Strange behaviour of SU when molding a door

-

Yes, that's a good way, but only for "regular" angles, as you said.

-

@brandy20 said:

Yes, that's a good way, but only for "regular" angles, as you said.

well, the sphere technique only works with 'regular' angles..

using the first method shown in the video, you can do 'unknown' angles via the standard copy_divide_array function of the rotate tooljust copy/rotate something then enter " /<# of copies> " in the meas. box...

the angle will be divided by that amount. -

Yes, what I meant is that it could be a problem if you have odd angles as in my door, with several values after comma. If you can easily manage it with the plugin, you could have some trouble with your last method.

-

@tig said:

Mac1, isn't that all 100x too small ?? Look at the dimensions no door is 3mm wide ?

Look at the OP he shows it scaled by 100X. I know look at why I questioned his scale above.

-

@unknownuser said:

@mac1 said:

For general interest here is the widow to scale using the follow me tool and better modelling practice.

Started extrusion further from bottom corner.

Use 2nd order Bezier to form better tangents than the arc tool.mac, i think you're missing a key element of this thread.. the corners are rounded.. not square as in your drawings..

i think it's been stated a few times in this thread by a few different people that follow-me is ok for angular intersections.. the problems arise when the path is an arc/curve[attachment=0:1xvr54f4]<!-- ia0 -->sporty_ello_diff.jpg<!-- ia0 -->[/attachment:1xvr54f4]

Look at my above post=> I model as I build. I have stated more than once the OP has indicated to build as separate components and that is dangerous or at least I think so. I will not post anything I think can lead to a safety issue. Maybe you can build and cut the profiles with a router but I cannot not.

-

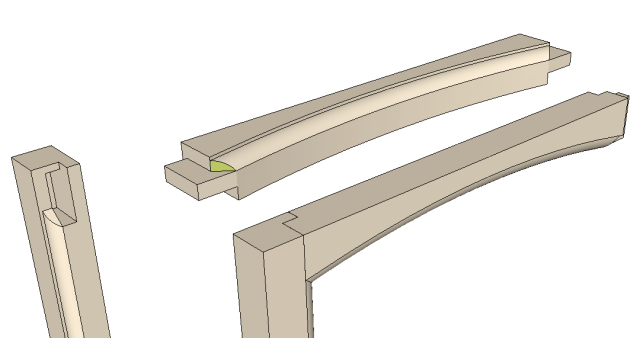

Hello,

attached how I would do that frame door in my workshop.

Moulding will be done piece by piece (rails and stiles) and without any risk.

Just a question of method with a jig for the top rail.

-

@mac1 said:

@unknownuser said:

@mac1 said:

For general interest here is the widow to scale using the follow me tool and better modelling practice.

Started extrusion further from bottom corner.

Use 2nd order Bezier to form better tangents than the arc tool.mac, i think you're missing a key element of this thread.. the corners are rounded.. not square as in your drawings..

i think it's been stated a few times in this thread by a few different people that follow-me is ok for angular intersections.. the problems arise when the path is an arc/curve[attachment=0:tkmtx0re]<!-- ia0 -->sporty_ello_diff.jpg<!-- ia0 -->[/attachment:tkmtx0re]

Look at my above post=> I model as I build. I have stated more than once the OP has indicated to build as separate components and that is dangerous or at least I think so. I will not post anything I think can lead to a safety issue. Maybe you can build and cut the profiles with a router but I cannot not.

Mac, I'm sorry but I don't understand what you mean in your post. What is dangerous and can lead to safety issues?

Could you please reformulate it?

Tks,

Luca

-

@jean-franco said:

Hello,

attached how I would do that frame door in my workshop.

Moulding will be done piece by piece (rails and stiles) and without any risk.

Just a question of method with a jig for the top rail.[attachment=1:p1b69xr2]<!-- ia1 -->'s door_640.png<!-- ia1 -->[/attachment:p1b69xr2]

[attachment=0:p1b69xr2]<!-- ia0 -->Sportello_mac1+Jean-Franco.skp<!-- ia0 -->[/attachment:p1b69xr2]

I know this is going off topic, but I in my opinion, assembling the frame and routing next is safe and pretty fast. If you want corners instead of angles you can just remove them later with a chisel. Your is another available method, safe as well, but a little more time consuming.

Off topic closed.

-

@brandy20 said:

Yes, what I meant is that it could be a problem if you have odd angles as in my door, with several values after comma. If you can easily manage it with the plugin, you could have some trouble with your last method.

yeah, the manual draw method does work with the oddball angles.. that's how i've been doing it for years.

when TIG wrote lathe, i immediately started hounding him to figure out a way to allow the user to pick points on screen to deal with angles that sketchup is incapable of measuring precisely... which he accomplished..i haven't done the manual building since!

-

@brandy20 said:

@mac1 said:

@unknownuser said:

mac, i think you're missing a key element of this thread.. the corners are rounded.. not square as in your drawings..

i think it's been stated a few times in this thread by a few different people that follow-me is ok for angular intersections.. the problems arise when the path is an arc/curve[attachment=0:2doecb5p]<!-- ia0 -->sporty_ello_diff.jpg<!-- ia0 -->[/attachment:2doecb5p]

Look at my above post=> I model as I build. I have stated more than once the OP has indicated to build as separate components and that is dangerous or at least I think so. I will not post anything I think can lead to a safety issue. Maybe you can build and cut the profiles with a router but I cannot not.

Mac, I'm sorry but I don't understand what you mean in your post. What is dangerous and can lead to safety issues?

Could you please reformulate it?

Tks,

Luca

i think it means something like:

"the follow-me tool is fully accurate... if the follow-me tool fails to draw an accurate extrusion then that means the part is too dangerous to build in the real world therefore it doesn't matter.."

[but ok.. i'm being a jerk now.. i'll stop]

-

Jeff sorry but not quite.

I was coming off the fact I got the message from the OP he was going to build the components as shown and yes I know the scale shown in the OP is not reasonable ,but I consider that immaterial to the safety issue. Those components show a short stub on the component that would have to be milled some way either by a bearing guided bit or a table + fence or bearing bit + guide post or

IMHO that can become dangerous very quickly if by router. That was what I have been screaming about. Hope the OP can enlighten me and I will obviously learn some thing. Probably I am stupid

IMHO that can become dangerous very quickly if by router. That was what I have been screaming about. Hope the OP can enlighten me and I will obviously learn some thing. Probably I am stupid

-

Mac, nobody's stupid here, sometimes written words may lead to misunderstandings.

Honestly...I think that there's not safety issue in routing that door in a workshop, whose measures are (just to be clear) 568mm by 328mm. A pretty normal door, I'd say. What's the problem when you safely clamp the piece on the workbench and rout with a hand router, side by side, every time changing the position of the clamps?

For the use of the Follow Me tool, it's alrealdy been stated that it is not accurate for this kind of molding and Extrude by Lathe works efficiently, as well explained in the above posts.

I post you a similar door I did some time ago, in the real world. My ten fingers are all there, and safety was never compromised.

-

brandy20 thanks for the clarification.

Sorry for getting back late. Struggling with computer and trying to deleted old w98 set as dual boot with my XP. Would you believe.

I got the small dimensions from the original post showing they were scaled by x100 but that is not the real issue.

Is it correct to assume when you route you do like a dry fit of the two mating rail and stile so you have something to ref from. Doing separately was my concern.

I guess I mislead everyone on the follow me tool. Was just trying to show one can get down to relative small size. It has served many people well.BTW: The older I get the more I realize it is dumber, dumber and dumber when I see all the great talent around. It's like the older one gets the better you were. That is just a fact of life =>technology marches on.

-

Everything is clear now, I like this!

BTW it was a very interesting discussion.

Luca

-

Since I found this an interesting discussion, at least for me, I made this video, showing how I drew the molding door on Jeff's hints. I hope it will be useful and interesting for someone.

[flash=800,600:7ro5mgri]http://www.youtube.com/v/D4yh_df7flo[/flash:7ro5mgri]

Advertisement