[Plugin] Slicer5

-

Hi there Tig Really smart Plugin It works really well

I do have a question :

Is it possible to make thickness bigger than spacing

I have a solid I have to divide in to several pieces with a spacing smaller than the thickness of the piecesThanks in advance for your answer

-

Hi there TIG,

Firstly, thanks, this is an amazing tool.

I have a problem exporting DXF - it crashes every time - was doing a quick test with a cube, quite large, about 8m3 it starts to compile the export, but never completes and goes to the bugsplat screen.?

Using latest Pro sketchup on 64 bit

Any ideas?

Thanks, Andrew

-

@dcorrigan said:

Hello,

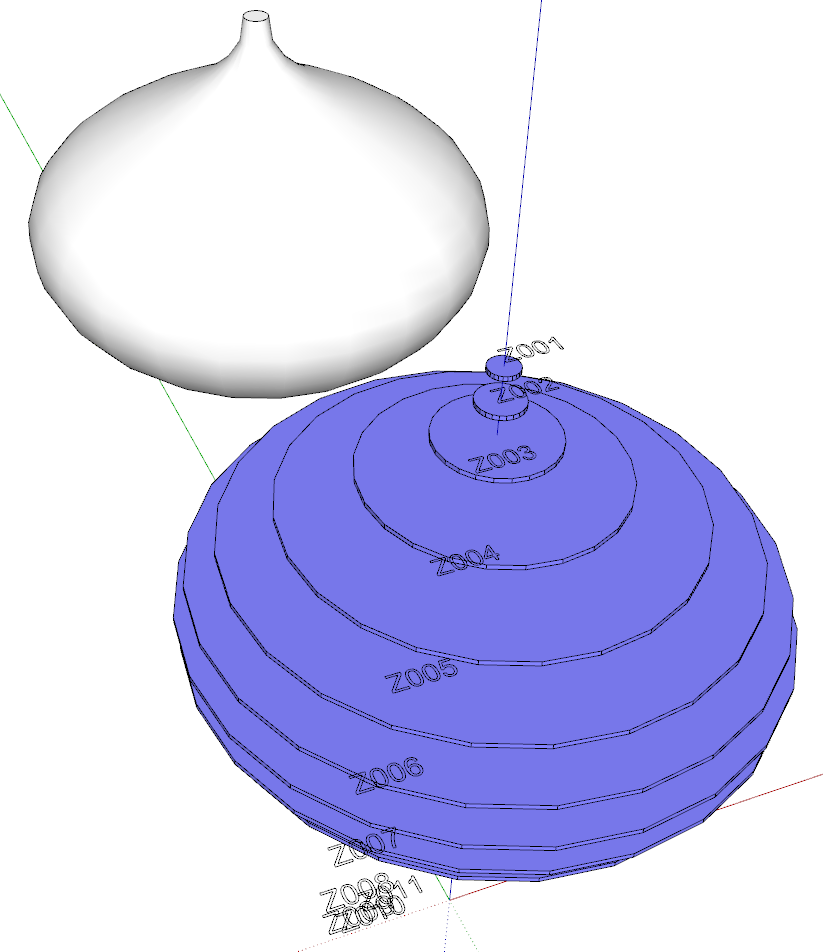

I am working on making an extension to Slicer to allow it to export .svg files.

When Slicer goes through and flattens the model it appears to do some layout optimization so each layer takes up only enough space for itself. I am making a 3d printer that reads svg files so ideally each layer would have the same origin in it for repeatable stacking. I have quite a lot of ideas for fixing it but was wondering if you had any input on a good path to follow.The other problem that I have encountered when using Slicer is that it is unstable once the number of layers gets above 100. I think the best way to fix this instability would be to use the top and bottom offsets to create several sections that are then cut. I think I can write code to do that but again, any help or advise would be greatly appreciated.

A video of my plugin in action as well as my problem with alignment: https://www.youtube.com/watch?v=4bdfIMw5uiI%26amp;feature=youtu.be

When I get the code for the svg export fully working I would be happy to send you a copy if you would like to include it in your plugin.

Thank you very much,

Dan CorriganHi, did you get this version working? Could I have a copy please?

Thanks, Andrew

-

Great extension!

Slicer5 is a bit more picky than SliceModeller regarding Solid Manifold requirements.

My model is a STL exported from another program called BoardCAD. It has 900 short edges, 66 internal faces and 3 surface borders which I will need to correct to use this plugin. SlicerModeller doesn't need me to do this. sliced with slicemodeller that couldn't with slicer5

If you are trying to correct a model I suggest to use MeshMixer because it has many functions specifically designed for this purpose. I spent weeks trying to fix these mesh to solid problems (SOlidSolver, FixSolid, SolidInspector) until I found this! Also bear in mind that many tutorials for it are out of date - the tool now is much better. Bear in mind that it's designed with mm scale in mind... whereas sketchup needs metre scale really due to it's own shortcomings. Still, you can export and import with STL import/export sketchup plugins and work between the both.

-

I need to get in contact with the creator of this plugin (TIG). Anyone know how?

Thanks -

@boardslice said:

I need to get in contact with the creator of this plugin (TIG). Anyone know how?

Thanks -

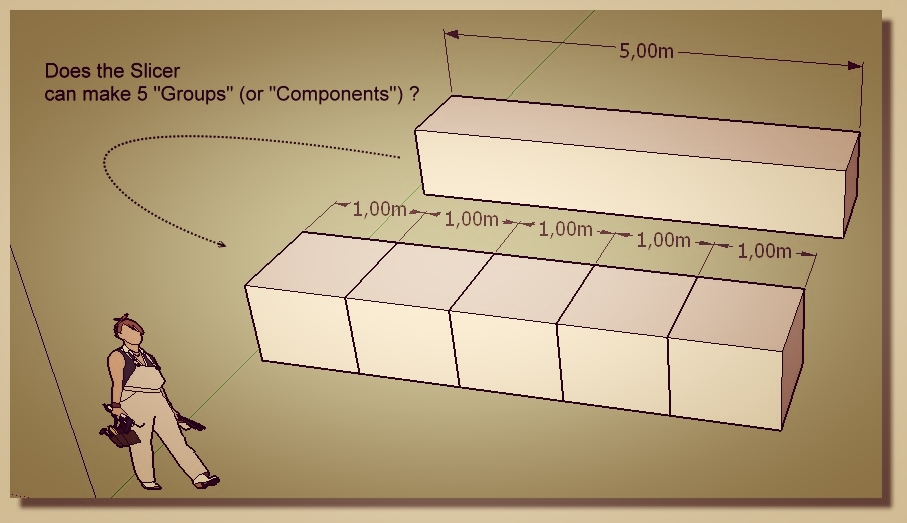

Possible ? ( 5 groups "pasted" )

I find many things except that!

-

Great plugin TIG, thanks !

I've done a lot of tests and it took me a while to understand how to generate exactly the number of slices I needed (by leaving the spaces value at zero at first and choosing number of spaces afterward)

The only thing I can't figure out so far is how to NOT generate start and end slices.

Tried negative value for offset without success.

What should the settings look like to generate just a central slice ?

For example to generate just one central slice in X and one in Y (resulting in a 2 pieces X shaped object when seen from above).Is this possible with the actual version ?

Cheers !

-

Thanks TIG, for this plugin ! It's really good BUT... There is a recurent bug i can't fix. After my settings finished, the tool runs but at the end the whole model disappears. I tried to uninstall it, and retried many times, in vain. One or two times, it worked correctly on a test ( a simple cube), but not on my model. I don't understand, it's really a shame ! Could you help me please ? Thanks a lot !

-

Hi Tig, I just submitted a message, and I just realize I wrote "it's a shame" ! So sorry, I'm french, and exhausted : I wanted to say "It's a pity", of course !!!

Apologise...

Apologise... -

@jago25_98 said:

Great extension!

Slicer5 is a bit more picky than SliceModeller regarding Solid Manifold requirements.

My model is a STL exported from another program called BoardCAD. It has 900 short edges, 66 internal faces and 3 surface borders which I will need to correct to use this plugin. SlicerModeller doesn't need me to do this. [attachment=1:2cvc0050]<!-- ia1 -->sliced3.skp<!-- ia1 -->[/attachment:2cvc0050] [attachment=0:2cvc0050]<!-- ia0 -->sliced when should not be possible.PNG<!-- ia0 -->[/attachment:2cvc0050]

If you are trying to correct a model I suggest to use MeshMixer because it has many functions specifically designed for this purpose. I spent weeks trying to fix these mesh to solid problems (SOlidSolver, FixSolid, SolidInspector) until I found this! Also bear in mind that many tutorials for it are out of date - the tool now is much better. Bear in mind that it's designed with mm scale in mind... whereas sketchup needs metre scale really due to it's own shortcomings. Still, you can export and import with STL import/export sketchup plugins and work between the both.

Hi jago, Slicer5 doesn't work correctly anymore, after many tries. So I Just see your post, and looked for slice modeller and Mesh mixer (cause as you, solid inspector and edge inspector from fredotools can't save me). I can't find those plugins, neither on extension store, nor extension warehouse, nor in google. Could you give me a lead, please ? Thanks !

-

@cacommenceamefairechier said:

Hi jago, Slicer5 doesn't work correctly anymore, after many tries.

What do you mean it doesn't work anymore? I just installed it and it works just as it should.

-

@dave r said:

@cacommenceamefairechier said:

Hi jago, Slicer5 doesn't work correctly anymore, after many tries.

What do you mean it doesn't work anymore? I just installed it and it works just as it should.

[attachment=0:31yy8x49]<!-- ia0 -->Screenshot - 7_18_2016 , 9_42_14 AM.png<!-- ia0 -->[/attachment:31yy8x49]I mean the program either runs and bugs with no answer,or the whole model disappears at the end of the slice. I did tests with a same simple shape (a cube),and sometimes the work is done but very rarely. I tried to uninstall and reinstall it, in vain. However when i installed it for the first time, it worked correctly. It camed suddenly. Could it be a competition with another plugin ?

-

It could be you have a conflicting extension or something else causing the problem. Or it could have something to do with the way you are using it. There haven't been any other recent reports of problems.

-

Ok thanks ! I will try to clean my plugins files, and will report here if it's ok. And I ask for again concerning mesh mixer plugin. Is it still available ?

-

I'm using Windows Vista with SketchUp Ver. 8.0.14346(>=Ver. 8). Can't install SketchUp update because of Vista. I have Slicer5 installed but I keep getting the error "Object is not manifold". I've check for problems in Blender and in MeshLab, my mesh is manifold. I'm just testing with a simple cylinder. Any ideas or help appreciated, thanks.

-

Let's assume you have made a group or a component-instance that you want to slice...

Select it and look at Entity Info...

If it is a manifold solid then it will say 'Solid' in the description in the top bar, it will also show a volume.

Slicer needs a solid to process, so it can make proper slices through it.

-

I did not have a solid component. I just right clicked on the mesh, selected 'edit component' and that made the mesh a solid based on the Entity Info box.

I've been able to make single axis slices(x or y or z) but not able to make multi axis slices with slots. Except for on simple meshes like a cube or cylinder created in SketchUp. On the more complex models I get a Bug Splat error in SketchUp.

-

@andre205th said:

I did not have a solid component. I just right clicked on the mesh, selected 'edit component' and that made the mesh a solid based on the Entity Info box.

It sounds like you have a nested component. If it isn't nested, Entity Info won't show it as solid if it's open for editing because you'd have raw geometry selected.

-

I was in the process of learning how to write and code for something just like this, and behold...TIG

You are a genius man. I did my first model of a cape cod that I used the solid inspector on to make it solid for this plugin and it works well! There are a few missing parts/sheets here and there but I will do the scaling up x10 or x100 again with different settings to see how that works then scale back as suggested and maybe it will become flawless! I have spent many months doing this by hand this past year so donations will be on the way, and possibly more steady if I can get my models consistent

You are a genius man. I did my first model of a cape cod that I used the solid inspector on to make it solid for this plugin and it works well! There are a few missing parts/sheets here and there but I will do the scaling up x10 or x100 again with different settings to see how that works then scale back as suggested and maybe it will become flawless! I have spent many months doing this by hand this past year so donations will be on the way, and possibly more steady if I can get my models consistent  I was able to get down to 1/32" (about 0.79mm (thickness of my watercolor paper for 3d modeling real-time) and I am going to make a paper model of this soon!

I was able to get down to 1/32" (about 0.79mm (thickness of my watercolor paper for 3d modeling real-time) and I am going to make a paper model of this soon!By far one of the best additions to V8+ I have encountered as an artist! Hats off, and models on!

Flaws so far (either my user error or just fyi that may already be noted(:

- When processing, flattening says fattening

minor I know but it is something to help

minor I know but it is something to help

- Skipped slices. Maybe due to my scale, Ill keep working

- zooming (maybe major?) sometimes when finished, the model disappears all together from any view and camera settings. zoom does not work or possibly too sensitive due to my scale? Not sure but just something I found that had me saving and reloading SU to get it back. The undo saves as expected, but still nothing to show. Not happening often, rare.

The guts of this are extreme and amazing! I will make sure within the next few months (remind me lol) that you are compensated for saving me so much time with something I have extreme passion for!

- When processing, flattening says fattening

Advertisement