Archimedes screw - engineering help needed

-

I am re-writing this post - it was lost because of the reset.

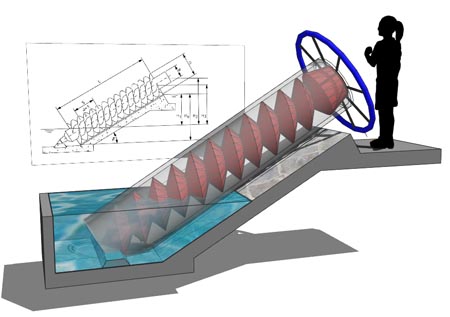

I am designing an activity garden for a school. We have an idea to build a working archimedes screw to raise water that the kids can play with. Do any engineering minded people out there have any tips about constructing an archimedes screw?

-

Dear Jon,

Do you still require help, or is this a repeat because of the bug? What help do you need exactly?

Kind regards,

Bob -

Yet again Watkins, your in there staight away, us early morning people.

Just a repeat post really. Thanks for the quick response, I just wondered if anybody had any experience or ideas about this. I know an excellent engineer who can fabricate this and I think I'll be fine when it comes to the working drawings, but just thought I'd post it here in case anybody had advice to offer. -

Dear Jon,

I know an excellent engineer who is now retired. He has just got interested in Sketchup so I will pass on this link. He might have some advice. It would also be nice to have more engineers contributing to this forum.

Good luck with the design.

Regards,

Bob -

@unknownuser said:

Yet again Watkins, your in there staight away, us early morning people.

Just a repeat post really. Thanks for the quick response, I just wondered if anybody had any experience or ideas about this. I know an excellent engineer who can fabricate this and I think I'll be fine when it comes to the working drawings, but just thought I'd post it here in case anybody had advice to offer.Jon,

The attached skp I made might help you a bit to see which way to go.

(For kids you need to adjust the scale though )

)

And as an example of the helical screw see: (credit to NoelD this time)

http://sketchup.google.com/3dwarehouse/details?mid=77d22eb035e66c59244b1e8fee0e9e34Wo3Dan

-

Wo3Dan

Thanks for that, that's great

edit: just opened it, it's really great!

-

Dear Jon,

Presumably you would like some suggestions on how to manufacture the screw at a reasonable cost.

May I start by suggesting you look for a supplier of plastic sewer pipe (or mains water supply pipe) as that looks to be a low cost option for the tube. Seeing as it is such a small piece, you may even get the company to supply FOC. The pipe should have a reasonable wall thickness (say around 10 mm)so that it doesn't distort under load. End pieces could be made from 25 mm thick plastic (polypropylene?) plate and fixed to the ends of the tube using M10 stainless steel studding running between the plates on the outside. The plastic end pieces could be machined to provide the bearing surfaces or you could use a suitable low friction plastic bearing, such as: http://www.igus.co.uk/iPro/iPro_02_0002_00_GBen.htm?ArtNr=&C=gb&L=en and add additional features to retain the bearings. [NB. I just did a quick search on the Web and so the choice of plastic bearing is probably not optimum, and perhaps not even close].

The impellor is the tricky part as the edges of the screw have to 'wipe' the inner bore of the tube to minimise the flow back. Therefore, they have to be made accurately. Weldable plastic sheet (3 to 5 mm thick) might be used to make up the impellor blades. The sections could be water jet cut to high accuracy (a few tenths of a mm), shaped using a hot air gun (you will require a jig so that the forming can be done accurately), welded together to form the spiral impellor, and then welded to a plastic shaft (thick-walled plastic tube).

As Jean would say, "just ideas".

Kind regards,

Bob -

Thanks watkins.

-

There's one of these at a place called Oxford Island Nature Centre on the shore of Lough Neigh (that's the big hole in the middle of Northern Island).

If I remember correctly its about 600mm dia, and has a simple hand crank on the end instead of the wheel you have, this way a child could turn it as fast as they can!.

I think its made from stainless steel.

The size is almost identical to your sketch.

It sits in a very shallow paddling pool with a sump similar to yours under the base.

I'm unsure as to the sealing between the screw and the inner wall of the tube but I think there isn't any.

If I remember right there is a 15-30mm round bar welded to the blade edge of the screw to prevent injury.I've looked online, but other than general area photos there are non of the play area, sorry

Just a thought:

Would a grain elevator from a combine harvester do the trick, the only other time I've seen them being used is at sewerage treatment plants to move the 'stuff' from sediment tank to sediment tank. -

In the one I have seen (but don't remember where-some activity park I suppose) the tube and the "screw" turned together and the screw was tightly welded inside the tube, so no leaking.

Anssi

-

Ahhhh, Anssi, you got it, I knew that there was something I forgot about the one I saw, the tube and screw were turning together.

-

Thanks Paul and Anssi. When I've drawn it up properly I'll post the result.

-

When you make the screw and the tube together, it actually works like those big concrete carrying trucks (or even the smaller concrete mixers). Examine them and you'll have the idea.

-

Dear Jon,

You have probably done your own search for suppliers, but see the attached file for UK manufacturers of screw conveyors. It is likely that you can design around standard parts, which would be a saving.

Regards,

Bob

-

Watkins your effort and help is great, thanks so much.

-

Dear Jon,

The engineering looks fun, and so I couldn't resist getting involved.

Regards,

Bob

Advertisement