[Plugin] Slicer5

-

Hi there ,

I have just installed the slicer 5 to have it to help me to slice up a site topography model for lazer cutting purposes .I wanted to slice the site model up vertically with having cardboard material of 3 mm thick for it . I have tried various way to get the model slice up but it always end up missing.

I have attached the sit model image below. I tried to upload the file but the file size is too big , so here is the link for it : https://drive.google.com/file/d/0Bzbv-1flN2CiNzg3OGoxamx2enM/view?usp=sharing . Any help will be much appreciated !

-

SketchUp treats points within 1/1000" of each other as coincident, therefore tiny edges don't get made and the faces relying on those edges don't get formed.

Consider doing it this way...

Add the site geometry group into a component.

Make a copy of that component-instance off to one side.

Scale that copy up by x1000.

Edit the copy and slice the group inside it - using 3000mm cuts rather than 3mm ones.

When you are done exit the edit.

You should now have a set of slices with retained geometry inside both the original sized and giant version of the component.

Select and delete the giant version.

Within the original version you should still have the slices with their tiny edges etc intact.

Tiny edges and related faces can exist, but they cannot be created from scratch. -

Hi TIG ,

Thanks you for the fast response . I tried to do as according to what you said, however , i try creating over more than 100 ++ planes , the file would start to load and the same thing would happen again ( the model inside would be missing ) . Is there anything that i would have done wrong in the process ?

-

I finally got a chance to download your SKP.

I sliced it at 35mm thickness - so it was quicker x10 !

It seems OK, even at the original size ?

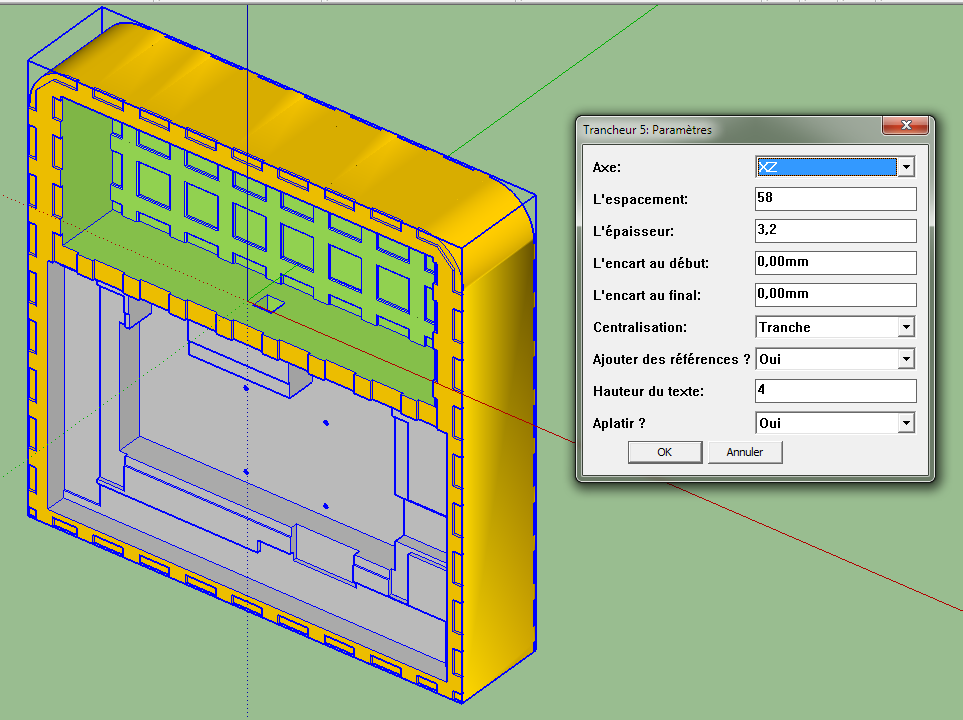

The reason the original 'disappears' is that it's assigned to a HIDN layer...Can you supply a screenshot of your Slicer dialog, so I can see your actual settings...

-

TIG,

Yida requested "VERTICAL" slices.

Is there a reason you sliced "HORIZONTAL"? -

When making a topo model it's usual to use horizontal sheets - say 3 or 6mm thick.

Cut along 'contours'.

These are overlaid on top of each other to make a surface in 3d.

Note how I chose the option to imprint the outline of the next sheet above onto each sheet, that is for easier alignment when assembling the cutout sheets in 3d...The wording of 'vertical' slices is ambiguous.

It could mean what I showed, or mean one of several other slicing options - X, Y, X+Y etc...

If the OP wants one of those alternatives, then it should work much the same.That's one reason I asked for a screenshot of the Slicer dialog - otherwise we must guess...

It worked for me, but not for the OP, so something is awry. -

Tig,

Thank you for the tip!"...Note how I chose the option to imprint the outline of the next sheet above onto each sheet,

that is for easier alignment when assembling the cutout sheets in 3d ..."I was not aware of this option, it will certainly help in the fabrication of a

contour model. Well done! -

Is it possible to use this on the currently set axes and not the original "world axes"?

I have a model where I have moved the axes some and I have to move and rotate every piece I want to slice to original world axes for it to work ok.

Or am I missing something? -

Sorry but it's the 'world' axes only.

-

Hi, I really like your plugin. Recently I was using the slicer tool, there is always such a mistake, as in the picture.

-

@Andrew

We don't have permission to view your image please just attached it to your post so we can see it... -

Hey!

Don't know if it's just my machine, but have been able to consistently reproduce an error when exporting in SKP 2018 (I understand that it's not currently listed as supported) -

Following slicing, I run the audit tool and there are no errors.

Then PNGs export just fine, but when exporting DXFs, the first one exports just fine but SKP crashes while exporting the second one.

When running the extension in 2017, the same error occurs. I am running Slicer v5.23

-

There used to be issues like this with MACs, but that was fixed.

My setup on PC sounds similar to yours, and I tested it in v2018 with this latest Slicer version and it quickly exported the DXF slices...

Does it always crash after DXF-001 ?

Can you supply a simple SKP that crashes for you.

You can pre-make the slices in it...

Then I can test it to see if I also get a failure exporting them as DXFs... -

Hi, first of all a very fine script that fit my needs.

one thing i would see is the posibilityto increase the number of

sides/polygons on curves and circles. i would like to export the files to a milling machine and cutter with perfect circles without steps.keep doing the good work.

-

@carpa65 said:

Hi, first of all a very fine script that fit my needs.

one thing i would see is the posibilityto increase the number of

sides/polygons on curves and circles. i would like to export the files to a milling machine and cutter with perfect circles without steps.keep doing the good work.

The number of sides on curves and circles is determined by the user when they draw them, not by Slicer. If you want smoother curves in the slices, draw smoother curves in the slicee.

-

Hi TIG,

The quality of your work is impressive.

I meet a problem with a model :

When i do a XZ slices it crashes but not with Z only.

Could you tell me what is wrong with this model ?

I'm awaiting for your answer.Regards

Alain

-

It's probably because the slicing spacing results in tiny length edges, which SketchUp can't make - < 1/1000"

Either rotate the object and try slicing it in the pseudo-z axis...Or use a pseudo 'Dave' method...

With just your object in its own model...

Scale the object up by x100.

Do the slicing, increasing all of the slice measurements by x100 too.

Do the slicing.

Assuming it's all done successfully...

Rescale the results by 1/100 - you can do this using the Tapemeasure tool - pick two points on the object and type in what the distance should be when scaled-back.

Choose to scale the model.

Now everything is back to the small size.

Some geometry can exist, but SketchUp's native tools, and by extension Ruby code, cannot create it ! -

thanks for your help.

I'll let you know. -

I tried both solutions with no luck

-

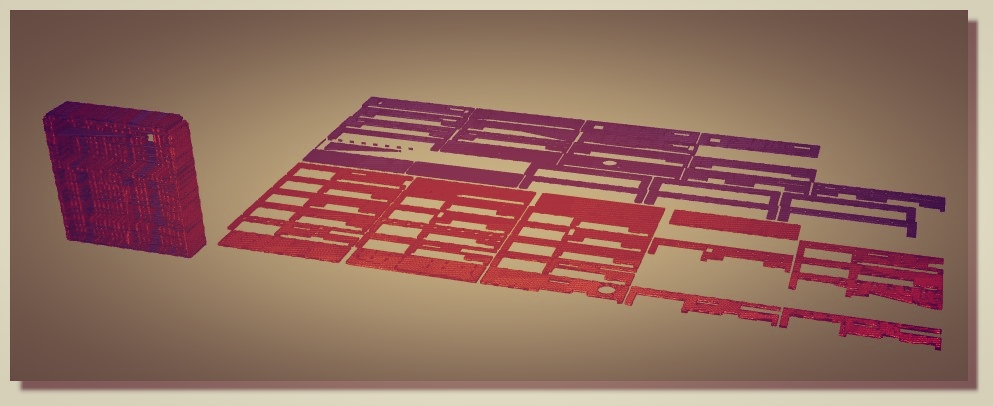

Works for me : I have Scale * 1000

Advertisement