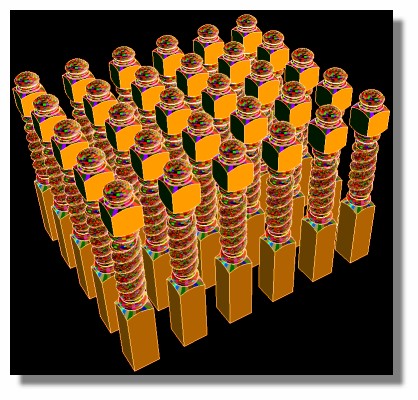

Barley Twist Spirals

-

@gilles said:

Here is your model with some corrections and the use of components,note it is 650Kb instead of 1950.

Looks better than mine. So you redid the spiral?

-

@unknownuser said:

@unknownuser said:

found a situation where a group made more sense than a component.

You have some plugins who works only with groups!

You're right. And when I use them I wind up converting the groups to components. I'd be happier if a component was just created by the plugin.

I haven't found a need to use any plugins that only work on groups.

-

@dave r said:

Gilles version of your model illustrates very clearly the reduction in file size that I mentioned earlier.

And even 100 of them is only 820 Kb. That's a couple of hours of production in your shop, right?

Wish I could make them that fast. I missing something - would like to know your work flow on the spiral

-

I'd be happy to show you. I can't do it at the moment, though. Maybe another live demo with you or I'll make a video.

-

@unknownuser said:

found a situation where a group made more sense than a component.

You have some plugins who works only with groups!

-

@dave r said:

I'd be happy to show you. I can't do it at the moment, though. Maybe another live demo with you or I'll make a video.

Dave

That'd be great!! -

and here for example after explode the original component for paint each faces

I don't need to make a component again, but just a group!

-

-

-

I just want to thank you all for this thread. It has been a great learning experience.

-

-

This thread is hot! Another point I would make is with screw.rb one can then make a component of spiral section that would stack directly beneath the other (without turning) and so you could increase, vary the height (within a module) easily.

I assume that can be done with Gilles' version.

-

Yes we can!

huhu couldn't resist.

-

@pbacot said:

This thread is hot! Another point I would make is with screw.rb one can then make a component of spiral section that would stack directly beneath the other (without turning) and so you could increase, vary the height (within a module) easily.

I assume that can be done with Gilles' version.

If I understand you right this is one method I used - I made a 2 1/2" profile (the profile of my barley twist router cutter) then used the screw plugin to make a 5" high one revolution spiral. I grouped it, then copied and stacked it on top the other spiral. I then selected those to array the rest of the way.

-

That's pretty much it but use a component instead of a group.

-

@dave r said:

That's pretty much it but use a component instead of a group.

Still not sure why there is such a difference in file size -

I believe it's quasi the same size maybe a little less for the group because there is less informations inside no Glue etc..., but same info as pure geometry.

-

@unknownuser said:

illes wrote:

Here is your model with some corrections and the use of components,note it is 650Kb instead of 1950.Isn't it a big difference?

Also modifying all instances at once.

Create libraries for further use in other models. -

Re: file size of my barley twist stair newel

I'm still perplexed by the size of my file. I started over with a new SU file and made my newel without the barley twist. After imported my profile from CAD, did a sweep, created a component of the newel and my file size is 3 MB. What gives?

BTW I have purged layers from the CAD file import -

How many segments did your imported profile turn out to have? The profile I created last night with the Bezier tool had 22 (including the two little short segments I added at the ends. And the total number of entities after one turn of the screw was 2686.

Advertisement