Joint Push Pull Classic (Old version) - v2.2a - 26 Apr 17

-

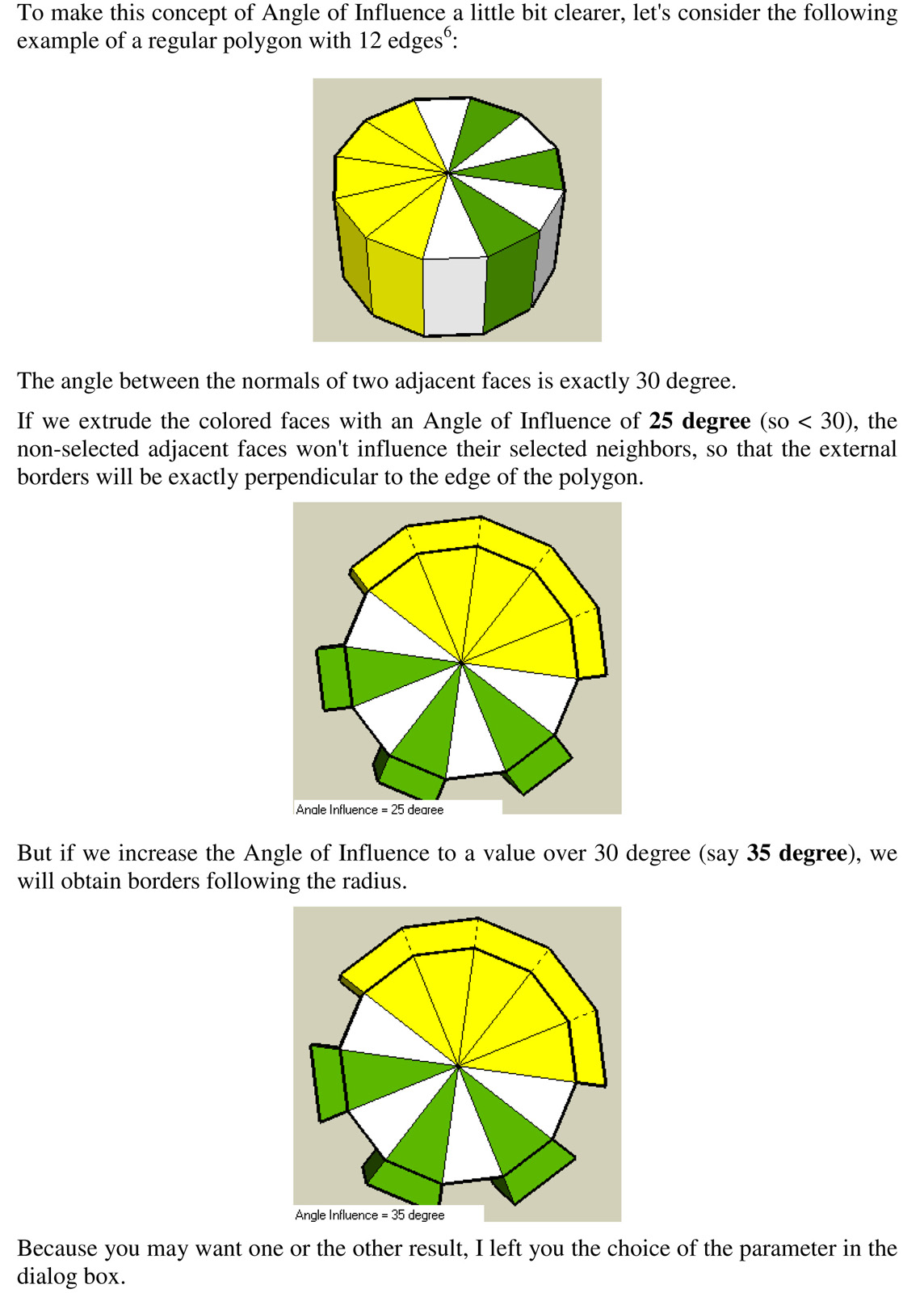

pbacot is correct. I've attached the relevant portion of Fredo6's support document to make the point clearer. In attempting to reproduce his example, I find that no matter what the angle of influence is, I only get the results of the Fredo's middle image. That is, extrusions next to deselected faces are normal. pbacot, you said this feature worked before. I wonder if your file was done with a previous version of JPP? I grant you the support doc is now 4 years old.

-

Hi there,

This script is very close to doing exactly what I need, and I'm hoping somebody might help me figure out how to take it the rest of the way... I'm trying to take roof systems that are drawn as single-faces, and then vector push them vertically into their proper thickness. JPP works fine for this, but it ends up with vertical hidden lines between the upper and lower face, which make it messy to turn the final roof into a solid, which is necessary for further editing. Outside of going through the complex roof form and deleting or filling-in every hidden edge, is there a way that vector push pull can just make a standard solid geometry?

Thanks!

-

Look through the tools options [and help docs].

You can set it to retain the original face, and also NOT to make 'internal partitions'... -

@engineeric said:

pbacot is correct. I've attached the relevant portion of Fredo6's support document to make the point clearer. In attempting to reproduce his example, I find that no matter what the angle of influence is, I only get the results of the Fredo's middle image. That is, extrusions next to deselected faces are normal. pbacot, you said this feature worked before. I wonder if your file was done with a previous version of JPP? I grant you the support doc is now 4 years old.

Since JPP 2.0, the angle of influence is not used any longer (see release note).

I don't remember why I had to suppress this.

I'll try to have a look at the code to see if I can re-stablish itFred

-

incredible, thanks.

-

Hello,

I discovered and tried your tool with the last Catchup edition 15 to create the Hans Wegner chair.

Following this tutorial, I discovered that 2 of the 3 extrusion possibilities cause problems; the J and N where the result pulled face creates unclosed faces. The problem doesnt occur when we use the V tool.

The attachments illustrate the problem.

Regards,

Alain

-

Tiny differences can cause issues with SketchUp/OpenGL that filter down through the API code.

Two points can end up appearing to the 'engine' as being coincident when they are not and thereby a face is missed off. In your case it looks like a creeping tolerance issue.To avoid this if you scale up what you are working on [temporarily] by say x10 chances are that the extrusion vertices will all play nicely and no faces will get omitted. Scale back down afterwards and the issue won't reappear - it's the creation involving small dimensions/edges/facets etc that's the issue, but they can exist, just not be 'made' at those values.

-

Ok TIG, I'll try to work like that.

Thanks -

Genius plugin

Thank you very much -

I'm another mac user experiencing some issues with this incredible plugin, (but I'm banking on user error). I thought it might be due to running SU 7.1 on a G4 mac, but after reading the previous posts I'm not so sure. JPP works for me 1 out of 20 times. The other 19 I have to hard reboot the computer. What I've tried:

- Verified the latest versions of plugins

- Scaled the model up (twice)

- Cut larger faces into much smaller segments, pulled one at a time

- Tried while grouped/ungrouped

- Removed all other plugins and reinstalled FredoLib and JPP only

- Many times I let the computer sit untouched for hours, just to make sure I wasn't causing the freezes by interrupting a process

I've attached a model of a simple curtain I'm looking to thicken by 1/16" (either direction). The model is cut into segments, and all segments would be JPP'd (verb?) out to the same thickness.

If someone could point out the error of my ways, or take a crack at thickening it yourself, I would be indebted indeed.

-

Hi wtrouser,

I tried to thicken your model on SU 8 Pro M2 and the last plugin and I got the same result as you.

Even scaling it up by 10, all push-pull tools end in an infinite loop....

-

Alainbo... thanks, that actually makes me feel better. I tried x10 and x100, and I segmented the big face into something like 15 segments. Frozen pizza. Perhaps it's too complex of a face for the plugin?

-

Perhaps. It's a pity anyway. 'J' tool could be a very powerfull feature!!!

-

Worked fine for me.

Scaled it up x100 first.

1/16" >>> 6.25"

JPP keeping original faces and no partitions.

It became unresponsive about 13% in, BUT that doesn't mean it's bust !

After 3mins it completed OK.

Scale down 0.01 to return to ~6' high...the proof...

-

TIG... fantastic! I don't suppose I could talk you into uploading your result, could I? I tried scaling up x100, and I once even let my computer go overnight. It didn't seem to matter how long I left it, I couldn't even call up the mac equivalent of the Task Manager after running JPP, the computer was so solidly frozen.

-

I didn't bother to save it...

I'll redo it after my dinner... -

Here it is [v7]...

For some reason it stalled at 5% and took 9 mins this time

No problem! I did have other things running this time...

-

TIG - many thanks again for the extra help! It's greatly appreciated.

-

You are right, I didn't tried to scale it up by 100. It was the trick.

I got it in les than 2 mns. -

All Sketchup processes that create new edges/facets [pushpull, followme, intersect, scripted tools doing similar things], can fail if the resultant geometry is tiny.

Sketchup/OpenGL cannot cope with things < ~0.1mm.

There are tolerances built in to allow two points in space that are not exactly coincident to be regarded as 'equal', otherwise it'd be difficult to do many operations as calculations must always be somewhat approximated. This can mean that two very very close points might not form a line between them, as Sketchup expects two different points, the missing line then fails to split an existing face during an intersect or to complete a loop for a face, which is then missing...

Using a tool like JPP on a very complex mesh with small resultant parts [like this thin curtain] might end up with some tiny bits of geometry/faces missing - it can even splat given the right errors...

The trick of Scaling things up x10 or x100 etc, creating the facets etc, will avoid the tininess issues.

Any Scaling of the tiny parts back down afterwards isn't an issue - very tiny things can exist, it's just their creation that causes issues.Incidentally, there can be similar issues with very very large objects too, because the enormous numerical values get ever approximated too... In that case scale down, process then scale up.

Sketchup is really designed to model building and related objects.

So doing complex modeling on the innards of a swiss-wristwatch [or an entire city] at 'real size' can/will cause issues at some point...

Advertisement