[Plugin] Center of Gravity

-

Outstanding work TIG, thanks that was quick, I can confirm it works after the upgrade of the plug-in.

Cheers

-

The plugin does not seem to be able to detect hollow spaces. Am I doing something wrong? I am trying to find the CoG of steel assemblies but when it calculates the weight, it includes the space between plates and gives me a number much higher than the actual weight.

-

Your image attachment isn't showing.

An object needs to be a sensibly formed 'solid' - as reported in Entity Info.

Otherwise results can be flaky...

'Hollows' are accounted for, if it's a proper solid...If you attach your SKP we can look at it...

-

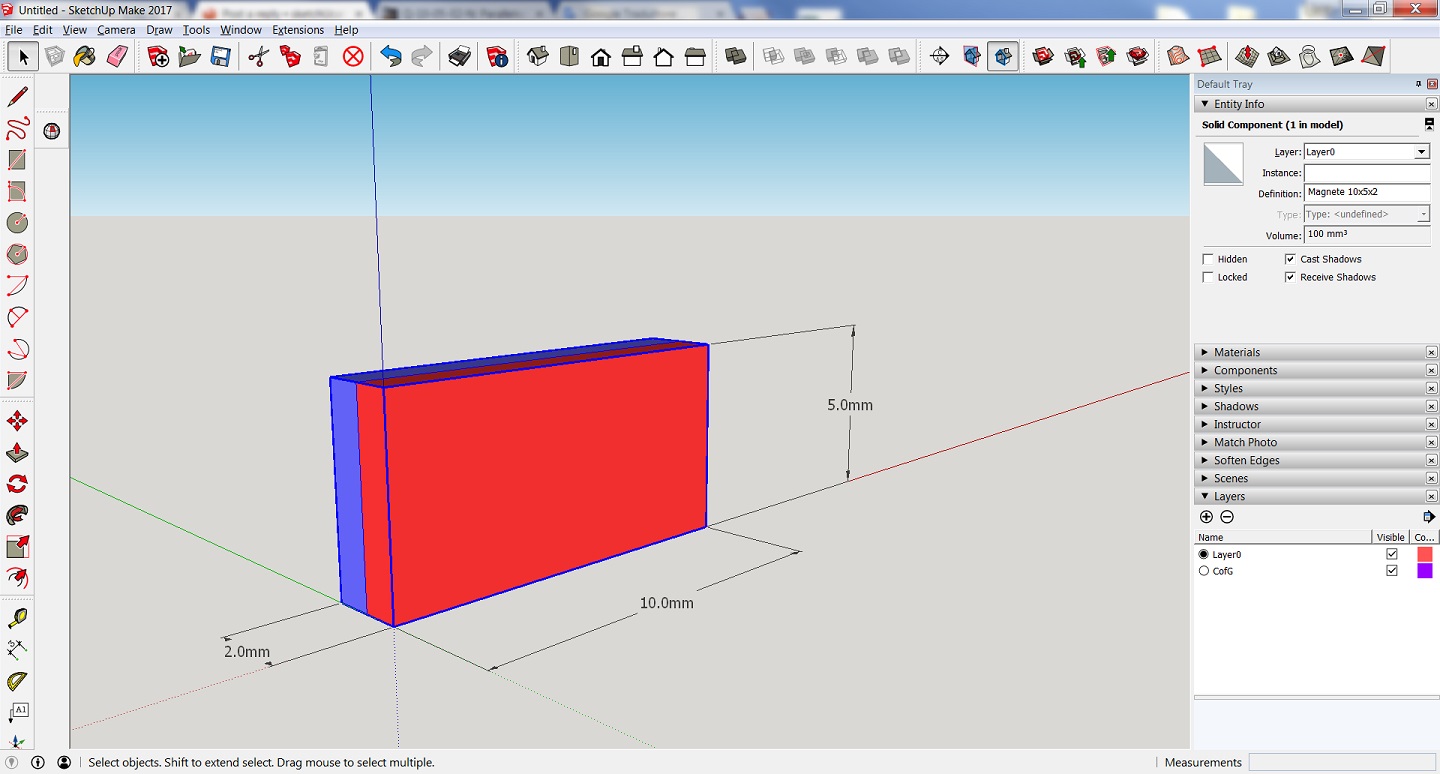

Hello All, hello TIG,

I want to calculate the center of gravity of a small magnet, but the calculation always report volume = 0 and eventully weight = 0.The plugin works perfectly on my pc with larger objects, the density is 7.6 g/cm3, I'm a newbie with sketchup in general, I'm probably doing something wrong

Luca

-

It must be a rounding issue.

The object looks like it has no volume to SketchUp, therefore no weight.I'll investigate...

-

Yes, I see it.

It was never intended for such small objects.

It rounds to the nearest cu", so your small object appears to have no volume !

I'll look at a way of adjusting it... -

Wow, very interesting. Thank you very much!

-

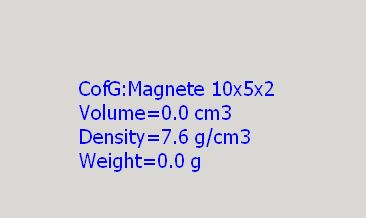

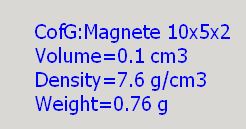

Here's v3.0 https://sketchucation.com/pluginstore?pln=CofG It now reports the Volume/Weight of very small objects with more dp etc...

-

Thank you very much, I will use it tomorrow!

Luca

-

It obviously works!!!

Thank you very much TIG, extremely useful plugin.

Luca

-

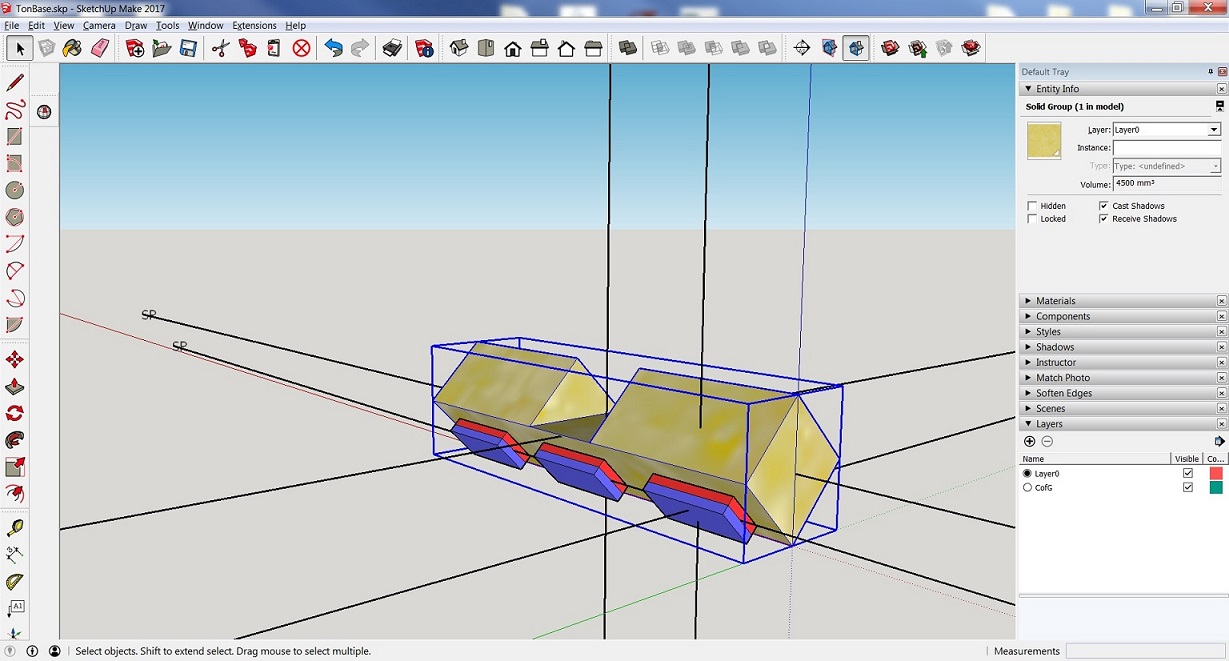

Other little thing I can't understand.

The little magnets of my previous post goes attached to a wood base that according to sketchup is 4500 mm3, but calculated by CoG is 4000.

The volume of the magnet is ok regardless is far little than the wood base.

Bye,

Luca

-

My feeling is that if the volume is only mantissa, ie 0.04555 cm3 works good, when volume is ie 4.75 cm3 decimal part is truncated.

Luca

-

Must be a glitch somewhere in the 'rounding'...

I'll fix it... -

Here's v3.1 https://sketchucation.com/pluginstore?pln=CofG The rounding glitch on some small values is now fixed.

The Volume/Weight now shown with between 1dp and 4dp, suppressing trailing zeros beyond .0 as necessary. -

It works!

Thank you very much,

Luca -

Mine does not show up with the added component information. It just turnes the solid into a bunch of layers (horizontal lining). SU 8 Pro windows 7 64bit

-

Version 8 is by now pretty much unsupported, but it should still work.

If you have the Ruby Console open what errors do you see when it fails ?

It's clearly doing its temporary slicing to get the centroid... but not completing...How big is this object ?

Can you upload the SKP you are having issues with...

-

@tig said:

Version 8 is by now pretty much unsupported, but it should still work.

If you have the Ruby Console open what errors do you see when it fails ?

It's clearly doing its temporary slicing to get the centroid... but not completing...How big is this object ?

Can you upload the SKP you are having issues with...

TY for the quick response

So, the console shows in the attachment.

It initializes, goes through the steps, and gets to call.

Or looks like ruby reads up maybe idk

The skp is attached also

Thank you for helping! I notice the ruby icon is not right also, so is it possible it is a ruby issue with SU8 atm?

Thank you for helping! I notice the ruby icon is not right also, so is it possible it is a ruby issue with SU8 atm?

-

Can you please post the top half of the error message [or even better expand the RC window and attach the whole error].

Without all of it, the cryptic second half is somewhat useless...PS: I confirm that your SKP works fine in v2017/v2018 so it's probably a v8 glitch where making it compatible for the last half dozen updates generated an error in very old ones, like v8.

Unfortunately I don't have v8 loaded any more, but I can try and see what the RC error is, make some tweaks that maintain the current versions' usage and PM you that fixed RB to try and see if that works for you...

If so I'll then republish it... -

PS: I'd still like to see the full v8 error, but I've also PM'd you an older version of the RB, which I am hopeful will work in v8 for you...

Advertisement