[Plugin] Slicer5

-

There is nothing intrinsically wrong with using non-solid objects when modeling - provided that you don't want to report true volumes, or to do boolean operations using the 'Solid' tools etc... Some tools rely on the object being 'a manifold solid' for them to work properly...

"Slicer5" needs to make multiple intersections of the object of a plane that steps up/across/through the object... and then for each of those slices it has to decide what is a solid and what is a void, so it can then add faces appropriately to the cut-edges and then pushpull them into 3d slices.

So if the object is not a manifold solid it's going to be possible to intersect it with the plane and on some occasions we'll get a set of edges that won't be able to form a continuous loop, so this in turn can't take any faces and then in turn there is nothing to be pushpulled into a 3d slice.A 'manifold solid' contains just edges and faces, and every edge has exactly two faces - no more and no fewer - so no holes in surfaces and no flaps where some edges have only one face, no faceless-edges, no internal-partition faces where some edges will have three or more faces, and of course no nested groups/components etc which also render the object non-solid [even if they themselves are 'solids' in their own right]. Exceptionally 'Guides-lines/points' are allowed inside a 'solid' but not recommended...

The earlier [much more limited version] of 'Slicer' [still available] did not have the v8 solidity check, and if you were to try it it might offer what you want, always provided that you realize that the 'leakiness' of non-solid forms will never give a full set of 'true' slices...

Non-solids are repairable...

Thomthom's 'Solid Inspector' tool reports on a selected object - highlighting areas where its solidity is compromised.

My 'SolidSolver' tool [get the latest/recent update] tries to fix such issues.

If there are obvious issues like 'large holes' in the surfaces, I suggest you edit it and manually repair those first.

However, 'SolidSolver' can be useful for tidying up the less obvious internal-partitions, tiny flaps and minuscule holes etc... that can all compromise 'solidity'. The more things you have that need fixing the longer the repair might take - some repairs break other aspects which then need fixing themselves etc, and of course anyone can contrive an object with such convoluted non-solidity that after several attempts at a fix it will remain firmly 'non-solid'...

SolidSolver will eventually report [in desperation] that the object is indeed 'irreparable' unless you do some significant manual reworking of its geometry...Also note that if a solid object has tiny facets it might fail to form the intersected edges <~0.5mm and also fail to face/extrude into slices. In that case scale-up the model, scale-up you slicer settings to match, make the slices successfully and then scale-down - the tiny edges/facets can exist but their creation reaches a finite minimum limit as the tolerances can consider two points as being coincident when they are only a tiny distance apart, so no edge is made to span that tiny gap, and of course a face needs a continuous loop of edges to exist so it can't form...

-

Hi TIG,

I have a similar error like pbeseda:@pbeseda said:

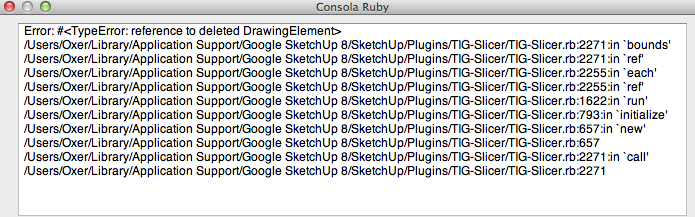

Error; #<TypeError; reference to deleted Face> > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2041;in `pushpull' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2041;in `fatten' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2041;in `each' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2041;in `fatten' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2035;in `each' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;2035;in `fatten' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;1612;in `run' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;793;in `initialize' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;657;in `new' > C;/Program Files (x86)/Google/Google SketchUp 8new/Plugins/TIG-Slicer/TIG-Slicer.rb;657This is my Console Ruby Error:

I work on Mac OSX Mountain Lion 10.8.2 and SU Pro v 8.0.1517

-

Here's v5.14 http://sketchucation.com/forums/viewtopic.php?p=374969#p374969

It adds a submenu item to activate/deactivate its toolbar without having to search through the View>Toolbars list...

It also traps errors that can occur with the Outline option etc where tiny edges can fail to form properly [size related issue].

Now if they do fail then the tool continues, so now the outline might have a few tiny bits missing, but the tool doesn't 'crash-out'.Oxer: I hope this addresses your issue.

If not, then try Scaling everything up x10 or x100, doing the 'slotting' [making due allowance for the size changes], then Scaling back down to the original size.

The small geometry can exists, it just has problems in its creation.

By now we should all be aware of the tiny edge/facet creation issues, which prevent some native-tools and also some scripted equivalents from successfully making very small geometry... -

@tig said:

adds a submenu item to activate/deactivate its toolbar without having to search through the View>Toolbars list...

Clever, I'd never had thought of such cool feature

-

Thanks TIG, I'm going to test the version v5.14.

EDIT: The same error message in the Console Ruby with v5.14 -

TIG

thanks for the update! -

@oxer said:

Thanks TIG, I'm going to test the version v5.14.

EDIT: The same error message in the Console Ruby with v5.14

Can you post the SKP or PM it if you like... with details about what you are trying to do [settings etc]...

Have you noted the issues about smallness?

It can also apply to largeness too...

SketchUp/OpenGL can't cope with very tiny or very gigantic geometry and some edges/facets can fail to form... Also have the objects miles from the origin can also cause issues.

Obviously I'd prefer that my tools don't 'fail', but sometimes it's the nature of SketchUp and not my code.

If I can see the issue first hand I can perhaps see if I can trap for such errors better, or at least advise on the best way to model to avoid the issue... -

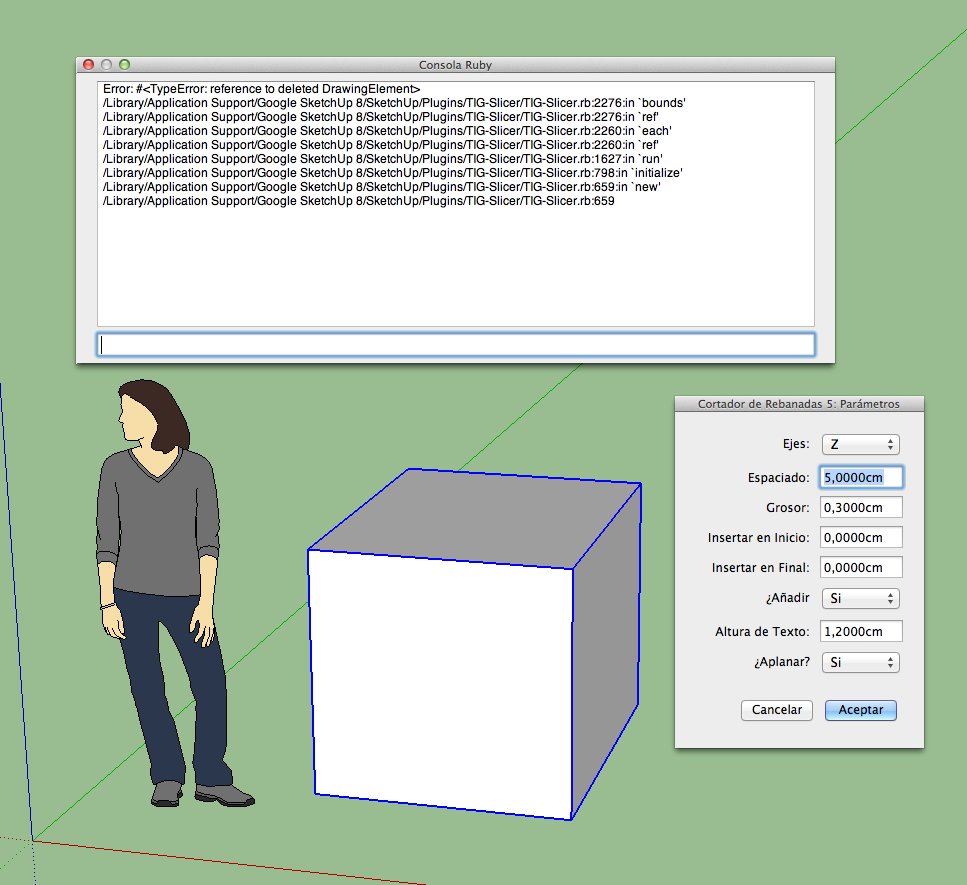

It's a very simple geometry, a cube and you can see the settings in the image below:

Perhaps there is a conflict with another plugin, i'm going to uninstall other plugins.

-

The following are the usual suspects [messing with base-class/methods ill-advisedly etc]...

SketchyPhysics [current version]

Podium [some earlier version]

SunPosition [all versions]

Matchbox [all versions] -

I have uninstalled all plugins except Slicer.rb and the problem persists, don't worry TIG, i'll use SliceModeler.rb

-

@oxer said:

I have uninstalled all plugins except Slicer.rb and the problem persists, don't worry TIG, I'll use SliceModeler.rb

That's not the point!

Are you using Slicer5 or Slicer - I am confused ?

Can you please PM a copy of the SKP that has the problem, and the settings you are trying to use...

This ought to work without issues ?? -

New Sketch Up user. Having difficulty installing on apple OS X running free Sketch Up 8. Do you have instructions posted anywhere on the steps.

-

So my aim is to use this tool to create corrugated cardboard furniture. The pieces will be cut and glued together. Should the spacing be set to the same as the thickness. Will this slice the pieces so that they lay face to face.

Also, when slicing it is prompting me if I would like to "Add the Outlines of Adjacent Slices ?" What does this mean?

-

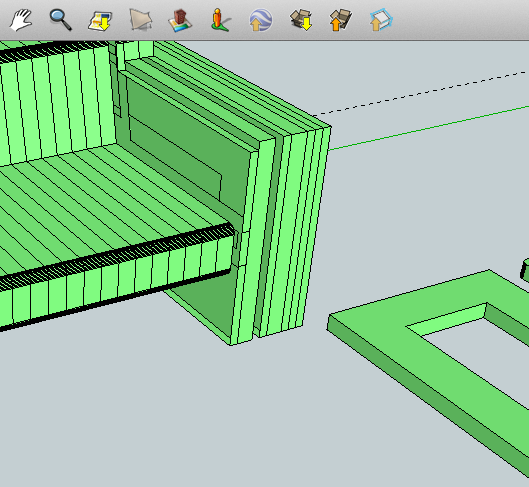

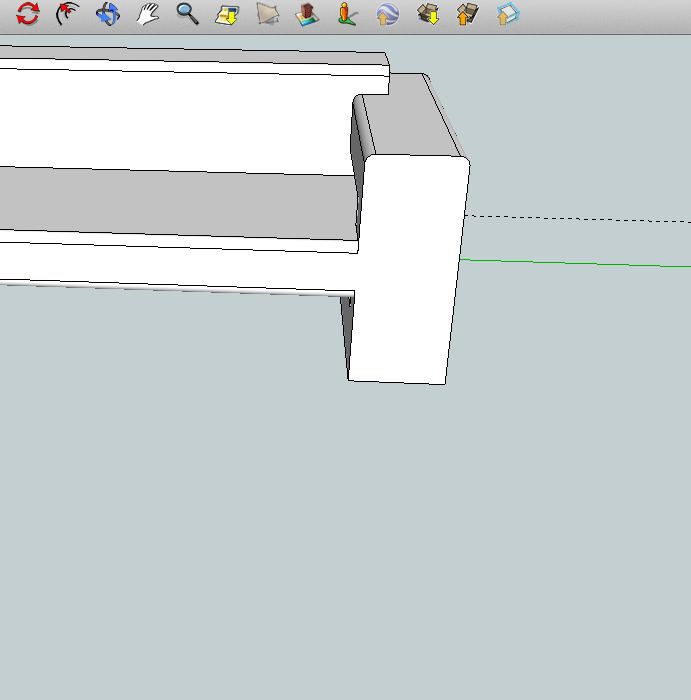

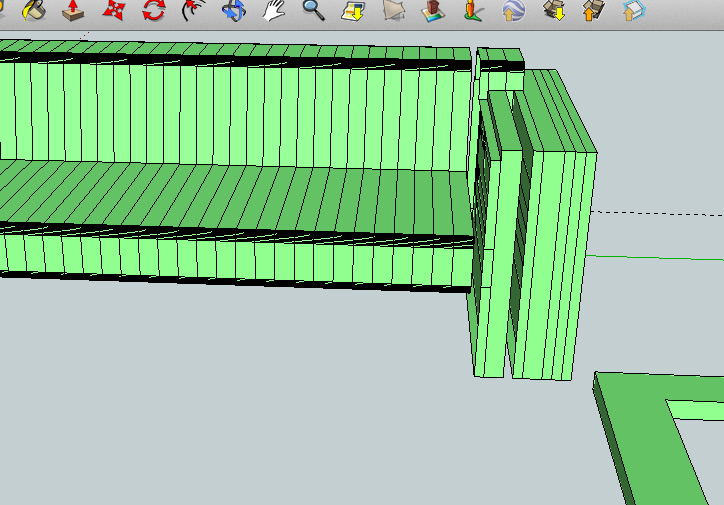

Any idea why I am loosing slices? Seems to be doing some odd stuff and loosing data. See the attached photos.

-

@tig said:

Are you using Slicer5 or Slicer - I am confused ?

Can you please PM a copy of the SKP that has the problem, and the settings you are trying to use...

This ought to work without issues ??I have used Slicer always but like the last version don't work for me i use SlicerModeller v1.3 now.

SKP file and settings that i'm using:

SU file and settings.zip

Remember I work on Mac. -

Excuse me, excuse me, excuse me TIG!!!!

The problem were that I haven't installed the font txt_____.ttf

this happens to me for not having read the first post entirely.

Excuse me again TIG. -

@nmballa said:

Any idea why I am loosing slices? Seems to be doing some odd stuff and loosing data. See the attached photos...

If you look where the slices are failing to form it where you have a curved corner. I suspect that you have made a very segmented arc in the extrusion, although even 12 segments at that small size means that the facets forming the curve are very narrow.

As explained in other posts SketchUp open GL has problems working with very tiny edges or facets, as their end points converge in tolerances and are considered equal and therefore no faces form.

This limitation extends from the native-tools into their API Ruby based equivalents.

Slicer uses 'Intersect'. It iterates across 3d space and loops of edges are obtained by intersecting a temporary 'disc' with your selected object at each step. This loop should then form faces which are extruded using PushPull to the desired thickness [other convoluted operations are used to add slots when slicing in two directions, add outlines of one slice on the adjacent slice if they are touching etc, are done as your settings].

IF the slice's loops of edges are incomplete then there is no face available to PushPull, so the slice is either 'empty' or perhaps only partially formed. The missing tiny pieces of the loop are a result of SketchUp's limitations when cutting through the tiny facets on your rounded corners, the Intersection fails to form the tiny lengths of edges and the face can't form.

If you must include these tight rounded-corners then try fewer segments in them.

Alternatively scale your whole model up, slice [using suitably adjusted settings] then scale down.

A simple 'trick' if you are working in 'cm' is to draw a line 100cm long in the model, then set your Model Info > Units to 'meters', without a units prefix and 0.0 accuracy etc.

Use the Tapemeasure tool to pick the start/end points of the 1m line, the VCB says 1.0, you type in 100 + <enter> and answer Yes to rescale the whole model.

Now do your Slicing, set the values in the dialogs as if they were 'cm' [they are actually in meters but as there are no units shown, who cares?]

The slices form and because the object's facets that are getting sliced are now 100 times larger there should now be no issues with missing faces etc.

When you are done slicing, and before exporting etc, change your Model Info > Units back to 'cm' and repeat the Tapemeasure trick, this time the VCB says 10000, type in 100.

the model scales down back to its original size. Tiny edges/facets can survive, it's just their creation that has difficulties... Now when you export the slices' sizes should be as expected and they should all have been perfectly made... -

@oxer said:

Excuse me, excuse me, excuse me TIG!!!!

The problem were that I haven't installed the font txt_____.ttf

this happens to me for not having read the first post entirely.

Excuse me again TIG.

OK, I never thought of that omission !

OK, I never thought of that omission !

On a PC if you don't have that TXT ttf font then the last used font is automatically used by 3dtext anyway, but on a MAC it just crashes out unexpectedly. The TXT 'stick' font is the best for CNC engraving of the slices references [important on complex slicing to keep track of the pieces], because this font is as near to a single stroke in 3dText as we can get.

TXT is one of the oldest AutoCAD fonts, made for use in really old pen-plotters - this is the TTF version of their even older SHX shape font [because SUp needs TTF for its 3dText]...Anyway... I hope it's now working OK for you...

-

@tig said:

@nmballa said:

Any idea why I am loosing slices? Seems to be doing some odd stuff and loosing data. See the attached photos...

If you look where the slices are failing to form it where you have a curved corner. I suspect that you have made a very segmented arc in the extrusion, although even 12 segments at that small size means that the facets forming the curve are very narrow.

As explained in other posts SketchUp open GL has problems working with very tiny edges or facets, as their end points converge in tolerances and are considered equal and therefore no faces form.

This limitation extends from the native-tools into their API Ruby based equivalents.

Slicer uses 'Intersect'. It iterates across 3d space and loops of edges are obtained by intersecting a temporary 'disc' with your selected object at each step. This loop should then form faces which are extruded using PushPull to the desired thickness [other convoluted operations are used to add slots when slicing in two directions, add outlines of one slice on the adjacent slice if they are touching etc, are done as your settings].

IF the slice's loops of edges are incomplete then there is no face available to PushPull, so the slice is either 'empty' or perhaps only partially formed. The missing tiny pieces of the loop are a result of SketchUp's limitations when cutting through the tiny facets on your rounded corners, the Intersection fails to form the tiny lengths of edges and the face can't form.

If you must include these tight rounded-corners then try fewer segments in them.

Alternatively scale your whole model up, slice [using suitably adjusted settings] then scale down.

A simple 'trick' if you are working in 'cm' is to draw a line 100cm long in the model, then set your Model Info > Units to 'meters', without a units prefix and 0.0 accuracy etc.

Use the Tapemeasure tool to pick the start/end points of the 1m line, the VCB says 1.0, you type in 100 + <enter> and answer Yes to rescale the whole model.

Now do your Slicing, set the values in the dialogs as if they were 'cm' [they are actually in meters but as there are no units shown, who cares?]

The slices form and because the object's facets that are getting sliced are now 100 times larger there should now be no issues with missing faces etc.

When you are done slicing, and before exporting etc, change your Model Info > Units back to 'cm' and repeat the Tapemeasure trick, this time the VCB says 10000, type in 100.

the model scales down back to its original size. Tiny edges/facets can survive, it's just their creation that has difficulties... Now when you export the slices' sizes should be as expected and they should all have been perfectly made...Hmmm... Having issues with defining the value of the segments in the arc. You are correct, it is defaulted to 12. Not sure how to change it. Will try scaling and report back.

-

And now on to my next issue. I am trying to slice this file down to 1/4 inch or even 1/8 inch. Seems its just too much processing and the program locks up. Running processor 1.86 GHz Intel Core 2 Duo, 4 GB of Ram. It only seems to happen in the Y axis. Z is not an issue. Thoughts?

Advertisement