Arc deforming ???

-

@gilles said:

Ever heard of Kito Raupp? A master of SU tricks.

i don't think kito ever heard 'righty-tighty lefty-loosey'

-

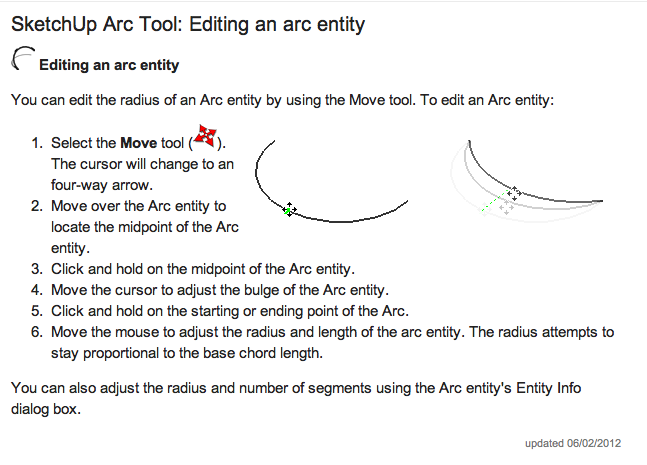

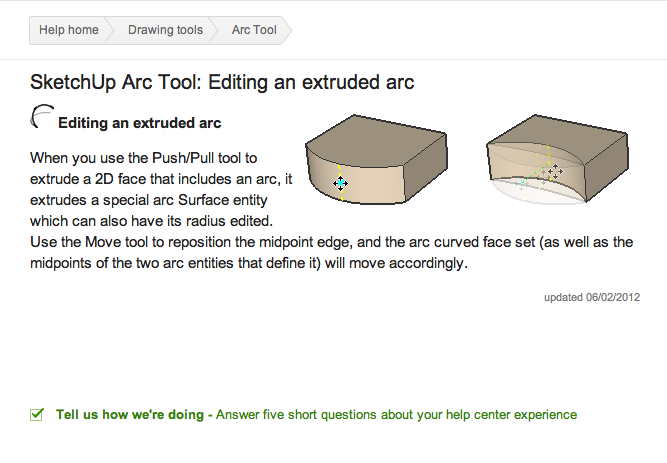

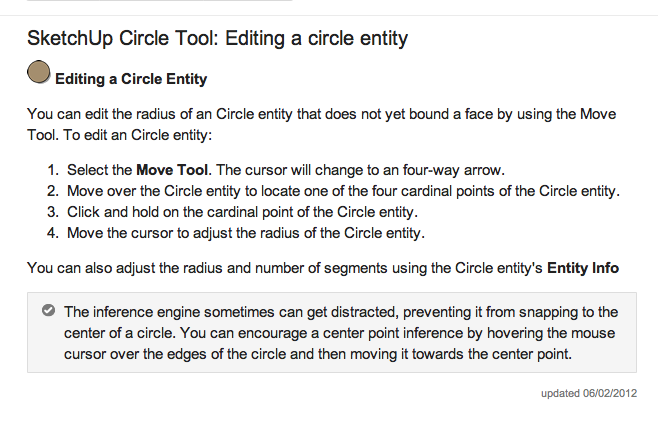

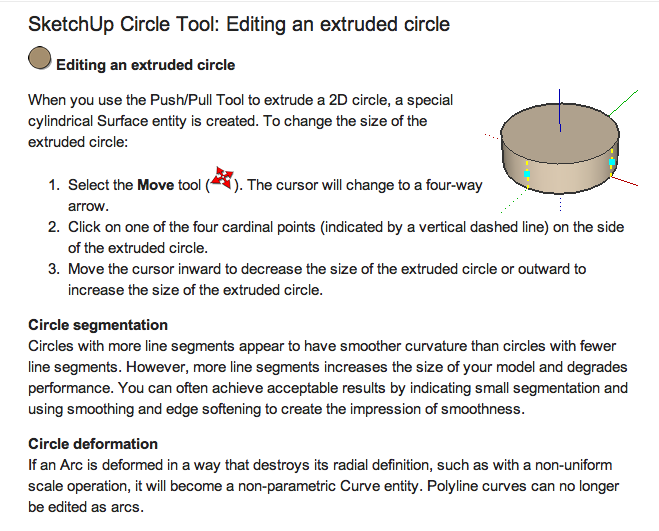

He may have read this

http://en.wikipedia.org/wiki/Screw_thread@unknownuser said:

By common convention, right-handedness is the default handedness for screw threads. Therefore, most threaded parts and fasteners have right-handed threads. Left-handed thread applications include:

Where the rotation of a shaft would cause a conventional right-handed nut to loosen rather than to tighten due to fretting induced precession. Examples include:

The left hand pedal on a bicycle.[3]

The left-hand grinding wheel on a bench grinder.

The lug nuts on the left side of some automobiles.

The securing nut on some circular saw blades - the large torque at startup should tend to tighten the nut.

In combination with right-handed threads in turnbuckles and clamping studs.[4]

In some gas supply connections to prevent dangerous misconnections, for example in gas welding the flammable gas supply uses left-handed threads.

In a situation where neither threaded pipe end can be rotated to tighten/loosen the joint, e.g. in traditional heating pipes running through multiple rooms in a building. In such a case, the coupling will have one right-handed and one left-handed thread

In some instances, for example early ballpoint pens, to provide a "secret" method of disassembly.

In mechanisms to give a more intuitive action as:

The leadscrew of the cross slide of a lathe to cause the cross slide to move away from the operator when the leadscrew is turned clockwise.

The depth of cut screw of a “Stanley” type metal plane (tool) for the blade to move in the direction of a regulating right hand finger.

Some Edison base lamps and fittings (such as formerly on the New York City Subway) have a left-hand thread to deter theft, since they cannot be used in other light fixtures.

The term chirality comes from the Greek word for "hand" and concerns handedness in many other contexts. -

Jeff, thanks for your contributions to this thread, useful stuff. As to which is the right solution to the OP I guess we will never know unless he comes back and posts. My initial reaction was he may have been trying to add a sloping cut to his semi-circle.

-

@arcad-uk said:

My initial reaction was he may have been trying to add a sloping cut to his semi-circle.

right.. that's what a helix is

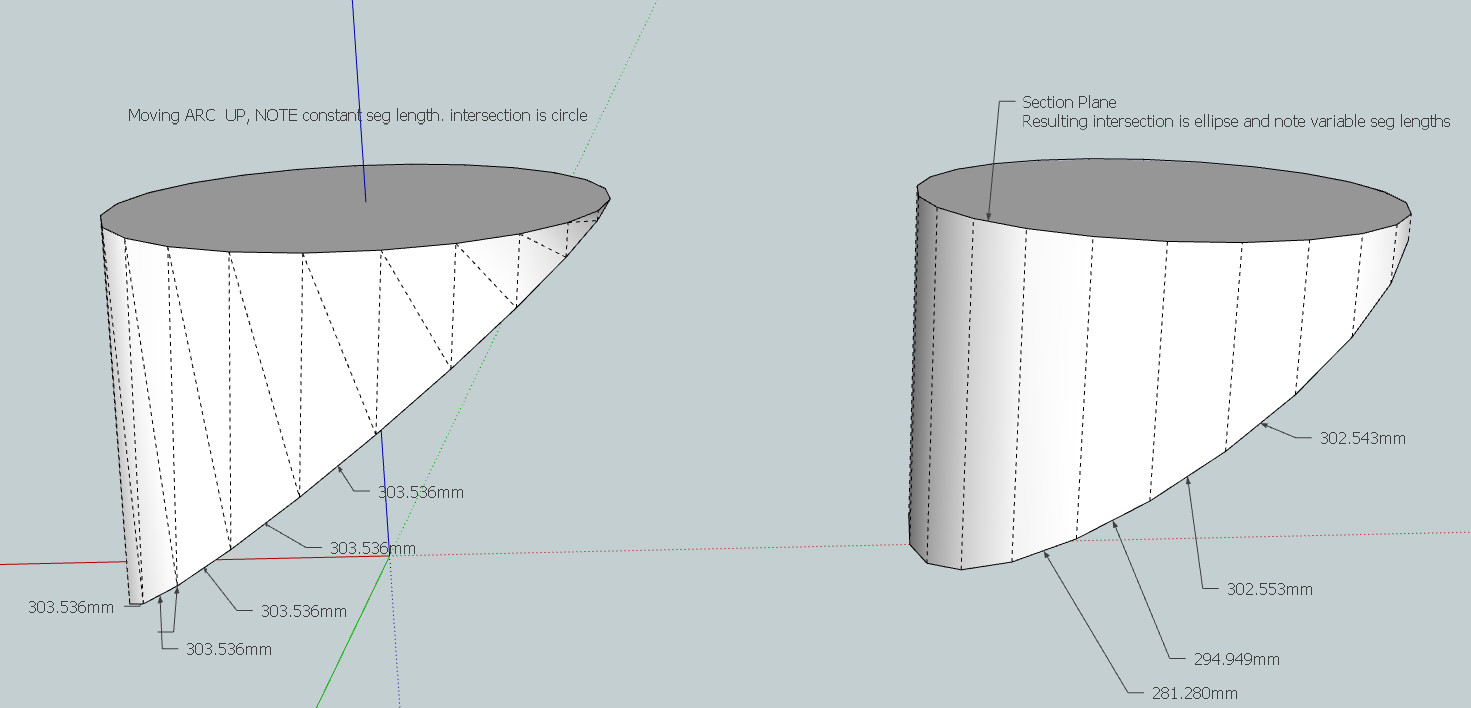

lift one end of an arc and it will make a helix.. a continuous slope around the cylinder..intersecting a plane with a cylinder, while it may seem at first to create a sloping cut, actually creates something fairly complex and less usable.. it doesn't create a sloping cut -- it makes a cut that varies in slope (and won't continue upwards either.. it goes up for a semi-circle then back down)

dunno, i went through this stuff years ago and my first tries used similar methods as intersecting a plane with a cylinder.. it took a little while to figure out why the method wasn't working out properly but i eventually realized a helix is the proper shape..

i guess i'm being lazy in not fully explaining it and i know me saying "hey, just trust me on this" doesn't hold much weight but…. -

An helix is nothing else than a straight line wrap around a cylinder with angle.. I guess.

-

@arcad-uk said:

Jeff, thanks for your contributions to this thread, useful stuff. As to which is the right solution to the OP I guess we will never know unless he comes back and posts. My initial reaction was he may have been trying to add a sloping cut to his semi-circle.

As I did write earlier I just saw a video where the method was used to make a thread on a screw - and I could see that was wrong when you take it to the extreem - but I WOULD TOO HAVE exspected it to be THE method - why scale it up just because I move the end point along the normal vector to the original "arc" - to me the original arc IS a strait line wrapped around a cylinder between the two end points - why should it NOT continue to be that because I move the one end point ?

Why did the developers choose to scale it UP from the surface of the cylinder ?

Maybe it's tuff to do the coding for "what I would exspect" - then why not be more "naturel" and just tighten "the NON-elastic robe" between the two end points - to me it's NON SENCE to make the robe SUPER MAGIC ELASTIC so it lifts itself from the surface !

-

FYI

FYI -

@ksor said:

@arcad-uk said:

Jeff, thanks for your contributions to this thread, useful stuff. As to which is the right solution to the OP I guess we will never know unless he comes back and posts. My initial reaction was he may have been trying to add a sloping cut to his semi-circle.

As I did write earlier I just saw a video where the method was used to make a thread on a screw - and I could see that was wrong when you take it to the extreem - but I WOULD TOO HAVE exspected it to be THE method - why scale it up just because I move the end point along the normal vector to the original "arc" - to me the original arc IS a strait line wrapped around a cylinder between the two end points - why should it NOT continue to be that because I move the one end point ?

Why did the developers choose to scale it UP from the surface of the cylinder ?

Maybe it's tuff to do the coding for "what I would exspect" - then why not be more "naturel" and just tighten "the NON-elastic robe" between the two end points - to me it's NON SENCE to make the robe SUPER MAGIC ELASTIC so it lifts itself from the surface !

I'm with you ksor. like I said earlier, I too wish sketchup would act as you're expecting it to.. I believe it would be difficult to code and the UI would become more cluttered because there would have to be a way to differentiate between the current behavior and your expected behavior (in many situations, the current behavior is desired such as moving an arc between two points while maintaining an arc shape)

so sketchup would have to become more intelligent in its handling of curves etc but from what I gather via other similar requests, the developers aren't interested in making this happen..in short, you'll just have to use another method to properly draw this thing

-

@gilles said:

An helix is nothing else than a straight line wrap around a cylinder with angle.. I guess.

right.. a helix used to be sort of mysterious to me until I realized what it actually was

it's a pretty simply thing in reality.

(likewise, it can be a straight line wrapped around a cone etc ) -

@unknownuser said:

As I did write earlier I just saw a video where the method was used to make a thread on a screw

You mean this:

@unknownuser said:

I've seen WRONG methods for making a threads using this method

Those equivalencies are not quite so in my book. Did I miss something more? Something more explicit would have helped, a link to the video, a pic, etc., even if Jeff could be trusted, in this case, apparently.

Where's kito?

SU menus, etc., where shown, are in German.

-

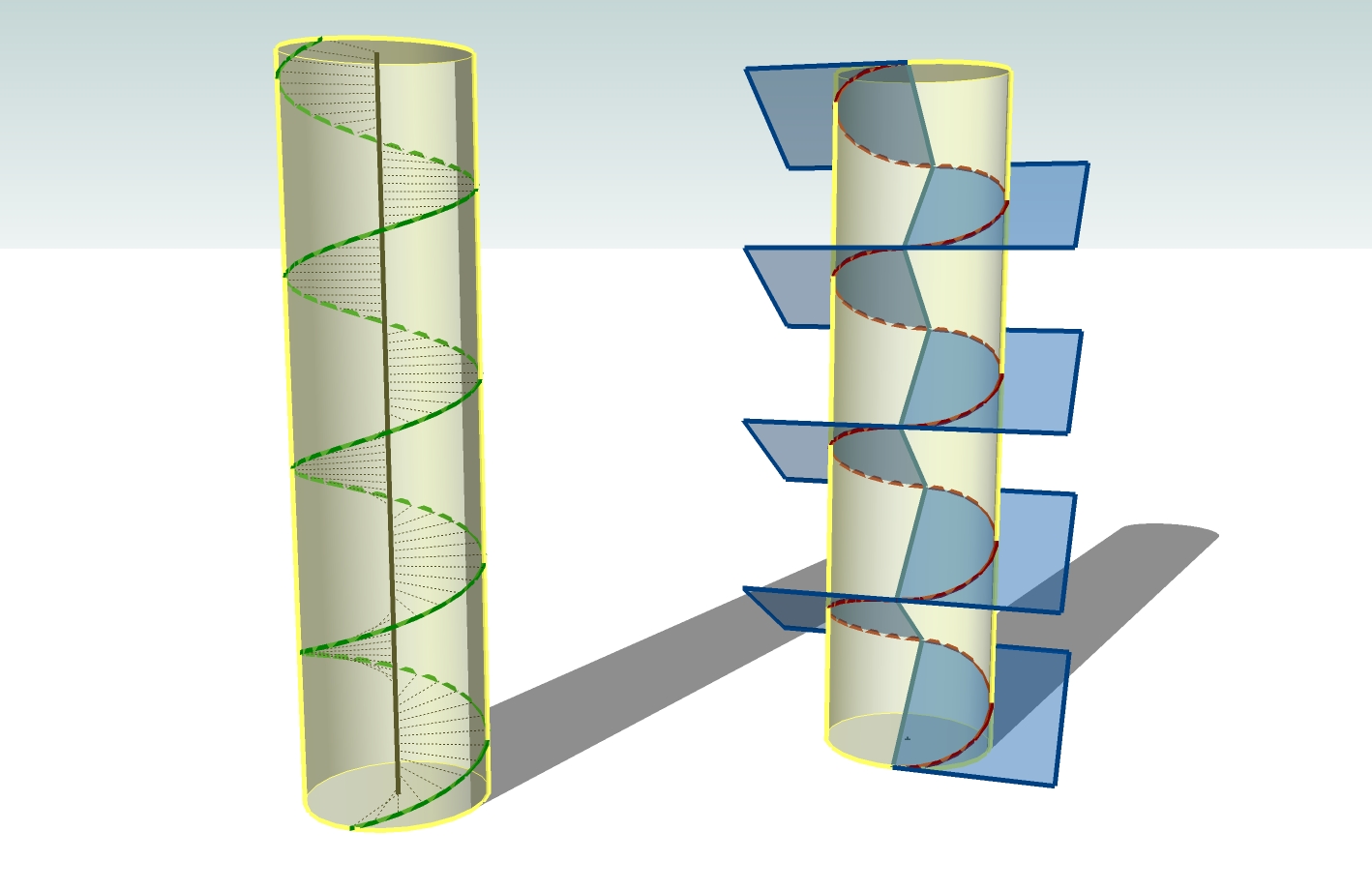

i'm not sure if there's even a question or discussion left in this thread but….

another visual on the difference between these two shapes..

the green is a helix.. the red is from intersecting a plane with a cylinder (though in reality, this shape wouldn't continue up in a similar fashion as the helix.. it goes up for 1/2 turn then back down -- it loops.. but i've shown it this way instead)[flash=960,720:2ycix9jo]http://www.youtube.com/v/8hUljMbRxSI?version=3&hl=en_US&rel=0[/flash:2ycix9jo]

-

@brookefox said:

That's nice, Jeff. For me the only thing that's missing is a pic of the plane slicing the cylinder... to show the lack of continuity and stepping (which isn't cause you say it's a sin curve?). You sliced it and multiple copied it? Show it all, man, cylinder with multiple slicing planes.

[but to be honest.. i'm not even sure what the discussion is

what's the question?

what's the question?  ]

]@unknownuser said:

BTW, is that a dynamic component spinning or what?

sort of.. dc to rotate in increments then manual export 2D -> img sequence

-

Thank you very much.

After thinking I'm done, I'm reminded that it seems more disjointed in your ani and looks smoother in your last pic. Just a point of view thing I guess, but for me that disjointedness was odd.

I am not complaining, as the world resists strangely my specification.

-

-

That's nice, Jeff. For me the only thing that's missing is a pic of the plane slicing the cylinder... to show the lack of continuity and stepping (which isn't cause you say it's a sine curve?). You sliced it and multiple copied it? Show it all, man, cylinder with multiple slicing planes.

BTW, is that a dynamic component spinning or what?

Advertisement