Twinmotion 2019 (if you have loaded it) !

Looks like it would be fun, but for me it would just be one more thing I wouldn't be able to figure out. I'm really trying to minimize my frustration level

-

-

I'm going to be boring and go with the WOW, very nice to see your models here, bloody marvelous.

-

@mike amos said:

I'm going to be boring and go with the WOW, very nice to see your models here, bloody marvelous.

Hey Mike,

Many thanks for the nice words

Steve

-

Great idea and good looking design Steve. I can relate to your need for this contraption.

I use a couple of short metal auto ramps to raise the front of my 61 inch zero for deck cleaning and blade changes. Only gives me about 16 inches of work height and my old body aches for about a week after.

The wooden ramps you built for your previous stand look a bit like the ones Evel used at Caesars Palace.

Huh... Wouldn't be thinking of some mower jumping would you? Just find a couple of surplus WWII JATO (jet assist take off) packs to strap on each side of that MTD and make the rounds of church carnivals and county fairs. You could jump over a childs wading pool with a fake shark in it.

Just a thought... -

JIM!!!!!

So good to see you here! How are you doing? Have you fully recovered from that fall and head injury? And what have you been up to? I sure hope you have been creating more fantastic SU models. You have way too much talent to not be. If you have I would love to see them, and I know everybody here would also.

Yeah, I know what you mean about having to crawl around under the mower, and paying dearly for it afterwards. I probably have mine raised maybe ten inches or so, and have been under it countless times trying to figure out what the heck is wrong with it. And of course you never have the tool you need once you manage to get down there. Between that and having to use my push mower to do the lawn, I'm lucky to crawl back to the house at night. Say, you wouldn't consider loaning me that zero-turn for a while, would you? Just for a couple of years.

I actually figured out a way to slap together a quick and dirty version of my stand, just to get me thru this current problem. And then, after I figured out what I would need to do, I realized that there would be no way to get the damned mower up there. If it had power to the rear wheels there wouldn't be a problem to solve! Just another example of how my brain is constantly falling short of the mark. Very frustrating

So you think I should take my show on the road and jump the shark, huh. Wasn't Caesars Palace the one where the video showed his body being totally mangled in slow motion? That was gruesome. I may need to pass on that.

Well, again, it's so good to see you here again. Try not to be a stranger. I hope this current craziness is not affecting you too badly. Personally I have painted over my door with lamb's blood, just to cover all the bases. You never know.

Steve

Advertisement