Sketchup is Inacurrate???

-

Sketchup is inacurrate???

Hard to answer. As has been said by others here, it depends on what you model and on what you need as a result.

I read the question as: can you rely on SU if you know what you are doing?

Just saying that SketchUp’s limitation is 0.001 inch (0.0254mm) may be difficult to understand. Can’t it do better than that? Is it realy that inaccurate?

See John Bacus’s answer in this thread: http://groups.google.com/a/googleproductforums.com/forum/#!searchin/sketchup/precision$2Binch$2Bjohn/sketchup/MqyEMnjVXjs/rVPdazWSUX4JAt first (at that time) I didn’t fully understand the meaning of this threshold mentioned by John.

Precision goes way beyond that limit. (Although its setting only serves how to display dimensions, etc. It doesn’t have any effect on the modeling itself.)Thomthom “proved” to me that SketchUp conciders length differences equal to or less than 0.001” as not existing.

To shed some light on what this threshold realy means when modeling I had to put some simple examples together in a model. I’ll share them (the model) here, together with some of my conclusions.

-

SU can’t have any two endpoints in the same context with a distance less than (or equal to) 0.001”.

So the shortest edge is 0.001”+… -

to model with smaller distances between certain objects you can go way below that 0.001”. But the geometry has to be split over different contexts (groups) to allow endpoints to come as close as 0.000001mm. This can be demonstrated by setting the precision to 0.000001mm.

-

If somehow SU doesn’t accept the small input that you wish to feed, move away first and then back by [same distance+small] input.

FAIK SU itself uses that high precision (and even higher) for correct intersections etc. This is (to me at least) very good to know. It gives me the feeling that at this point I can trust SU’s inferencing engine and what is under the hood.

Even if you model in mm or round inches or more, the program has to do its job at way higher precision to still give you an accurate model.

A (maybe not the best) example:

Think of a stairway, floor to floor 2.75m, 15 steps. => rise 183.333333mm

You may not want to know the rise in three decimals. Millimeters is enough to check its correctness. But it’s good to know that SU divides correctly. Now you don’t have to care about chain dimensions. You can just measure from ground to any of these steps.p.s. I haven’t played with angles in a similar way (yet).

-

-

@unknownuser said:

@genma saotome said:

I don't have a problem with SU circles and arcs being a collection of tangents. I do have a problem with the Followme tool not being able extrude a face that is actually congruent to that collection. That, IMO, is an instance of what I would call inaccurate... as in wrong enough that I must do manual corrections to make it right.

can you attach an example .skp to illustrate your issue?

(and yeah, I agree that there's all sorts of problems with follow me... I'm just curious as to what you're trying to do with it)

Sure, I've attached an example. My work flow is to import a template of what I want to extrude along an arc, then create a circle of the required radius, use the protractor to measure off a set distance (n the example it is 20d), clean away what's not needed, select the line of the arc and hit Followme.

All you need to do is download the model, highlight the arc and use Followme on the vertical face standing at 0,0,0.

What you will find is none of the four corners of the extruded shapre are where they belong. The two corners closest to the center of the circle are farther apart than they should be and the two farthest form the center are too close together. The example has a set of faces that should be where the corners fall. You'll see they fall short or have pushed thru.

-

Dave, I wouldn't extrude in that manner for complete accuracy. If I'm understanding the problem correctly, this is an example of the limitation of SU when it comes to aligning faces with the beginning and end of an extrude path. The face to be extruded is not fully perpendicular to the beginning of the path...as witnessed by the slight gap between the original template and the extrusion.

In these kind of situations you need something of a lead-in and follow-through to get the shape to extrude properly. I'd be thinking in terms of extruding along a greater section of arc, then trimming either end.Another solution is to edit either end of the extrude path so that it starts and finishes perpendicular to the existing faces. I have done this in the attached file. I have then welded the entire path back together with Recurve. You'll find that the profile now extrudes perfectly...even to cutting a hole in the diameter wall of the semicircle.

-

@alan fraser said:

The face to be extruded is not fully perpendicular to the beginning of the path...as witnessed by the slight gap between the original template and the extrusion.

I think it is perpendicular Alan. The Y value of every point of the original face is zero... and so is the the centerpoint of the circle and the start of the arc. I'll recap my procedure:

- Place the face to be extruded at 0,0,0.

- Draw a vertical line up 2-5m from 0,0,0

- Draw aline on the dotted red axis of the necessary length -- in this example I used 100m

- Draw a circle at the end of the previous line, using a radius of 100m

- Change the number of segments of the circle from 24 to 360.

- Use the protractor at the center of the circle to map out 20d of arc.

- Draw a line from the center of the circle along the dotted line, intersecting the circle.

- Delete what is not needed.

- Highlight the arc.

- Use followme on the original face.

Considering the above, I see a mistake could be made at step 2, failing to draw a line on the axis, and at step 4, failing to center the circle on the endpoint of the line. Either would create an arc that is not perpendicular to the face. Wouldn't the proper quality check be to verify that both steps 2 and 4 have a Y axis value of 0?

I havn't had a chance to review the model you uploaded... I'll check later tonite or first thing tomorrow.

WRT your suggestion to use a lead in and follow thru, that is what I do and is what I had in mind when I wrote needs to be manually corrected. I have created several thousand of these extrusions... each one needing to be manually corrected. Either I'm using the tool improperly or it doesn't do what it is supposed to do.

-

@genma saotome said:

...I think it is perpendicular Alan. ...

Both sides of the path are at an angle of 89.5 degrees (not perpendicular) to the connected faces. So the follow me starts and ends incorrectly.

-

Let's keep in mind that it is called SKETCHup Not GoogleCAD.

SU was originally designed for architectural concepts, not as an engineering CAD.

Accuracy and precision in those fields take on totally different definitions.Yes, I use SU as a Pseudo-CAD because I cannot afford nor justify SOLIDWORKS for what I am doing.

It does the job real fine, but I wished it could do more, especially in the area of solids animation.I have to keep reminding myself constantly when defining my airplane parts that I an NOT making shop drawings; I DON'T have to concern myself with parts micro-fitting and dimensional precision beyond making it look right.

If it came to really making that airplane, I would be using SOLIDWORKS or more likely; CATIA, using my SU model as a CONCEPTUAL MODEL.

-

@genma saotome said:

I do have a problem with the Followme tool not being able extrude a face that is actually congruent to that collection.

In the "DUH" thread this problem with Follow-me came up. Here is my (copied) reply.......

Re: The "Duh!" thread (aka the Doh! thread)

Postby jgb on Sun, 25 Mar 2012 12:03 pm

Another thing with Follow-Me I discovered a while back (and reported) is when you are defining a path that has curves, place the template face somewhere on a straight portion of any line segment, NOT at an endpoint.

If follow-me starts on an endpoint, the face template follows one of the subtended angles and royally screws up at the end, with an end face out of alignment. This is especially a major factor with closed loops.

However, if started on a straight section, it will end perpendicular to the last line of the path, and if the path is a closed loop, it will join properly.

-

This is a good piece of advice. But would placing the profile on the segment rather than the vertex on a specified radius change the radius of the extruded figure somewhat, and thereby possibly creating a misalignment somewhere else?

-

@jgb said:

Let's keep in mind that it is called SKETCHup Not GoogleCAD.

so going off that train of thought, I should just buy AutoCad then all my drawings will be done automatically.

-

@mitcorb said:

This is a good piece of advice. But would placing the profile on the segment rather than the vertex on a specified radius change the radius of the extruded figure somewhat, and thereby possibly creating a misalignment somewhere else?

correct.

follow me simply doesn't recognize an arc if it's part of a path.. align the profile properly at one point on the arc will cause an error elsewhere.. and vice versa.. and there's no simple fix to or (other than using a plugin) -

-

@genma saotome said:

@wo3dan said:

@genma saotome said:

...I think it is perpendicular Alan. ...

Both sides of the path are at an angle of 89.5 degrees (not perpendicular) to the connected faces. So the follow me starts and ends incorrectly.

Am curious how you determine that. Could you explain please?

Use the 'Protractor' tool constrained to blue (R/G plane) on the beginning endpoint of the path. Begin measuring the angle somewhere on/along the profile. End measuring the angle somewhere on the first arc segment. It measures 89.5 degrees.

-

@mitcorb said:

This is a good piece of advice. But would placing the profile on the segment rather than the vertex on a specified radius change the radius of the extruded figure somewhat, and thereby possibly creating a misalignment somewhere else?

Yes, but that is a subjective "accuracy" syndrome.

SU creates arcs, curves and circles whose defined dimensions are at the endpoints of the segments, so anything dimensioned at the segments centerpoint will be not quite "accurate".

And until SU draws analog arc, curves and circles, rather than with digital segments, you can never get away without some inaccuracy of the extruded form.

The only way to avoid (minimize actually) this; is to create arcs, curves and circles with way more segments, which then creates a practicality problem.

Alternatively, create the extrusion face at a vertex/endpoint and then copy it to some position on the adjacent segment, keeping its origin point on the line.

-

@unknownuser said:

@jgb said:

Let's keep in mind that it is called SKETCHup Not GoogleCAD.

so going off that train of thought, I should just buy AutoCad then all my drawings will be done automatically.

But only for drawing cars........

-

Going back to the FollowMe around Arcs...

There's no 'inaccuracy'.

Sketchup takes a profile Face and Extrudes it around path of Edges.

The orientation of that Face to the first Edge in the path [at its start] determines the extruded form.

If the Face is perpendicular to the first Edge in the path it's perpendicular to the last Edge in the path too.An Arc consists of several Edges as 'Segments'.

Let's say the Arc is a semi-circle'

If the Face is perpendicular to the first Segment it will end perpendicular to the last one,

The extruded form won't therefore be a half circle of extrusion.

If you draw the Face at a Vertex it will be auto-adjusted to be projected so it is square to the first path Edge...

If you want a full half-circle there are tools like EEbyLathe [use 180 degrees], OR simply start the FollowMe at a mid-point on a Segment and end on the equivalent mid-point 180 degrees around the circle; it will then be the full half-circle form.

-

@tig said:

Going back to the FollowMe around Arcs...

There's no 'inaccuracy'.

Sketchup takes a profile Face and Extrudes it around path of Edges.the thing is, as you roundabout just said in the above three sentence, is that you can't use follow me on an arced path. (well you can, it just won't be accurate).. in the exact same way that you can't accurately offset an arc in sketchup..

sketchup ignores the 'arc' part and just treats it as a series of segments which results in an error..

this post on pg2 has an example file attached which shows the error:

http://forums.sketchucation.com/viewtopic.php?p=394122#p394122here's another way to see the error:

dunno.. maybe i'm using the wrong word here but this is definitely inaccurate in my book..

-

Dave, I'm afraid Gerrit (Wo3dan) is correct, the start of the arc is not perpendicular. You don't even need to use a protractor to confirm this. If you go into the Styles dialog and change the edge colouring from All The Same to By Axis, then explode the arc, you will see that it isn't. If the first segment was perpendicular it would show up as green...because it ought to be running along the green axis. It doesn't, 'cos it's not.

TIG is absolutely right about SU...there is no inaccuracy when extruding around curves, just incorrect implementation. There have been other posts about SU being innacurate because of this slight adjustment when starting an extrusion along a path that is not exactly perpendicular. Some people seem to think that SU should just perform the extrusion and leave the original face where it is. However this really would be inaccurate...because it would mean that the face was being extruded obliquely along the path. This in turn would mean that at no point along the entire extrusion would the cross section be be the same as the original template.

-

It's not an error, it's not inaccurate.

As you say, Sketchup extrudes along the segment path.

There are no real Arcs in Sketchup, jut edges.

So as long as you bear that in mind, and ensure your extrusion starts on a segment and not a vertex, you can get a 'correct' extrusion around an 'Arc'

-

I got it dah thanks TIG

-

@tig said:

It's not an error, it's not inaccurate.

As you say, Sketchup extrudes along the segment path.

There are no real Arcs in Sketchup, jut edges.

So as long as you bear that in mind, and ensure your extrusion starts on a segment and not a vertex, you can get a 'correct' extrusion around an 'Arc'

seriously, i understand that there are no 'real' arcs in sketchup.. that said, if you have a sketchup arc, all the vertices will be true distances from the centerpoint.. when using follow me, an arc's vertices and what happens at the vertices is inaccurate..

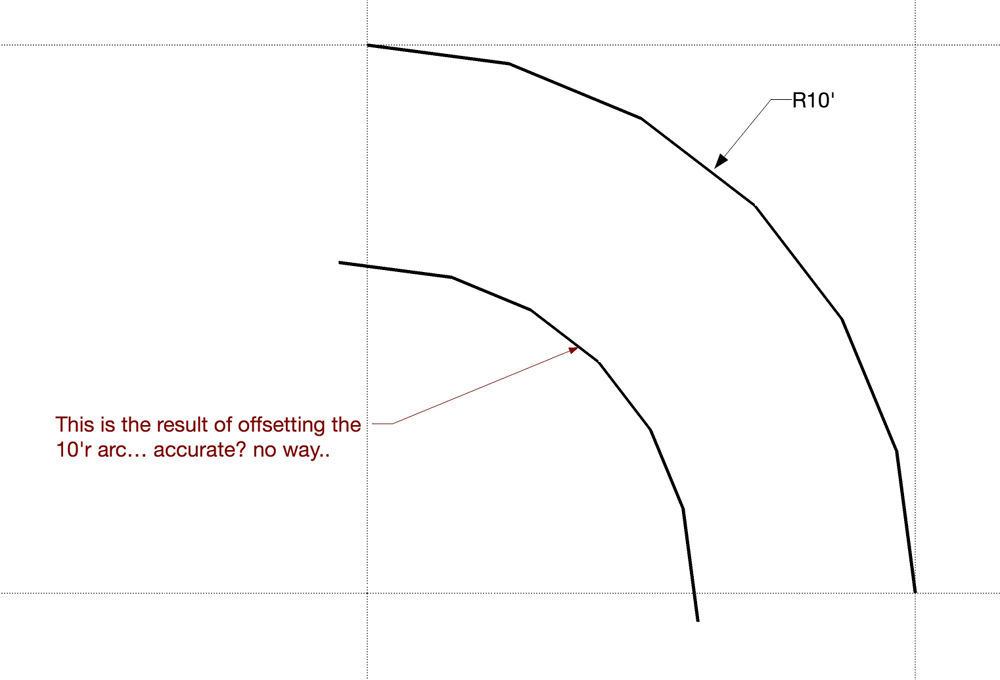

for simplifying the point i'm trying to make, let's forget about followme and look at the error in 2D using the offset tool…

so you're saying this arc has been properly and accurately offset?

my whole point is that if sketchup recognizes the arc (as evident in entity info / gives proper arc length as opposed to sum of it's segments / etc.) then it should also be able to offset the arc properly.. it's an error that could (and should) be prevented through proper programming.

Advertisement