Twisted Dovetail

-

Very interesting. Might make a good corner joint for a box.

Best,

dh -

@krisidious said:

What I wonder is how it could actually be used in real life... Doesn't seem possible.

True....Its not possible to join them

-

@pcmoor said:

@krisidious said:

What I wonder is how it could actually be used in real life... Doesn't seem possible.

True....Its not possible to join them

maybe if it's printed that way?

-

Oh ye of little faith. Just google it

Shep

-

Cool.

@pcmoor said:

@krisidious said:

What I wonder is how it could actually be used in real life... Doesn't seem possible.

True....Its not possible to join them

There are similar looking joints that can be assembled.

Scott beat me to it.

-

I did and most of what I saw looked faked... Others were built in a way that they could be angled together first. I'd love to see video of it being done.

-

Kris, twisted dovetails like Scott's can and are made in real wood. Whether or not they look faked, they can be cut to work.

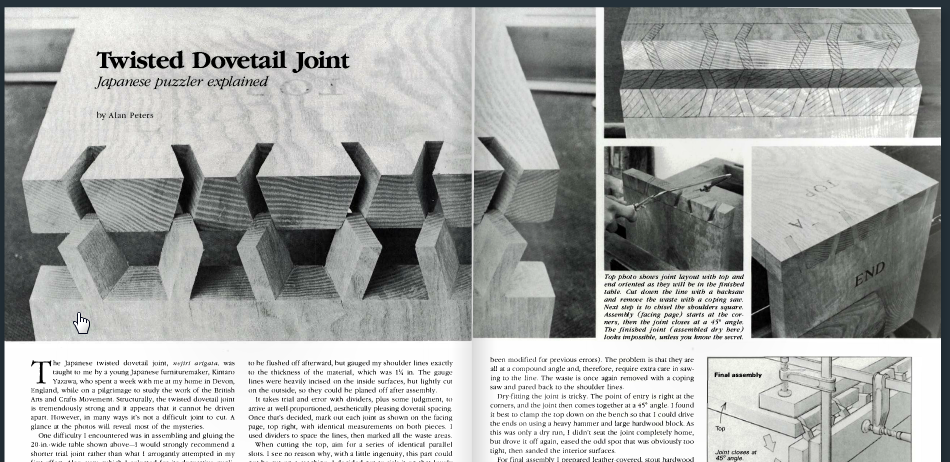

From Fine Woodworking Magazine #61

-

i guess if the pins&tails line up at some point (in the middle somewhere) then it can slide together? if the angles are right?

-

See if this helps. The first image I posted is the starting position.

-

@s shepherd said:

The first image I posted is the starting position.

oops, i missed that bit.. was thinking the coincident point would have to be in the middle somewhere. the animation clears it up though.

-

Nice animation Shep...

This is one of the ones that looked faked.

-

So the twist has to be identical on the inside front as it is on the backside top for it to work?

-

@krisidious said:

Nice animation Shep...

This is one of the ones that looked faked.

What makes it look fake?

-

@dave r said:

What makes it look fake?

because it looks like there's not a way to assemble/dissemble it.. that's what the joint is for anyway, right?

like-- "hey bud, why don't you try to figure that one out hehheh"..

or is it inherently stronger than a traditional dovetail? -

@krisidious said:

Nice animation Shep...

This is one of the ones that looked faked.

One thing that's different about this is the miter on the end pair. I think it's done like this.

-

-

@krisidious said:

@dave r said:

What makes it look fake?

The seam along the dovetails...

That's not a seam. It's a marking gauge line for the baseline. You'll sometimes see it on hand cut non-twisted dovetails too. It's part of the marking out for the joint. The baseline is often cut deep because it forms a guide for the chisel when cleaning out the waste.

-

The mental hurdle in this joint as nicely illustrated in Scott's video is that the joint slides together along a 45 degree sloped line, not straight in as we are accustomed to. That fools the mind and eye into thinking it can't go together at all!

Steve

-

if memory strikes right , the late Tage Frid shows how to layout , cut and fit this joint in his book " Tage Frid Teaches Woodworking" . Hope to give it a try just for grins one of these days.

-

I had the pleasure of watching Tage Frid handcut dovetails once years ago. He came to speak to a college woodworking class I was in. We watched as he laid out and quickly cut a set of dovetails. When he was finished, he put the joint together and then he looked around the room. Not at us but at the walls of the shop. The professor asked him what he was looking for and he replied, "A dovetail hammer." No one in the class including the professor ever heard of a dovetail hammer before. Frid broke into a smile and walked over to the hand tool wall and grabbed a claw hammer. He walked back over to where he'd been working and gave one of the pins a few whacks to spread out the fibers and fill a small gap he'd created when cutting the joint. Then he held up the hammer with a grin and said, "This is a dovetail hammer."

Advertisement